Preparation and Properties of Polyurethane/Nickel Nanofiber with Core-Shell Structure Using Coaxial Electrospinning Method

FU Shaoju(付少舉), ZENG Pei(曾 佩), HOU Xuemei(侯雪梅), ZHAN Jianchao(詹建朝)

1 College of Textiles, Donghua University, Shanghai 201620, China

2 Key Laboratory of Textile Science and Technology, Ministry of Education, Donghua University, Shanghai 201620, China

3 College of Materials and Textile Engineering, Jiaxing University, Jiaxing 314001, China

Abstract: Nanofiber has been widely used in numerous fields for its good advantages such as large surface area and porosity. However, the relationship between nanofiber structure and coaxial electrospinning process is still not clear and deserved to be studied. In this work, a kind of polyurethane/nickel(PU/Ni) nanofiber with core-shell structures was developed, and the effects of electrospinning parameters on the properties of nanofiber were evaluated. The results showed that the optimized parameters of core-shell electrospinning speeds were 1 mL/h(core) and 1 mL/h(shell), respectively. Sample c with the core-shell electrospinning speed ratio of 1∶1, exhibited the relatively smooth surface, good orientation, and bonding points. It also had the largest tensile strength at 99 cN, tensile elongation at 44.86%, and the best electricity conductivity, which showed great potential in the application of nanofiber fields.

Key words: nanofiber; surface area; porosity; core-shell structure; electrospinning speed

Introduction

The nanofiber defined as the ultra-fine fiber, is a special liner material with diameter less than 100 nm, and has been widely used in the flexible energy storage[1-4], smart fabric[5], environmental management[6],etc. Compared with other ordinary fiber materials, fibers with diameters reduced to nanometer level show many excellent properties, including large surface area, large porosity, large aspect ratio and large surface energy[7-9]. Among them, the large specific surface area was benefical to its surface energy, increasing its activity and specificity, and these characteristics would promote some special effects of extensibility in temperature, optics, electricity, magnetism and other aspects[10-11].

Electrospinning is one of the technologies that can prepare nanofiber, which is easier to be operated, more flexible and more adaptable[12]. With more extensive application of nanofiber, the research on the improvement of electrospinning device is more and more common and in-depth[13]. The coaxial electrospinning is a special electrospinning method developed from the traditional technology by improving the nozzle parts of the electrostatic equipment[14-15]. However, the relationship between nanofiber structure and coaxial electrospinning condition is still not clear and deserved to be studied furtherly.

In this work, a kind of polyurethane/nickel(PU/Ni) nanofiber with core-shell structure is developed, and the effects of electrospinning parameters on the properties of nanofiber such as scanning electron microscope(SEM) images, tensile properties, and electrical conductivity are fully investigated and optimized.

1 Experiments

1.1 Materials

PU and Ni are provided by the college of materials and textile engineering, Jiaxing University, China. Tetrahydrofuran(THF) andN,N-dimethylformamide(DMF) are supported by Jiangsu Qiangsheng Functional Chemicals Co., Ltd., China.

1.2 Preparation of PU/Ni nanofiber with core-shell structure

PU is mixed with THF at a ratio of 1∶1 as the core layer(0.06 g/mL), and Ni is contained with the PU solutions as the shell layer(0.000 6 g/mL). An electrospinning device with a coaxial needle is adopted, different electrospinning parameters such as core-shell electrospinning speed ratios at 1∶0.25, 0.25∶1, 1∶1, 1∶0.5, 0.5∶1, respectively are used in this work, The receive distance is 10 cm, and the supply voltage is 15 kV.

1.3 Testing method and devices

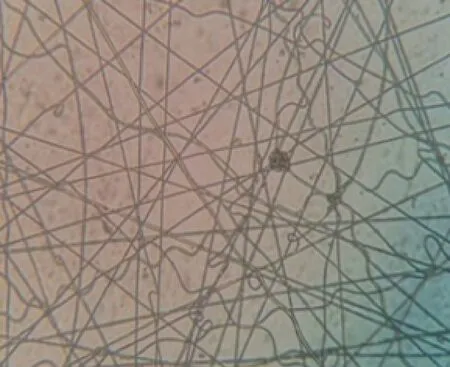

(1) Surface morphology. A metallographic microscope(Mit500, Japan) and an SEM(Hitachi TM 3000, Japan) were adopted to evaluate the surface morphologies of samples.

