Ce添加對Mg–Ca擠壓合金力學性能與熱穩定性影響研究

李景仁,謝東升,張棟棟,謝紅波,潘虎成,任玉平,秦高梧

輕合金成形

Ce添加對Mg–Ca擠壓合金力學性能與熱穩定性影響研究

李景仁,謝東升,張棟棟,謝紅波,潘虎成,任玉平,秦高梧

(東北大學 材料各向異性與織構教育部重點實驗室,沈陽 110819)

研究在Mg–0.2Ca擠壓合金基礎上分別添加質量分數為0.3%的Ce和0.6%的Ca后對合金的組織、力學性能和熱穩定性的影響,探究Ce和Ca 2種合金元素對鎂合金的強化和中高溫條件下的穩定化效果。首先,熔煉制備Mg–0.2Ca、Mg–0.2Ca–0.3Ce和Mg–0.8Ca 3種成分的合金;隨后,對3種合金進行擠壓變形,并對擠壓合金組織和力學性能進行表征和測試;最后,在300 ℃下對3種合金進行等溫退火,研究其組織演變過程和力學性能的衰減情況。在Mg–0.2Ca合金基礎上添加質量分數為0.3%的Ce可將擠壓態合金再結晶分數由約92%降至約53%,再結晶晶粒尺寸由約1.64 μm細化至約0.86 μm,Mg–0.2Ca–0.3Ce三元合金的屈服強度可大幅提升至約364 MPa,該屈服強度與Mg–0.8Ca合金相當(約361 MPa),表明單位質量Ce的添加對強度提升的效果優于Ca。退火3 h后,Mg–0.2Ca–0.3Ce三元合金屈服強度的下降幅度約為124 MPa,顯著低于Mg–Ca二元合金(約170 MPa)。以Mg–0.2Ca–0.3Ce合金為例進行靜態再結晶組織演化分析表明,靜態再結晶過程產生了稀土織構,其再結晶機制為不連續靜態再結晶。在Mg–0.2Ca擠壓合金中添加質量分數為0.3%的Ce后,屈服強度由約307 MPa提升至約364 MPa,其強度與繼續添加質量分數0.6%的Ca合金相當,Mg–Ca–Ce三元合金熱穩定性優于Mg–Ca二元合金。

變形鎂合金;微合金化;力學性能;位錯;熱穩定性

鎂合金由于具有低密度的特點,在亟待“輕量化”的諸多領域中,如航空航天、軌道交通、3C產品等具有巨大的應用前景[1-3]。然而,傳統鎂合金材料一直面臨著絕對強度偏低和室溫成形性差等瓶頸問題[4]。在可持續發展的背景下,“低合金化”逐漸成為鎂合金的一個新發展方向,以期使用盡可能低的溶質含量獲得高的綜合力學性能[5]。然而,合金元素的減少通常會削弱固溶強化和第二相強化的效果。因此,對于具有高的Hall–Petch斜率的鎂合金而言,選取一種有效的晶粒細化手段便成為開發新型高性能鎂合金的有效途徑[6]。例如,通過劇烈塑形變形(Severe Plastic Deformation,SPD)的手段,包括等通道轉角擠壓(Equar Channel Angular Pressing,ECAP)[7]、累積疊軋(Accumulative Roll Bonding,ARB)[8]、高壓扭轉(High-Pressure Torsion,HPT)[9-10]、旋鍛(Rotary Swaging,RS)[11],鎂合金的晶粒一般可以細化至納米尺度。然而,SPD方法制備的樣品尺寸受限且加工成本較高,無法滿足鎂合金材料大規模的工業化應用。

合金化是實現鎂合金晶粒細化的另一個有效手段[5]。在軋制、擠壓等工業化流程的變形工藝條件下,有效的合金化元素可以通過促進動態再結晶(Dynamic recrystallization,DRX)形核和抑制再結晶晶粒長大而獲得細小的晶粒尺寸。近期研究表明,非稀土Ca元素的添加可以在變形鎂合金中起到強烈的細化晶粒的效果[12],并據此開發出了Mg–Ca– Al–(Zn)[13]、Mg–Ca–Zn–(Mn)[14]、Mg–Ca–Sn–(Mn)[15]等合金體系,屈服強度普遍可以達到350 MPa以上。

然而,目前開發的Mg–Ca系合金中所含Ca元素含量依然較高(質量分數普遍大于0.7%),在合金熔煉與擠壓件質量控制等方面均面臨諸多挑戰,因此,文中以添加超低含量的Ca(質量分數約為0.2%)為基礎,結合微量Ce元素(質量分數約為0.3%),以期實現超高強度、超低合金化的變形鎂合金。事實上,輕稀土元素Ce是鎂合金中的重要合金元素之一,可起到顯著弱化織構和提升塑性的效果,并據此開發出了Mg–Ce–Mn(ME20)等商用鎂合金牌號[16]。然而,關于Ce和Ca兩種元素對鎂合金微觀組織與力學性能的協同調控作用的研究目前還鮮有報道。與此同時,針對中高溫環境下的服役要求,鎂合金的熱穩定性同樣亟待解決。由此,文中擬研究Ce和Ca元素對鎂合金力學性能和熱穩定性能的影響規律并闡明其微觀機理。

