酸性介質環境中溫度對Ti–Mo合金耐蝕性的影響

魏亞,付禹,潘志敏,王雪飛,余偉,何石磊,苑清英,駱鴻,李曉剛

腐蝕與防護

酸性介質環境中溫度對Ti–Mo合金耐蝕性的影響

魏亞1a,付禹1a,潘志敏1a,王雪飛1a,余偉1b,何石磊2,苑清英2,駱鴻1a,李曉剛1a

(1.北京科技大學 a.新材料技術研究院 b.工程技術研究院,北京 100083;2.寶雞石油鋼管有限責任公司,陜西 寶雞 721008)

研究Ti–Mo合金在不同溫度的20% HCl溶液中的腐蝕行為和腐蝕規律,并探究其環境腐蝕機理。采用X射線衍射儀、掃描電子顯微鏡、電化學工作站以及X射線光電子能譜等對Ti–Mo合金的微觀組織結構和不同介質環境中的耐蝕性進行了探究。溶液介質溫度對Ti–Mo合金的腐蝕行為具有顯著影響。當溫度從20 ℃上升到70 ℃時,腐蝕電位從?548.9 mV(vs. Ag/AgCl)降低到?593.3 mV(vs. Ag/AgCl),且腐蝕電流密度在20 ℃時最低,為36.925 μA/cm2,維鈍電流密度也隨溫度升高而增加。此外,溫度升高不會改變氧化膜的成分,但會使膜內載流子密度升高,導致氧化膜的半導體特性發生n–p型轉變。當溶液溫度為20、30、50、70 ℃時,腐蝕速率分別為1.138 3、2.931 7、35.217、39.838 6 mm/a,且腐蝕速率隨著溫度升高而增加。溶液溫度升高會使Ti–Mo合金氧化膜內缺陷增多,氧化膜的穩定性和耐蝕性降低。在腐蝕過程中α相與β相會形成微原電池,α相作為陽極更容易發生優先腐蝕,這是由于β相中Mo元素含量較高所致。

Ti–Mo合金;溫度;氧化膜;微原電池

隨著現代工業體系對石油需求量的增多,石油管道的安全性也越來越引起人們的重視[1-2],管道中的活潑金屬元素易與石油介質發生化學反應,從而導致材料發生腐蝕失效現象[3]。石油在開采和運輸過程中管道常會受到酸性和Cl?的侵蝕而產生腐蝕,因此現代工業對石油管道的耐蝕性提出了很高的要求。通常,服役環境的pH值越低,材料的腐蝕速率越高。例如氣藏中冷凝水的pH可達3.5以下,這對于管道輸送安全是一個巨大的考驗[4-5]。此外,Cl?對金屬材料表面的保護膜也有很嚴重的破壞作用,而且破壞作用隨著Cl?濃度的升高而增大[6-7]。普通金屬石油管道由于腐蝕原因造成的各種事故給國民經濟帶來了極大的損失,因此需要開發新型耐蝕合金來提高石油管道的服役安全性。

鈦及鈦合金具有密度低[8]、強度高[9]、耐腐蝕性能優異[10]特點,在石油化工、航空航天、生物醫療等領域應用廣泛[11]。Ti與O有著很強的親和力,在與O2、H2O相互作用后會形成亞穩態的Ti(OH)4,由于Ti(OH)4在自然條件下極其不穩定,容易分解為TiO2和H2O,TiO2化學穩定性強。因此,會在鈦合金基體表面形成一層致密的保護膜,可以有效阻礙腐蝕介質對基體金屬的侵蝕,達到保護鈦合金基體的作用,這是鈦合金耐蝕性優異的主要原因[12-13]。目前石油管道運輸的金屬材料主要采用管線鋼,管線鋼在酸性和中性含Cl?溶液中不易形成完整的氧化膜。面對如此的服役條件,管線鋼容易發生局部或均勻腐蝕,加速其腐蝕失效[14-15]。相比之下,鈦合金表面形成的TiO2氧化膜更加致密,TiO2氧化膜在較寬的pH范圍內都有很高的穩定性,極大減少各類腐蝕的可能性,而且其表面的氧化膜被破壞后有很強的自修復能力,所以鈦合金的耐蝕性能也更好[16-17]。因此,鈦合金管道在復雜石油工況環境中的服役時間更長,效果更好[18]。為了進一步提高鈦合金的耐蝕性,學者們常常在其中添加Mo、Al等元素。研究表明Mo元素能提高鈦合金在Cl?環境中的耐蝕性,其表面形成的MoO2和MoO3可以作為Cl?向基材運動的屏障,阻礙腐蝕介質對基體的侵蝕,進一步提升鈦合金的耐蝕性[19]。此外,外界服役溫度對于石油管道腐蝕有很大的影響,溫度升高會使腐蝕動力學反應加速,氧化膜出現溶解,氧化膜破壞之后基材會直接接觸侵蝕性環境,造成耐蝕性能下降[20]。

從上述分析可知,研究鈦合金石油管道在嚴苛環境下的腐蝕行為和規律,并探究其腐蝕機理有非常重大的理論和現實意義。本文主要探究Ti–Mo合金在不同溫度變化的20% HCl溶液中的腐蝕行為和規律,旨在揭示Ti–Mo合金的腐蝕機制,為Ti–Mo合金在石油化工領域的應用提供一定的參考價值。

1 試驗

1.1 材料

本試驗所用鈦合金(Ti–Mo合金)為寶雞石油鋼管有限責任公司生產,其主要成分(質量分數)為:2.99% Mo,0.60% Zr,0.044% Fe,0.014% C,0.005 1% N,余量為Ti。

