重型復雜結構件過渡槽焊接變形工藝研究

董曼淑 劉龍 董志波

摘要: 為了有效控制重型復雜結構件過渡槽焊接變形,采用基于熱-力耦合分析的有限元軟件MSC.Marc對過渡槽建立1∶1比例模型進行模擬。通過縮比件數據分析來驗證建模的準確性,并設計了兩種不同路徑方案進行對比分析,提出優化建議。選取典型產品對兩種方案進行了現場驗證,結果表明,方案二較之于方案一效果明顯,有效控制了重型復雜結構件過渡槽的焊接變形。

關鍵詞: 重型復雜結構件過渡槽; 縮比模型; 有限元分析; 焊接變形

中圖分類號:TG 442

Study on welding deformation technology of transition slot

for heavy complex structures

Dong Manshu1,2, Liu Long1,2, Dong Zhibo3

(1. Ningxia Tiandi Benniu Industrial Group Co., Ltd., Shizuishan 753001, Ningxia, China;

2. Ningxia Field of Activity Heavy Equipment Technology Co., Ltd., ?Shizuishan 753001, Ningxia, China;3.Harbin Institute of Technology, Harbin 150001, Heilongjiang, China)

Abstract: The model of transition slot was established by using the finite element software Msc.Marc based on the thermomechanical coupling analysis in order to control the welding deformation of the transition groove of the heavy complex structure. The accuracy of simulated results is verified by the experimental data of scale model. The optimization suggestions are put forward by the comparative analysis of two different schemes. The experimental results of two typical products show scheme two is better than scheme one in effectively controlling the welding deformation of transition slot of heavy complex structure.

Key words: transition slot of heavy complex structure; scale model; finite element analysis; welding deformation

0?前言

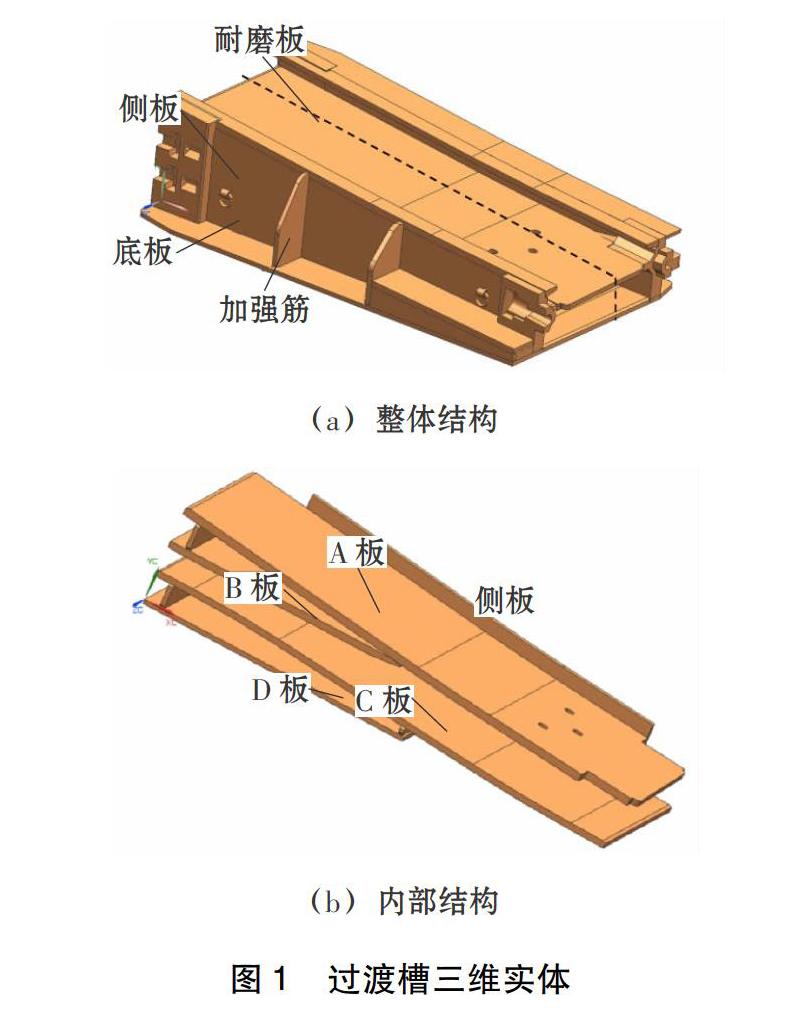

重型復雜結構件過渡槽是煤機產品“三機一架”[1]中的刮板輸送機裝備的關鍵部件。三機一架即采煤機、刮板輸送機、轉載輸送機和液壓支架。由于刮板輸送機在運行過程中受力復雜、條件惡劣容易造成設備損壞或斷裂,因此刮板輸送機性能的可靠性是進行高效作業的根本保證。過渡槽用于連接機頭(尾)和中部段,使刮板由中部段到機頭(尾)平穩運行。中板為弧形,在運輸過程中中板、側板上沿最易磨損,導致刮板鏈運行過程中存在刮卡、跳鏈等問題。過渡槽結構復雜,由40多個零件焊接而成,實際生產制造過程中焊接量大、焊接變形不易控制[2]、變形矯正困難等問題。目前,國內外煤礦制造業對過渡槽的焊接變形及可靠性研究很少,在實際生產制造過程中出現了大量過渡槽結構焊接變形超標的問題。

文中主要對過渡槽進行了有限元模擬[3],典型焊縫縮比件數據驗證,設計不同焊接路徑方案以及方案現場驗證等研究,達到有效控制重型復雜結構件過渡槽焊接變形的目的,提高刮板輸送機可靠性。……