1 試驗

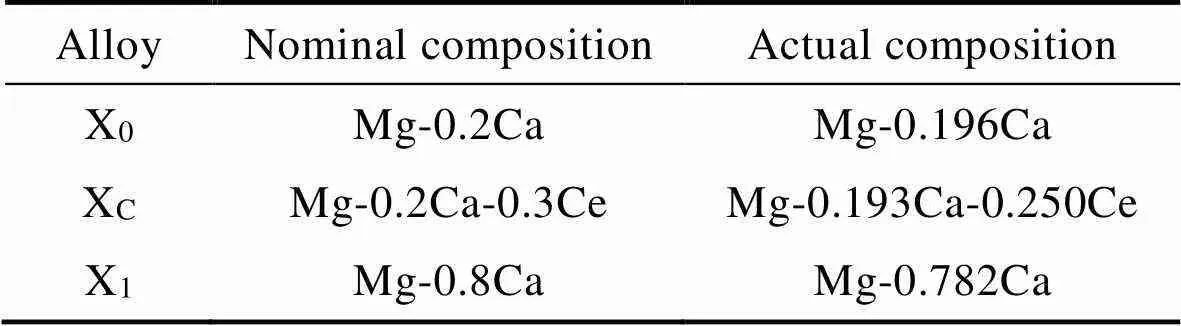

在真空感應熔煉爐中制備名義成分Mg–0.2Ca、Mg–0.2Ca–0.3Ce、Mg–0.8Ca的合金(分別標注為X0、XC和X1)。采用電感耦合等離子光譜發生儀(ICP)進行成分檢測,實際成分如表1所示。將鑄錠在530 ℃下保溫12 h進行固溶處理,隨后將45 mm×80 mm圓柱擠壓成10 mm圓棒,擠壓比20∶1,擠壓速度0.4 mm/s,樣品、模具和擠壓筒的溫度均設置為280 ℃。隨后,對擠壓態合金進行300 ℃下保溫0.5~ 3 h的退火處理。將合金試樣加工成直徑5 mm、標距25 mm的拉伸試樣。并在電子萬能材料試驗機(Schimazu AG–X Plus)上測試其室溫力學性能,拉伸方向平行于擠壓方向,應變速率為0.001 s–1,每種合金測試3個平行樣。采用光學顯微鏡(OM,GX71)、場發射掃描電子顯微鏡(SEM,ZEISS–Crossbeam 550)及配備的背散射電子衍射探頭(EBSD),場發射透射電子顯微鏡(TEM,JEOL JEM–2100F)對制備樣品的微觀結構進行系統表征。EBSD樣品經由亞離子拋光(PIPS–II,GATAN 695)技術制備得到,TEM樣品經由手動研磨及后續的離子減薄(PIPS–II,GATAN 691)制備。

