壓敏標簽供送裝置中剝離機構的設計

蔡建新 陳松

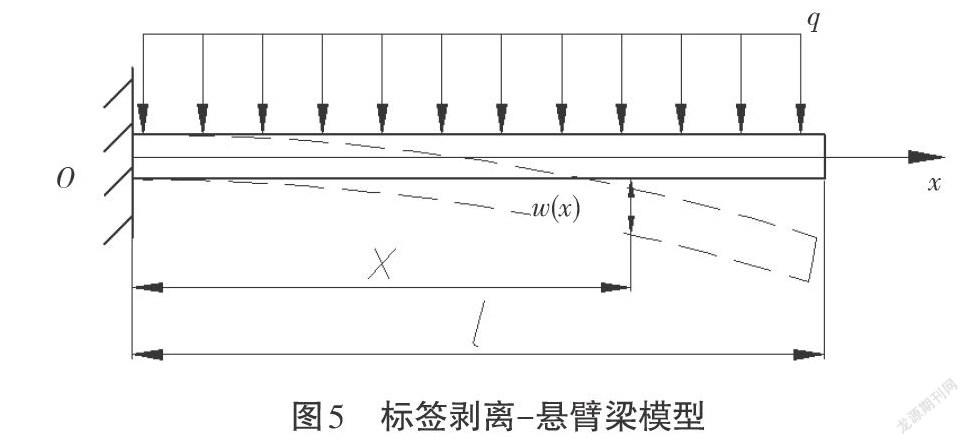

摘 要:當前的自動化貼標設備大多采用壓敏標簽,以卷材形式供應。標簽供送是貼標中的重要環節之一,如果標簽供送不可靠,將導致后續的貼標操作無法順利完成。本文通過對標簽供送工藝進行分析,設計了標簽供送裝置的總體結構。基于剝離力與標簽彎曲曲率半徑的關系,建立了標簽剝離時的力學模型,設計了標簽供送裝置中的剝離機構。

關鍵詞:標簽供送;剝離;力學模型;結構設計

中圖分類號:TB486 文獻標識碼:A 文章編號:1003-5168(2019)34-0044-03

Structural Design of the Feeding Device of Pressure Sensitive Labels

CAI Jianxin CHEN Song

(Wuxi Institute of Technician,Wuxi Jiangsu 214153)

Abstract: Pressure sensitive labels in roll form are widely used in existing automated labeling equipment. Label feeding is an important part of labeling. Unreliable feeding would lead to the failure of the subsequent labeling operation. The process of feeding label was studied and the structure of a label feeding device was developed in this paper. Based on the relationship between the peeling force and the curvature radius of the label, the mechanical model of the label peeling was established, and the peeling mechanism of the label feeding device was designed.

Keywords: label feeding;peeling;model of mechanics;structural design

標簽供送是貼標中的重要環節之一,如果標簽供送不可靠,將導致后續的貼標操作無法順利完成。而且,標簽供送的精度也會影響貼標的精度。因此,標簽供送裝置是整個貼標系統里的關鍵部件。標簽供送裝置主要解決標簽從底紙上可靠剝離、標簽及時供送、標簽供送位置準確等問題。

