玉米免耕播種機主動式秸稈移位防堵裝置的設計與試驗

王韋韋,朱存璽,陳黎卿,李兆東,黃 鑫,李金才

?

玉米免耕播種機主動式秸稈移位防堵裝置的設計與試驗

王韋韋,朱存璽,陳黎卿,李兆東,黃 鑫,李金才※

(安徽農業大學工學院,合肥 230036)

針對黃淮海麥玉輪作區小麥秸稈全量還田下苗床整備前存在多機具多次下田、生產成本高以及傳統玉米免耕播種機在小麥秸稈全覆蓋地作業時存在開溝壅堵、架種、晾種等問題,該文設計了一種基于“秸稈移位”防堵思路的主動式秸稈移位防堵裝置。運用EDEM軟件構建無支撐秸稈全覆蓋土壤離散元模型,在秸稈-土壤-主動式防堵裝置系統中進行秸稈移位虛擬仿真,設定了主動式秸稈移位防堵裝置的刀軸驅動轉速為500 r/min、回轉半徑為120 mm、刀盤幅寬為216 mm及刀齒入土深度為10 mm,利用仿真數據對秸稈擾動位移、清秸率進行分析,檢驗主動式秸稈移位防堵裝置結構參數和運動參數設計的合理性。田間試驗結果表明,安裝主動式秸稈移位防堵裝置的玉米免耕播種機的作業通過性穩定,改善種床環境,開溝壅堵次數為0次,秸稈清秸率為90.21%,相比仿真減少8.29個百分點。該研究可為小麥高留茬、秸稈全覆蓋地的玉米免耕播種機的設計與推廣提供參考。

機械化;設計;計算機仿真;秸稈移位;離散元法;秸稈全覆蓋地;免耕播種;主動式防堵

0 引 言

中國華北麥玉輪作區以冬小麥收后播種夏玉米為主,傳統耕作模式為小麥秸稈拋灑還田后使用滅茬機、旋耕機、播種機順次作業下田完成播種。多機具多次下田導致耕層板結嚴重,影響玉米播種質量、出苗差、苗質弱[1-2]。且小麥秸稈覆蓋地板茬直播玉米依然存在以下主要問題:機具入土部件掛草壅堵,作業順暢性難以保證;種子易播在秸稈上,造成架種;覆土不可靠,易造成晾種[3-5]。因此,解決開溝器鏟柄堵塞問題是設計免耕播種機的關鍵。

秸稈覆蓋還田和免耕播種是機械化保護性耕作的核心技術[6]。目前國內外免耕播種機上防堵裝置工作方式主要包括分茬和切茬2種類型。其中分茬主要是將粉碎的無支撐秸稈推離播種區,如凹形圓盤[7]、拔指輪[8]、伸縮拔桿[9]、分草鏟[10]等。這類防堵裝置在秸稈全量還田時分茬效果不顯著,防堵性能降低。切茬主要是將播種區秸稈進行二次切斷,以防止秸稈纏繞機具入土部件。切茬的方法又分為被動式和主動式2種類型。其中被動式開溝防堵裝置多采用破茬圓盤等結構[11],該類型主要依靠機具自身質量和地面摩擦驅動圓盤刀刃口滾動切斷秸稈、切開土壤開溝,防堵能力強,但當地表秸稈覆蓋量過大時,秸稈不能被切斷而被壓入土壤,導致開溝器入土困難,出現晾籽,影響播種質量;而主動式開溝防堵裝置是利用高速旋轉的旋耕刀[12]、滅茬刀[13]、破茬圓盤[14]對播種條帶進行旋耕、滅茬,特點是開溝能力強,防堵效果好,但存在土壤擾動量大,破壞墑情、功耗高,機具振動強烈,作業環境惡劣且存在安全隱患等問題。

本文研究針對傳統玉米免耕播種不適應高留茬、秸稈覆蓋地作業,存在開溝壅堵、架種、晾種等問題,設計了一種基于“秸稈移位”防堵思路的主動式秸稈移位防堵裝置,基于離散元法構建土壤-秸稈-防堵裝置系統模型,利用防堵裝置仿真作業性能試驗檢驗秸稈移位裝置工作參數設計的合理性;通過秸稈移位免耕播種機田間試驗,驗證離散元土壤-秸稈-防堵裝置系統模型的準確性和可行性,保證玉米免耕播種機在小麥高留茬、秸稈全量還田時的通過性。

1 總體結構與設計原理

1.1 總體結構

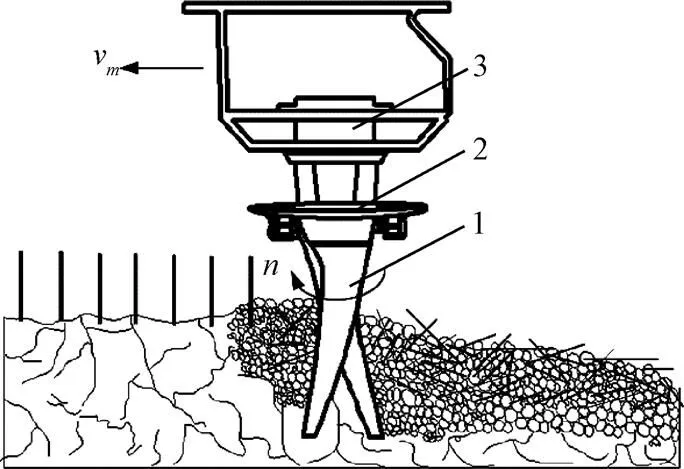

2BMY-4型玉米免耕播種機主要由主機架、主動式秸稈移位防堵裝置、開溝施肥裝置、播種單元體、覆土鎮壓裝置組成,如圖1所示。該機具采用秸稈移位的方式,一次下田作業可有效完成秸稈全覆蓋板茬地種床整備、側深施肥、單粒播種、覆土鎮壓等作業環節。

1.2 秸稈移位防堵裝置設計原理

如圖2所示,秸稈移位防堵裝置結構主要包括交叉對偶立式刀片、旋轉刀盤和旋轉軸承。小麥秸稈全覆蓋地“秸稈移位播種”的作業思路指:待播區地表上的秸稈在防堵裝置旋轉擾動作用下,沿著回轉刀尖切線方向向種床一側進行移位,實現待播區地表平整無秸稈,隨后開溝器完成開溝破土、苗床整理、施肥播種。其中,立式刀片與秸稈、土壤間相互作用依次為砍切、擾動、平整。且刀片對稱交叉布置主要為了擾動作業過程中滿足動平衡要求。

1.對偶立式刀片 2.旋轉刀盤 3.旋轉軸承

1.Dual vertical blade 2.Rotating cutter head 3.Rotary bearing

注:v為作業前進速度,m·s-1;為刀盤工作轉速,r·min-1。

Note:vis forward operation velocity, m·s-1;is driving velocity of the cutter shaft, r·min-1.

