不同復烤方式對復烤片煙質量的影響

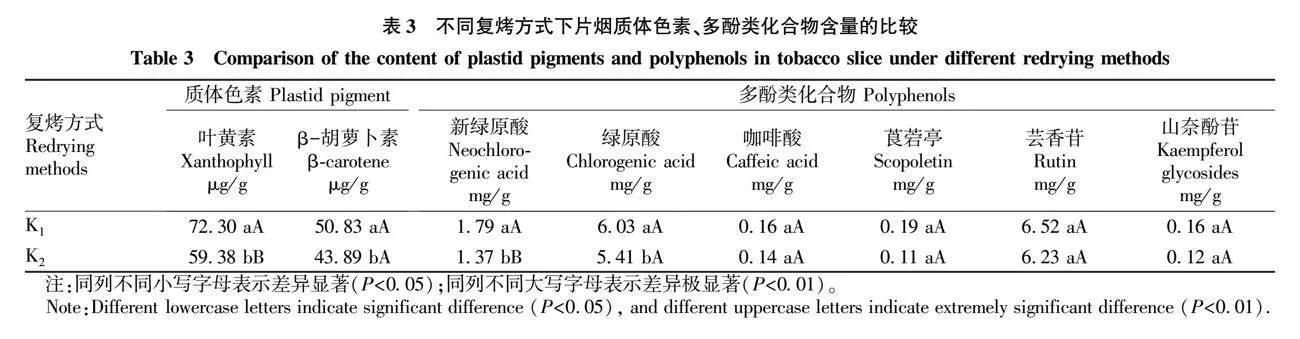

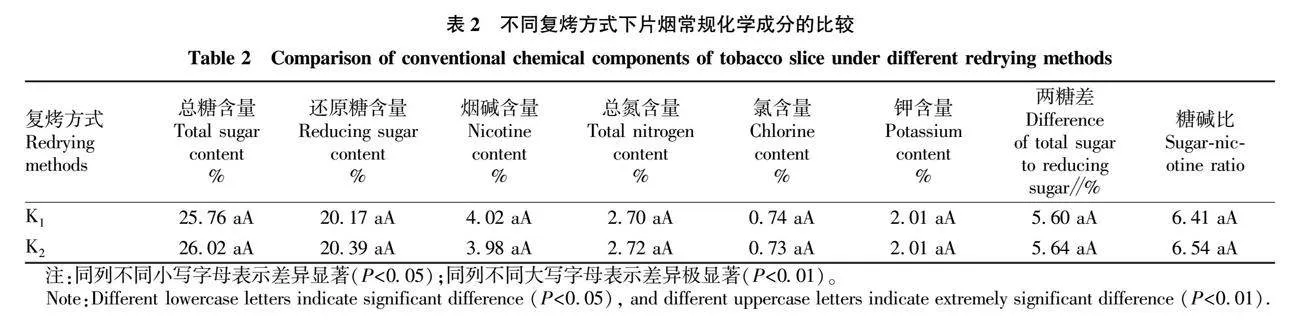

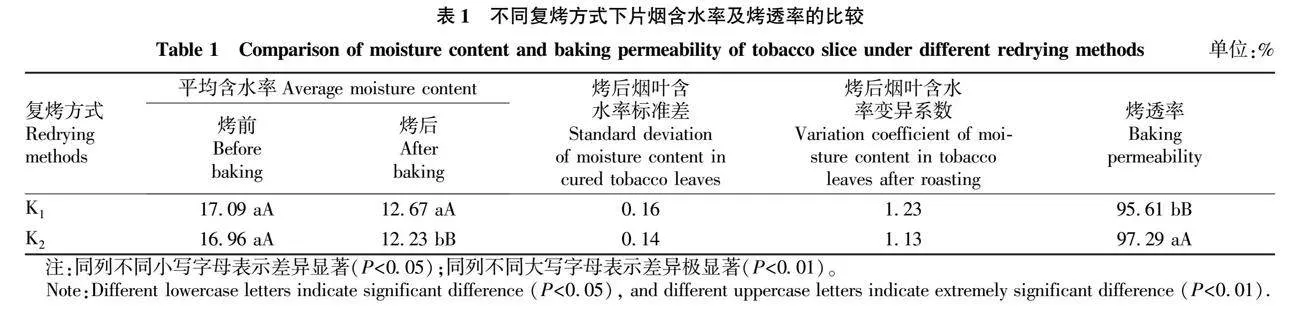

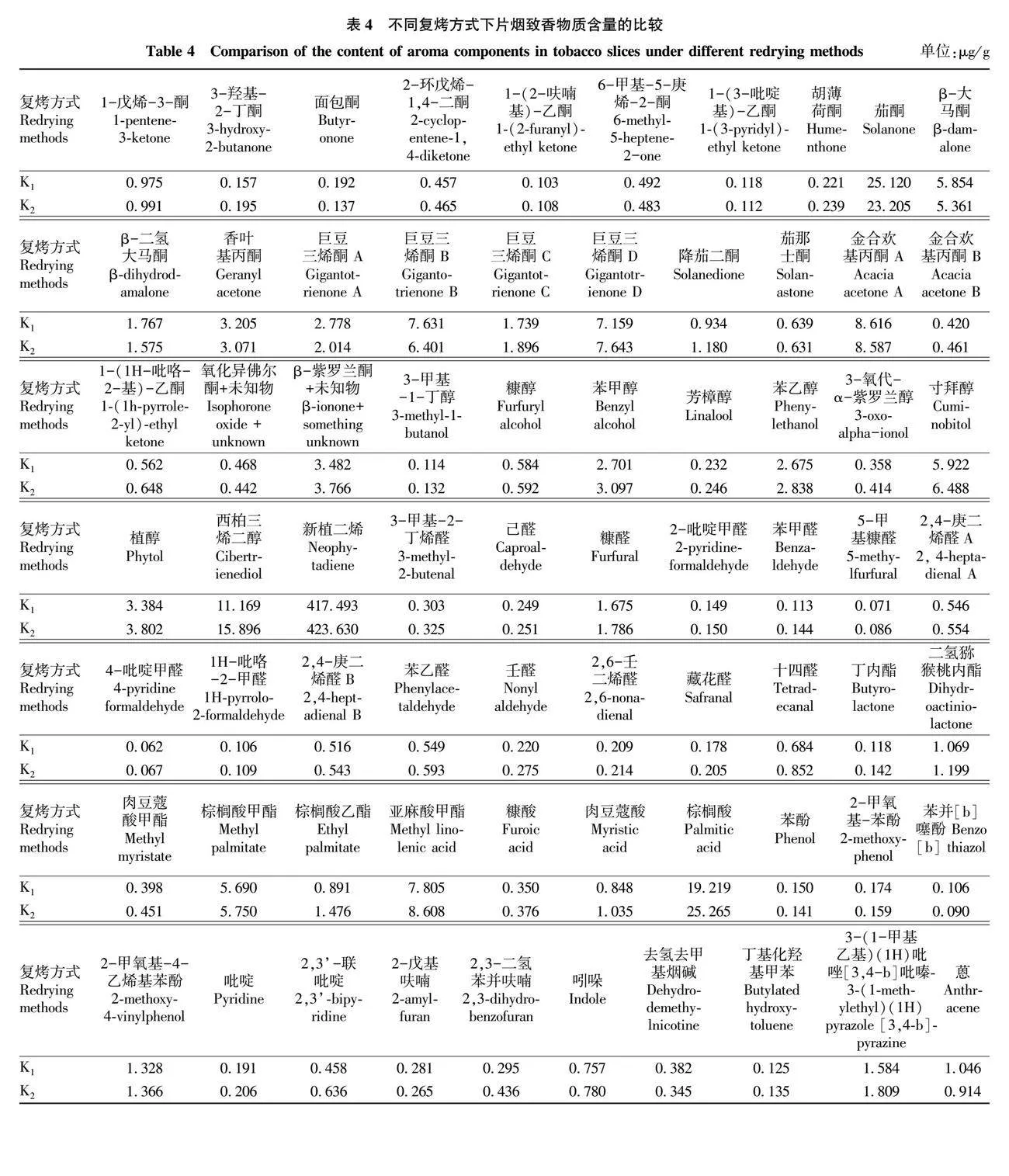

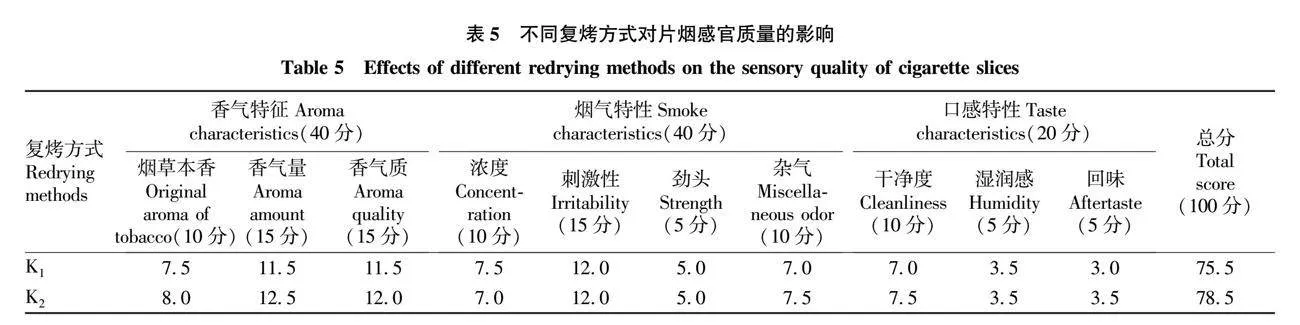

摘要 為解決目前復烤工藝存在的復烤后片煙含水率標準差大、易產生水漬煙、煙草香氣物質流失、烤片機出現滴水等問題,在烤片機回潮區設置蒸汽加水復合回潮復烤、純蒸汽直接復烤方式進行試驗,研究其對烤片機煙草復烤片煙理化特性、感官特性及香氣成分的影響。結果發現,與蒸汽加水復合回潮復烤相比,純蒸汽直接復烤可以明顯降低復烤片煙的含水率標準差,并明顯減少水漬煙的產生,使片煙水分分布更均勻。此外,純蒸汽直接復烤方式可以有效防止復烤片煙醇類、醛類、酯類、揮發性酸類等香氣成分的流失。綜合評價表明, 純蒸汽直接復烤是更優的烤片機回潮復烤方式,可以有效控制復烤加工后片煙含水率, 有利于卷煙工業企業后續的倉儲醇化作業,進而實現“保香提質”加工目標。

關鍵詞 復烤方式;回潮區;產品質量;保香提質

中圖分類號 TS 44+3 文獻標識碼 A 文章編號 0517-6611(2024)23-0180-04

doi:10.3969/j.issn.0517-6611.2024.23.039

Effects of Different Redrying Methods on the Quality of Redried Tobacco Slices

WANG Zi-chong1, TANG Yun-hai1, HE Jing2 et al

(1.Baoshan Redrying Factory of Yunnan Tobacco Redrying Co., Ltd., Baoshan, Yunnan 678000;2.Hongyun Honghe Tobacco (Group) Co., Ltd., Kunming, Yunnan 650000)

