不同排濕方式的空氣能熱泵密集烤房烘烤效果對比研究

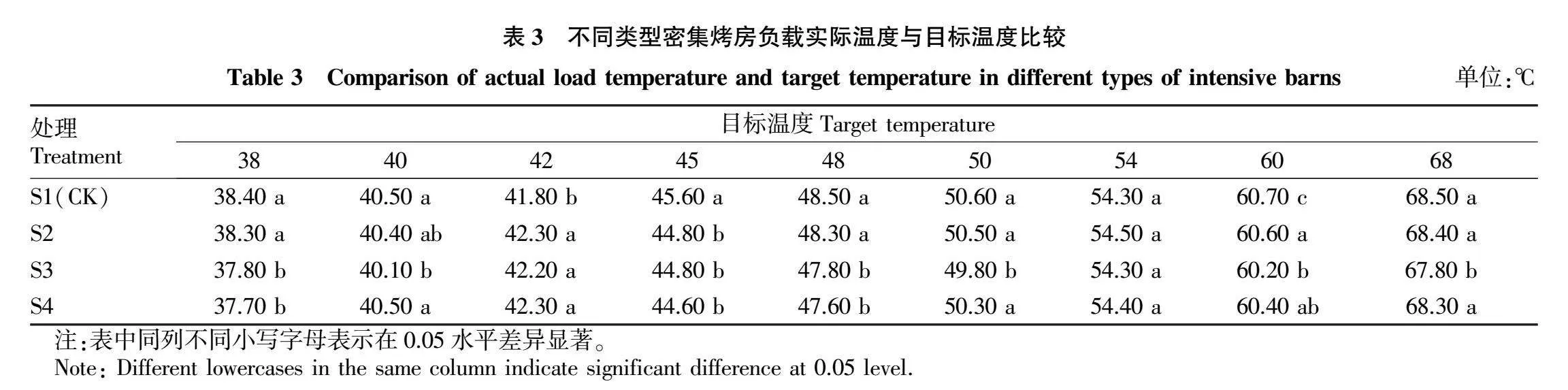

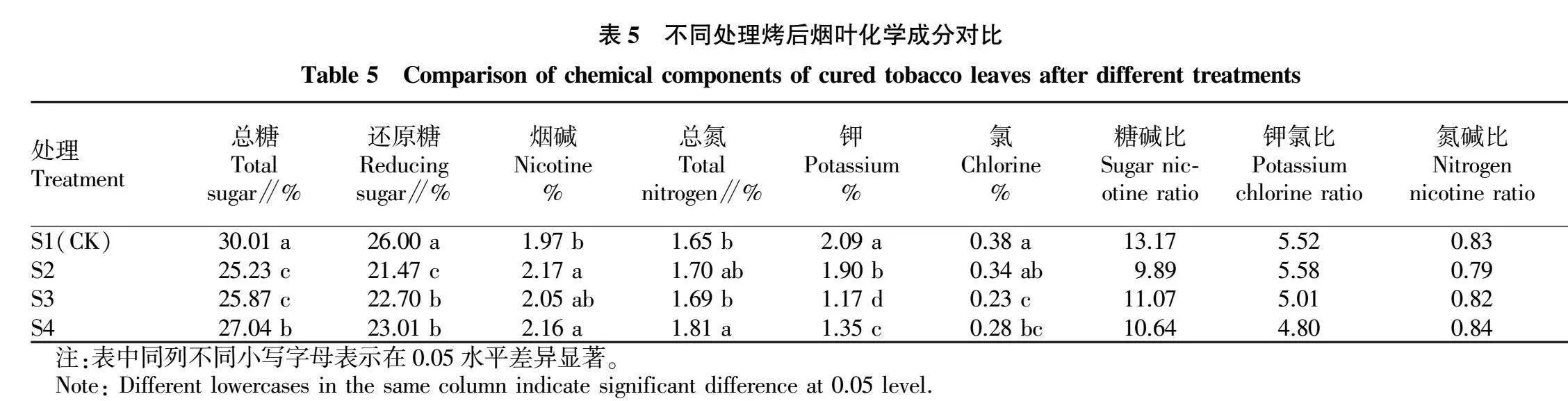

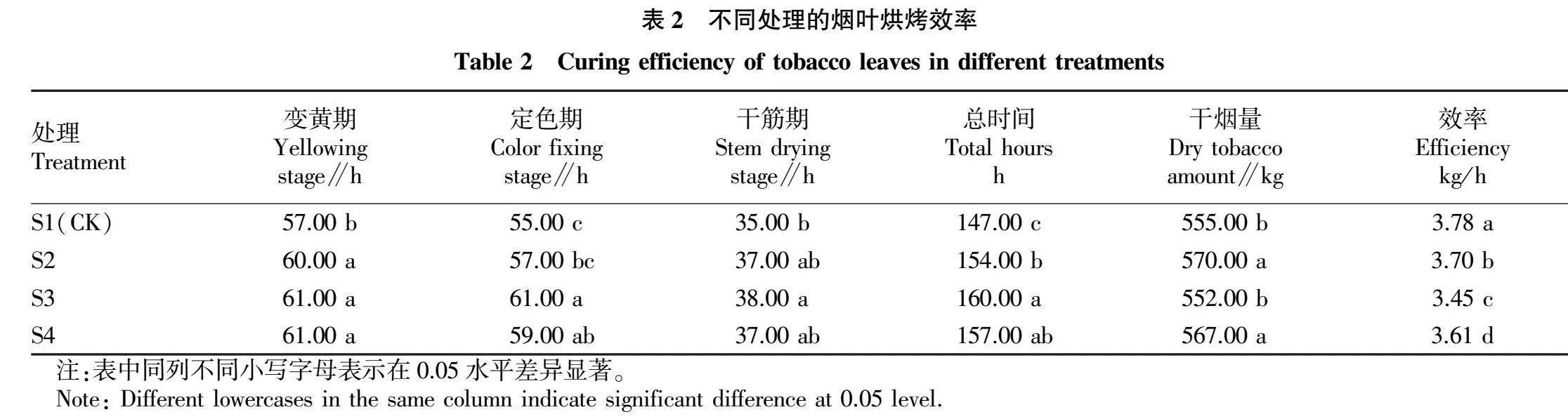

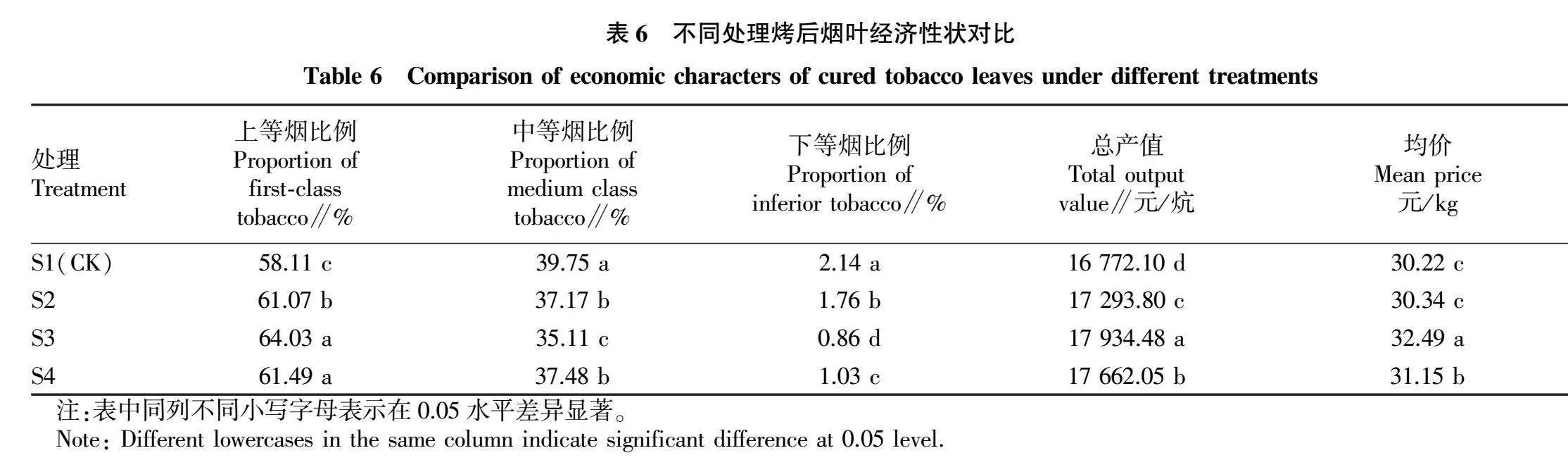

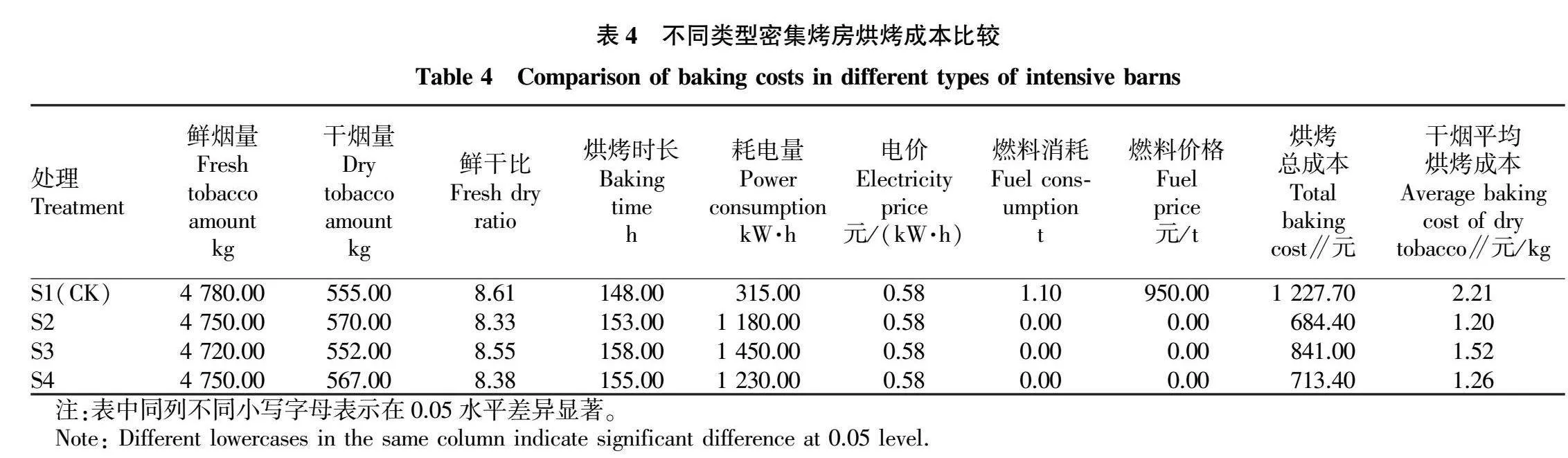

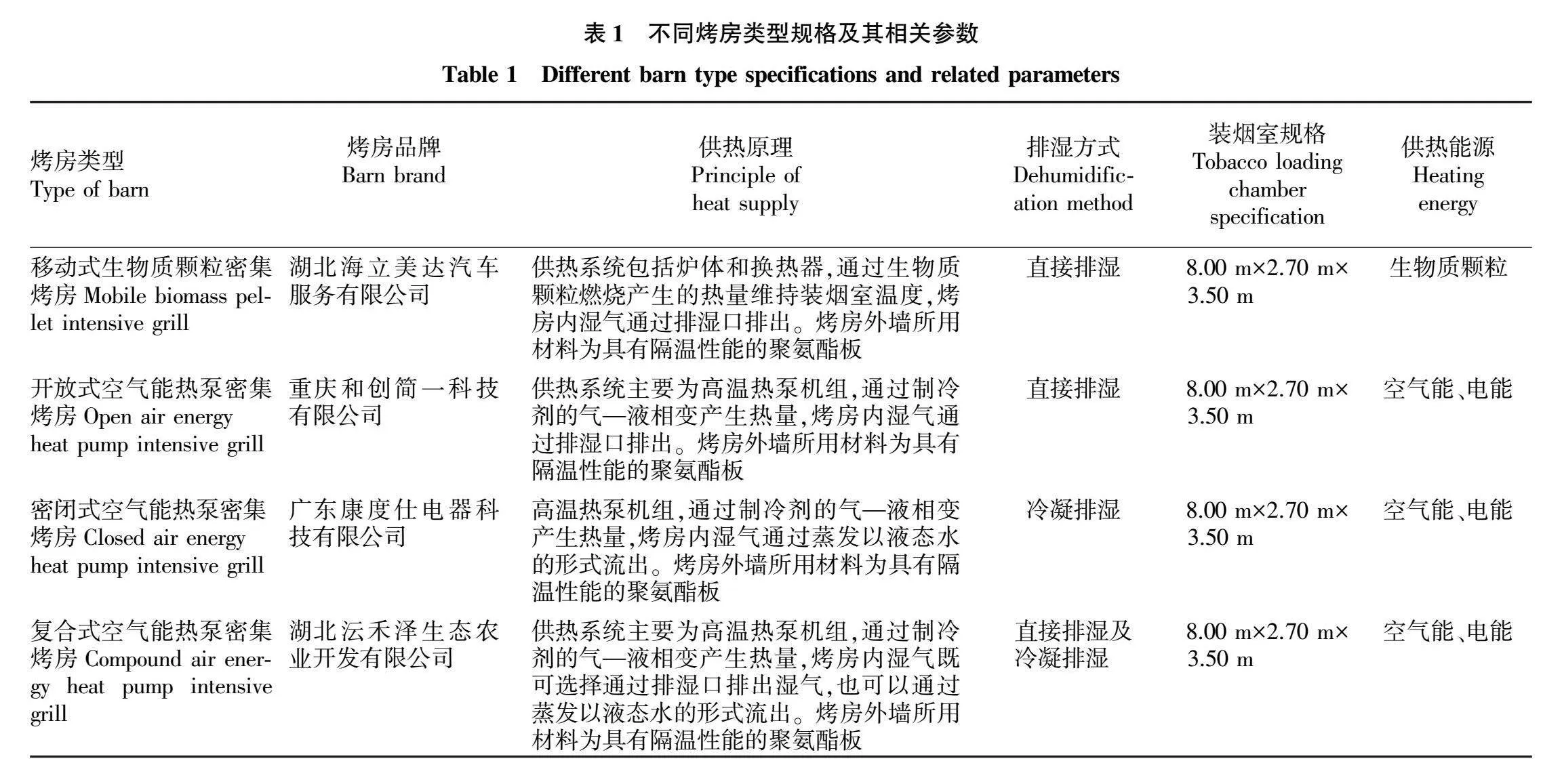

摘要 為探究湖北襄陽地區(qū)新能源烤房的降本增效烘烤效果,開展3種不同排濕方式空氣能熱泵烤房與生物質烤房的烘烤效果對比試驗。試驗共設4個處理:S 移動式生物質顆粒密集烤房為對照(CK);S2,開放式空氣能熱泵密集烤房;S3,密閉式空氣能熱泵密集烤房;S4,復合式空氣能熱泵密集烤房。對各處理的負載烘烤效率、烘烤關鍵溫度控制、烘烤成本、煙葉常規(guī)化學成分、烤后煙葉經濟性狀進行對比分析,驗證烘烤效果。結果表明:與生物質烤房相比,新能源熱泵烤房烘烤效率稍低,但關鍵烘烤溫度控制更精準,烘烤成本減少;新能源熱泵烤房的單位干煙平均成本僅為1.20~1.52元/kg,遠低于生物質烤房,下降了0.69~1.01元/kg,降幅高達31.22%~45.70%,每炕煙能節(jié)省386.7~543.3元;熱泵烤房煙葉內在質量化學成分協調性提升,以密閉式和復合式效果更加;密閉式空氣能熱泵密集烤房上等煙比例顯著提升了5.92百分點,煙葉均價顯著增加了2.27元/kg,總產值最佳。總體來看,熱泵密集烤房與生物質密集烤房相比,省工降本,提質增效,具有十分良好的推廣前景。

