綜合式電動汽車傳動系統的解決方案

Approach to an Integrated Electric Vehicle Drive Solution

1 動因

為在不斷增加的燃油價格和必須減少CO2排放努力之間到達平衡,汽車制造商采用了以下不同途徑。通過最佳的內燃機、傳動系統以及更大范圍的使用混合動力技術來滿足今天CO2的排放指標。在今后幾年內傳統技術的改進仍將扮演重要角色[1,2],而混合動力技術將在中期內對市場產生影響。在一個純電動汽車的虛擬世界中,其它技術將被放棄,盡管各種混合動力技術的各種部件(電動機、蓄電池)可被重復利用。從這點看,混合動力技術經常被標注成一個“過渡期”的方案。但是,今天有大批專家認為用純電動汽車完全替代現有車輛將在很久以后出現或者根本不可能實現。如果假設上述所有技術并行存在的話。因而開發包括混合動力在內的高效傳統技術和諸如純電動汽車的新型傳動概念必須同時加速進行。

2 定義,電氣化等級

對于即將到來的車輛電力傳動而言,重要的是在討論車輛電氣化問題時采用同一種語言。在從電力傳動中區分混合動力傳動或者從串聯結構從區分增程器時,給出一個清晰定義是必要的。

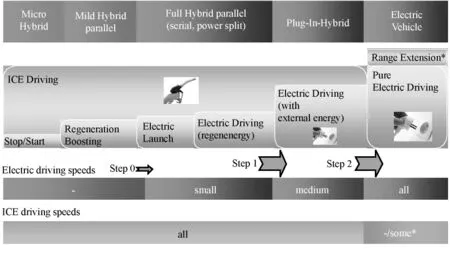

通常傳動系統電氣化的路標被描述成從“大內燃機、小電動機”到“大電動機、無內燃機”等這樣一個連續報道。為明確技術方案,必須避免這種連續化描述。因此規范必須進行分類、組合,差別必須被定義而各組別間的技術等級必須建立,圖1。

1 Motivation

In an effort to strike a balance between increasing fuel prices and the necessity to reduce CO2emissions,different paths are followed by the automotive industries.The pursuance of optimization measures concerning combustion engines and transmissions as well as the broader use of hybrid technology provide the possibility of achieving today’s CO2targets.

The improvement of conventional technologies will still play a decisive role in the near future[1,2],while hybrid technology will affect the market in the medium term.In a fictional world of only pure electric drivelines,other technologies would be replaced,even if various components of the hybrid technology(electric motors,batteries)could be reused.On that score,hybrid technology is often labeled as“transitional”solution.However,nowadays lots of experts agree that an entire substitution by electric vehicles will take place very late or maybe never.It is rather assumed that all mentioned technologies will exist in parallel.Consequently the development of both,highly efficient conventional technology including hybrids and new driveline con-cepts such as drivelines for pure electric mobility,has to be pushed forward.

圖1 不同功能等級和規范的電氣化道路圖Fig.1 Electrification road map with functional steps and specifications

混合動力車輛(HEV)

根據聯合國組織的定義,混合動力車輛具有兩種不同的功率轉換設備和兩種不同的能量存儲裝置。通常該類車輛在內燃機(ICE)和一個或多個電動機(EM)之間轉換。因此被定義成混合動力車輛(HEV)。HEV的儲能裝置是向內燃機供油的油箱和向電動機供能的蓄電池(或超級電容)。

HEV的主要潛力是在減速期間可以回收動能。其優點是能夠向電力儲能裝置輸送和存儲能量。當電動機作為發電機使用時,原來制動時所耗散的能量可轉換成電能。ZF公司的經濟型并聯混合動力方案早已投放市場[1,2]。

純電動車輛(EV)

純電動車輛僅由電動機驅動,電能來源于蓄電池。電力驅動能夠滿足所有規范。EV的一種特殊變型是增程型電動汽車,除了滿足上述條件外,這類車輛還可采用增程驅動模式,例如臨時使用內燃機,如果內燃機與驅動橋相聯的話。從定義上理解,該增程器僅用來擴展行駛里程而并不滿足電力驅動的其它行駛規范(諸如最高車速、性能等)。EV車輛的增程器驅動形式類似于混合動力車輛。并聯結構將內燃機直接聯接到驅動橋上;串聯結構則需要一個額外的發電機向蓄電池充電或向電動機供能,詳見第五節。

2 Definitions,Steps of electrification

With the upcoming of electric vehicle drives it is important to speak the same language when discussing vehicle electrification issues.Clear definitions are essential to distinguish e.g.hybrid drives from EV drives or serial architectures from range extender solutions.