Abstract In order to solve the problems of high standard deviation of moisture content in redried tobacco, the production of water stained tobacco, loss of tobacco aroma substances, and dripping in the curing machine in the current redrying process, steam and water composite redrying, and pure steam direct redrying methods were set up in the moisture regain area of the curing machine to conduct the experiments.The effects of these methods on the physical and chemical properties, sensory characteristics, and aroma components of redried tobacco in the curing machine were studied.The results showed that compared with steam and water combined moisture regain, pure steam direct redrying could obviously reduce the standard deviation of moisture content in redried tobacco, and obviously reduce the production of water stained tobacco, making the distribution of moisture content in tobacco more uniform.In addition, the pure steam redrying processing method could effectively prevent the loss of aroma components such as alcohols, aldehydes, esters, and volatile acids in redried tobacco slices.Comprehensive evaluation showed that pure steam direct redrying was a better way for the machine to regain moisture and redry tobacco, which could effectively control the moisture content of the tobacco after redrying processing, and it was beneficial for the subsequent storage and aging operations of cigarette industry enterprises, thereby achieving the goal of “aroma preservation and quality improvement” processing.

Key words Redrying method;Rebound zone;Product quality;Preserving fragrance and improving quality

基金項目 云南煙葉復烤有限責任公司2022年度科技計劃項目(2022FK05)。

作者簡介 王子沖(1971—),男,云南保山人,政工師,從事煙葉復烤基礎管理及設備管理工作。*通信作者,助理工程師,碩士,從事打葉復烤質量檢測工作。

收稿日期 2023-11-29;修回日期 2024-01-18

在打葉復烤加工過程中,煙葉水分含量不僅影響其彈性、韌性、填充性和燃燒性等物理特性,而且影響其顏色、光澤、香氣、吃味等外觀和內在質量,同時也影響煙葉內部的生物化學變化,比如各種酶的活動、霉菌的繁殖、內含物質的分解轉化等。……