關鍵詞 烤煙;排濕方式;空氣能;熱泵烤房;生物質密集烤房

中圖分類號 TS 44 文獻標識碼 A

文章編號 0517-6611(2024)20-0169-04

doi:10.3969/j.issn.0517-6611.2024.20.041

開放科學(資源服務)標識碼(OSID):

Comparison of the Baking Effect of an Air EQO932uyfl/1E+zGR01BPnyFphiUOmMpWE2tbD7fUTRk=nergy Heat Pump Intensive Baking Room Using Different Humidity Removal Methods

CHEN Yong-wei, TIAN Hui-wen, CHEN Yong-de et al

(Xiangyang Branch of Hubei Tobacco Corporation, Xiangyang, Hubei 441000)

Abstract In order to explore the cost reduction and efficiency improvement baking effect of new energy baking houses in Xiangyang, Hubei, comparative experiments on the baking effects of three different dehumidification methods of air energy heat pump baking room and biomass baking room were conducted. A total of 4 treatments were set up in the experiment, with S1 (CK) mobile biomass particle dense baking house as the control;S2 open air energy heat pump dense baking room;S3 closed air energy heat pump dense baking room;S4 composite air energy heat pump dense baking room. The load baking efficiency, key baking temperature control, baking cost, conventional chemical composition of tobacco leaves, and economic benefits of cured tobacco leaves for each treatment are compared and analyzed to verify the baking effect. The results show that compared