1.2 組織觀察和性能測試

采用X射線衍射(XRD)對Ti–Mo合金進行物相分析。采用Quanta 250掃描電子顯微鏡(SEM)對Ti–Mo合金的形貌進行觀察。電化學測試采用典型的三電極系統,飽和氯化銀電極為參比電極,對電極為鉑電極,工作電極為鈦合金試樣,工作電極面積為1 cm2,試驗溫度為20~70 ℃。電化學試驗所用儀器為Prin-ceton VersaSTAT 3F 電化學工作站。為了保證試驗結果的準確性,樣品在電化學測試之前統一在空氣中放置48 h。極化曲線電位范圍為?0.8~2 V(vs. Ag/AgCl),由于掃描范圍較大,掃描速率選取為1 mV/s。電化學阻抗譜(EIS)的正弦電位擾動為10 mV,掃描頻率為10?2~105Hz。采用美國賽默飛的250Xi X射線光電子能譜儀(XPS)對氧化膜的化學組成進行研究,成膜電位為0.5 V(vs. Ref),時間為7 200 s。采用Mott–Schottky對半導體膜的性質進行探究,Mott– Schottky試驗頻率為1 000 Hz,掃描電位為2~ ?1 V,步長為20 mV。選擇了20% HCl溶液作為靜態浸泡測試溶液,溶液的溫度分別保持在20、30、50、70 ℃。由于Ti–Mo合金在常溫下腐蝕較慢,為了使腐蝕前后的形貌變化更明顯,選取浸泡時間為15 d。浸泡15 d后用蒸餾水和酒精超聲清洗,干燥后用精度為±0.1 mg的天平稱量,并用3D共聚焦和掃描電子顯微鏡觀察腐蝕后的形貌。

2 結果與討論

2.1 鈦合金原始樣品組織結構分析

如圖1的Ti–Mo合金的XRD圖譜所示,鈦合金原始樣品主要由α相和β相組成,是典型的雙相結構。圖2為鈦合金原始樣品微觀結構和元素分布,圖中α相和β相相間分布。EDS結果顯示,基體Ti元素的整體分布比較均勻,Mo元素和Zr元素主要富集在β相中,在α相中含量較少。

圖1 Ti–Mo合金樣品的XRD圖譜

2.2 電化學分析

2.2.1 開路電位和極化曲線

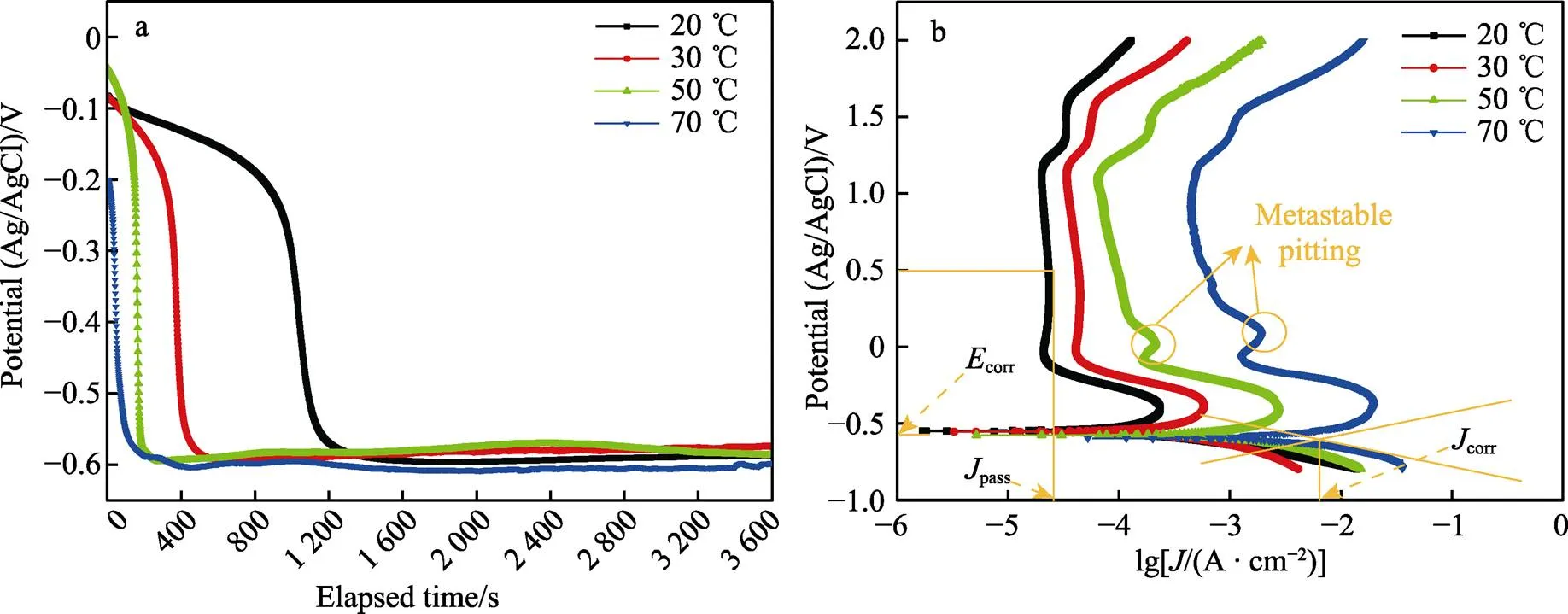

圖3a為Ti–Mo合金在不同溫度條件下20% HCl溶液中的開路電位變化曲線。開路電位的下降對應著鈦合金表面自然氧化膜的溶解,溫度升高使表面氧化膜的溶解速度逐漸加快。圖3b所示的陰極區主要為析氫反應[21-22],陽極區由活化溶解區、活化鈍化過渡區、一次鈍化區、二次鈍化區和過鈍化區5種區域組成。活化溶解區內鈦基體被氧化成可溶的Ti3+并進入到溶液中,電流密度逐漸增大。當活化溶解區的陽極電流達到最大,表明活化鈍化過渡區的開始,此區域內TiO2氧化膜生成,電流密度開始減小。活化鈍化過渡區之后,在?0.2~1.2 V之間出現了明顯的鈍化區,20、30 ℃時鈍化區內的電流密度基本保持不變,50、70 ℃時區域內的電流密度出現了波動,發生了亞穩態點蝕,此區域內的電流密度波動是由氧化膜的溶解和生成的競爭作用所致,在發生亞穩態點蝕之后電流密度又逐漸減小,說明氧化膜重新生成,表明Ti–Mo合金有很好的自修復能力[23]。在1.2~1.6 V內出現了二次鈍化區,二次鈍化區的形成是氧化膜的溶解和競爭重新達到平衡所致。當電壓大于1.6 V后出現了過鈍化現象,此時鈍化膜的溶解速度加快,電流密度加速增大。采用Tafel外推法從動電位極化曲線得到corr和corr值見表1。結果顯示,Ti–Mo合金在20 ℃時的腐蝕電位corr最高(?554.889 V),同時腐蝕電流密度corr也最低(36.925 μA/cm2),20 ℃時耐蝕性最好。維鈍電流密度能夠較好地反映鈍化膜的環境穩定性,在極化曲線的鈍化區內,選取0.5 V對應的電流密度為維鈍電流密度(pass),維鈍電流密度隨溫度升高逐漸增大,表明耐腐蝕性能隨溫度升高逐漸下降。