Often the roadmap of driveline electrification is described as a continuous ramp from “much ICE,little EM”to“much EM,no ICE”.To develop distinct technical solutions such a continuous approach has to be avoided.The specifications rather have to be separated and grouped,differences have to be identified and technological steps between the groups have to be found,Figure1.

Hybrid Vehicles(HEV)

By definition of the UNO a hybrid vehicle has two different power converters and two different storage devices.In comm on hybrid electric vehicles the converters are a conventional internal combustion engine(ICE)and one or more electric motors(EM).Therefore the term hybrid electric vehicle arose(HEV).The storage devices of HEVs are a fuel tank which supplies the ICE with energy and a battery(or super-capacitor).

One of the main potentials of HEVs is the possibility to recover kinetic energy in deceleration phases.It is taken advantage of the ability of the electric storage device to deliver and to collect energy.Thereby energy,that was formerly lost while braking mechanically,can be transformed into electric energy by using the EM as a generator.Economic parallel hybrid solutions from ZF are in the market already[1,2].

HEV EV的差別

上述兩種驅動的差別主要在于為實現傳動系統所有行駛規范所采用的功率轉換方式。在HEV中100%來源于內燃機,而在EV中則來自于電動機。

3 電動汽車行駛-發展目標

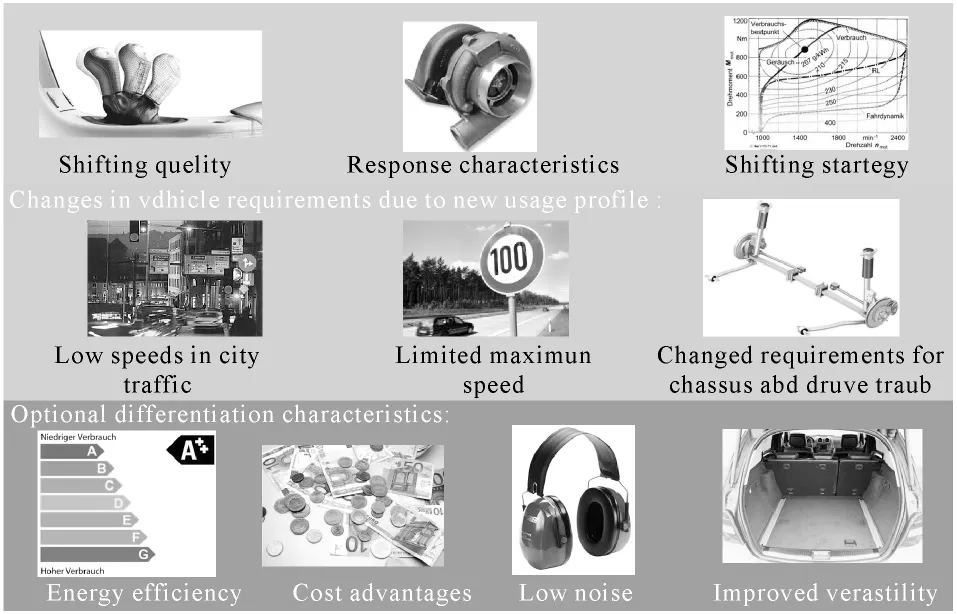

電動汽車常被稱為未來車輛。事實上零排放的潛力似乎很具吸引力。對使用者而言,必須了解電力驅動的優缺點。圖2歸納了一些重要因素。

圖2 最終用戶的電力驅動優缺點Fig.2 Drawbacks and benefits of electric mobility for the end customer.