圖2 秸稈移位防堵裝置結構示意圖

Fig.2 Structural diagram of straw-removing anti-blocking device

2 秸稈移位防堵裝置工作參數設計

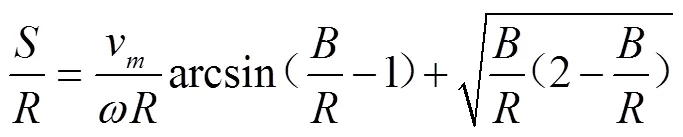

2.1 刀刃運動軌跡分析

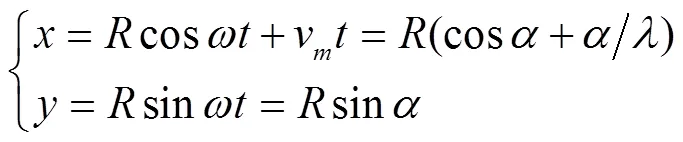

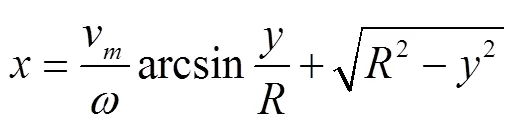

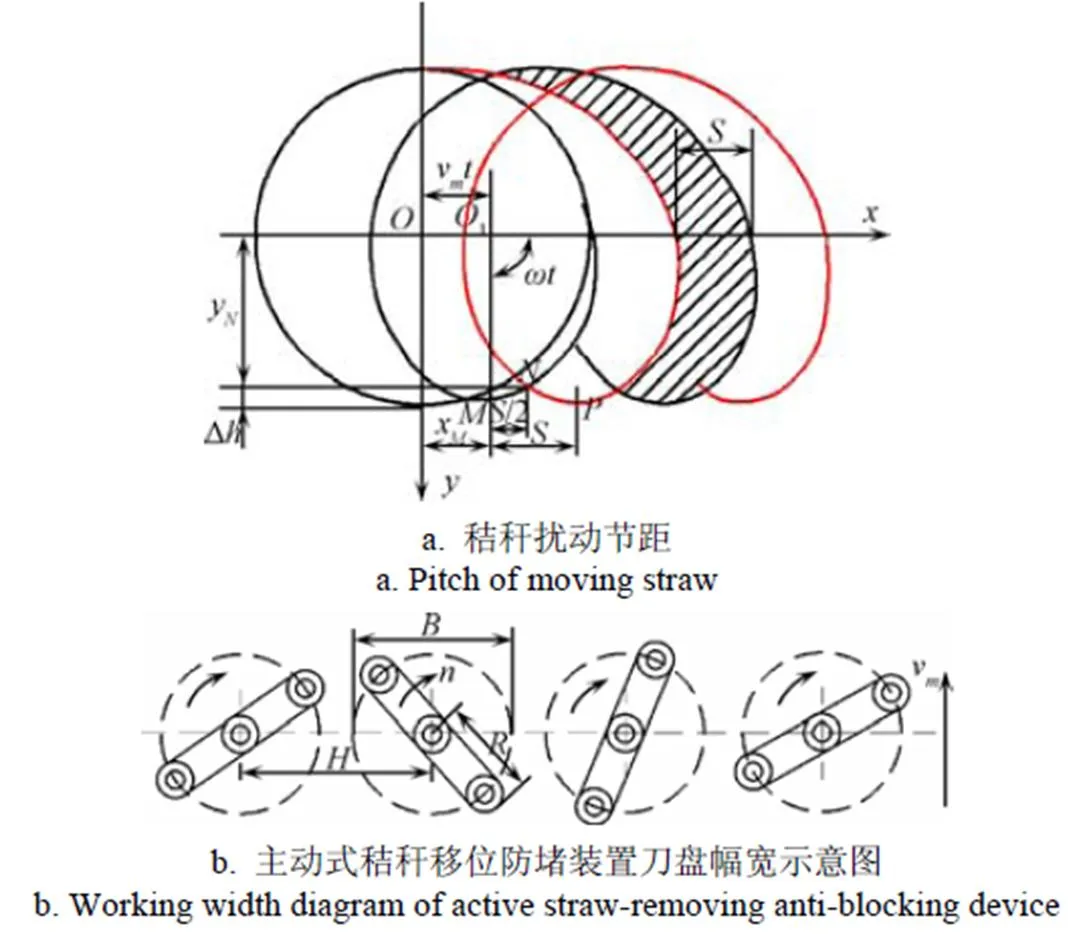

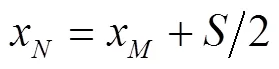

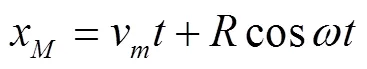

防堵裝置在旋轉工作時呈現往復運動,對偶立式旋刀繞刀盤中心旋轉為相對運動,作業機組勻速前進運動為牽連運動,以防堵裝置旋轉中心為原點建立固定坐標系,軸正方向與作業機組前進方向一致,軸為與機組前進方向垂直平面的水平向右方向,如圖3所示。為刀軸回轉角速度,v為刀刃端點的切向速度,作業機組前進速度v,其中防堵裝置回轉方向與機組作業方向垂直,開始時對偶立式刀片的端點位于前方水平與軸重合,則防堵裝置端點的運動軌跡方程為

將式(1)[15-16]中消除時間參數數,可得刀齒運動軌跡方程

式中、為立式對偶刀端點在任意時刻的位置坐標;防堵裝置轉角;刀刃端點的切向速度v=R;令為速度比:λ=v/v;為時間,s。

當<1時,由(1)式可得,無論防堵裝置運動到什么位置,秸稈的位移方向與機組作業方向相同,其運動軌跡呈短擺線,不能夠達到清秸防堵的目的;當1時,防堵裝置運動軌跡呈余擺線,對偶刀片才能滿足向種床側后方進行秸稈移位。

注:O為防堵裝置旋轉中心;O1為防堵裝置t時刻轉動中心;N為作業刀刃起始位置;N1為作業刀刃t時刻位置;α為刀軸轉角,(°);R為防堵裝置旋轉中心O到刀刃端點的距離(防堵裝置回轉半徑),mm;ω為防堵裝置的角速度,rad·s-1。

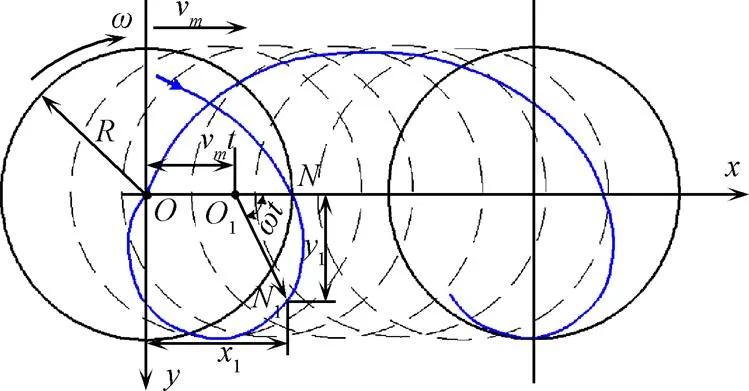

四行免耕播種機防堵裝置布置示意圖如圖4所示。

注:M為第一刀刃t時刻作業位置;N為2個刀刃作業重合位置;P為第二刀刃t時刻作業位置;B為刀盤幅寬,mm;S為秸稈擾動節距,mm;Δh為凸起高度,mm;H為播種行距,mm。

2.2 刀軸轉速、回轉半徑、刀盤幅寬參數確定

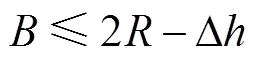

麥茬田秸稈量大,為了不破壞土壤墑情且保證玉米播種質量,必須確保防堵裝置將施肥、播種開溝器正前方的秸稈從作業行移位至苗床行間。為了使四行免耕玉米播種機(圖4)在麥茬田全面作業,秸稈移位防堵裝置刀盤位置參數應滿足