圖3 Ti–Mo合金在20~70 ℃的20% HCl溶液中的開路電位和極化曲線

表1 由動電位極化曲線推導出的參數

Tab.1 Parameters derived from the potentiodynamic polarization curve

2.2.2 電化學阻抗譜(EIS)分析

為了進一步闡明介質溫度變化對Ti–Mo合金腐蝕性能的影響,在20% HCl溶液中進行EIS測試,相應的Nyquist和Bode圖如圖4所示。圖4a的Nyquist圖出現2個容抗弧,表明存在2個時間常數。高頻電容回路對應于電解液與Ti–Mo合金基體界面處的雙電層,低頻電容回路對應于表面的氧化膜。高頻電容回路半徑減小說明電荷轉移電阻減小,低頻電容回路半徑減小表明表面膜電阻減小。圖4b是在20% HCl溶液中測量的Bode圖,Bode圖中相位角隨著溶液溫度的升高逐漸減小,相位角越大表明氧化膜越致密,在70 ℃時相位角接近30°表明形成的氧化膜已經非常不致密[24-25]。

采用圖5所示的等效電路對阻抗譜進行擬合,在等效電路中,S是溶液電阻,1和ct分別是與雙電層電容和電荷轉移電阻有關的元件,2和f分別是與氧化物/腐蝕產物膜電容和氧化物/腐蝕產物膜電阻有關的元件[26]。擬合的電化學阻抗譜數據如表2所示,極化電阻(p)可以用來評估耐蝕性[27],其中p=f+ct。經過計算,20、30、50、70 ℃時,Ti–Mo合金在20% HCl溶液中的極化電阻分別為314.20、111.29、27.29、8.76 ?·cm2。極化電阻隨著溶液溫度的升高逐漸減小,Ti–Mo合金的耐蝕性逐漸變差。

圖4 Ti–Mo合金在20~70 ℃的20% HCl溶液中的阻抗譜

圖5 Ti–Mo合金在20% HCl溶液中阻抗譜的等效電路圖

2.3 XPS分析

Ti–Mo合金的耐蝕性與表面氧化膜的成分密切相關,因此采用XPS對Ti–Mo合金在溶液中形成的氧化膜的成分進行分析。從圖6所示的XPS全譜中,可以看到O 1s、Ti 2p、C 1s、Mo 3d、Zr 3d的存在,其中C 1s的存在是由于檢測過程中引入的污染物C。