表1 試驗合金的化學成分

Tab.1 Chemical composition of the test alloys wt.%

2 結果與分析

2.1 力學性能

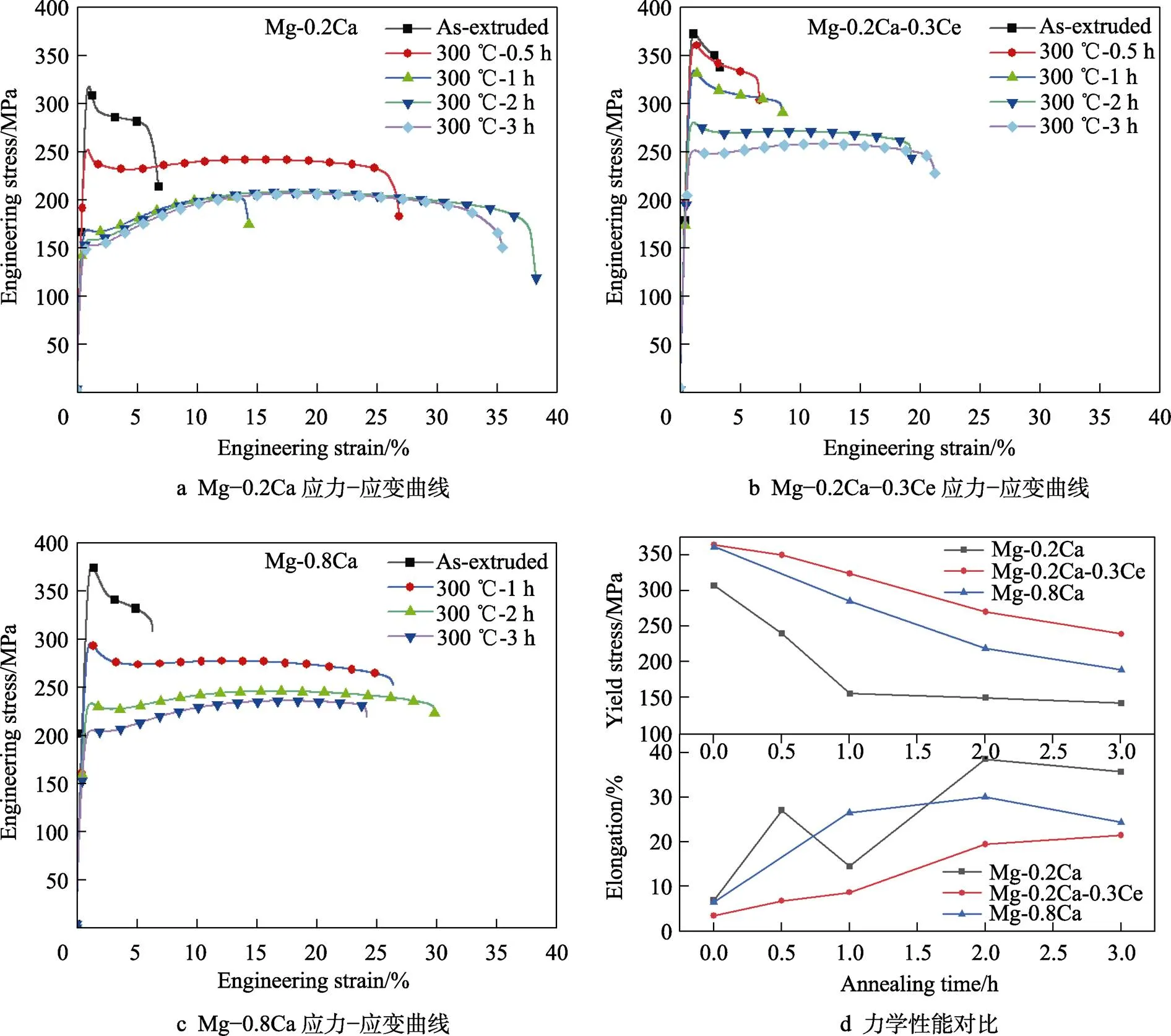

圖1顯示了X0、XC和X1合金的工程應力–應變曲線,擠壓態X0合金的屈服強度(YS)、抗拉強度(UTS)和伸長率(EL)分別為307 MPa、317 MPa和6.8%,如圖1a所示。添加質量分數為0.3%的Ce后,擠壓態XC合金的YS、UTS分別提高至364、374 MPa,提高值約為60 MPa,如圖1b所示。進一步提升Ca的質量分數至0.8%后,X1合金的的YS、UTS同樣可分別提升至361、374 MPa,如圖1c所示。為進一步研究3種合金的熱穩定性,圖1a—c還顯示了退火態X0、XC和X1合金的工程應力–應變曲線。3種合金的YS值和EL值隨退火時間發生變化,如圖1d所示。隨著退火時間的延長,3種合金的塑性顯著提升,強度均有下降,但XC合金的YS值下降幅度最小。譬如,退火處理3 h后,XC合金的YS降低值=124.3 MPa,顯著低于X0合金(= 165.2 MPa)與X1合金(=172 MPa),表明Mg–Ca–Ce三元合金具有更優的熱穩定性。

2.2 擠壓態合金微觀組織

圖2顯示了擠壓態X0、XC和X1合金的金相組織,3種擠壓態合金均表現為雙組態晶粒結構,即由細小的再結晶晶粒和沿擠壓方向(ED)拉長的未再結晶晶粒組成。X0、XC和X1合金的再結晶比例分別約為92%、53%和77%,且Mg–Ce合金未再結晶區存在較寬的分布,表明Ce元素的添加可強烈抑制再結晶進程,該結果與Li等[17]報道的擠壓Mg–Ce二元合金具有低的再結晶比例結果相一致,其微觀機制與Ce元素可誘導鎂基體中的高比例非基面滑移有關。

圖1 X0、XC和X1擠壓態和退火態合金的力學性能

圖3為擠壓態合金的EBSD結果。根據圖3a、d、g的帶對比度(BC)圖可知,擠壓態X0、XC和X1合金的再結晶晶粒平均尺寸分別約為1.64、0.86、0.87 μm,即在Mg–0.2Ca基礎上繼續添加0.3Ce和0.6Ca可產生類似的晶粒細化效果。圖3b、e、h分別為沿ED的IPF模式取向成像圖(IPF map),可以看出,未再結晶晶粒均表現為<10–10>||ED取向,而再結晶晶粒取向更為隨機。從X0合金的反極圖(圖3c)可以看出,該合金具有典型的擠壓絲織構,織構強度為5.62 mrd,同時含有弱的稀土織構組分(<44– 83>||ED)。Guan等[18]和Zeng等[19]研究發現,Ca元素具有類似稀土元素的作用,能夠促進稀土織構的形成。XC和X1合金的整體織構強度接近(7.5~7.7 mrd),而XC合金再結晶晶粒的織構強度(約3.33 mrd)明顯弱于X0和X1合金(5.6~6.0 mrd)。以上結果表明,相較于Ca,Ce具有更強的抑制再結晶和弱化織構效果,但對織構的種類不產生顯著影響。

圖2 擠壓態X0、XC和X1合金的金相圖片

圖3 擠壓態X0、XC和X1合金的EBSD結果

擠壓態X0和XC合金的典型位錯組態如圖4所示。圖4a、b為電子束B~11–20,衍射矢量分別為=0002和=10–10條件下的弱束暗場像(Weak-Beam Dark-Field,WBDF)結果,可以看出,擠壓態X0合金中存在含

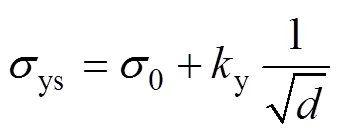

大量研究表明,合金的屈服強度與再結晶晶粒的比例、尺寸有很大的關聯性[22-23]。根據經典的Hall–Petch公式可以評估晶粒細化對屈服強度(ys)的貢獻,見式(1)[24]。

式中:σ0為晶格摩擦力;ky為Hall–Petch斜率;d為平均晶粒尺寸。可知晶粒越小,對屈服強度的貢獻越大。XC合金具有細小的再結晶晶粒及更高的未再結晶比例,因此,XC合金的高強度來源于再結晶區的晶界強化和未再結晶區的織構強化。與此對應,XC合金中較高的未再結晶區占比帶來的硬取向導致拉伸過程中不利于基面滑移和拉伸孿晶的啟動,而更易于形成