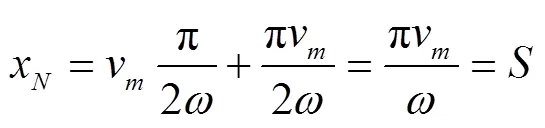

同一個刀盤上安裝2把立式刀片,則一周內兩刀齒相繼對秸稈的擾動間隔時間為π/,秸稈擾動節距為

其中刀盤每分鐘的轉速n=v/π。

從圖4a可以看出π/2,則π/2,并將式(4) 代入式(6)并變換式(7)得

由方程(2)和方程(7)聯合可得

令=,取≤2,其中為相鄰刀盤的重疊量系數,則有

由方程式(11)可知,與成正比例關系,隨著的減少而減少,從而秸稈擾動節距減小,由于覆蓋秸稈屬于無支撐多自由度群體,擾動節距越小,開溝器正前方作業行內的秸稈量越小。根據保護性耕作要求玉米播種時土壤擾動量越小,保墑效果越好,盡量確保主動式秸稈移位防堵裝置刀刃不入土或淺入土。播種開溝實際壟形寬度為40~60 mm[17-19],側位施肥法要求施肥開溝器與播種開溝器距離30~50 mm,為了同時保證播種和施肥開溝器的空間位置及開溝壟行寬度要求,故防堵裝置回轉半徑取120 mm。結合農藝要求播種行距為600 mm,播種機作業速度取4 km/h。根據文獻及對偶立式刀片安裝刀盤的強度要求,系數不宜過小,故取1.5~1.8[20-23],則刀盤幅寬為216~240 mm,同時結合方程(4)、(11)可得速度比為2.9~3.5,則秸稈移位防堵裝置刀軸轉速為445~538 r/min。

3 離散元仿真分析

為了驗證秸稈移位防堵裝置結構參數和運動參數設計的合理性,運用離散元法進行主動式秸稈移位防堵裝置作用下秸稈移位虛擬仿真試驗。本文采用EDEM 2.6軟件建立秸稈全覆蓋土壤模型,為了能夠準確地反映防堵裝置移位秸稈的作業效果,首先需要確定離散元仿真參數。

3.1 離散元土壤接觸模型與本征參數確定

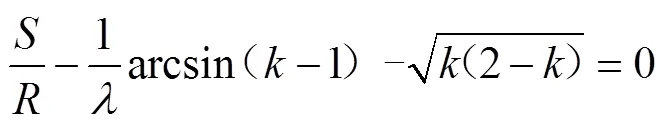

接觸模型是離散元法的重要基礎,其實質是準靜態下顆粒固體的接觸力學彈塑性分析結果[24]。接觸模型的分析計算直接決定了顆粒所受的力、力矩和位移的大小,對不同的仿真對象,須建立不同的接觸模型,確保仿真結果的準確性。在離散元單元法中,顆粒在運動過程中主要受2種力作用,即自身重力mg,土壤-秸稈顆粒間或者秸稈顆粒與防堵裝置法向碰撞接觸力F、法向阻力F、切向碰撞接觸力F、切向阻力F。根據牛頓第二運動定律,容易得到顆粒運動方程如式(12)所示。

其中

式中I為顆粒的轉動慣量,kg·m2;n為與顆粒的碰撞接觸總數,Hz;v為顆粒的移動速度,m/s;T為顆粒受切向力形成的力矩,N·m;T為顆粒受到滾動力矩,N·m;F為顆粒法向結合力,N;A為顆粒接觸面積,m2;k為黏附能量密度,kg/m3。

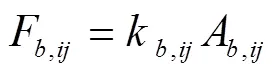

F根據秸稈顆粒是否有粘聚力進行設定。試驗區土壤為砂姜黑土,具有散粒體物料特性,顆粒表面黏附力較小,且具有一定的壓縮性,因此本研究設定土壤顆粒塑性變形的Hysteretic Spring接觸模型和添加一個法向黏聚力的Linear Cohesion接觸模型。土壤本征參數經測量及多數研究者在離散元土壤模型相關文獻[25-26]可得如表1。