(2) Mechanical property. An electronic single yarn strength tester(YG061FQ, Changzhou, China) was used to evaluate the tensile properties of samples, and testing parameters such as breaking strength and breaking elongation were adopted in this work.

(3) Conductivity test. A digital multimeter(Vc830l, Shijiazhuang, China) was adopted to test the electricity conductivity of samples.

2 Results and Discussion

2.1 Surface morphology

Surface morphologies of PU/Ni nanofiber with core-shell structure at different electrospinning speed ratios has been measured by SEM technology. As shown in Fig. 1, the samples presented different surfaces characteristics with the changing of electrospinning speed ratios. In detail, some coarse or fine knots were observed for Sample a and Sample b, while the other nanofiber(Sample d and Sample e) were bonded each other. Sample c was observed to have relatively smooth surface, the tow was clear and its orientation was good, and the bonding point was less. Moreover, samples exhibited the relatively smooth surfaces and uniform fineness for the nanofiber, and no obvious string beads or bonding points were observed from the SEM images.

(a) Sample a (1∶0.25)

These findings illustrated that nanofiber had different surface structures with the changing of electrospinning speeds ratios, and the inappropriate speed caused the bonding or winding in the intersections, and the surface morphologies would be changed at different electrospinning speed ratios. The reason was that surface morphologies of nanofiber would change their rheological properties, further causing the diameter and fineness changes for samples.