2.3 退火態合金微觀組織

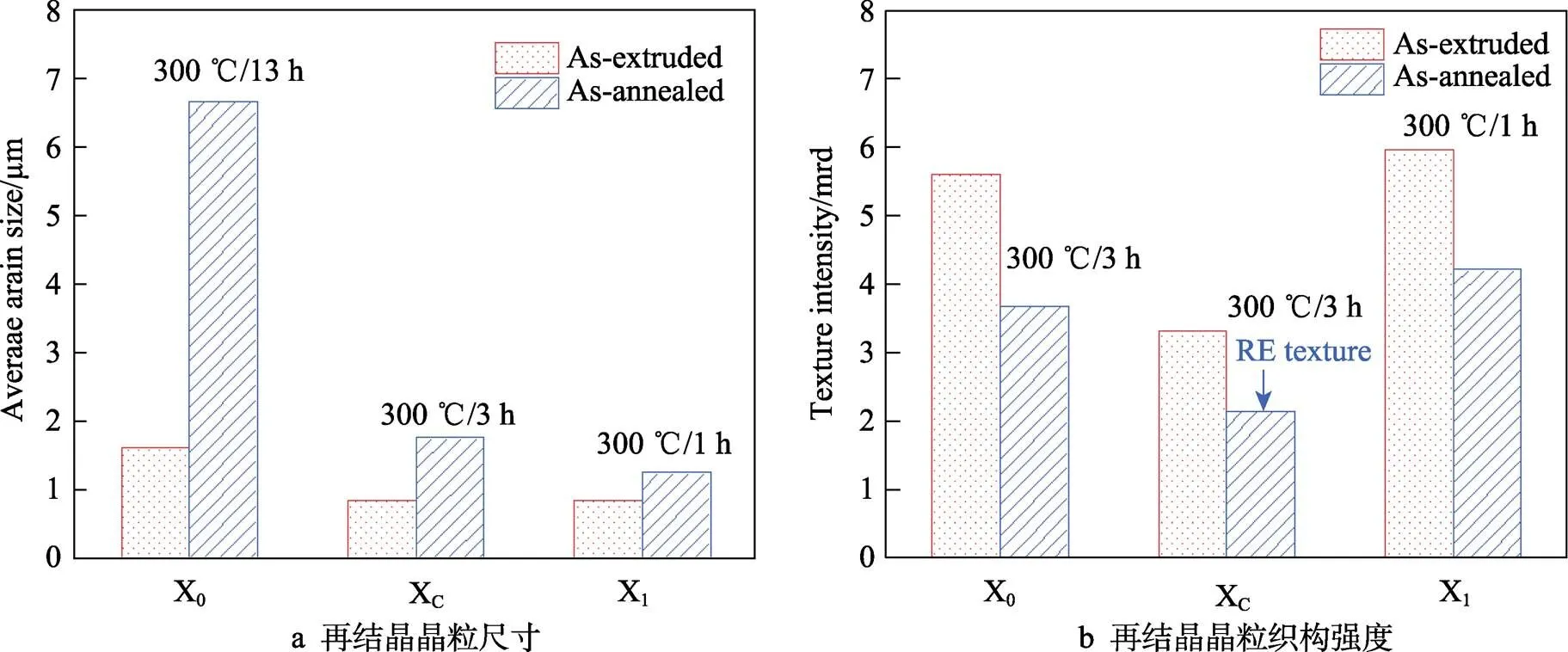

圖5所示為X0、XC和X1合金在300 ℃下退火后的微觀組織。經過3 h退火處理后,X0合金已發生明顯的晶粒長大,而XC合金仍保留大量的未再結晶區域。圖6a統計了3種合金退火前后再結晶晶粒尺寸的變化,X0合金退火后晶粒尺寸約是擠壓態合金的4倍,XC合金退火后晶粒尺寸約是擠壓態合金的2倍。Ca含量高的X1合金經過1 h的短時間退火即已呈現出完全再結晶的狀態。經過退火后,3種合金再結晶晶粒的織構強度都有不同程度的降低(圖6b)。此外,XC合金再結晶晶粒的織構類型發生了變化,即由擠壓態<10–10>||ED的絲織構轉變為<11–21>–<22– 43>||ED的稀土織構;由于大量未再結晶區的存在,XC合金的整體織構仍為<10–10>||ED的絲織構。分析認為,混晶組織是維持退火態XC合金高強度的主要原因,而退火過程中具有稀土織構組分的靜態再結晶晶粒的生成則使得合金塑性升高。