表1 土壤參數和接觸參數

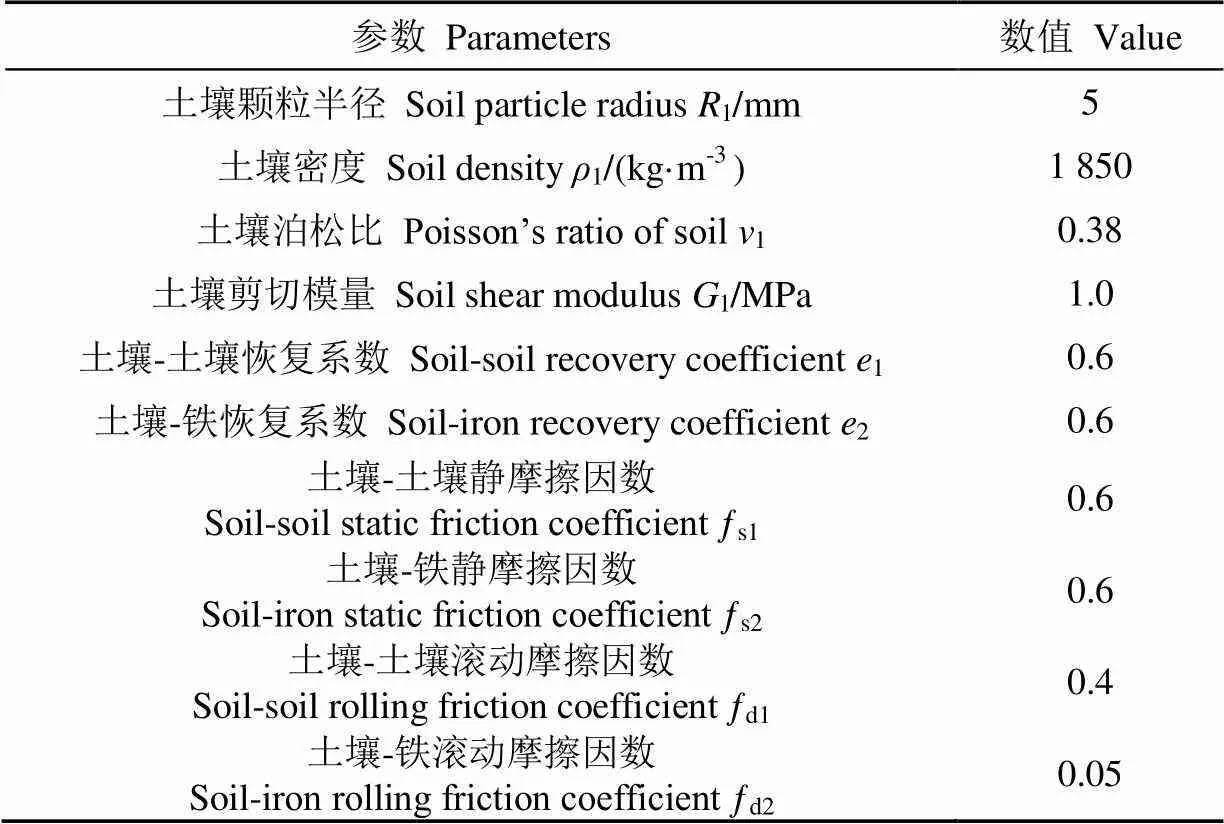

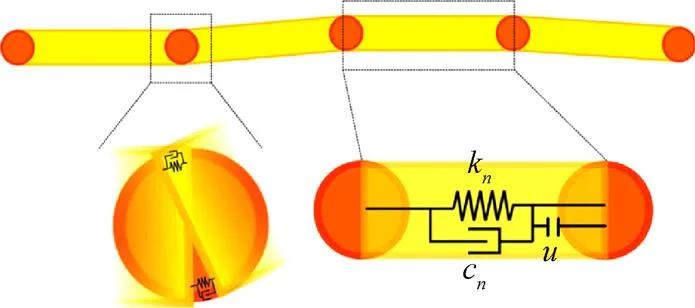

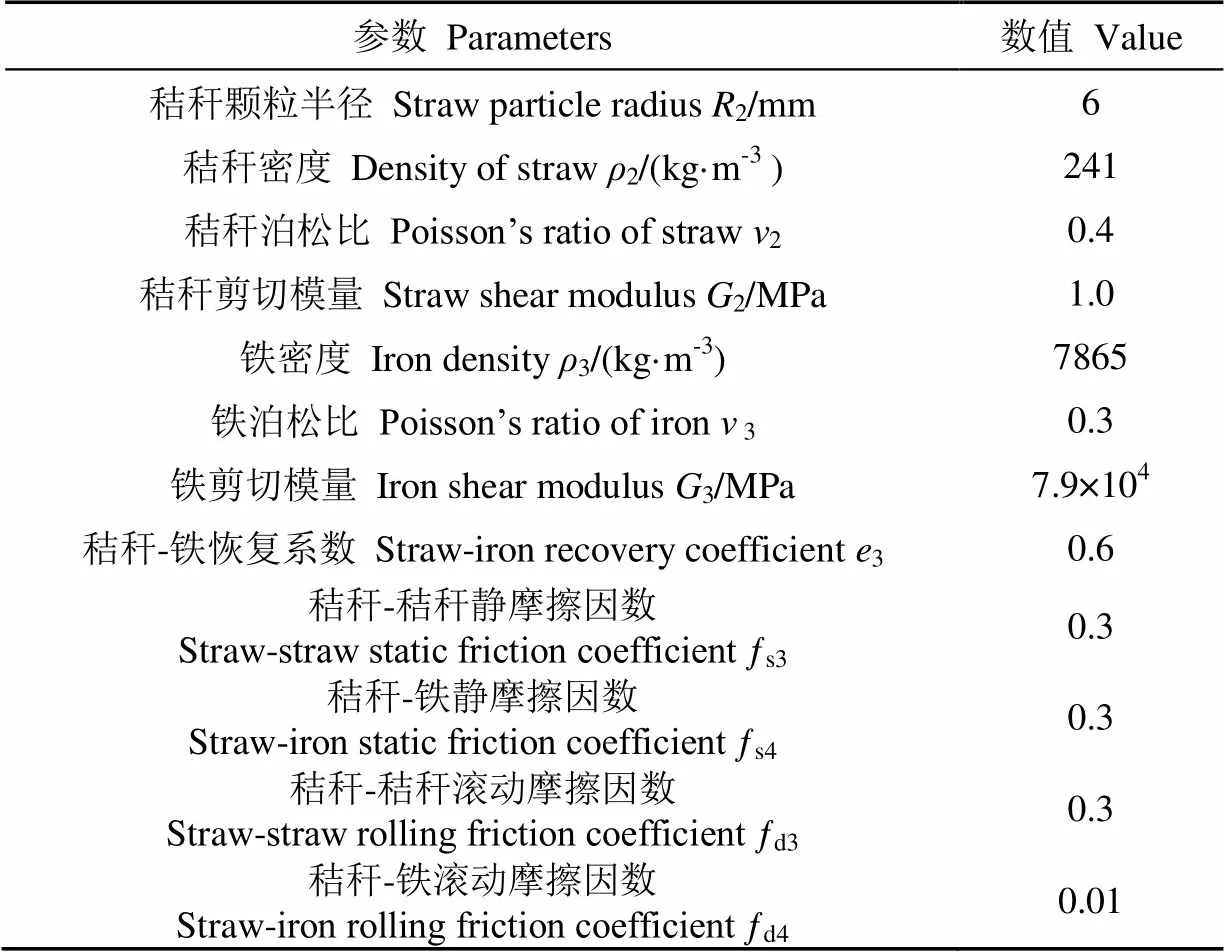

3.2 離散元秸稈接觸模型與本征參數確定

通過掃描電子顯微鏡及傅里葉紅外光譜測定小麥秸稈是一種典型的多相、篩狀、不連續、不均勻、各向異性的復合材料,故仿真小麥秸稈難度較大。至今未見有運用商業離散元軟件建立全方位柔性體秸稈模型的相關研究[27-28],本文采用EDEM中軟球模型建立秸稈顆粒模型,其中軟球顆粒的法向力簡化為彈簧k和阻尼器C,切向力簡化為彈簧k、阻尼器c和滑動摩擦器。選用10個半徑為6 mm、球心間隔為14 mm組成的長為140 mm的長線性模型作為秸稈顆粒,如圖5所示,每1節是具有剛度和阻尼的空心圓柱體連接2個圓球顆粒形成的。仿真過程中所使用的防堵裝置參數及秸稈顆粒之間的恢復系數、靜摩擦因素、滾動摩擦因素參照文獻[29-32],如表2所示。

注:kn為秸稈顆粒模型的剛度,N·m-1;cn為秸稈顆粒模型的阻尼系數;μ為秸稈相鄰顆粒模型的摩擦系數。

表2 秸稈參數和接觸參數

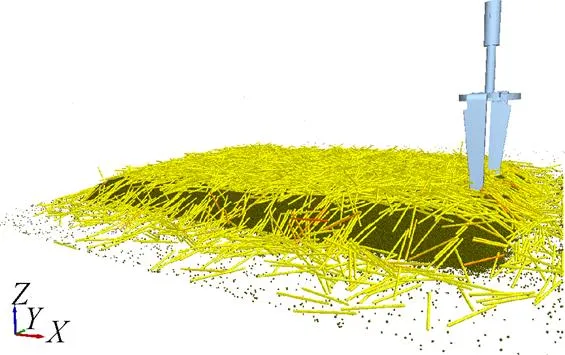

3.3 土壤-秸稈-防堵裝置幾何模型的建立

通過對土壤-秸稈-防堵裝置系統相互接觸模型及仿真參數的測定,建立2 400 mm(長)×800 mm(寬)× 200 mm(高)離散元秸稈全覆蓋土壤模型,為了減少土壤表層仿真秸稈與實際對應的覆蓋秸稈密度的誤差,虛擬秸稈覆蓋土槽0~150 mm深度的耕作層土壤顆粒為隨機排列;150~200 mm深度的秸稈顆粒采用隨機(孔隙率12.5%)排列;仿真共生成250 000個土壤顆粒和4 000個秸稈顆粒。防堵裝置采用65 Mn鋼加工,選用“L”型立式刀片,為了減少覆蓋秸稈下耕作層的土壤擾動量,達到保墑的目的,主動式秸稈移位防堵裝置刀齒入土深度設為10 mm。結合上述秸稈移位防堵裝置參數分析,應用UG/NX軟件創建不同參數的防堵裝置幾何仿真模型,并將幾何仿真模型導入EDEM中。仿真開始前,防堵裝置位于系統模型的一端,圖6所示為土壤-秸稈-防堵裝置系統模型。

圖6 土壤-秸稈-防堵裝置系統模型

3.4 結果分析與討論

利用建立的秸稈全覆蓋土壤離散元模型對主動式秸稈移位防堵裝置進行仿真試驗。根據2.2節運動方程求解及后期整機設計中換向器傳動比選型要求,仿真設置中對刀軸轉速進行取整為500 r/min、回轉半徑為120 mm、刀盤幅寬216 mm、刀齒入土深度為10 mm、前進速度為4 km/h。通過導出防堵裝置刀刃切向力、秸稈位移量、秸稈作用力及移位效果等指標,驗證秸稈移位防堵裝置結構參數和運動參數設計的合理性。在保證秸稈移位仿真過程中秸稈顆粒運動的連續性的前提下,設定仿真時間步長為3.5×10-3s,仿真總時間為6.5 s。