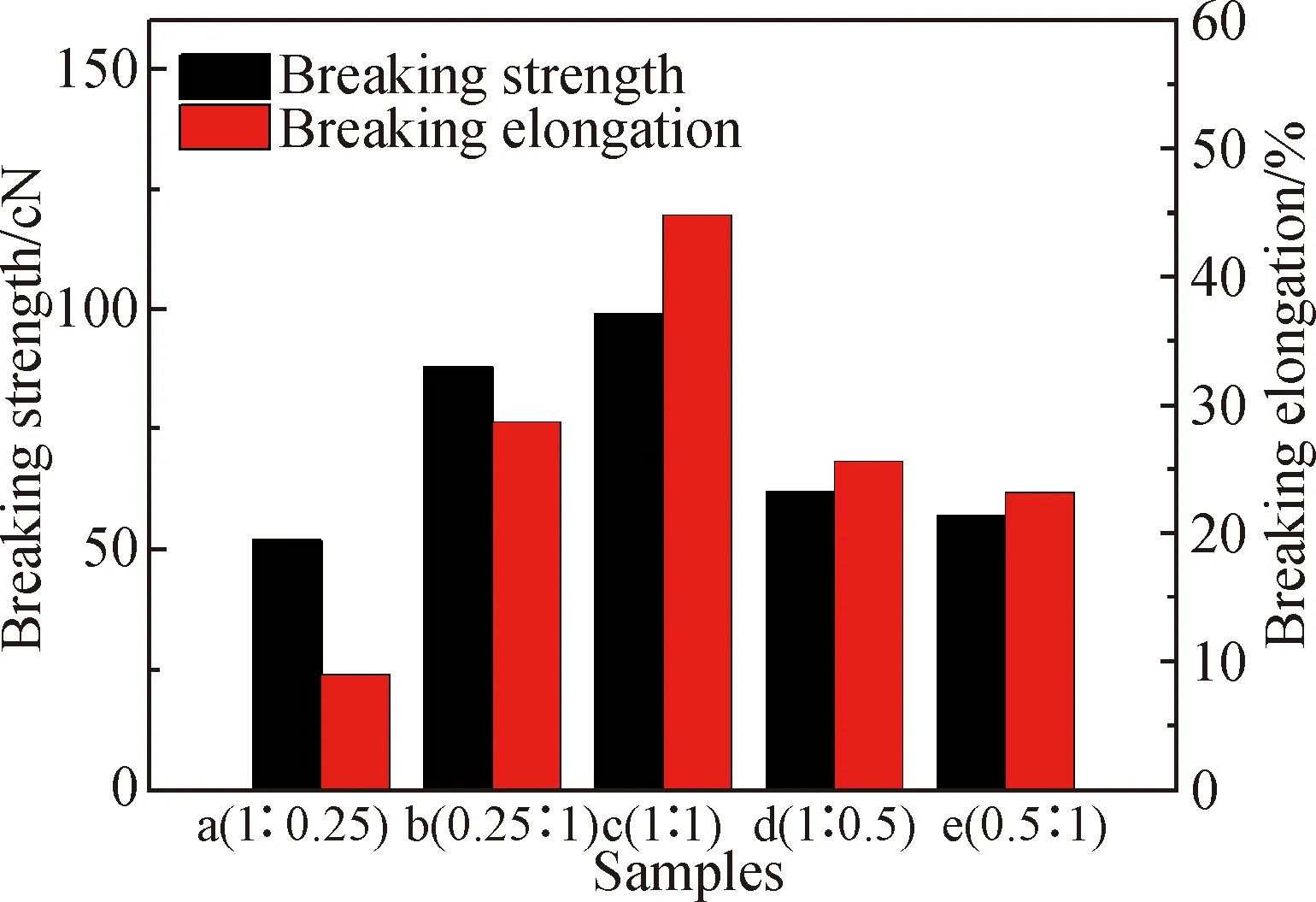

2.2 Mechanical property

Tensile properties of PU/Ni nanofiber with core-shell structure at different electrospinning speed ratios were tested to evaluate the mechanical properties(shown in Fig. 2). As the increase of electrospinning speed ratio, mechanical properties of samples increased firstly, and then decreased with the further increasing. Finally, Sample a with the electrospinning speed ratio at 1∶0.25 showed the smallest tensile strength(52 cN) and tensile elongation(9.06%), respectively, while that of Sample c(1∶1) reached the largest tensile strength and tensile elongation values at 99 cN and 44.86%, respectively. Sample d and Sample e presented the similar tensile strength and tensile elongation values, which were much smaller than those of Sample c.

Fig. 2 Tensile properties of PU/Ni nanofiber with core-shell structure at different electrospinning speed ratios

These phenomena revealed that the proportional of core-shell would cause the changes for tensile properties directly, and both the tensile strength and tensile elongation values increased in the first stage, then decreased with the further increase of core-shell electrospinning speed ratio. The reason was that the molecular orientation of nanofiber increased with the electrospinning speed ratio, causing the increase of mechanical properties of samples. As the further increase of electrospinning speed ratio, tensile properties of samples were decreased.