在開發傳動系統時,感興趣的是純電動汽車的傳動和常規傳動系統的不同之處。顯然裝置的特殊化因素發生了變化。先前的標準如換檔品質、響應和換檔模式等的重要性下降,而傳動系統的效率、質量和變速器的聲學特征等變得很重要,圖3。

將來純電動汽車傳動系統最重要的特性之一是效率。即便在全新緊湊型車身的設計中加熱、冷卻成為非常重要的議題,或者純電動汽車關鍵部件-蓄電池在功率能量密度方面取得突破的話:絕大部分的能量傳遞仍將出現在傳動系統中,該系統包括逆變器、電動機和介于電動機及車輪之間的變速器。傳輸必須盡可能的高效,尤其是在驅動/制動雙向傳輸工況時。

Electric Vehicle(EV)

An electric vehicle(EV)is driven exclusively by electric power coming from the vehicle battery.All driving specifications can be fulfilled by the electric drive.A special variant of EVs are range extended electric vehicles,for which the last mentioned condition is valid as well,but with the addi-tion that these vehicles might be driven by the range extender device–e.g.an ICE–temporarily,if this device is connected to the drive axle.The range extender by definition does only extend the range and does not fulfill other driving specifications(like top speed,performance...)than the electric drive.The drive structures of range extender EVs are comparable to those of hybrid drives.Parallel structures are offering a direct connection of the above mentioned ICE to the axle;serial structures need an additional generator to re-charge the battery or to supply the motor with energy,see chapter 5.

Differentiation between HEV and EV

Like mentioned above the difference between the two drives should be defined by the power converter which is designed for all driving specifications of the driveline.In an HEV 100per cent of the spec shall be fulfilled by the ICE,in an EV all of by the EM.

3 Electric Vehicle Drives– Development goals

Electric vehicles very often are described as the future mobility solution.And indeed the potential of emission free driving seems to be attractive for the benefit of mankind.The meaning of electric mobility for the user–with all its benefits and drawbacks–has to be mentioned as well.Figure2 summarizes the important factors.

For the development of driveline systems it is of great interest how the characteristics of EV drives differ from the conventional ones.Obviously the set of differentiation factors changes.Former criteria like shift quality,response and shift patterns lose importance,while the efficiency of the driveline,its weight as well as the acoustic behavior,e.g.of the transmission,become very important,Figure3.

One of the most important characteristics of an EV drive of the future will be the driveline efficiency.Even if there will be energetically important issues like heating and cooling with new impacts on the cabin design,and even if battery developers will achieve big successes concerning the power and energy density of the EV drive’s key component:the biggest part of energy transformation will still take place in the driveline system consisting of the inverter,the electric motor and the transmission between the latter and the wheels.This transformation has to be as efficient as possible,especially because it occurs both for driving and braking(regeneration)phases.

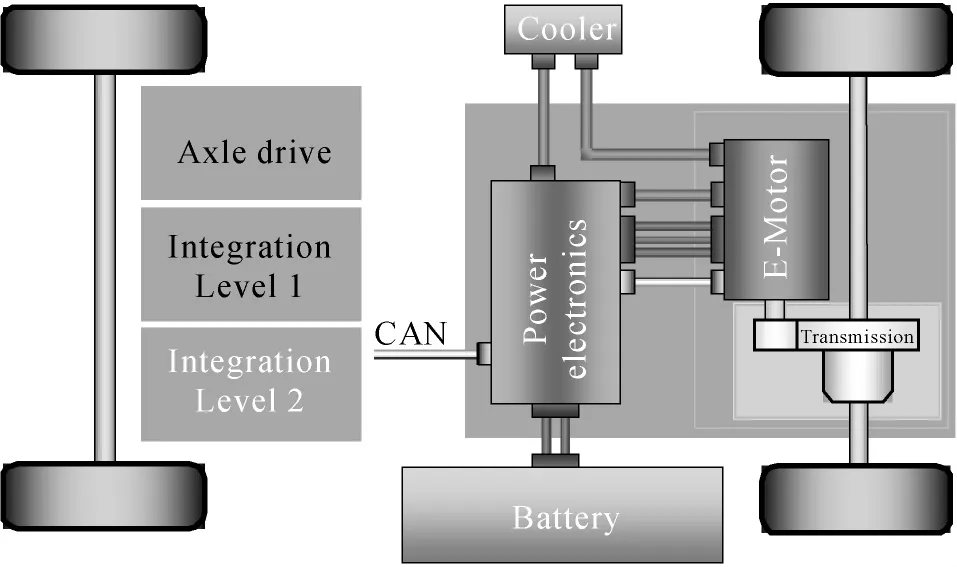

從傳動系統開發者的觀點看,最重要的是研究整個動力傳輸鏈即包括“逆變器、電動機、齒輪”的整個系統而不是單一部件。必須加以綜合考慮,見圖4。

圖3 純電動汽車賣點的變化Fig.3 Change of Unique selling propositions(USP)of electric vehicles