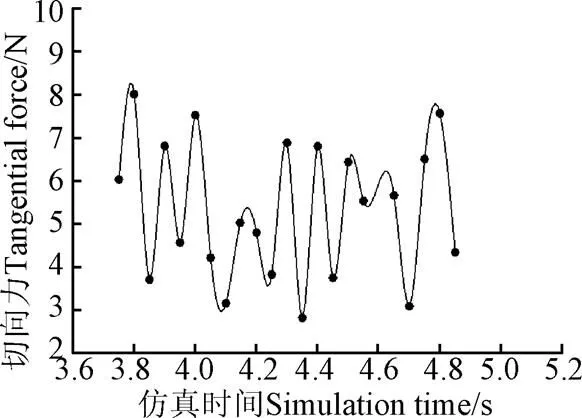

3.4.1 秸稈微觀運動

全覆蓋無支撐秸稈顆粒隨機排列在土壤顆粒表層,每一時刻秸稈所受刀齒的切向力的EDEM仿真結果可以用來研究擾動過程中秸稈的運動軌跡。首先分析余擺運動的刀齒在50 mm深的秸稈顆粒中擾動作業時所受切向力如圖7所示,刀刃所受切向力隨時間變化呈出不規律的上下浮動,其切向力平均值為5.8 N。

圖7 50 mm深處刀刃所受切向力的時域曲線

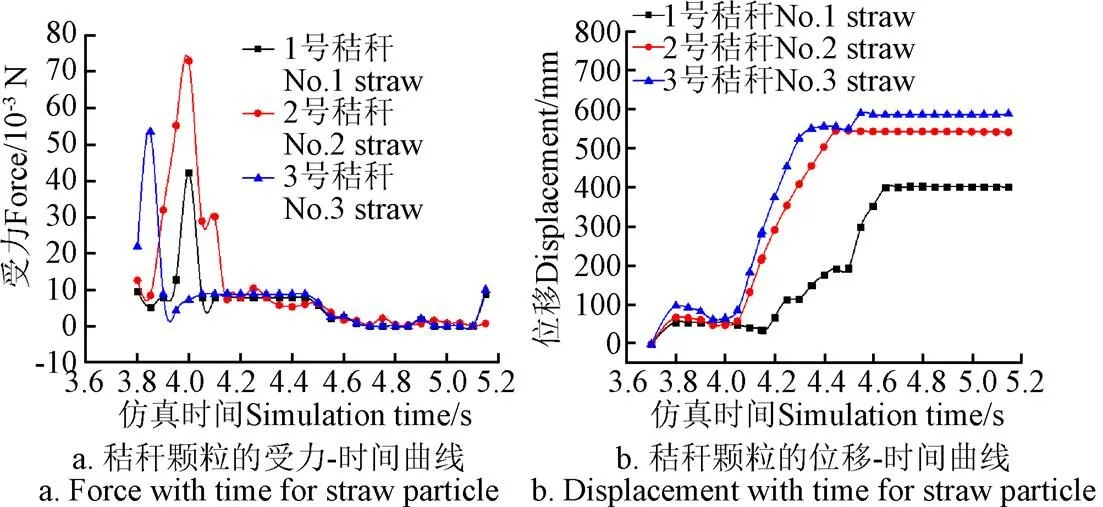

為了更好地分析秸稈的運動軌跡,隨機選取的3根秸稈顆粒(1號、2號、3號)在主動式秸稈移位防堵裝置的擾動下運動,設定所有秸稈顆粒的初始位置為坐標原點,從圖8a受力-時間曲線可以看出旋轉刀刃的瞬間滑切擾動作用產生一個波峰力,隨后秸稈顆粒移位脫離刀刃接觸,作用力開始衰減至0左右,其中單根秸稈顆粒受力平均值為55.2×10-3N。從圖8b位移-時間曲線圖中可以看出秸稈位移在作用力0.2 s以后位移量瞬間突增,后來的飛濺運動靠自身的慣性,作用力消失后1.2 s左右,秸稈位移矢量值穩定在400~580 mm范圍內,秸稈顆粒從作業行移位至苗床行間,符合農藝行要求。

圖8 防堵裝置作業秸稈顆粒的運動分析

3.4.2 秸稈移位效果

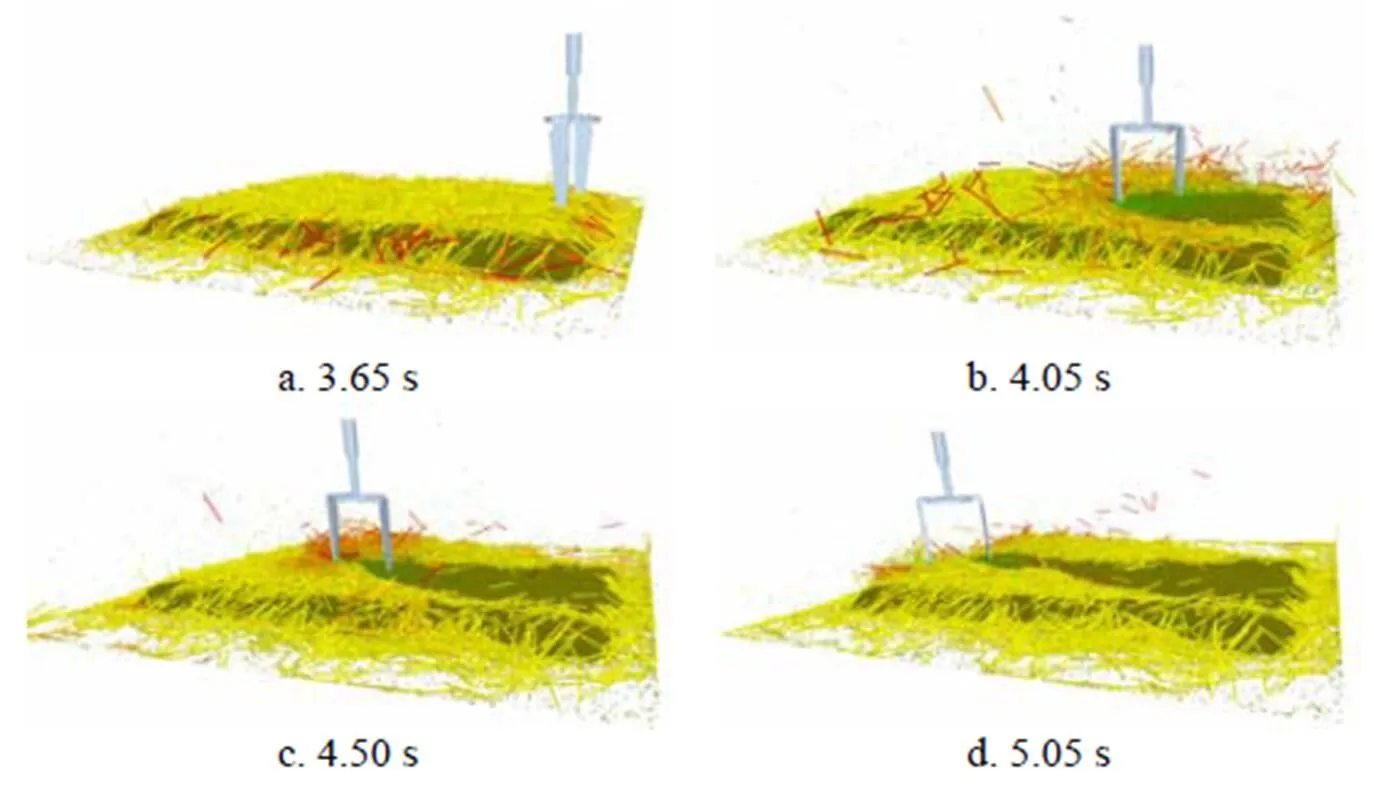

仿真過程中秸稈受防堵裝置刀齒作用力發生運動,不考慮秸稈被切斷的情況。由于仿真時間0~3.65 s內,沒有前進運動,裝置處于下降調整入土深度運動。3.65 s后防堵裝置開始作前進和回轉耦合運動,秸稈顆粒開始發生位置變化,對回轉區域內的約1 200根秸稈顆粒進行位移追蹤,同時對作業區初始位置秸稈顆粒數和仿真結束后該位置秸稈顆粒數進行統計,設定作業區內初始位置秸稈顆粒數與被移至的秸稈顆粒數比值百分數為秸稈清秸率,則仿真試驗統計在回轉區域內秸稈清秸率達98.5%,同時對無秸區行寬進行隨機采樣測量取平均值為245.5 mm,符合無秸區開溝施肥、播種要求,故秸稈移位防堵裝置的機構參數和運動參數設計可行。如圖9所示不同時刻秸稈移位追蹤效果圖,隨著防堵裝置擾動前進出現一片無秸稈區域。

