畢赤酵母高密度發酵產β—甘露聚糖酶的工藝優化

張曉龍+肖靜+王瑞明

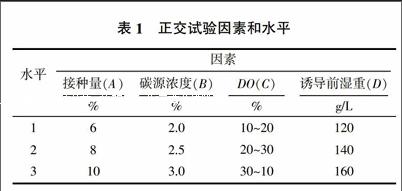

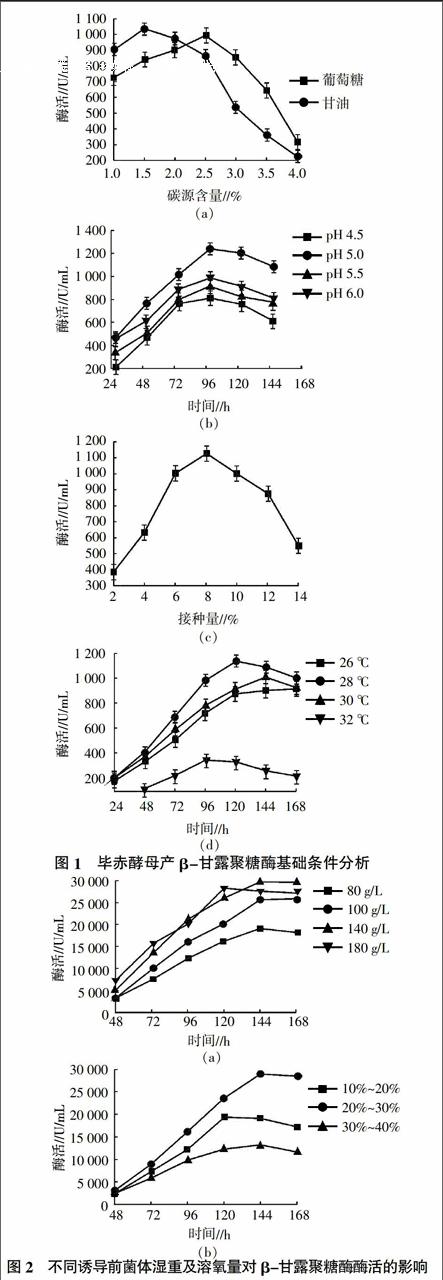

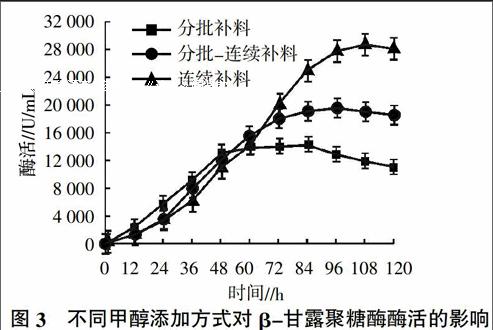

摘要:以表達β-甘露聚糖酶的畢赤酵母工程菌為研究對象,采用搖瓶發酵確定碳源、接種量、溫度、pH基礎條件,通過30 L發酵罐高密度發酵,探究菌體濃度、甲醇濃度、甲醇補料方式、溶氧量等條件對目的蛋白產量的影響,并通過正交試驗優化發酵工藝條件。結果表明,最佳產酶條件為接種量10%,初始葡萄糖質量濃度30 g/L,誘導溫度28 ℃,pH 5.0,溶氧量10%~20%。在此發酵條件下,最終細胞干重135 g/L,目的蛋白表達量5.04 g/L,最高酶活力29 600 U/mL,較優化前提高24倍,已滿足工業化要求。

關鍵詞: β-甘露聚糖酶; 巴斯德畢赤酵母; 高密度培養; 發酵優化

中圖分類號:Q815 ? ? ? ?文獻標識碼:A ? ? ? ?文章編號:0439-8114(2015)23-5978-06

DOI:10.14088/j.cnki.issn0439-8114.2015.23.047

Optimization Technology of β-Mannanase Fermented by Pichia pastoris

ZHANG Xiao-long,XIAO Jing,WANG Rui-ming

(Institute of Biological Engineering of Qilu University of Technology, Shandong Province Key Laboratory of Microbial Engineering,

Jinan 250353,China)

Abstract:The fermentation conditions of genetically engineered Pichia pastoris for β-Mannanase were studied. Basic conditions of the carbon source, immunization rates, temperature, pH were optimized in shake-flask. The tests in 30 L fermenter was applied to study the effects of DCW,methanol concentration and DO on enzyme production. Through the orthogonal design to optimize the fermentation conditions. The results indicated that the optimum conditions were as follows:10% inoculum size,30 g/L initial glucose concentration, 10%~20% DO,pH 5.0 at 28 ℃. The dry cell weight was 135 g/L,the target protein concentration could reach to 5.04 g/L. And the β-Mannanase activity got to be 29 600 U/mL,which was 24 times of that the results in the shake flask under these conditions.

Key words:β-Mannanase;Pichia pastoris;high cell density culture;fermentation optimization

β-甘露聚糖酶(β-1,4-D-mannan mannohydrolase,EC 3.2.1.78)是β-1,4甘露聚糖甘露糖苷水解酶的簡稱,屬于半纖維素酶類,廣泛應用于食品、飼料、醫藥、紡織印染等方面[1],在飼用酶制劑應用方面尤其重要[2],添加β-甘露聚糖酶可以降解飼料中含有的β-甘露聚糖,有助于消除甘露聚糖對機體胰島素分泌和胰島素樣生長因子(IGF)生成的抑制作用,提高葡萄糖吸收速率,促進碳水化合物代謝過程,提高日糧能量利用率,是一種良好的飼料添加劑,也是抗生素的理想代替品[3]。

畢赤酵母(Pichia pastoris)表達系統既具有原核表達系統易于培養、繁殖快速、表達量高的優點,又具有真核表達系統外源蛋白翻譯后再加工修飾等特點,目前已有超過500種外源蛋白在畢赤酵母中獲得成功表達。山東省微生物重點實驗室成功構建一株表達枯草芽孢桿菌β-甘露聚糖酶基因畢赤酵母工程菌,在前……