圖4 純電動汽車的集成水平。水平2有望實現在經濟性和效率方面的最佳系統Fig.4 Integration levels for electric drives.Level 2promises best results in terms of system optimization towards economics and efficiency

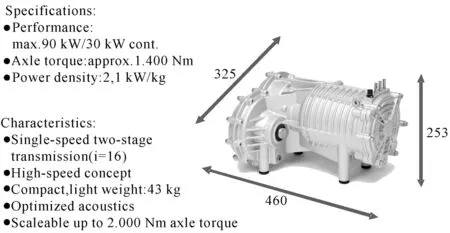

4 ZF公司的純電動汽車傳動系統方案

ZF EVD1(純電動汽車傳動系統)是ZF已經研制成功的第一個產品。在這個高速方案中,所有動力電子設備、電動機和機械(例如傳動、軸承)方面的知識和總體設計(處于水平1)的各種可能性都被用來開發一套電動傳動系統,使其滿足質量輕、緊湊、高功率密度和聲學最優。圖5。

From the driveline developer’s point of view it is absolutely crucial to focus on the whole chain of power transformation,i.e.the complete system“inverter,motor,gears”instead of the single components.An integration approach has to be considered as shown in Figure4.

4 ZF’s solution for an Electric Vehicle Drive

A first approach has been made by ZF with the ZF EVD1(Electric Vehicle Drive 1).In this high speed solution all knowledge on power electronics,electric motors and mechanics,like gearings and bearing concepts and all possibilities of integrated design(on level 1)have been used to develop an electric vehicle drive which is light-weight,compact,highly power dense and acoustically optimized,Figure5.

圖5 作為集成化設計成果的ZF EVD1 Fig.5 ZF’s Electric Vehicle Drive 1as result of an integrated design

速比

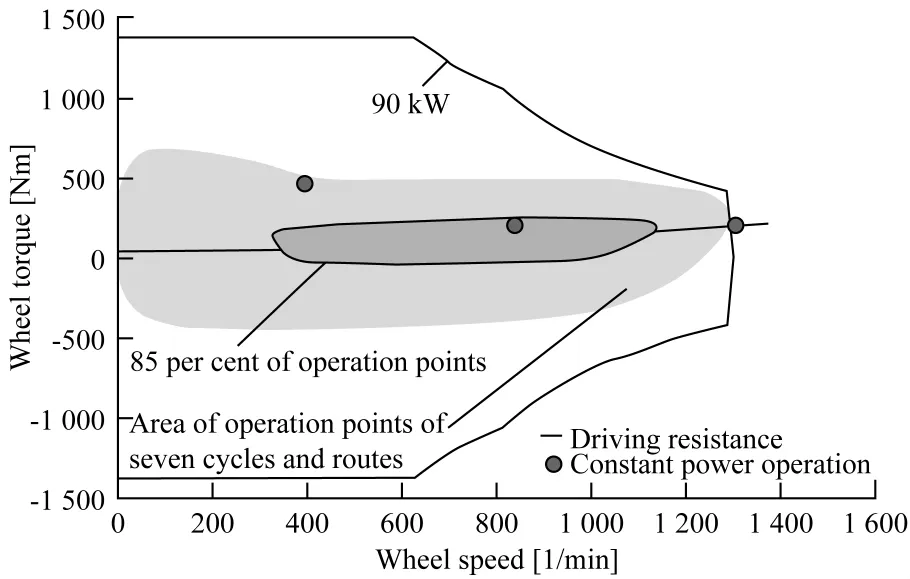

經常討論的問題是關于EV傳動系統的速比。許多專家都同意,在假設電動轎車主要用于通勤目的,也就是短途行駛的話,其最高車速約在130km/h[3-7]左右這樣一個較低的水平。同樣也假設該緊湊型轎車的爬坡能力一般。因此可以設想驅動橋最大轉矩約為1 200Nm。將轉矩和車速這兩個主要需求與現代化電動機的轉矩-車速圖相比,便能夠清晰地發現無需多級變速,除非最高車速或最大轉矩超過了上述限值。而行駛效率則必須加以考慮。圖6是該研究的仿真結論。