圖9 不同仿真時刻秸稈移位效果圖

4 田間試驗

4.1 試驗條件

田間試驗選定安徽省宿州市現代農業示范園安徽農業大學皖北試驗站進行試驗。主要考核麥秸稈粉碎全量還田,秸稈留茬高度40 mm、秸稈覆蓋量均值為1.24 kg/m2下玉米免耕播種防堵技術試驗。將主動式秸稈移位防堵裝置安裝在2BMY-4型玉米免耕播種機機架上,整機作業幅寬2 400mm,作業效率為0.56 hm2/h。使用功率55 kW拖拉機進行田間試驗,其中拖拉機后輸出最高轉速為720 r/min,其中換向器傳動比為0.9,實際田間試驗時實測作業轉速可達到秸稈移位防堵需要刀軸轉速為500 r/min的條件,開溝器深度為150 mm,機具的前進速度4 km/h。

4.2 試驗方法

1)通過性

根據農業行業標準《免耕播種機質量評價技術規范》[33](NY/T1768-2009)及農業部農機鑒定總站免耕播種機性能檢測要求,按照正常的作業速度前進,觀察機具在作業過程中能否正常作業,記錄機具停下來清茬的次數,本試驗采用往返作業300 m為一組,共記錄5組。并與傳統玉米免耕直播機進行對比。

2)秸稈清秸率

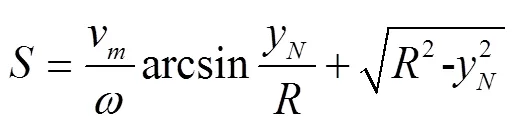

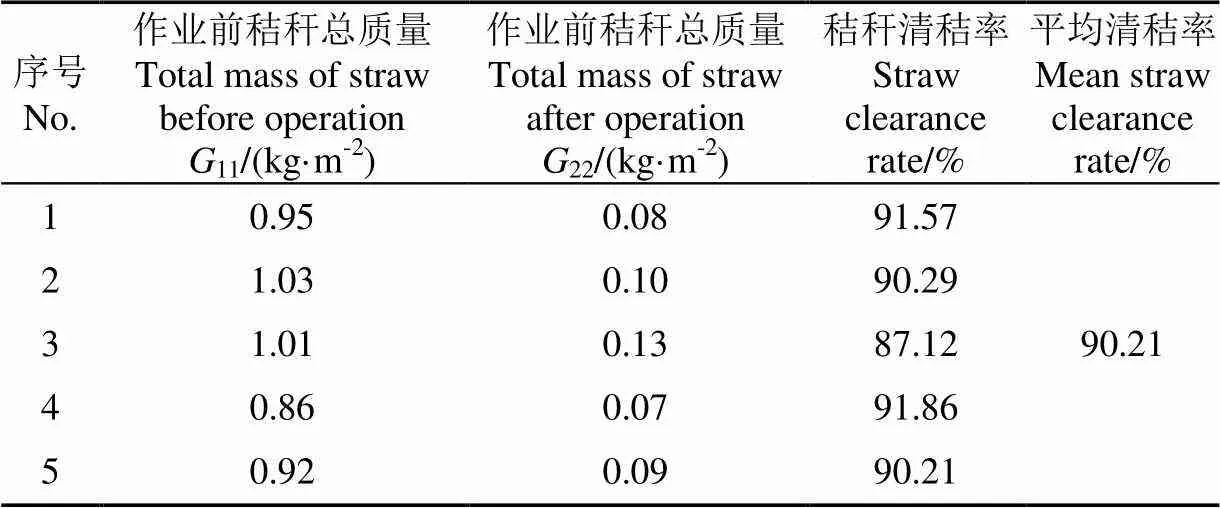

秸稈清秸率的測定,利用五點取樣法進行隨機取樣,選取秸稈移位裝置作業區域測量作業前后每平方米地表覆蓋的秸稈量,并稱質量11、22。按照式(14)計算作業前后開溝器正前方測定區內秸稈清秸率[11]。

式中為秸稈清秸率,%;11為作業前單位面積秸稈總質量,kg/m2;22為作業后單位面積秸稈總質量,kg/m2。

4.3 試驗對比結果與分析

4.3.1 通過性

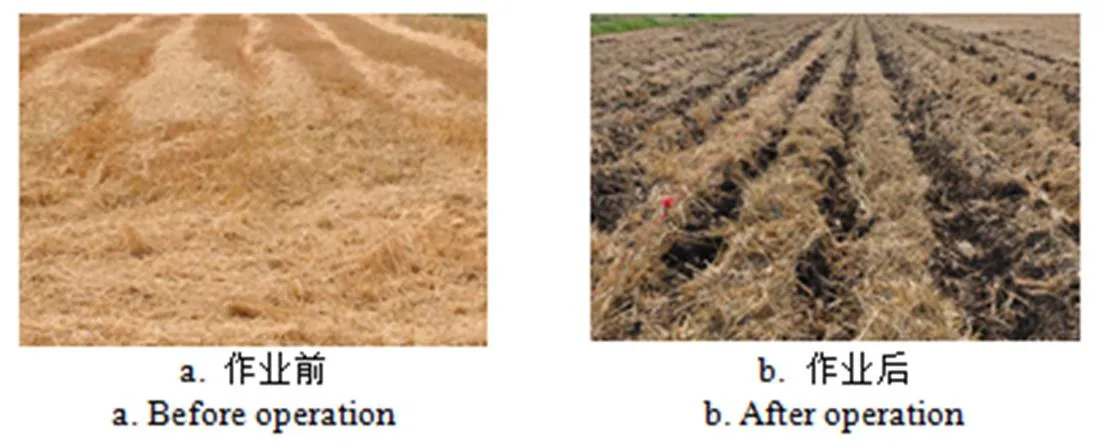

相同試驗條件下,使用安裝主動式秸稈移位防堵裝置的玉米免耕播種機進行田間作業,試驗過程中未發現開溝器壅堵現象;對照組使用傳統免耕播種機作業,在試驗過程中開溝器一共出現8次壅堵并進行清茬工作。其中秸稈移位玉米免耕播種機田間作業前后效果如圖10所示,通過田間試驗驗證秸稈移位防堵裝置功能的可行性。

圖10 主動式秸稈移位防堵裝置作業前后秸稈覆蓋效果

4.3.2 秸稈清秸率

為了減少覆蓋秸稈下耕作層的動土量,達到保墑的目的,主動式秸稈移位防堵裝置刀齒入土深度為10 mm。表4測定結果表明:采用加裝秸稈移位裝置的免耕播種機,秸稈清秸率平均值為90.21%,相比仿真減小8.29個百分點。

表4 秸稈清秸率測定結果

5 結論與討論

本文基于“秸稈移位播種”作業思路,設計了麥茬秸稈全覆蓋地玉米免耕播種開溝防堵裝置,有效解決了傳統玉米免耕播種在秸稈全覆蓋地作業過程中出現開溝器壅堵、架種和晾種等問題。