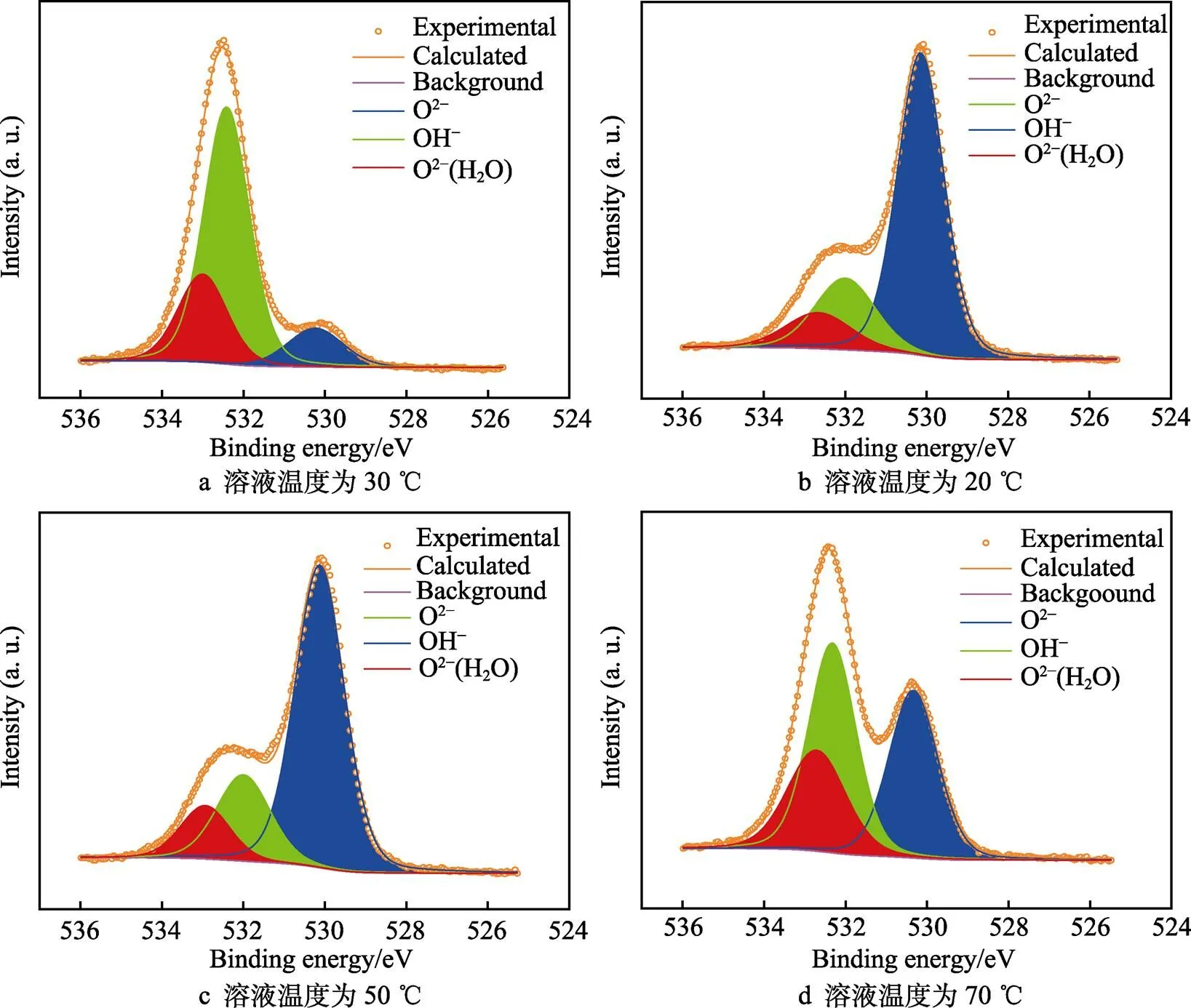

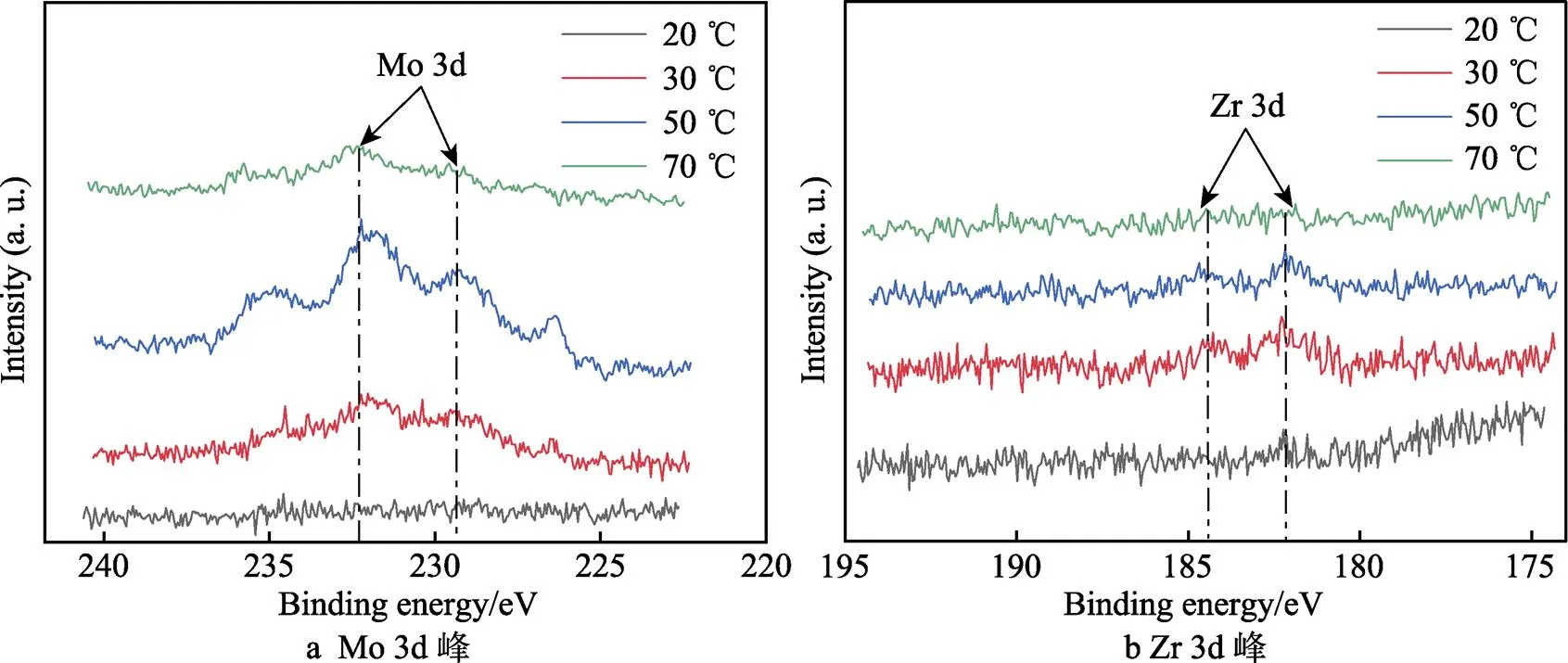

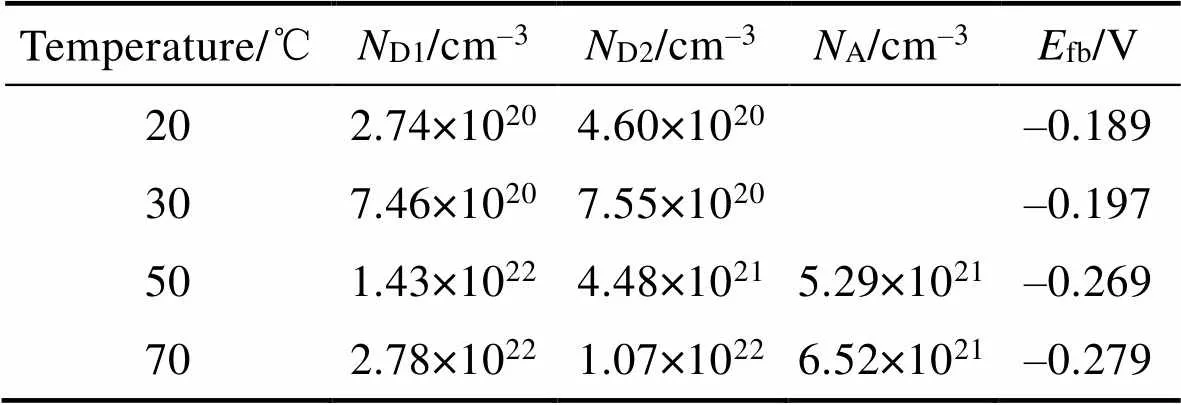

Ti 2p的擬合圖譜如圖7所示,458.7 eV的峰位可以擬合成雙峰,分別對應于459.1 eV的TiO2和457.0 eV的Ti2O3,453.8 eV的峰位對應于金屬Ti[28]。圖8所示的O1s的峰位也可擬合成3種物質,分別是530.4 eV的O2?、532.3 eV的OH?和533.0 eV的 O2?(H2O)[29]。從圖9a可以看到,Mo 3d在229.1 ev和232.2 eV處有2個明顯的峰位,分別對應于 MoO2和 MoO3氧化物[30]。Zr 3d在182.4 ev和184.1 eV處也有ZrO2峰的出現,但峰位較弱,表明含量較少[31]。通過對擬合的Ti 2p峰進行計算可知,20、30、50、70 ℃下,氧化膜中TiO2的占比分別為81.9%、88.8%、78.8%和84.2%,Ti2O3的占比分別為13.0%、8.2%、13.6%和11.6%,Ti的占比分別為5.1%、3.0%、7.6%和4.2%,對比各相的比例得不出明顯規律。通過XPS分析可知氧化膜的成分由鈦合金的氧化物、氫氧化物以及Mo和Zr的氧化物組成。但XPS不能獲得氧化膜的半導體特性和膜內載流子密度,所以采用Mott–Schottky測試繼續分析合金表面氧化膜的特性。