2.4 Mg-0.2Ca-0.3Ce合金靜態再結晶與稀土織構

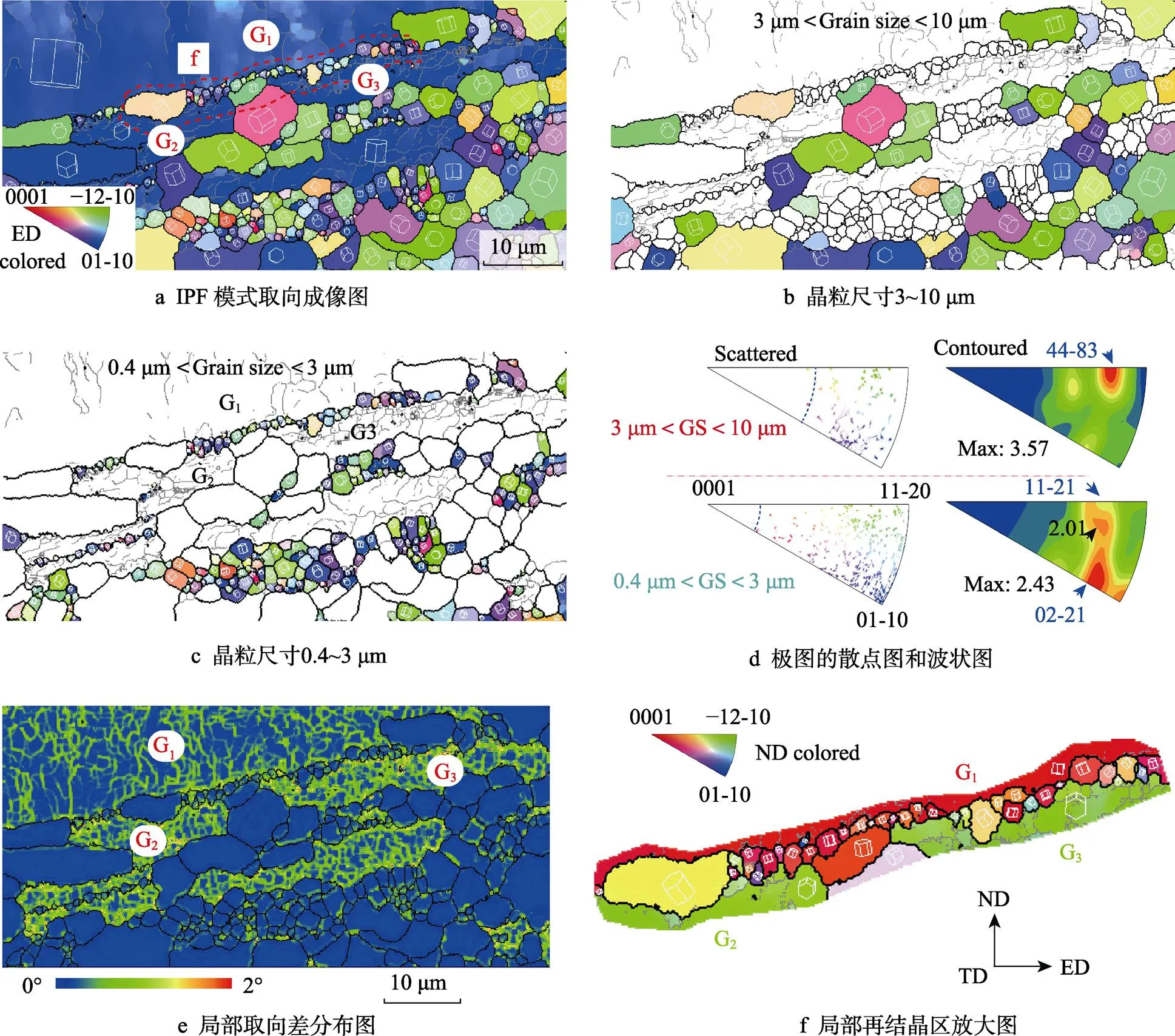

XC合金在退火過程中呈現出多尺度的晶粒結構,既包括沿擠壓方向拉長的晶粒,又包括尺寸范圍10~20 μm的粗晶,還含有尺寸<3 μm的細晶。為了進一步分析該合金的靜態再結晶機制,對圖5e中紅色框線內區域進行EBSD精細分析,如圖7所示。從圖7a可以看出,再結晶普遍發生在拉長晶粒之間,且再結晶晶粒取向較為隨機。一般認為,稀土織構的形成可分為擇優形核機制和晶粒擇優生長機制[26]。對不同尺寸再結晶晶粒分別進行統計,將大于和小于3 μm的晶粒分別提取出來,如圖7b、c所示,并將各晶粒取向繪制成散布圖和波狀圖(圖7d),可以看出,較大的晶粒(>3 μm)主要具有<44–83>||ED的取向,而較小的晶粒(<3 μm)主要具有<02–21>–<11– 21>||ED的取向。可以得出,對于XC合金,其靜態再結晶過程中稀土織構主要來源于晶粒擇優生長機制。進一步提取圖7a中紅色虛線區域,將其進行ND方向著色,如圖7f所示,可以看出,晶粒G2和G3取向接近,G1取向與G2/G3偏差接近90°,而再結晶晶粒帶中的晶粒取向更接近G1,圖7e為該區域的局部取向差圖(KAM圖),可以看出,晶粒G2和G3內部的位錯密度高于G1內部。以上結果表明,該再結晶晶粒鏈形核為晶界“弓出”機制,屬于不連續靜態再結晶(DSRX)[27]。再結晶方向為低位錯密度晶粒向高位錯密度晶粒方向弓出。