1 壓敏標簽

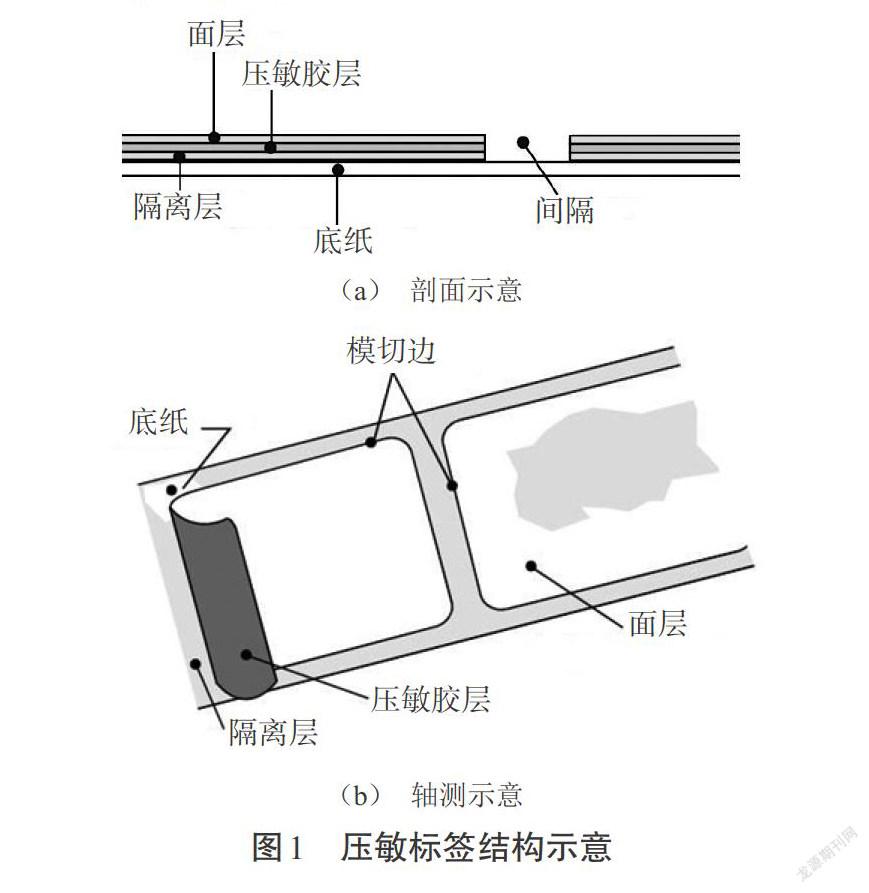

標簽的種類繁多,主要可以分為片式標簽、卷筒狀標簽、熱黏性標簽、感壓性標簽及收縮筒形標簽。壓敏標簽由面層(基材層)、隔離紙層和壓敏膠層組成[1],如圖1所示。面層材料可以是紙張、薄膜、特種材料或層疊體;隔離紙層由隔離層和底紙構成,涂有硅保護的隔離層覆蓋在底紙上,使標簽更易從底紙上撕下。壓敏標簽可以片材、卷材或折疊形式供應,而卷材對自動化生產是較為有利的形式。