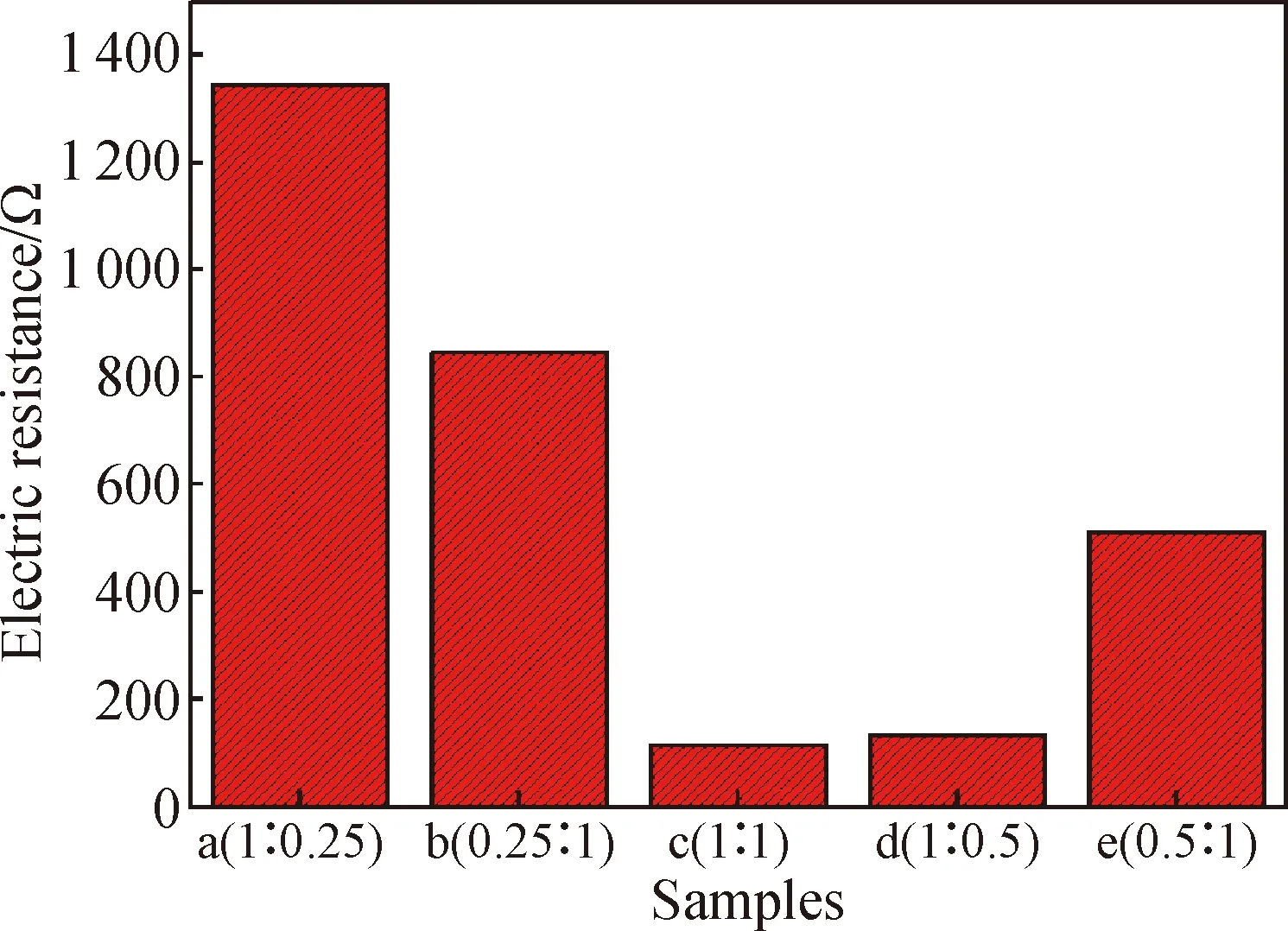

2.3 Electricity conductivity

Electric resistance of PU/Ni nanofiber with core-shell structure at different electrospinning speed ratio was adopted to evaluate the electricity conductivity. As shown in Fig. 3, samples were observed to present a decrease of electric resistance with the increase of electrospinning speed ratio, and then to be decreased with a further decrease of electrospinning speed ratio. It could be observed that Sample c had the smallest electric resistance, while Sample a showed the largest value, and Sample d showed the similar electric resistance values compared to those of Sample c. These results revealed that the electric resistance of nanofiber would change with the core-shell proportion, the electricity conductivity of samples became better with the increase of electrospinning speed ratios in a certain range, and the core-shell electrospinning speed ratio of 1∶1 would have best electricity conductivity. The reason was that the good orientation and bonding points of nanofiber were benefical to electricity conductivity, causing the increase of charge transfer among nanofiber macromolecules, further enhancing the electricity conductivity of nanofiber.

Fig. 3 Electricity conductivity of PU/Ni nanofiber with core-shell structure at different electrospinning speed ratios

3 Conclusions

In this research, PU/Ni nanofiber with core-shell structures were prepared and effects of electrospinning parameters on their properties were further discussed. Sample c (1∶1) for its core-shell electrospinning speed ratio, having the relative fine diameters and smooth surface, and Sample a with the electrospinning speed ratio at 1∶0.25 showed the smallest tensile strength(52 cN) and tensile elongation(9.06%), while Sample c(1∶1) reached the largest tensile strength and tensile elongation values at 99 cN and 44.86%, respectively. Sample c had the smallest electric resistance, while Sample a showed the largest value, and Sample d showed the similar electric resistance values compared to that of Sample c. In sum, Sample c which had the best mechanical and electricity conductivity was selected as the optimized sample, showing great potential in nanofiber fields.

Journal of Donghua University(English Edition)2021年2期

Journal of Donghua University(English Edition)2021年2期

- Journal of Donghua University(English Edition)的其它文章

- Rational Design of a High-Performance KMnO4-Fe(Ⅱ)-Si Coagulant for Dye Removal

- Advances in Electrospun Nanofiber Yarns

- Thermal Insulation Properties of Microfibrillated Cellulose Aerogel

- Mechanical and Thermal Properties of Apocynum and Ramie Fiber Mat Reinforced Polylactic Acid Composites

- Symmetry Classification of Partial Differential Equations Based on Wu’s Method

- Numerical Simulation of Space Fractional Order Schnakenberg Model