圖6 擠壓態和退火態再結晶晶粒尺寸及織構強度對比

圖7 圖5e中紅色矩形框線內EBSD精細結果

2.5 Mg-0.2Ca-0.3Ce高熱穩定性機理分析

鎂合金的再結晶行為與位錯運動行為密切相關[28]。室溫下,純鎂中

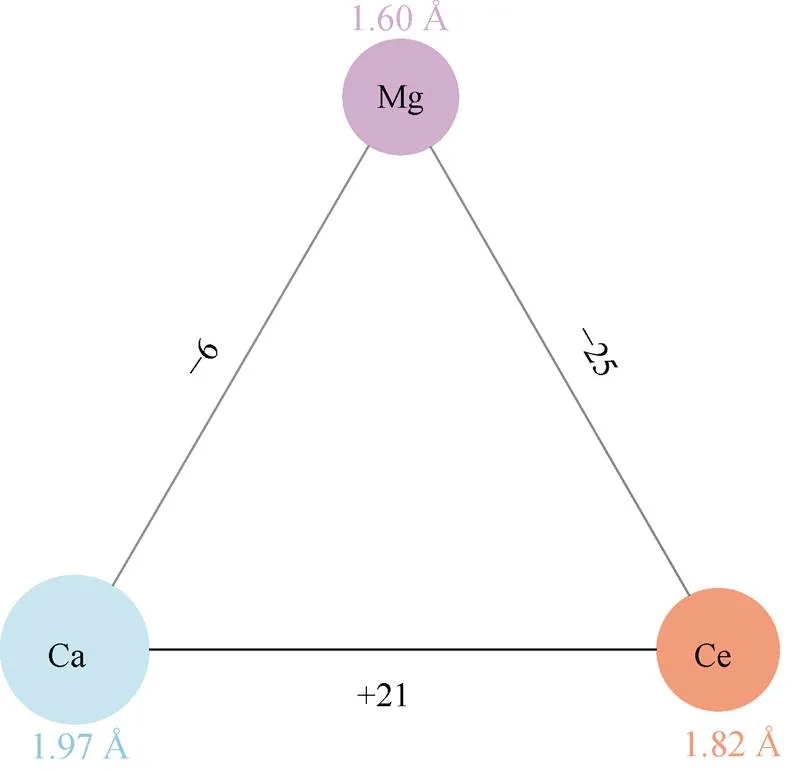

圖8 Mg、Ca、Ce元素原子尺寸和元素之間混合焓示意圖

3 結論

系統研究了Ce元素添加對擠壓態Mg–0.2Ca基合金微觀組織、力學性能和熱穩定性的影響,并闡明了Ce添加對提升鎂合金組織熱穩定性的微觀機制,得到以下主要結論。

1)在Mg–0.2Ca合金基礎上,添加質量分數為0.3%的Ce后,屈服強度由約307 MPa提高到約364 MPa;高Ca含量的Mg–0.8Ca合金表現出與Mg–0.2Ca–0.3Ce合金類似的強化效果,屈服強度可達到約361 MPa。

2)與同等強度的Mg–0.8Ca合金相比,Mg–0.2Ca–0.3Ce合金表現出更優的熱穩定性,經300 ℃/3 h退火處理后,Mg–0.2Ca、Mg–0.2Ca–0.3Ce和Mg–0.8Ca合金屈服強度下降值分別約為165.2、124.3、172 MPa。

3)Mg–0.2Ca–0.3Ce合金退火過程為不連續靜態再結晶機制,且再結晶晶粒產生的稀土織構為晶粒擇優生長機制。

[1] NIE J F, SHIN K S, ZENG Z R. Microstructure, Deformation, and Property of Wrought Magnesium Alloys[J]. Metallurgical and Materials Transactions A, 2020, 51(12): 6045-6109.

[2] 曾小勤, 王杰, 應韜, 等. 鎂及其合金導熱研究進展[J]. 金屬學報, 2022, 58(4): 400-411.

ZENG Xiao-qin, WANG Jie, YING Tao, et al. Recent Progress on Thermal Conductivity of Magnesium and Its Alloys[J]. Acta Metallurgica Sinica, 2022, 58(4): 400-411.

[3] 潘復生, 蔣斌. 鎂合金塑性加工技術發展及應用[J]. 金屬學報, 2021, 57(11): 1362-1379.

PAN Fu-sheng, JIANG Bin. Development and Application of Plastic Processing Technologies of Magnesium Alloys[J]. Acta Metallurgica Sinica, 2021, 57(11): 1362-1379.

[4] 夏琴香, 江鵬, 肖剛鋒, 等. 鎂合金帶內筋筒形件熱強旋成形質量及參數優化[J]. 精密成形工程, 2022, 14(5): 1-7.

XIA Qin-xiang, JIANG Peng, XIAO Gang-feng, et al. Forming Quality and Parameters Optimization for Hot Power Spinning of Magnesium Alloy Cylindrical Parts with Inner Ribs[J]. Journal of Netshape Forming Engineering, 2022, 14(5): 1-7.

[5] 王慧遠, 夏楠, 布如宇, 等. 低合金化高性能變形鎂合金研究現狀及展望[J]. 金屬學報, 2021, 57(11): 1429-1437.

WANG Hui-yuan, XIA Nan, BU Ru-yu, et al. Current Research and Future Prospect on Low-Alloyed High-Performance Wrought Magnesium Alloys[J]. Acta Metallurgica Sinica, 2021, 57(11): 1429-1437.

[6] 吳國華, 童鑫, 蔣銳, 等. 鑄造Mg–RE合金晶粒細化行為研究現狀與展望[J]. 金屬學報, 2022, 58(4): 385-399.

WU Guo-hua, TONG Xin, JIANG Rui, et al. Grain Refinement of As-Cast Mg-RE Alloys: Research Progress and Future Prospect[J]. Acta Metallurgica Sinica, 2022, 58(4): 385-399.

[7] STRáSKá J, JANE?EK M, ?í?EK J, et al. Microstructure Stability of Ultra-Fine Grained Magnesium Alloy AZ31 Processed by Extrusion and Equal-Channel Angular Pressing (EX-ECAP)[J]. Materials Characterization, 2014, 94: 69-79.

[8] PéREZ-PRADO M T, VALLE D, RUANO O A. Grain Refinement of Mg-Al-Zn Alloys via Accumulative Roll Bonding[J]. Scripta Materialia, 2004, 51(11): 1093-1097.

[9] SUN W T, QIAO X G, ZHENG M Y, et al. Altered Ageing Behaviour of a Nanostructured Mg-8.2Gd-3.8Y- 1.0Zn-0.4Zr Alloy Processed by High Pressure Torsion [J]. Acta Materialia, 2018, 151: 260-270.

[10] DE OLIVEIRA P C, MONTORO L A, PEREZ-PRADO M T, et al. Development of Segregations in a Mg-Mn-Nd Alloy during HPT Processing[J]. Materials Science and Engineering: A, 2021, 802: 140423.

