基于有限元法的旋沖破巖提速仿真分析

玄令超 王甲昌 張仁龍

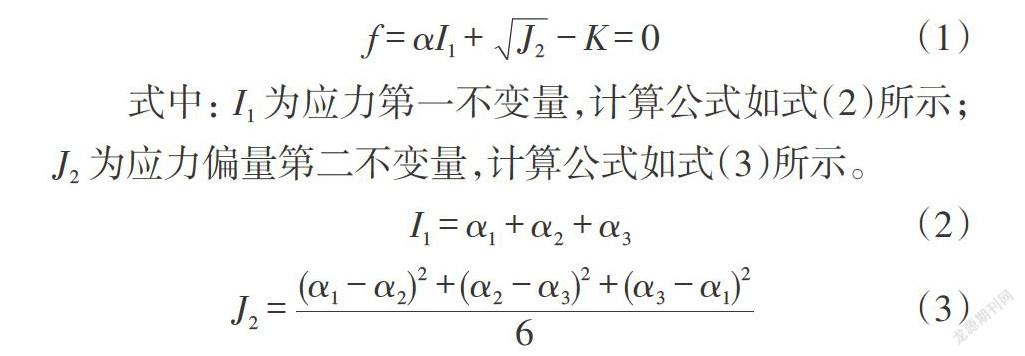

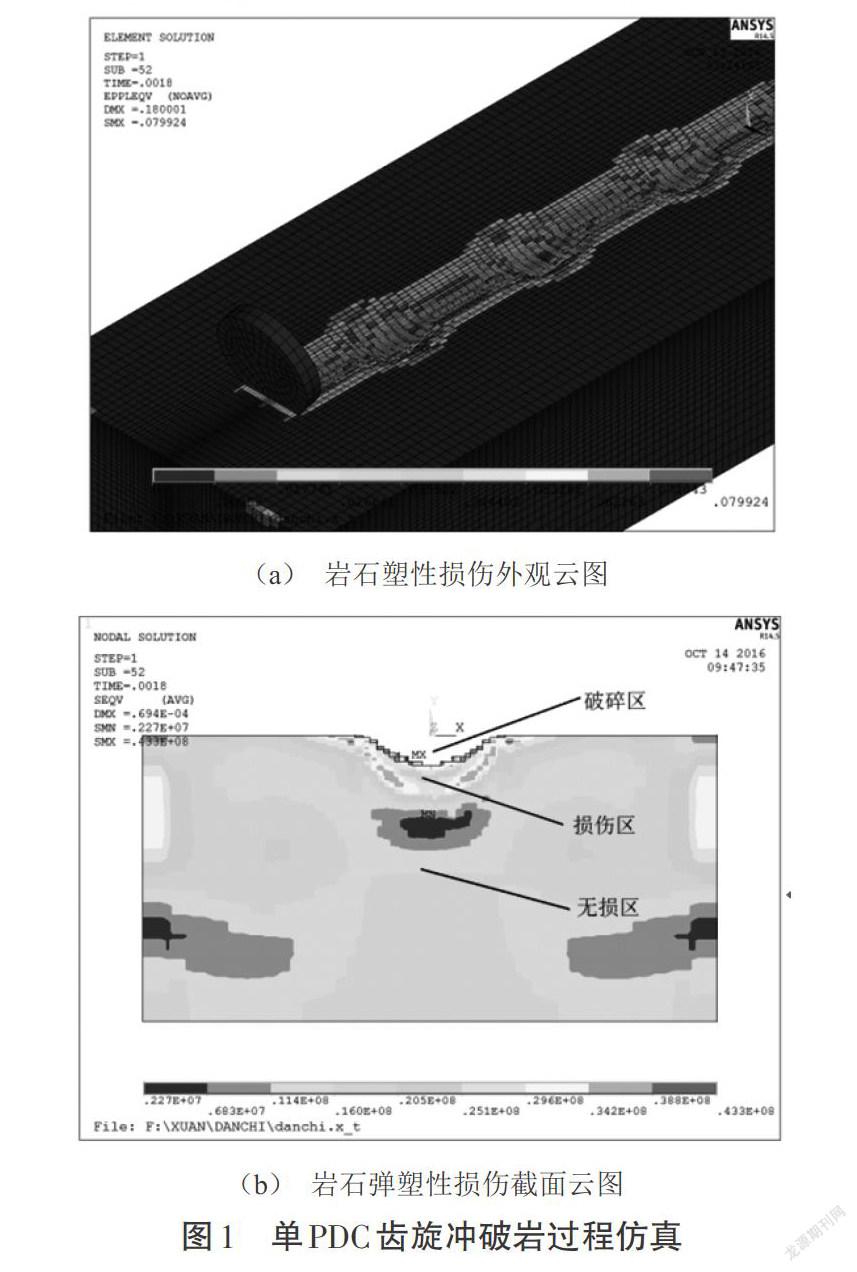

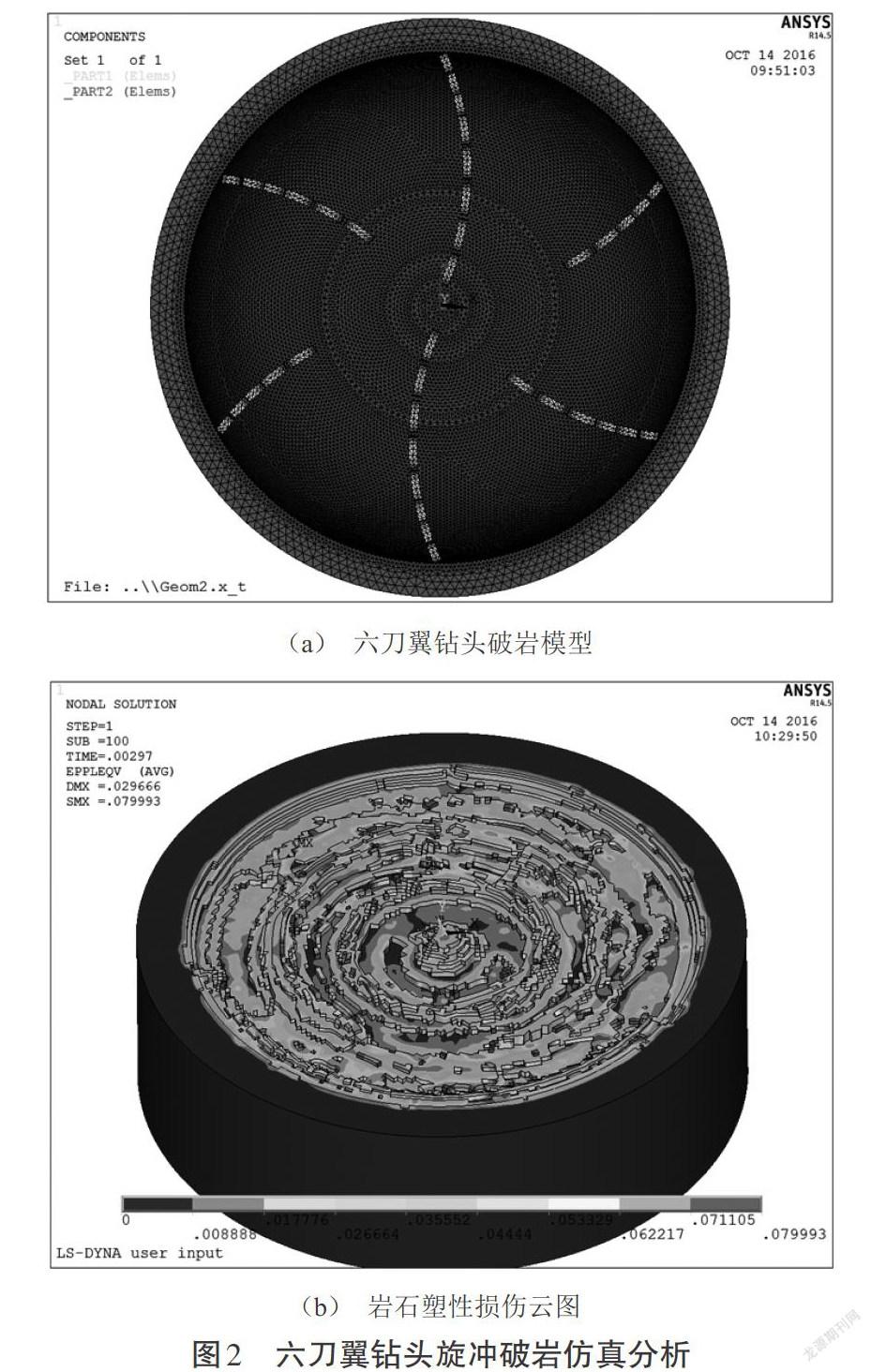

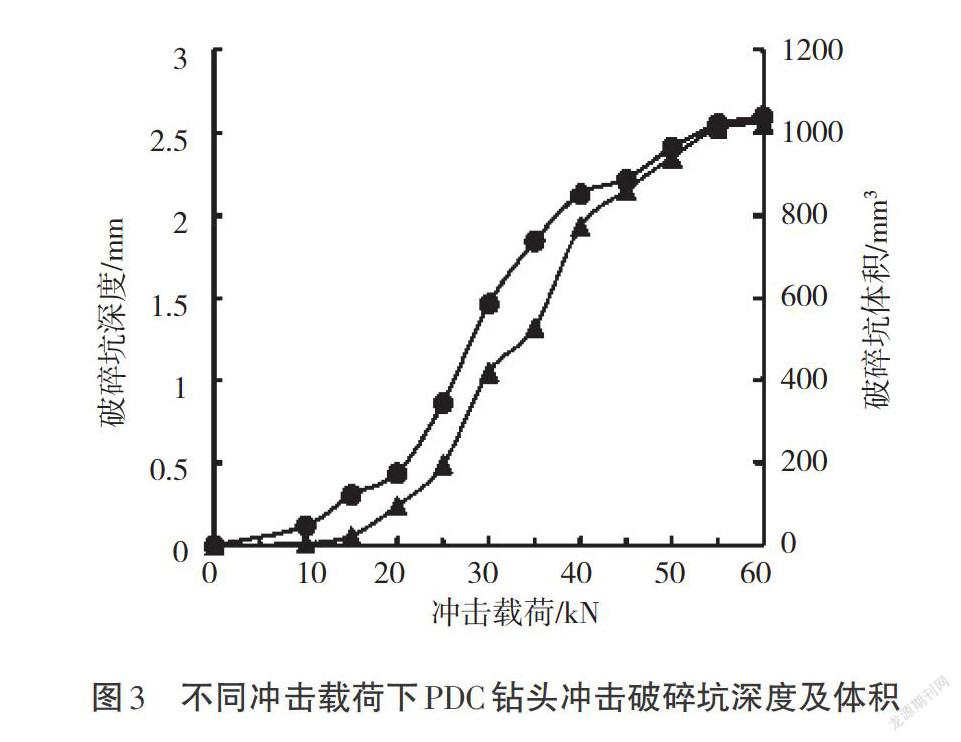

摘 要:旋轉沖擊鉆井技術是深井、超深井鉆井常用的提速措施之一,可以有效提高鉆頭破巖速率。相較于旋沖工具的迅速發展,沖擊參數對鉆頭破巖效率影響的量化研究還不多見。本文利用有限元法研究旋沖鉆井配合PDC鉆頭的破巖提速機理,研究沖擊參數對巖石破碎體積、機械鉆速的影響。仿真結果表明:隨著沖擊載荷增加,沖擊破碎坑深度和體積相應增加,增加趨勢先快后慢;使用Φ215.9mmPDC鉆頭旋沖鉆井,中硬地層推薦沖擊力20~45kN。利用有限元法模擬鉆頭破巖過程,可針對不同巖性地層、鉆頭類型、鉆井參數進行沖擊參數優選,為旋沖工具的參數優選和性能改進提供理論支撐。

關鍵詞:旋沖鉆井;破巖機理;沖擊載荷;有限元仿真;參數優選

中圖分類號:TE242 文獻標識碼:A 文章編號:1003-5168(2019)34-0069-03

Simulation Analysis of Rotary Percussion Drilling Based

on Finite Element Method