表2 Ti–Mo合金在20% HCl溶液中的電化學阻抗譜擬合參數

Tab.2 Fitting parameters of Ti-Mo alloy in 20wt.% HCl solution

圖6 Ti–Mo合金在不同溫度的20% HCl溶液中表面氧化膜的全譜圖

圖7 XPS結果中的Ti 2p峰擬合圖

圖8 XPS結果中的O 1s峰擬合圖

圖9 XPS結果中的Mo 3d峰和Zr 3d峰

圖10 Ti–Mo合金在20~70 ℃的20% HCl溶液中的Mott–Schottky結果

表3 由Mott–Schottky曲線擬合得到的載流子密度和平帶電位

Tab.3 ND/A and flat-band potential derived from Mott-Schottky in 20wt.% HCl solution

2.4 靜態浸泡試驗

由圖11a可知,Ti–Mo鈦合金的單位面積失重從20 ℃的21.051 2 mg/cm2增加到70 ℃的736.742 2 mg/cm2。采用公式(3)對鈦合金的腐蝕速率做出了直觀的計算,式中代表鈦合金腐蝕速率(mm/a),1是鈦合金腐蝕前質量(g),2是鈦合金腐蝕后質量(g),代表鈦合金試樣表面積,代表試驗時間(h),代表鈦合金密度(4.5 g/cm3)[37],經過計算得到20、30、50、70 ℃時,腐蝕速率分別為1.138 3、2.931 7、35.217 4、39.838 6 mm/a。