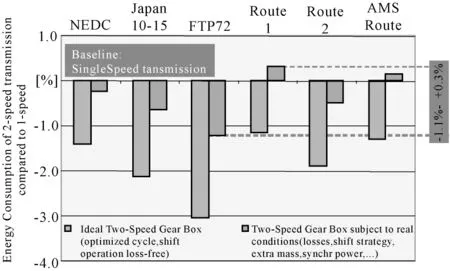

圖6 與單級方案相比,兩級速比變速器在EVD1中的效率優勢相當小。其優勢在于更好地利用電動機的效率圖。這些優勢(部分優勢)被附加部件和質量以及換檔操作所抵消Fig.6 The efficiency-wise advantage of a two-speed transmission in an EVD1versus a simple one-speed solution is quite low.The advantages are linked to the better use of the efficiency map of the electric drive.These advantages are(partly over-)compensated by losses originated by additional parts and masses as well as by operations like the synchronization during shifting

高速傳動概念

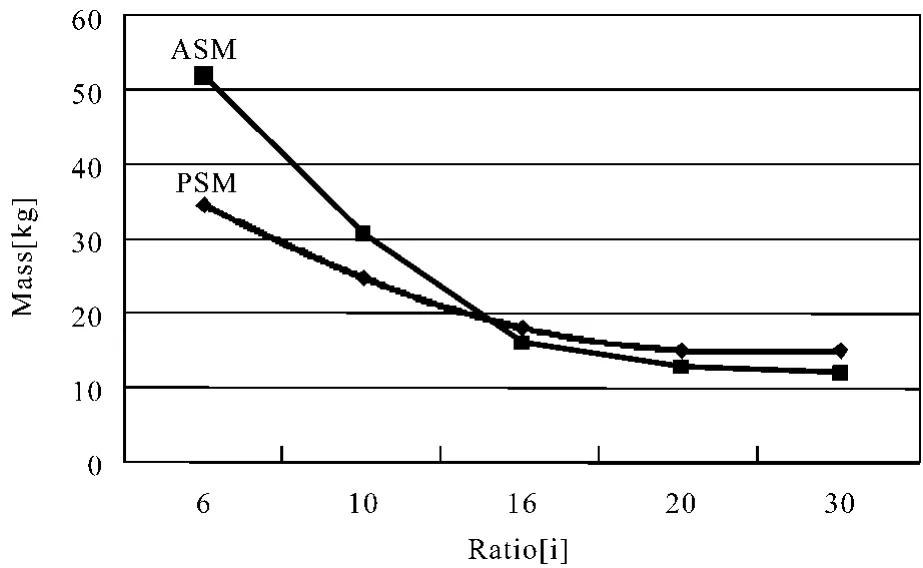

為獲得小尺寸、低質量和低成本方面的優勢,ZF決定電動機采用高速傳動概念,其最高轉速達到21 000r/min同時變速器速比約為16。高速傳動概念可減輕電動機質量約50%,而采用異步技術(ASM)帶來的功率密度劣勢也可被消除。這意味著,降低成本和質量的雙重目標可通過采用高速傳動的ASM實現,圖7。

Number of speeds

A discussion often starts when the question of gears for an EV driveline arises.Many authors agree on the assumption that an electric passenger car serves mainly for commuter purposes,i.e.on short trips with relatively low maximum speeds around 130km/h[3to 7].Also it is commonly assumed that the vehicle’s gradeability is that of a compact car in general.So a good assumption for a maximum axle torque could be around 1.200Nm.Comparing these two main demands–torque and speed–to the torque-speed map of modern electric motors,one can easily find out that multiple transmission ratios are not needed unless top speed or maximum torque exceeds the mentioned limits.At second sight the efficiency in cycles and customer routes has to be taken into account.The result of such an investigation by simulation means is described in Figure6.

High speed concept

To achieve the advantages of small package,low weight and cost advantages in comparison to standard approaches ZF decided to choose a highspeed concept with an electric machine that features a maximum speed of 21,000r/min and a transmission with a mechanical ratio of approximately 16.The high-speed concept reduces the weight of the electric machine by about 50per cent,and even the disadvantage of the asynchronous technology(ASM)in terms of power density can be eliminated.This means,that both targets,cost and weight reduction,are reached by choosing an ASM in a high-speed concept,Figure7.

Overall Efficiency

Besides compactness,efficiency is another target for an electric vehicle drive.With respect to this criterion,the advantages of a PSM over an ASM become negligible when choosing a high-speed concept.Although ZF has chosen the ASM technology,the technology investigation showed that both electric machine technologies(PSM and ASM)are feasible for the high speed concept with comparable performance data.The ASM technology was chosen,but for future developments the PSM technology is still a viable option.

