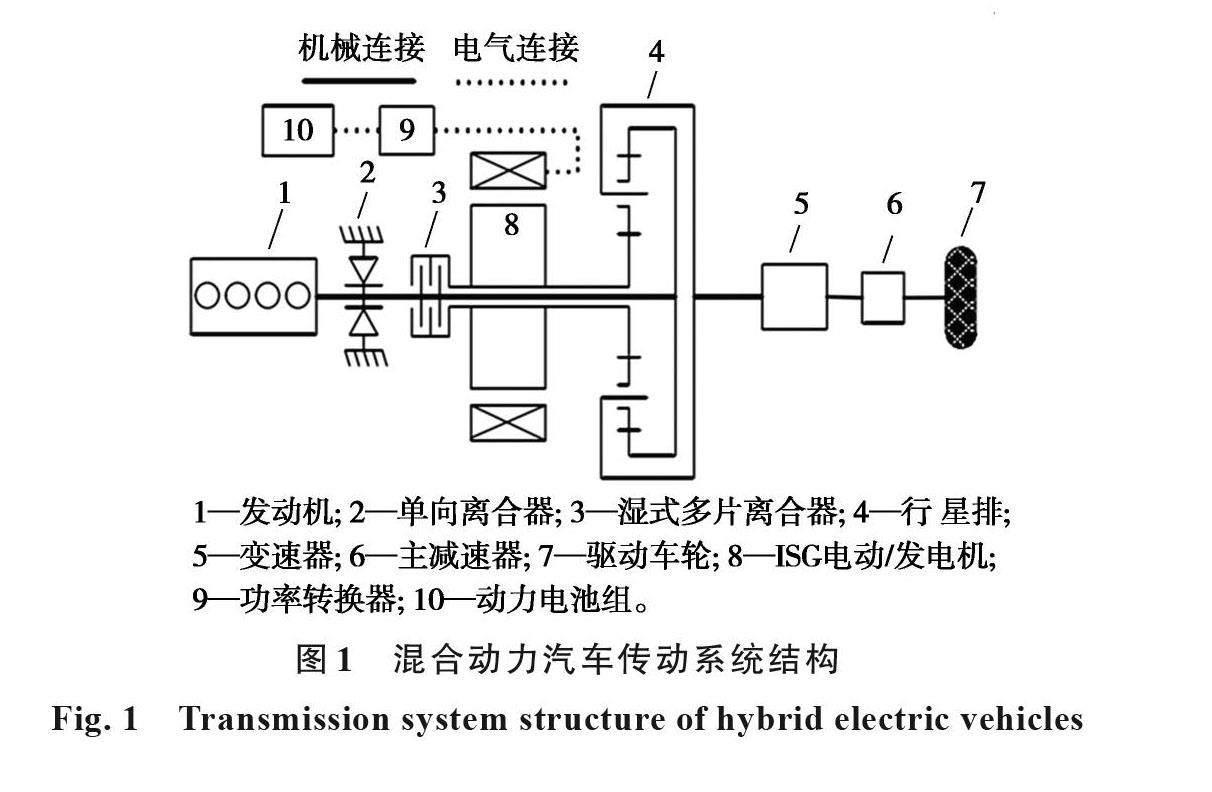

混合動力汽車濕式離合器摩擦副溫度場及其影響因素研究

蔡楊 王正武 王歡 胡明輝

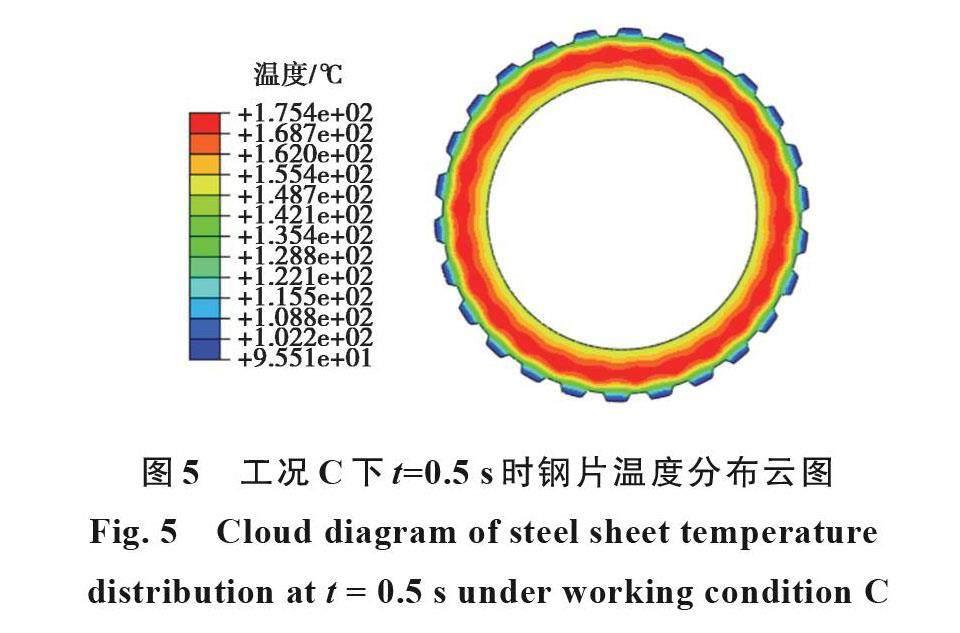

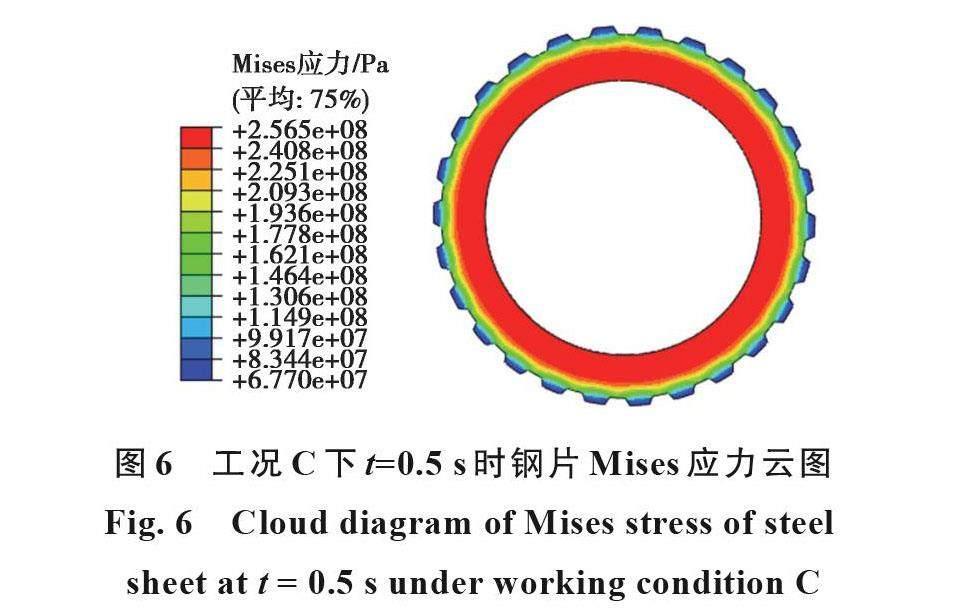

摘要:熱失效是混合動力汽車濕式離合器發生故障的主要原因之一。摩擦副滑摩過程中具有高度非線性,同時摩擦副溫度場受到多個參數影響。為深入研究混合動力汽車離合器摩擦副溫度場分布情況,通過搭建混合動力汽車離合器熱結構耦合分析模型,對滑摩過程進行仿真計算。在此基礎上,深入研究初始轉速、接合油壓、對偶鋼片厚度和摩擦襯片材料等因素對摩擦副溫度場的影響。

關鍵詞:濕式離合器;摩擦副;溫度場;影響因素

中圖分類號:U463.211????????? 文獻標志碼:A??????? 文章編號:1000-582X(2024)01-093-11

Temperature field and its influencing factors of friction pair of wet clutch of hybrid electric vehicle

CAI Yang1, WANG Zhengwu1, WANG Huan2, HU Minghui3

(1. School of Traffic & Transportation Engineering, Changsha University of Science & Technology,

Changsha 410114, P. R. China; 2. School of Vehicle Engineering, Chongqing University of Technology, Chongqing 400054,P. R. China; 3. The State Key Laboratory of Mechanical Transmissions,

Chongqing University, Chongqing 400044, P. R. China)