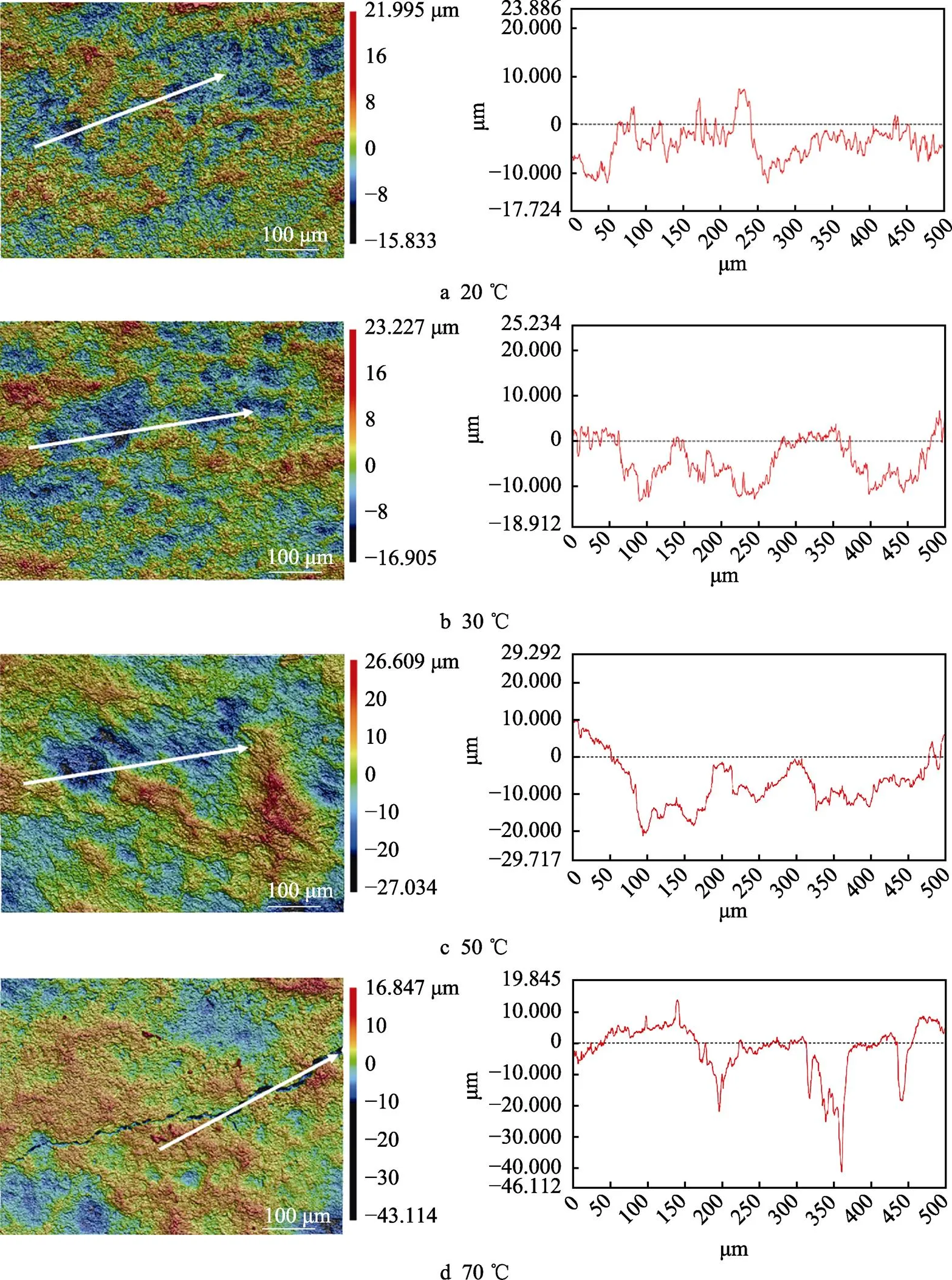

圖12a—d為腐蝕后樣品的3D共聚焦表面形貌及沿圖中白線分布的腐蝕坑深度。從圖12的3D共聚焦顯微鏡的結果可以看出,浸泡后樣品表面的溝壑逐漸增多,70 ℃甚至出現了開裂現象。3D共聚焦結果顯示,20、30、50、70 ℃時,最大腐蝕深度依次為12.426、13.601、23.957、41.492 μm。圖13為Ti–Mo合金浸泡15 d之后的腐蝕形貌,可以看到Ti–Mo合金已經嚴重腐蝕,說明此時的氧化膜已經破裂。圖13a為20 ℃浸泡15 d后的腐蝕形貌,Ti–Mo合金呈現出典型的不均勻腐蝕,α相腐蝕較為嚴重并出現了尖銳的棱角,β相腐蝕程度相對較輕,在浸泡過程中α相和β相會形成微原電池,這是因為β相中Mo含量較高,在腐蝕過程中作為陰極,α相作為陽極會加速腐蝕[38]。當溫度升高至30 ℃時,可以清楚看到α相與β相交錯分布,此時β相形狀為細條狀,相比20 ℃時腐蝕進一步加劇。50 ℃浸泡15 d后可以看到α相已無尖銳棱角,70 ℃浸泡15 d后樣品已經明顯疏松,腐蝕逐步加重。浸泡結果與之前的電化學測試結果保持一致。

圖12 Ti–Mo合金在20~70 ℃的20% HCl溶液中浸泡15 d的3D共聚焦形貌

圖13 Ti–Mo合金在20% HCl溶液浸泡15 d后腐蝕形貌

3 結論

1)電化學測試結果顯示,溶液介質溫度會使得Ti–Mo合金的腐蝕電流密度和維鈍電流密度增加,同時減小電荷轉移電阻和膜電阻。

2)結合XPS和Mott–Schottky分析結果可知,溶液介質溫度升高會造成Ti–Mo合金表面氧化膜內的缺陷增多,氧化膜半導體類型會發生轉變。

3)浸泡結果顯示,Ti–Mo合金的腐蝕速率和腐蝕坑深度都隨著溶液溫度升高而增大。在浸泡過程中α相和β相會形成微原電池,β相中Mo含量較高,在腐蝕過程中作為陰極,α相作為陽極,兩相耦合會加速鈦合金的腐蝕。

[1] 王正泉, 徐瑋辰, 周子揚, 等. X65管線鋼在成品油管道沉積物中的微生物腐蝕行為[J]. 表面技術, 2020, 49(7): 245-254.

WANG Zheng-quan, XU Wei-chen, ZHOU Zi-yang, et al. Microbial Corrosion Behavior of X65 Pipeline Steel in Product Pipeline Sediments[J]. Surface Technology, 2020, 49(7): 245-254.

[2] 王丹, 袁世嬌, 吳小衛, 等. 油氣管道CO2/H2S腐蝕及防護技術研究進展[J]. 表面技術, 2016, 45(3): 31-37.

WANG Dan, YUAN Shi-jiao, WU Xiao-wei, et al. Research Progress of CO2/H2S Corrosion in Oil and Gas Pipelines and the Protection Techniques[J]. Surface Technology, 2016, 45(3): 31-37.

[3] TSAY L W, LIN Y J, CHEN C. The Effects of Rolling Temperature and Sensitization Treatment on the Sulfide Stress Corrosion Cracking of 304L Stainless Steel[J]. Corrosion Science, 2012, 63: 267-274.

[4] AZAM M A, SUKARTI S, ZAIMI M. Corrosion Behavior of API-5L-X42 Petroleum/Natural Gas Pipeline Steel in South China Sea and Strait of Melaka Seawa-ters[J]. Engineering Failure Analysis, 2020, 115: 104654.

[5] IANNUZZI M. Environmentally Assisted Cracking (EAC) in Oil and Gas Production[M]. Amsterdam: Elsevier, 2011: 570-607.

[6] QIU Zhi-chao, XIONG Chun-ming, CHANG Ze-liang, et al. Major Corrosion Factors in the CO2and H2S Coexistent Environment and the Relative Anti-Corrosion Method: Taking Tazhong I Gas Field, Tarim Basin, as an Example[J]. Petroleum Exploration and Development, 2012, 39(2): 256-260.

[7] SUNABA T, ITO T, MIYATA Y, et al. Influence of Chloride Ions on Corrosion of Modified Martensitic Stainless Steels at High Temperatures under a CO2Environment[J]. Corrosion, 2014, 70(10): 988-999.

[8] SALEEM A, KHADIJA G, AKHTAR Z, et al. Short-Term Exposure to Titanium, Aluminum and Niobium (Ti-6Al- 4Nb) Alloy Powder can Disturb the Serum Low-Density Lipoprotein Concentrations and Antioxidant Profile in Vital Organs but not the Behavior of Male Albino Mice[J]. Drug and Chemical Toxicology, 2020, 43(3): 298-306.

[9] BLACKWELL P L, WISBEY A. Laser-Aided Manu-facturing Technologies; Their Application to the Near-Net Shape Forming of a High-Strength Titanium Alloy[J]. Journal of Materials Processing Technology, 2005, 170(1-2): 268-276.

[10] 許愛軍, 萬海峰, 梁春祖, 等. 低溫鈦合金材料應用現狀及發展趨勢[J]. 精密成形工程, 2020, 12(6): 145-156.

XU Ai-jun, WAN Hai-feng, LIANG Chun-zu, et al. Appli-cation Status and Development Trend of Cryogenic Titan-ium Alloy[J]. Journal of Netshape Forming Engineering, 2020, 12(6): 145-156.

[11] 陳正云. 鈦在石油化工中的應用[J]. 鈦工業進展, 2000, 17(4): 35-37.

CHEN Zheng-yun. Application of Titanium in Petroch-emical Industry[J]. Titanium Industry Progress, 2000, 17(4): 35-37.

[12] HE X, NO?L J J, SHOESMITH D W. Temperature Effects on Oxide Film Properties of Grade-7 Titanium[J]. Corrosion, 2007, 63(8): 781-792.

[13] NADY H, EL-RABIEI M M, SAMY M. Corrosion Behavior and Electrochemical Properties of Carbon Steel, Commercial Pure Titanium, Copper and Copper-Alum-inum-Nickel Alloy in 3.5% Sodium Chloride Containing Sulfide Ions[J]. Egyptian Journal of Petroleum, 2017, 26(1): 79-94.

[14] 高文平, 呂祥鴻, 謝俊峰, 等. 苛刻環境中鈦合金石油管材的抗腐蝕性能研究[J]. 稀有金屬材料與工程, 2018, 47(1): 151-156.