圖7 采用高速傳動降低質量和成本。電動機轉速為21 000r/min變速器速比為16時的最高車速為150km/hFig.7 Weight-and cost reduction due to high-speed concept.The transmission ratio 16gives a top speed of 150km/h at an electric motor rotational speed of 21 000r/min.Mass質量 Ratio速比

總效率

除了小型化,效率是純電動汽車傳動系統追求的另一個目標。就該標準而言,一旦選擇高速傳動后,PSM(永磁同步電機)相對于ASM(異步電機)的優勢可忽略不計。因此ZF采用ASM技術,技術研究表明在上述參考數據前提下兩種電機均能采用高速傳動概念。目前采用ASM技術,將來PSM仍將是一項可行的選擇。

就效率而言必須了解相應的工作模式。因此必須根據其性能需求分析消費者行駛循環與官方行駛循環的不同。分析發現,處于低或中等負荷下即接近車輛零阻力曲線附近時電力驅動車輛的效率是非常重要的。對應于預期最重要的城市使用工況,40-120km/h的車速范圍是一個有效的選擇,這時就功耗而言,高速遠比低速更重要。因此,EVD1的電動機被設計成在該模式下具有最佳的效率,圖8。

順便提及,該發現并不適用于以電動機或發電機模式經常工作在最高可用功率的HEV驅動。

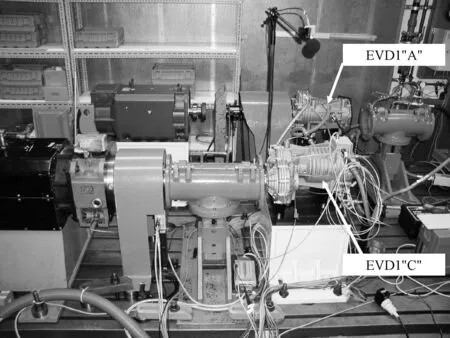

EVD1已造出數臺樣機,目前正在評估性能指標。試驗在臺架上進行圖9。試驗結論表明其載荷/效率和聲學特性很有前途。樣車上的集成工作正在進行中。EVD1的試驗情況即將公布。

5 增程器概念

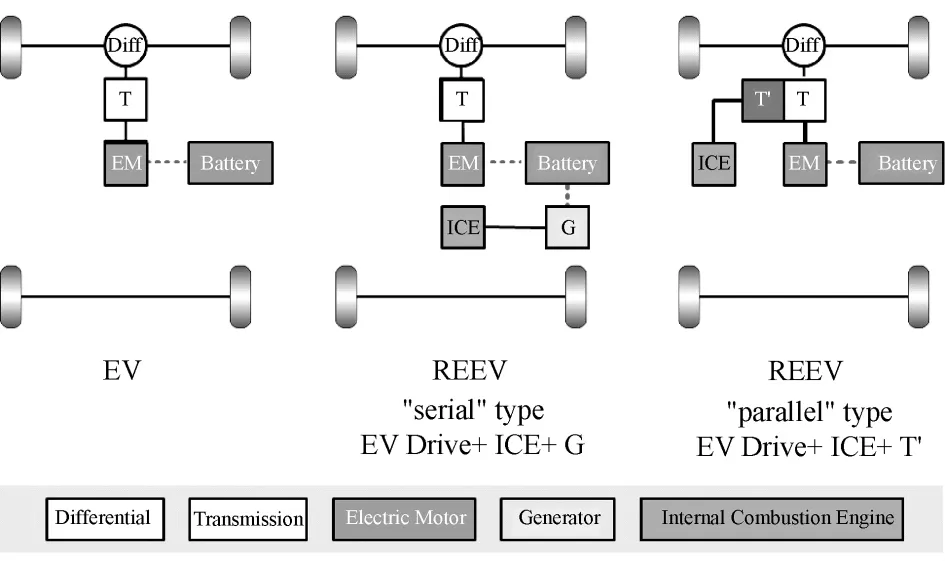

純電動汽車的瓶頸在于蓄電池。改進不僅涉及到功率密度、成本,還涉及到充電時間等。由于這些方面的進展很慢,目標定義為減少每車所需的總蓄電池量。為能夠使用容量有限的蓄電池,用戶要么接受行駛里程受限,或者采用通過車載附加能源擴展里程的裝置。通常該能源是燃油,用于驅動一臺小型內燃機。發動機的動力可經發電機轉化為電能向蓄電池充電,或者直接驅動電動機(串聯結構)。另一種選擇是機械能直接作用在驅動橋上。這通過一套附加的傳動裝置(并聯結構)實現。上述兩者均有其優缺點,這將導致兩者共存,正如并聯和功率分流混合動力那樣,圖10。