with biomass baking rooms, the baking efficiency of new energy heat pump baking rooms is slightly lower, but the key baking temperature control is more precise, and the baking cost is reduced;the average cost of dry smoke per unit in the new energy heat pump drying room is only 1.20-1.52 yuan/kg, which is much lower than that in the biomass drying room, with a decrease of 0.69-1.01 yuan/kg, a decrease of 31.22%-45.70%, and a savings of 386.7-543.3 yuan per unit of smoke. The chemical composition coordination of the internal quality of tobacco leaves in the heat pump drying room is improved, and the effect is better with closed and composite methods. The proportion of high-quality tobacco in the closed air enerygy heat pump intensive curing room significantly increased by 5.92 percentage point, and the average price of tobacco leaves significantly increased by 2.27 yuan/kg, with the best total output value. Overall, compared with biomass intensive baking houses, heat pump intensive baking houses save labor, reduce costs, improve quality and efficiency, and have a very good promotion prospect.

Key words Flue-cured tobacco;Dehumidification method;Air energy;Heat pump baking room;Biomass intensive baking room

煙葉的調制是把煙葉從農業(yè)產品加工成工業(yè)可用產品的一個關鍵過程,這個烘烤干燥過程需要大量消耗熱能,我國在2005年開始推廣使用臥式密集烤房,多以煙煤為主供能,因此產生了大量燃煤燃燒排放的SO2、CO2、CO及粉塵等,造成嚴重的環(huán)境污染[1-3]。……