GAO Wen-ping, LV Xiang-hong, XIE Jun-feng, et al. Corrosion Resistance of Titanium Alloy OCTG in Severe Environment[J]. Rare Metal Materials and Engineering, 2018, 47(1): 151-156.

[15] 高文玲, 高嘉喜, 尹志福, 等. 20和L245NS鋼在模擬低含硫飽和CO2油田污水中的電化學耐蝕行為研究[J]. 材料保護, 2021, 54(5): 29-34, 62.

GAO Wen-ling, GAO Jia-xi, YIN Zhi-fu, et al. Study on the Electrochemical Corrosion Resistance Behavior of 20 and L245NS Steels in Simulated Low Sulfur-Containing and CO2-Saturated Oilfield Sewage[J]. Materials Prote-ction, 2021, 54(5): 29-34, 62.

[16] 李沖, 陶歡, 宋德軍, 等. 鈦合金在高含硫化氫工況中的腐蝕性能研究[J]. 材料開發與應用, 2020, 35(6): 19-23.

LI Chong, TAO Huan, SONG De-jun, et al. Study on Corrosion Properties of Titanium Alloy in Gathering Line with High Sulfur Content[J]. Development and Applic-ation of Materials, 2020, 35(6): 19-23.

[17] GARFIAS-MESIAS L F, ALODAN M, JAMES P I, et al. Determination of Precursor Sites for Pitting Corrosion of Polycrystalline Titanium by Using Different Techn-iques[J]. Journal of the Electrochemical Society, 1998, 145(6): 2005-2010.

[18] UEDA M, KUDO T, KITAYAMA S, et al. Corrosion Behavior of Titanium Alloys in a Sulfur-Containing Environment[J]. Corrosion, 2006, 48(1): 596.

[19] KASEEM M, CHOE H C. The Effect of In-Situ Reactive Incorporation of MoOon the Corrosion Behavior of Ti-6Al-4V Alloy Coated via Micro-Arc Oxidation Coating[J]. Corrosion Science, 2021, 192: 109764.

[20] FEKRY A M. The Influence of Chloride and Sulphate Ions on the Corrosion Behavior of Ti and Ti-6Al-4V Alloy in Oxalic Acid[J]. Electrochimica Acta, 2009, 54(12): 3480-3489.

[21] CUI Zhong-yu, WANG Li-wei, ZHONG Ming-yuan, et al. Electrochemical Behavior and Surface Characteristics of Pure Titanium during Corrosion in Simulated Desulf-urized Flue Gas Condensates[J]. Journal of the Electro-chemical Society, 2018, 165(9): C542-C561.

[22] SU Bao-xian, LUO Liang-shun, WANG Bin-bin, et al. Annealed Microstructure Dependent Corrosion Behavior of Ti-6Al-3Nb-2Zr-1Mo Alloy[J]. Journal of Materials Science & Technology, 2021, 62: 234-248.

[23] WANG D B, WU J, WANG Q, et al. Temperature- Dependent Corrosion Behaviour of the Amorphous Steel in Simulated Wet Storage Environment of Spent Nuclear Fuels[J]. Corrosion Science, 2021, 188: 109529.

[24] WANG Z B, HU H X, LIU C B, et al. The Effect of Fluoride Ions on the Corrosion Behavior of Pure Titanium in 0.05 M Sulfuric Acid[J]. Electrochimica Acta, 2014, 135: 526-535.

[25] GONZáLEZ J E G, MIRZA-ROSCA J C. Study of the Corrosion Behavior of Titanium and some of Its Alloys for Biomedical and Dental Implant Applications[J]. Journal of Electroanalytical Chemistry, 1999, 471(2): 109-115.

[26] LUO Hong, WANG Xian-zong, DONG Chao-fang, et al. Effect of Cold Deformation on the Corrosion Behaviour of UNS S31803 Duplex Stainless Steel in Simulated Concrete Pore Solution[J]. Corrosion Science, 2017, 124: 178-192.

[27] ARGADE G R, PANIGRAHI S K, MISHRA R S. Effects of Grain Size on the Corrosion Resistance of Wrought Magnesium Alloys Containing Neodymium[J]. Corrosion Science, 2012, 58: 145-151.

[28] MILO?EV I, METIKO?-HUKOVI? M, STREHBLOW H H. Passive Film on Orthopaedic TiAlV Alloy Formed in Physiological Solution Investigated by X-Ray Photo-electron Spectroscopy[J]. Biomaterials, 2000, 21(20): 2103-2113.

[29] LUO Hong, SU Huai-zhi, YING Guo-bing, et al. Effect of Cold Deformation on the Electrochemical Behaviour of 304L Stainless Steel in Contaminated Sulfuric Acid Envir-o-n-ment[J]. Applied Surface Science, 2017, 425: 628-638.

[30] PARK P Y, AKIYAMA E, HABAZAKI H, et al. The Corrosion Behavior of Sputter-Deposited Mo-Ti Alloys in Concentrated Hydrochloric Acid[J]. Corrosion Science, 1996, 38(10): 1649-1667.

[31] OLSSON C O A, LANDOLT D. Atmospheric Oxidation of a Nb-Zr Alloy Studied with XPS[J]. Corrosion Science, 2004, 46(1): 213-224.

[32] BEHNAMI FAR V, JAFARZADEH K, SHOOSHTARI GUGTAPEH H, et al. A Study on Electrical Properties of Thermally Grown TiO2Film at the Interface of Ti/RuO2- IrO2-TiO2Anode Using Mott-Schottky and Electroche-mical Impedance Spectroscopy Techniques[J]. Materials Chemistry and Physics, 2020, 256: 123756.

[33] LI D G, FENG Y R, BAI Z Q, et al. Influence of Temper-ature, Chloride Ions and Chromium Element on the Electr-onic Property of Passive Film Formed on Carbon Steel in Bicarbonate/Carbonate Buffer Solution[J]. Electr-o-chimica Acta, 2007, 52(28): 7877-7884.

[34] BAUMANIS C, BAHNEMANN D W. TiO2Thin Film Electrodes: Correlation between Photocatalytic Activity and Electrochemical Properties[J]. The Journal of Physical Chemistry C, 2008, 112(48): 19097-19101.