Abstract: The sliding process in the friction pair involves highly nonlinear behavior, and the temperature field of the friction pair is affected by numerous parameters. To gain a comprehensive understanding of the temperature field distribution in the friction pair of a hybrid electric vehicle clutch, a thermal structure coupling analysis model of the hybrid electric vehicle clutch was constructed to simulate the sliding process. Building upon this model, an in-depth study was conducted to analyze the impact of various parameters, such as initial speed, engagement oil pressure, dual steel plate thickness, and friction lining material, on the temperature field of friction pair.

Keywords: wet clutch; friction pair; temperature field; influencing factors

濕式離合器具有傳遞轉矩大、散熱性能好及工作性能穩定等特點,被廣泛運用于混合動力汽車傳動系統中[1]。混合動力汽車在行駛過程中,受工作模式切換頻繁、路面狀態較差、車輛所受載荷太大等因素影響,濕式離合器的摩擦片和對偶鋼片在相互滑摩過程中產生大量摩擦熱,呈現出高非線性,造成摩擦片和對偶鋼片磨損、燒蝕和熱變形失效[2]。因此,研究混合動力汽車濕式離合器摩擦副溫度場及影響因素,對離合器失效分析和優化設計具有重要的理論價值和實踐指導意義[3]。

李和言等[4]針對多片濕式離合器在機械傳動過程中產生的熱失效問題,研究了摩擦副元件的非均勻接觸及溫度分布。熊涔博等[5]根據滑摩過程接觸傳熱模型,分析了熱流分配系數影響規律,研究了摩擦副溫度場情況。王立勇等[6]研究了鋼片溫度場在接合過程中的變化及與接觸應力變化的規律。……