XUAN Lingchao WANG Jiachang ZHANG Renlong

(SINOPEC Research Institute of Petroleum Engineering,Beijing 100101)

Abstract: Rotary percussion drilling technology is one of the commonly used measures for fast drilling, which can effectively improve the rock breaking rate. In this paper, the finite element method was used to study the rock breaking mechanism of rotary drilling with PDC bit. The simulation results show that as the impact load increases, the depth and volume of the impact crushing pit increase. The Φ215.9mm PDC bit with rotary percussion drilling for medium-hard formation is 20~45kN. By using the finite element method to simulate the rock breaking process of the bit, the impact parameters can be optimized for different lithological strata, bit types, and drilling parameters, which can provide theoretical support for the performance improvement of the rotary tool.

Keywords: well drilling;rock breaking mechanism;impact load;finite element simulation;parameter optimization

1 研究背景

旋轉沖擊鉆井技術是在穩定鉆壓基礎上疊加沖擊載荷的鉆井提速方法,在鉆井現場得到廣泛應用,并取得了良好的提速效果[1,2]。沖擊動載增加了PDC鉆頭的吃入深度,增大了巖石破碎體積,能大幅度提高破巖效率和鉆井速度[3]。目前,國內較為成熟的旋沖鉆井工具包括閥式、射流式、射吸式、自激振蕩式等幾類[4,5]。相較于旋沖工具的迅速發展,旋沖破巖的理論研究卻沒得到足夠重視,沖擊參數對機械鉆速影響的量化研究仍不多見[6]。ANSYS/LS-DYNA程序是一種可以進行顯式/隱式非線性計算的有限元仿真程序。利用有限元法研究旋轉沖擊工具配合PDC鉆頭的破巖機理,篩選不同地層、不同鉆頭條件下的旋沖鉆井最優參數,有助于旋轉沖擊鉆井技術的完善,為旋沖工具的參數優選和性能改進提供理論支撐。……