[11] WAN Ying-chun, TANG Bei, GAO Yong-hao, et al. Bulk Nanocrystalline High-Strength Magnesium Alloys Prepared via Rotary Swaging[J]. Acta Materialia, 2020, 200: 274-286.

[12] LI Jing-ren, ZHANG Ai-yue, PAN Hu-cheng, et al. Effect of Extrusion Speed on Microstructure and Mechanical Properties of the Mg-Ca Binary Alloy[J]. Journal of Magnesium and Alloys, 2021, 9(4): 1297-1303.

[13] PAN Hu-cheng, KANG Rui, LI Jing-ren, et al. Mechanistic Investigation of a Low-Alloy Mg-Ca-Based Extrusion Alloy with High Strength-Ductility Synergy[J]. Acta Materialia, 2020, 186: 278-290.

[14] DU Sen, YANG Kun, LI Man, et al. Achieving High Strength above 400 MPa in Conventionally Extruded Mg-Ca-Zn Ternary Alloys[J]. Science China Technological Sciences, 2022, 65(3): 519-528.

[15] 武華健, 程仁山, 李景仁, 等. Al含量對Mg–Sn–Ca合金微觀組織與力學性能的影響[J]. 金屬學報, 2020, 56(10): 1423-1432.

WU Hua-jian, CHENG Ren-shan, LI Jing-ren, et al. Effect of Al Content on Microstructure and Mechanical Properties of Mg-Sn-Ca Alloy[J]. Acta Metallurgica Sinica, 2020, 56(10): 1423-1432.

[16] LI X, QI W. Effect of Initial Texture on Texture and Microstructure Evolution of ME20 Mg Alloy Subjected to Hot Rolling[J]. Materials Science and Engineering: A, 2013, 560: 321-331.

[17] LI J R, XIE D S, ZENG Z R, et al. Mechanistic Investigation on Ce Addition in Tuning Recrystallization Behavior and Mechanical Property of Mg Alloy[J]. Journal of Materials Science & Technology, 2023, 132: 1-17.

[18] GUAN Di-kai, LIU Xing-guang, GAO Jun-heng, et al. Exploring the Mechanism of “Rare Earth” Texture Evolution in a Lean Mg–Zn–Ca Alloy[J]. Scientific Reports, 2019, 9: 7152.

[19] ZENG Z R, BIAN M Z, XU S W, et al. Effects of Dilute Additions of Zn and Ca on Ductility of Magnesium Alloy Sheet[J]. Materials Science and Engineering: A, 2016, 674: 459-471.

[20] ZHAO De-xin, MA Xiao-long, SRIVASTAVA A, et al. Significant Disparity of Non-Basal Dislocation Activities in Hot-Rolled Highly-Textured Mg and Mg-3Al-1Zn Alloy under Tension[J]. Acta Materialia, 2021, 207: 116691.

[21] LIU Bo-yu, LIU Fei, YANG Nan, et al. Large Plasticity in Magnesium Mediated by Pyramidal Dislocations[J]. Science (New York, N Y), 2019, 365(6448): 73-75.

[22] LI R G, LI H R, PAN H C, et al. Achieving Exceptionally High Strength in Binary Mg-13Gd Alloy by Strong Texture and Substantial Precipitates[J]. Scripta Materialia, 2021, 193: 142-146.

[23] ZHENG Rui-xiao, DU Jun-ping, GAO Si, et al. Transition of Dominant Deformation Mode in Bulk Polycrystalline Pure Mg by Ultra-Grain Refinement down to Sub-Micrometer[J]. Acta Materialia, 2020, 198: 35-46.

[24] 章歐, 胡紅軍, 胡剛, 等. 鎂合金復合細晶強化研究進展[J]. 精密成形工程, 2021, 13(6): 98-105.

ZHANG Ou, HU Hong-jun, HU Gang, et al. Research Progress on Composite Refinement Strengthening of Magnesium Alloy[J]. Journal of Netshape Forming Engineering, 2021, 13(6): 98-105.

[25] GUAN Di-kai, RAINFORTH W M, GAO Jun-heng, et al. Individual Effect of Recrystallisation Nucleation Sites on Texture Weakening in a Magnesium Alloy: Part 1- Double Twins[J]. Acta Materialia, 2017, 135: 14-24.

[26] ZHAO L Y, YAN H, CHEN R S, et al. Orientations of Nuclei during Static Recrystallization in a Cold-Rolled Mg-Zn-Gd Alloy[J]. Journal of Materials Science & Technology, 2021, 60: 162-167.

[27] 王忠堂, 劉永哲, 王明浩, 等. 基于復合變形的鎂合金動態再結晶及晶粒尺寸研究[J]. 精密成形工程, 2021, 13(4): 115-120.

WANG Zhong-tang, LIU Yong-zhe, WANG Ming-hao, et al. Study on Dynamic Recrystallization and Grain Size of Magnesium Alloy Based on Compound Deformation[J]. Journal of Netshape Forming Engineering, 2021, 13(4): 115-120.

[28] 王慧遠, 張行, 徐新宇, 等. 超塑性輕合金組織穩定性的研究進展及展望[J]. 金屬學報, 2018, 54(11): 1618-1624.

WANG Hui-yuan, ZHANG Hang, XU Xin-yu, et al. Current Research and Future Prospect on Microstructure Stability of Superplastic Light Alloys[J]. Acta Metallurgica Sinica, 2018, 54(11): 1618-1624.

[29] 安藤新二, 中村寛治, 高島和希, et al. マグネシウム単結晶の{11-22}<-1-123>すべり[J]. 軽金屬, 1992, 42(12): 765-771.