[35] CáMARA O R, DE PAULI C P, VASCHETTO M E, et al. Semiconducting Properties of TiO2Films Thermally Formed at 400 ℃[J]. Journal of Applied Electroc-hemistry, 1995, 25(3): 247-251.

[36] AMRI J, SOUIER T, MALKI B, et al. Effect of the Final Annealing of Cold Rolled Stainless Steels Sheets on the Electronic Properties and Pit Nucleation Resistance of Passive Films[J]. Corrosion Science, 2008, 50(2): 431-435.

[37] YANG Fen-fen, KANG Hui-jun, GUO En-yu, et al. The Role of Nickel in Mechanical Performance and Corrosion Behaviour of Nickel-Aluminium Bronze in 3.5wt.% NaCl Solution[J]. Corrosion Science, 2018, 139: 333-345.

[38] MENG Kang, GUO Kai, YU Qiang, et al. Effect of An-nea--ling Temperature on the Microstructure and Corro-sion Behavior of Ti-6Al-3Nb-2Zr-1Mo Alloy in Hydroc-hloric Acid Solution[J]. Corrosion Science, 2021, 183: 109320.

The Influence of Temperature on Corrosion Resistance of Ti-Mo Alloy in Acidic Medium

1a,1a,1a,1a,1b,2,2,1a,1a

(1. a. Institute for Advanced Materials and Technology, b. Institute of Engineering and Technology, University of Science and Technology Beijing, Beijing 100083, China; 2. CNPC Baoji Petroleum Steel Pipe Co., Ltd., Shaanxi Baoji 721008, China)

Titanium alloy pipeline is playing an increasingly important role in petrochemical industry. This paper mainly explores the corrosion behavior of Ti-Mo alloy in 20wt.% HCl solution with different temperature changes, aiming at revealing the corrosion mechanism of Ti-Mo alloy and providing certain reference value for the application of Ti-Mo alloy in petrochemical industry.

The titanium alloy used in this experiment is produced by CNPC Baoji Petroleum Steel Pipe Co., Ltd. The main components (wt.%) are as follows: 2.99 Mo, 0.60 Zr, 0.044 Fe, 0.014 C, 0.005 1 N, and the balance is Ti. X-ray diffraction (XRD) and Quanta 250 scanning electron microscope (SEM) were used to observe the phase and morphology of Ti-Mo alloy. Electrochemical test adopts typical three-electrode system, with saturated silver chloride electrode as reference electrode, platinum electrode as counter electrode, titanium alloy sample as working electrode with the area of 1 cm2. The electrochemical experiment temperature were 20, 30 50 and 70 ℃. The potential range of polarization curve was ?0.8 V (vs. Ag/AgCl) to 2 V (vs. Ag/AgCl) and the scanning frequency of electrochemical impedance spectroscopy (EIS) was 10?2Hz to 105Hz. The chemical composition of the oxide film was studied by 250Xi X-ray photoelectron spectroscopy. The oxide film was formed at 0.5 V (vs. Ref) for 7 200 s. Mott-Schottky was used to explore the properties of semiconductor films. The experimental frequency of Mott-Schottky was 1 000 Hz, the scanning potential was 2 to ?1 V with the step size of 20 mV. 20wt.% HCl solution was selected as the static immersion test solution, and the temperature of the solution was kept at 20 ℃, 30 ℃, 50 ℃ and 70 ℃ respectively. After soaking for 15 days, ultrasonic cleaning with distilled water and alcohol, drying, weighing with a balance with accuracy of 0.1 mg, and observing the morphology after corrosion with 3D laser confocal and scanning electron microscope.

The solution medium temperature produced a great influence on the corrosion behavior of Ti-Mo alloy. The corrosion potential decreased from ?548.9 mV (vs. Ag/AgCl) to ?593.3 mV (vs. Ag/AgCl) in the range of 20 to 70 ℃. Ti-Mo alloys had the lowest corrosion current density at 20 ℃, i. e., 36.925 μA/cm2, and the passive current density decreased as the temperature enhanced. In addition, the content of the oxide film had no obvious difference at various temperature, but the donor concentration in the film increased at elevated temperature. Besides, it caused the n-p type transition of the semiconductor characteristics. The corrosion rate of the Ti-Mo alloy in 20wt.% HCl solution were 1.138 3, 2.931 7, 35.217 and 39.838 6 mm/a when solution temperature were 20, 30, 50 and 70 ℃, which indicated that the corrosion rate accelerated with the temperature went by.

An increase in the temperature of the solution will promote the formation of defects and reduce the stability and corrosion resistance of the oxide film. The α and β phases form microgalvanic cells in the corrosion process, and the α phase is more prone to corrode acting as the anode, which is due to the higher content of Mo in the β phase.

Ti-Mo alloy; temperature; oxide film; microgalvanic cells

2021-07-09;

2022-01-25

WEI Ya (1995-), Male, Postgraduate, Research focus: titanium alloy corrosion and protection.

駱鴻(1980—),男,博士,教授,主要研究方向為先進金屬、鋼鐵材料的設計和服役安全。

LUO Hong (1980-), Male, Doctor, Professor, Research focus: design and service safety of advanced metal and steel materials.

魏亞, 付禹, 潘志敏, 等.酸性介質環境中溫度對Ti–Mo合金耐蝕性的影響[J]. 表面技術, 2022, 51(9): 168-177.

tg174

A

1001-3660(2022)09-0168-10

10.16490/j.cnki.issn.1001-3660.2022.09.000

2021–07–09;

2022–01–25

中國石油科技創新基金(2019D–5007–0308);國家重點研究開發項目(2016YFB0301204);中央高校基本科研業務基金(FRF– MP–20–51,FRF–BD–20–28A2)

Fund:PetroChina Innovation Foundation (2019D-5007-0308); National Key Research and Development Program of China (2016YFB0301204); Fundamental Research Funds for the Central Universities (FRF-MP-20-51, FRF-BD-20-28A2)

魏亞(1995—),男,碩士研究生,主要研究方向為鈦合金腐蝕與防護。

WEI Ya, FU Yu, PAN Zhi-min, et al. The Influence of Temperature on Corrosion Resistance of Ti-Mo Alloy in Acidic Mediu[J]. Surface Technology, 2022, 51(9): 168-177.

責任編輯:萬長清