With respect to efficiency the most relevant operating modes have to be known.Therefore different customer driving cycles and official driving cycles were analyzed with respect to their performance requirements.It could be found out,that especially for vehicles with electric traction the efficiency at small and medium loads,adjacent to the natural vehicle resistance curve,is of utmost importance.With the anticipated predominant urban usage profile,the speed range of 40to 120kph seems to be a viable choice,where,with respect to consumed power,higher speeds are more important than lower speeds.Therefore the EVD1electric machine is designed for optimum efficiency in these operation modes,Figure8.

This finding does–by the way–not apply to electric motors of HEV drives,which are most frequently used at maximum available power,be it in motor or regeneration mode.

The EVD1has been built up in several prototypes and is currently under thorough evaluation on the promised properties.Therefore test runs on load rigs are evaluated,Figure9.The results are– both with respect to load/efficiency and to acoustics–promising.The integration in a demonstrator vehicle is currently running.Experiences with driving the EVD1will be reported in presentations yet to come.

5 Range-Extender Concepts

The main bottleneck for pure electric mobility is the battery.Improvements have to be made particularly with regard to power density and costs,but also in terms of duration of recharge.Since these successes will be achieved slowly,efforts aim at reducing the required amount of stored electric energy per car.To enable the use of batteries with restricted capacity,either customers need to accept the limited range or devices are required that are able to extend the range by carrying extra energy supply onboard.Generally this energy is fuel which powers a small combustion engine.The engine power may then be transformed by agenerator into electric energy in order to charge the battery or to directly drive the motor(serial architecture).As an alternative the mechanical power may also be directed to the axle drive.This can be managed by an additional transmission module (parallel architecture).Both concepts have their pros and cons,which may result in a coexistence of solutions similar to those of parallel and power split hybrid drives,Figure10.

圖8 工況分析Fig.8 Analysis of relevant operation modes

圖9 試驗臺架上的EVD1樣機Fig.9 EVD1prototypes on the test rig

圖10 EV傳動系統增程器構架Fig.10 Range Extender architectures as derived from an EV driveline

References

[1] Wagner,G.;Naunheimer,H.;Scherer,H.;Dick,A.:Automatic 8-speed transmission for fuel consumption reduction.In ATZ,Automotive technology magazine,Issue 109(2007)

[2] Paul,M.,Domian,H.-J.and M.Mohr:Challenge CO2reduction–opportunities based on optimised drivelines.6.Internationales CTI Symposium ?Innovative Fahrzeuggetriebe“,Berlin,2007-12-04/05.

[3] Sch?fer,U.:Selection of EV motors with respect to gear.9.Internationales CTI Symposium ?Innovative Fahrzeug-Getriebe und Hybrid & Elektro-Antriebe“,Berlin,2010-11-29– 2010-12-02.

[4] Huckstep,A.,Kirkpatrick,G.:Development of Tata Vista EV S150transmission.9.Internationales CTI Symposium ?Innovative Fahrzeug-Getriebe und Hybrid& Elektro-Antriebe“,Berlin,2010-11-29–2010-12-02.

[5] Bertolotto,S.,Gay,R.,Torrelli,C.:2-Speed Electric Vehicle with Seamless Gearshift System.9.Internationales CTI Symposium ?Innovative Fahrzeug-Getriebe und Hybrid & Elektro-Antriebe“,Berlin,2010-11-29 –2010-12-02.

[6] Lugmayr,T.,Leitner,J.:Development of a highly efficient,two-speed electric powertrain for light commercial vehicles(LCV).9.Internationales CTI Symposium ?Innovative Fahrzeug-Getriebe und Hybrid & Elektro-Antriebe“,Berlin,2010-11-29–2010-12-02.

[7] Schneider,E.,Fickel,F.,Cebulski,B.,Liebold,J.:Highly integrative electric drive unit for Electric Vehicles.9.Internationales CTI Symposium ?Innovative Fahrzeug-Getriebe und Hybrid & Elektro-Antriebe“,Berlin,2010-11-29– 2010-12-02.