潛孔鉆+沖擊鉆組合施工方法在傾斜硬質巖層樁基施工中的應用

葉春 楊韜

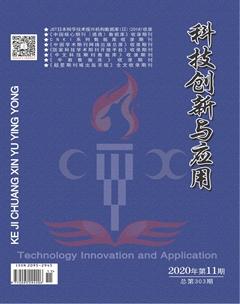

摘? 要:傳統的樁基成孔工藝有旋挖鉆、沖擊鉆、回旋鉆、反循環和人工挖孔樁成孔等。但對于一些特殊地質如硬質斜巖地層嵌巖樁基,單一施工方法在斜面巖進尺、孔平面偏位、豎直度、正常鉆進速度等方面存在不足,且已不能很好滿足工程要求,文章結合實例講述潛孔鉆+沖擊鉆組合施工方法在傾斜硬質巖層中的應用。

關鍵詞:傾斜硬質巖;潛孔鉆+沖擊鉆組合;原理;工藝;操作要點

中圖分類號:U445.5? ? ? ? ?文獻標志碼:A? ? ? ? ?文章編號:2095-2945(2020)11-0131-02

Abstract: The traditional hole-forming technology of pile foundation includes rotary drilling, impact drilling, rotary drilling, reverse circulation and manual digging pile and so on. However, for some special geology, such as rock-socketed pile foundation in hard oblique rock stratum, the single construction method has some shortcomings in inclined rock footage, hole plane deviation, verticality, normal drilling speed and so on, and can not meet the engineering requirements very well. This paper describes the application of the combined construction method of down-hole drilling and impact drilling in inclined hard rock with examples.

Keywords: inclined hard rock; DTH drill + percussion drill combination; principle; technology; operation points

1 概述

樁基工程是橋梁施工的關鍵環節,根據不同水文、地質、氣候條件,常規的樁基成孔工藝有旋挖鉆、沖擊鉆、回旋鉆、反循環和人工挖孔樁成孔等。但對于一些特殊地質如硬質斜巖地層嵌巖樁基,單一施工方法在斜面巖進尺、孔平面偏位、豎直度、正常鉆進速度等方面存在不足,且已不能很好滿足工程要求。

2 工程概況

本工程為104國道溫州西過境永嘉張堡至甌海桐嶺段改建工程(甌江特大橋),大橋于永嘉縣化學劑廠和礁下山南側先后跨越甌北陽光大道及甌江至鹿城區洞橋制革基地,連接鹿城區與永嘉縣甌北兩區縣,與甌江河道基本垂直,全長1332.72m。大橋主橋6#輔助墩樁基礎為10根直徑Φ2.0m的嵌巖鉆孔灌注樁,樁底標高-18.0m,樁頂標高-0.5m,設計樁長17.5m,該區原地面標高4.2m左右,上部覆蓋層主要為粉質粘土,淤泥夾粉細砂等,厚度為6.0m~15m,下部為強-中風化流紋質晶凝灰巖、流紋質晶玻屑凝灰巖,基巖面從北向南趨勢傾斜。根據實際情況擬采用沖擊鉆施工,但該范圍基巖為高強度斜巖面巖層,巖石強度達120MPa。……