1)運用EDEM軟件建立了土壤-秸稈-防堵裝置系統模型,設定刀軸轉速為500 r/min,回轉半徑為120 mm,刀盤幅寬為216 mm,秸稈移位玉米免耕播種機防堵裝置刀齒入土深度為10 mm,通過分析秸稈微觀運動和秸稈移位效果,檢驗了刀軸工作轉速、回轉半徑和刀盤幅寬等參數設計的合理性。

2)田間試驗表明,留茬高度40 cm、覆蓋量1.24 kg/m2的小麥秸稈全覆蓋田,使用主動式秸稈移位防堵裝置的2BMY-4型玉米免耕播種機作業,未發生堵塞現象,通過性良好,秸稈平均清秸率90.21%,較仿真結果低8.29個百分點。

本研究可解決麥玉輪作區麥茬秸稈全量還田下玉米免耕播種通過性提供可行性方案,影響秸稈移位免耕播種通過性能的因素較多,如刀軸轉速、回轉半徑及驅動裝置類型等,本研究建立的仿真模型是在小麥秸稈全覆蓋地某一特定的刀軸轉速、驅動裝置類型和回轉半徑條件下構建的,需進一步探究最佳組合參數。不同作物秸稈全覆蓋地免耕防堵要求不一,需要根據農業生產實際進行調節。

[1] 高煥文,李洪文,姚宗路. 我國輕型免耕播種機研究[J].農業機械學報,2008,39(4):78-82.

Gao Huanwen, Li Hongwen, Yao Zonglu. Study on the Chinese light no-till seeders[J]. Transactions of the Chinese Society for Agricultural Machinery, 2008, 39(4): 78-82. (in Chinese with English abstract)

[2] He Jin, Li Hongwen, Wang Xiaoyan, et al. The adoption of annual subsoiling as conservation tillage in dryland maize and wheat cultivation in northern China[J]. Soil and Tillage Research, 2007, 94(2): 493-502.

[3] 劉立晶,高煥文,李洪文. 玉米-小麥一年兩熟保護性耕作體系試驗研究[J]. 農業工程學報,2004,20(3):70-73.

Liu Lijing, Gao Huanwen, Li Hongwen. Conservation tillage for corn-wheat two crops a year region[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2004, 20(3): 70-73. (in Chinese with English abstract)

[4] 廖慶喜,高煥文,舒彩霞. 免耕播種機防堵技術研究現狀與發展趨勢[J]. 農業工程學報,2004,20(1):108-112.

Liao Qingxi, Gao Huanwen, Shu Caixia. Present situations and prospects of anti-blocking technology of no-tillage planter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2004, 20(1): 108-112. (in Chinese with English abstract)

[5] 楊麗,張瑞,張東興,等. 防堵和播深控制機構提高玉米免耕精量播種性能[J]. 農業工程學報,2016,32(17):18-23.

Yang Li, Zhang Rui, Zhang Dongxing, et al. Row cleaner and depth control unit improving sowing performance of maize no-till precision planter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(17): 18-23. (in Chinese with English abstract)

[6] 顧峰瑋,胡志超,陳有慶,等. “潔區播種”思路下麥茬全秸稈覆蓋地花生免耕播種機研制[J]. 農業工程學報,2016,32(20):15-23.

Gu Fengwei, Hu Zhichao, Chen Youqing, et al. Developmentand experiment of peanut no-till planter under full wheat strawmulching based on “clean area planting”[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of theCSAE), 2016, 32(20): 15-23. (in Chinese with English abstract)

[7] 王慶杰,李洪文,何進,等. 凹形圓盤式玉米壟作免耕播種機的設計與試驗[J]. 農業工程學報,2011,27(7):117-122.

Wang Qingjie, Li Hongwen, He Jin, et al. Design and experiment on concave disc type maize ridge-till and no-till planter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(7): 117-122. (inChinese with English abstract)

[8] 賈洪雷,趙佳樂,姜鑫銘,等. 行間免耕播種機防堵裝置設計與試驗[J]. 農業工程學報,2013,29(18):16-25.

Jia Honglei, Zhao Jiale, Jiang Xinming, et al. Design and experiment of anti-blocking mechanism for inter-row no-tillage seeder[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(18): 16-25. (in Chinese with English abstract)

[9] 王慶杰,何進,李洪文,等. 免耕播種機開溝防堵單元體設計與試驗[J]. 農業工程學報,2012,28(1):27-31.

Wang Qingjie, He Jin, Li Hongwen, et al. Design and experiment on furrowing and anti-blocking unit for no-till planter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(1): 27-31. (in Chinese with English abstract)

[10] 何進,李洪文,李慧,等. 往復切刀式小麥固定壟免耕播種機[J]. 農業工程學報,2009,25(11):133-138.

He Jin, Li Hongwen, Li Hui, et al. No-till planter with reciprocating -cutter for wheat permanent raised beds cultivation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2009, 25(11): 133-138. (in Chinese with English abstract)

[11] 張喜瑞,李洪文,何進,等. 小麥免耕播種機防堵裝置性能對比試驗[J]. 農業機械學報,2010,41(2):73-77.

Zhang Xirui, Li Hongwen, He Jinm, et al. Comparative experiment on anti-blocking mechanism for wheat no-till planter[J]. Transactionsof the Chinese Society for Agricultural Machinery, 2010, 41(2): 73—77. (in Chinese with English abstract)

[12] 趙旭,張祖立,唐萍,等. 被動式傾斜波紋圓盤破茬刀工作性能試驗[J]. 農業機械學報,2011,42(1):64-67.

Zhao Xu, Zhang Zuli, Tang Ping, et al. Behavior ofpassive stubble-cutting disc with oblique ripples[J]. Transactions of the Chinese Society for AgriculturalMachinery, 2011, 42(1): 64-67. (in Chinese withEnglish abstract)

[13] 趙佳樂,賈洪雷,郭明卓,等. 免耕播種機有支撐滾切式防堵裝置設計與試驗[J]. 農業工程學報,2014,30(10):18—28.

Zhao Jiale, Jia Honglei, Guo Mingzhuo, et al. Design and experimentofsupported roll-cuttinganti-blocking mechanismwith for no-till planter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2014, 30(10): 18-28. (in Chinese with English abstract)

[14] 王漢羊,陳海濤,紀文義. 2BMFJ-3 型麥茬地免耕精播機防堵裝置[J]. 農業機械學報,2013,44(4):64-70.

Wang Hanyang, Chen Haitao, Ji Wenyi. Anti-locking mechanism of type 2BMFJ-3 no-till precision planter for wheat stubble fields[J].Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(4): 64-70. (in Chinese with English abstract)

[15] 高娜娜,張東興,楊麗,等. 玉米免耕播種機滾筒式防堵機構的設計與試驗[J]. 農業工程學報,2012,28(12):31-37.

Gao Nana, Zhang Dongxing, Yang Li, et al. Design andexperiment of drum-type anti-blocking mechanism of no-tillplanter for maize[J]. Transactions of the Chinese Society ofAgricultural Engineering (Transactions of the CSAE), 2012, 28(12): 31-37. (in Chinese with English abstract)

[16] 蔣金琳,龔麗農,王東偉,等. 免耕播種機雙刀盤有支撐切茬破茬裝置的研制與試驗[J]. 農業工程學報,2012,28(21):17-22.

Jiang Jinlin, Gong Linong, Wang Dongwei, et al. Development and experiment for driving double coulters anti-blockage device of no-till planter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(21): 17-22. (in Chinese with English abstract)

[17] 林靜,李博,李寶筏,等. 阿基米得螺線型缺口圓盤破茬刀參數優化與試驗[J]. 農業機械學報,2014,45(6):100-104.