ANDO Shinji, NAKAMURA Kanji, TAKASHIMA Kazuki, et al. {11-22} <-1-123> slip in magnesium single crysta[J]. Journal of Japan Institute of Light Metals, 1992, 42(12): 765-771.

[30] OBARA T, YOSHINGA H, MOROZUMI S. {112?2}〈1123〉 Slip System in Magnesium[J]. Acta Metallurgica, 1973, 21(7): 845-853.

[31] YOSHINAGA H, HORIUCHI R. Deformation Mechanisms in Magnesium Single Crystals Compressed in the Direction Parallel to Hexagonal Axis[J]. Transactions of the Japan Institute of Metals, 1963, 4(1): 1-8.

[32] CONRAD H, ROBERTSON W D. Effect of Temperature on the Flow Stress and Strain-Hardening Coefficient of Magnesium Single Crystals[J]. JOM, 1957, 9(4): 503-512.

[33] BURKE E C, HIBBARD W R. Plastic Deformation of Magnesium Single Crystals[J]. JOM, 1952, 4(3): 295-303.

[34] WANG Jing-ya, CHEN Yi-wen, CHEN Zhe, et al. Deformation Mechanisms of Mg-Ca-Zn Alloys Studied by Means of Micropillar Compression Tests[J]. Acta Materialia, 2021, 217: 117151.

[35] LEE J K, LEE B J. The Origin of Activation of Non-Basal Slip in Mg-Ce Dilute Alloy: An Atomistic Simulation Study[J]. Metallurgical and Materials Transactions A, 2021, 52(3): 964-974.

Effect of Ce on Mechanical Property and Thermal Stability of Extruded Mg-Ca Alloy

LI Jing-ren, XIE Dong-sheng, ZHANG Dong-dong, XIE Hong-bo, PAN Hu-cheng, REN Yu-ping, QIN Gao-wu

(Key Laboratory for Anisotropy and Texture of Materials, Ministry of Education, Northeastern University, Shenyang 110819, China)

The work aims to investigate the effect of 0.3wt.% Ce and 0.6wt.% Ca on microstructure, mechanical properties and thermal stability of extruded Mg-0.2Ca alloy and explore the strengthening and stabilization effect of Ce and Ca on Mg alloy at medium and high temperature. Firstly, Mg-0.2Ca, Mg-0.2Ce-0.3Ce and Mg-0.8Ca alloys were melted and prepared. Then, the three alloys were extruded and the microstructure and mechanical properties of the extruded alloys were characterized and tested. Finally, the alloys were subject to isothermal annealing at 300 °C and their microstructure evolution process and decrease of mechanical properties were studied. Adding 0.3wt.% Ce to Mg-0.2Ca alloy reduced the recrystallization fraction of extruded alloy from about 92% to about 53% and the recrystallized grain size refined from about 1.64 μm to about 0.86 μm. The yield strength of Mg-0.2Ca-0.3Ce ternary alloy significantly increased to about 364 MPa, which was equivalent to that of Mg-0.8Ca alloy (about 361 MPa), indicating that Ce per unit mass had stronger strengthening effect than Ca. The yield strength of Mg-0.2Ca-0.3Ce ternary alloy decreased by about 124 MPa after annealing of 3 h, which was significantly lower than that of Mg-Ca binary alloy (170 MPa). With the Mg-0.2Ca-0.3Ce alloy as an example, static recrystallization microstructure evolution analysis revealed that the static recrystallization process produced rare earth texture, and its recrystallization mechanism was discontinuous static recrystallization (DDRX). In summary, adding 0.3wt.% Ce into extruded Mg-0.2Ca alloy increases yield strength from about 307 MPa to about 364 MPa, which is equivalent to the strength of 0.6wt.% Ca alloy. Mg-Ca-Ce ternary alloy has higher thermal stability than Mg-Ca binary alloy.

wrought Mg alloy; micro-alloying; mechanical properties; dislocation; thermal stability

10.3969/j.issn.1674-6457.2023.02.001

TG379

A

1674-6457(2023)02-0001-10

2022–07–01

2022-07-01

國家重點研發計劃(2021YFB3701002);國家自然科學基金(U2167213,51971053);中國科協“青年托舉”工程項目(2019–2021QNRC001,2019–2021QNRC002,2019–2021QNRC003);中央高校基本科研業務費項目(N2202020)

National Key Research and Development Program of China (2021YFB3701002); National Nature Science Foundation of China (U2167213, 51971053); Young Elite Scientists Sponsorship Program by CAST (2019-2021QNRC001, 2019-2021 QNRC002, 2019-2021QNRC003); Fundamental Research Funds for the Central Universities (N2202020)

李景仁(1992—),男,博士生,主要研究方向為擠壓鎂合金變形機制。

LI Jing-ren (1992-), Male, Doctoral candidate, Research focus: deformation mechanisms of extrusion magnesium alloys.

潘虎成(1988—),男,博士,副教授,主要研究方向為高性能鎂合金設計、制備及變形和強化機制。

PAN Hu-cheng (1988-), Male, Doctor, Associate professor, Research focus: design, preparation, deformation and strengthening mechanism of high performance magnesium alloys.

李景仁, 謝東升, 張棟棟, 等. Ce添加對Mg–Ca擠壓合金力學性能與熱穩定性影響研究[J]. 精密成形工程, 2023, 15(2): 1-10.

LI Jing-ren, XIE Dong-sheng, ZHANG Dong-dong, et al. Effect of Ce on Mechanical Property and Thermal Stability of Extruded Mg-Ca Alloy[J]. Journal of Netshape Forming Engineering, 2023, 15(2): 1-10.