2 標簽供送裝置整體設計方案

2.1 標簽供送工藝分析

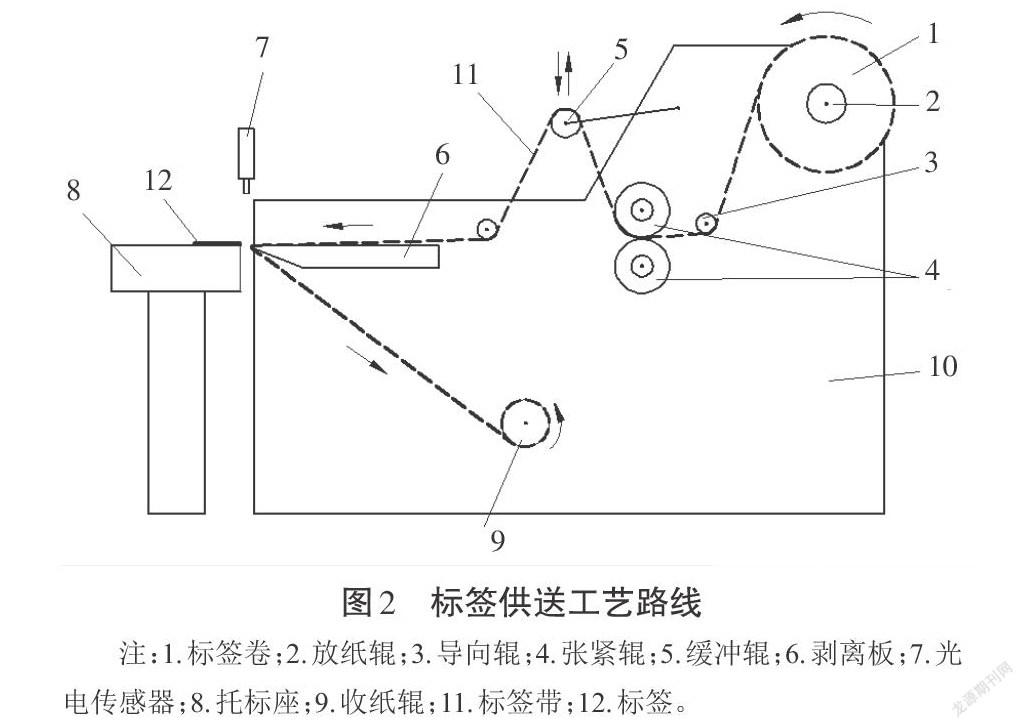

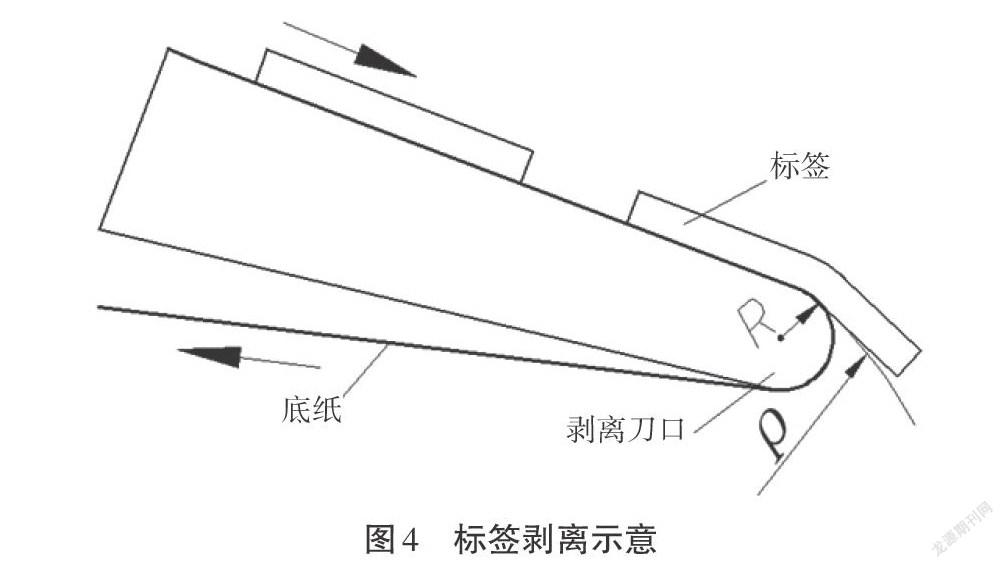

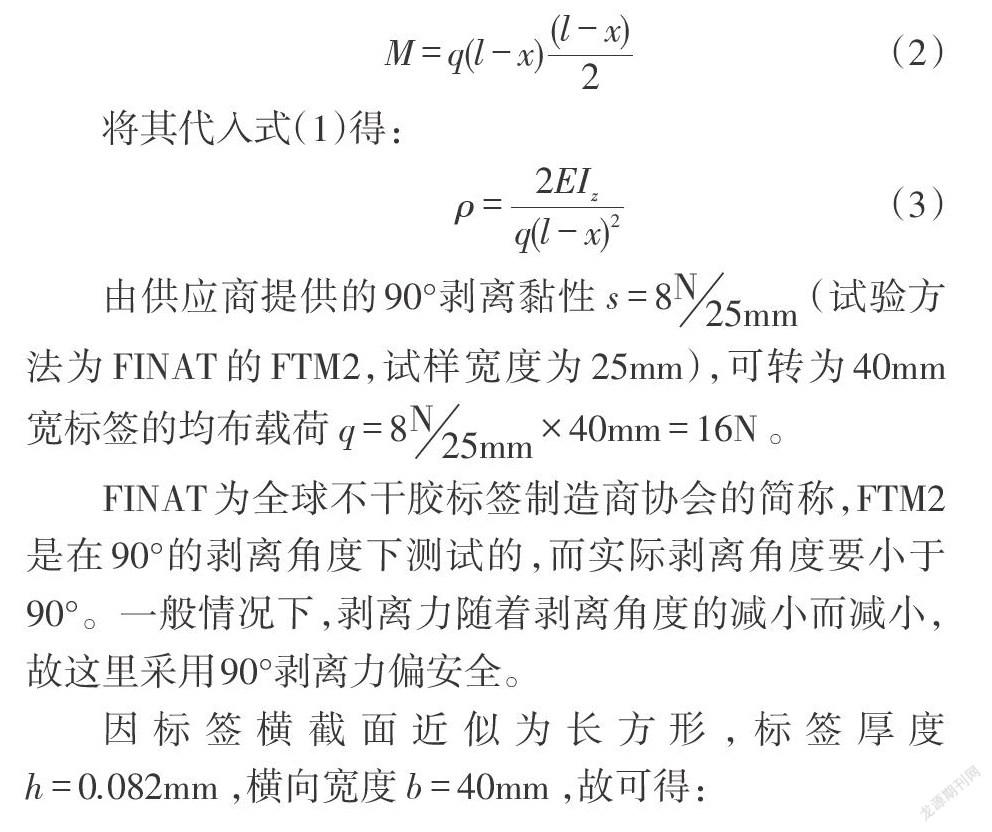

標簽供送裝置必須實現將壓敏標簽順利地從底紙上剝離及供送到取標位置的功能。……