Lin Jing, Li Bo, Li Baofa, et al. Parameter optimization and experiment on archimedes spiral type gap cutting disc[J]. Transactions of the Chinese Society for AgriculturalMachinery, 2014, 45(6): 100-104. (in Chinese with Englishabstract)

[18] 楊自棟,劉寧寧,耿端陽,等. 2BYM-12型折疊式動力防堵免耕播種機設計與試驗[J]. 農業機械學報,2013,44(增刊1):46-50.

Yang Zidong, Liu Ningning, Geng Duanyang, et al. Design and experiment on type 2BYM-12 folding and dynamic anti-locking no-ill planter[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(Supp.1): 46-50. (in Chinese with English abstract)

[19] 盧彩云,李洪文,何進,等. 小麥免耕播種機浮動支撐式防堵裝置[J]. 農業機械學報,2013,44(12):52-55,153.

Lu Caiyun, Li Hongwen, He Jin, et al. Floated supportanti-blocking device of wheat no-till seeder[J]. Transactionsof the Chinese Society for Agricultural Machinery, 2013, 44(12): 52-55, 153. (in Chinese with English abstract)

[20] 盧彩云,趙春江,孟志軍,等. 基于滑板壓稈旋切式防堵裝置的秸稈摩擦特性研究[J]. 農業工程學報,2016,32(11):83-89.

Lu Caiyun, Zhao Chunjiang, Meng Zhijun, et al. Straw friction characteristic based on rotarycutting anti-blocking device with slide plate pressing straw[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2016, 32(11): 83-89. (in Chinese with English abstract)

[21] 中國農業機械化科學研究院. 農業機械設計手冊(上冊)[M]. 北京:中國農業科學技術出版社,2007:288-299.

[22] 林靜,宋玉秋,李寶筏. 東北壟作區機械免耕播種工藝的研究[J]. 農業工程學報,2014,30(9):50-57.

Lin Jing, Song Yuqiu, Li Baofa. Mechanical no-tillage sowing technology for northeast ridge area in China[J]. Transactions of the Chinese Society of AgriculturalEngineering (Transactions of the CSAE), 2014, 30(9): 50-57. (in English with Chinese abstract)

[23] 林靜,錢巍,牛金亮. 玉米壟作免耕播種機新型切撥防堵裝置的研究與試驗[J]. 沈陽農業大學學報,2015,46(6):691-698.

Lin Jing, Qian Wei, Niu Jinliang. Design and experiment of stubble-cutting and anti-blocking mechanism for ridge-till and no-till planter[J]. Journal of Shenyang Agricultural University, 2015, 46(6): 691-698. (in Chinese with English abstract)

[24] 鄭侃,何進,李洪文,等. 基于離散元深松土壤模型的折線破土刃深松鏟研究[J].農業機械學報,2016,47(9):62-67.

Zheng Kan, He Jin, Li Hongwen, et al. Research on polyline soil-breaking blade subsoiler based onsubsoiling soil model using discrete element method[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(9): 62-67. (in Chinese with English abstract)

[25] 方會敏,姬長英,張慶怡,等. 基于離散元法的旋耕刀受力分析[J]. 農業工程學報,2016,32(21):54-59.

Fang Huimin, Ji Changying, Zhang Qingyi, et al. Force analysis of rotary blade based on distinct element method[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(21): 54-59. (in Chinesewith English abstract)

[26] 方會敏,姬長英,AHMED Ali Tagar,等. 秸稈土壤旋耕刀系統中秸稈位移仿真分析[J]. 農業機械學報,2016,47(1):60-67.

Fang Huimin, Ji Changying, AHMED Ali Tagar, et al. Simulation analysis of straw movement in straw soil rotary blade system[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(1): 60-67. (in Chinese with English abstract)

[27] 于建群,錢立彬,于文靜,等. 開溝器工作阻力的離散元法仿真分析[J]. 農業機械學報,2009,40(6):53-57.

Yu Jianqun, Qian Libin, Yu Wenjing, et al. DEM analysis ofthe resistance applied on furrow openers[J]. Transactions ofthe Chinese Society for Agricultural Machinery, 2009, 40(6): 53-57. (in Chinese with English abstract)

[28] Tagar A A, JiChangying, Jan A, et al. Finite element simulation of soil failure patterns under soil bin and field testing conditions[J]. Soil & Tillage Research, 2015, 145: 157-170.

[29] Ucgul M, John M F, Chris S. Three dimensional discrete element modeling of tillagedetermination of a suitable contact modeland parameters for a cohesionless soil[J]. Biosystems Engineering, 2014, 121: 105-117.

[30] Mari I A, Chandio F A, Ji Changying, et al. Performance and evaluation of disc tillage tool forces acting on straw incorporation soil[J].Pakistan Journal of Agricultural Sciences, 2014, 51: 1-6.

[31] Liu J, Chen Y, Kushwaha R L. Effect of tillage speed and straw length on soil and straw movement by a sweep[J]. Soil & Tillage Research, 2010, 109(1): 9-16.

[32] Lenaerts B, Aertsen T, Tijskens E, et al. Simulation of grain-straw separation by discrete element modeling with bendable strawparticles[J]. Computers and Electronics in Agriculture, 2014, 101: 24-33.

[33] 中華人民共和國農業行業標準. 免耕播種機質量評價技術規范:NY/T1768-2009[S]. 北京:中華人民共和國農業部,2009.

Design and experiment of active straw-removing anti-blocking device for maize no-tillage planter

Wang Weiwei, Zhu Cunxi, Chen Liqing, Li Zhaodong, Huang Xin, Li Jincai※

(230036,)

Conventional farming methods with multiple operations by multiple types of machinery may lead to serious shallow soil hardening and cost increases for wheat-maize rotation cropping areas in Huang-Huai-Hai Plain of China. In addition, there are several technical problems for the traditional maize no-tillage planter when seeding in the fields covered by heavy wheat straw, 1) soil-buried parts of the no-tillage planter are easy to be blocked by the wheat straw, which cannot guarantee the smooth operation; 2) the seeds may be improperly planted on the top of wheat straw since the soil is totally covered by the wheat straw; 3) the germinated seeds cannot grow up normally as no soil covered, which result in production declines. In the current study, an active anti-blocking device was designed for the maize no-till planter for removing wheat straw that covered on the soil surface. During seeding in the field, the wheat straw that covered on the surface was disrupted and thrown into the air by the device and was transferred backward before it landed. Then, the planter would ditch, fertilize and seed in the cleaned field produced by the device. At the last, the smashed straw was evenly covered on the fields after planting. The structural parameters and motion parameters of the anti-blocking device were determined based on a simulation model built by the discrete element method (DEM). The model was composed of soil, full-coverage straw, and device, which can be used to simulate the process of removing the unsupported straw from the soil surface. The model and interaction system was established in EDEM 2.6 simulation environment, and their physical properties were calibrated with the real properties of lime concretion black soil and wheat straw. According to theoretical design to set simulation parameters, the radius of the cutter head was set to 120 mm, the driving speed of the cutter shaft was set to 500 r/min, and the depth of the cutting edge was set to 10 mm, the operating velocity of the active anti-blocking device was set to 4 km/h.The simulation experiment was used to analyze the displacement and the clearance rate of straw for selecting suitable structural parameters and motion parameters for design. The simulation results indicated that the tangential force of the cutting edge was irregularly fluctuating with time, and the average tangential force was 5.8 N; the straw clearance rate was 98.5% in the disrupted zone, the average width of the area without straw was 245.5 mm according to the random sampling, which was in accordance with the requirement of ditching, fertilizing, and seeding. The field experiment was carried out by a straw-removing maize no-tillage planter with the designed anti-blocking device mounted, for ditching, fertilizing and seeding, within a field covered by 1.24 kg/m2wheat straw with stubble height of 40 mm. The planter was hauled by a high-power tractor of over 55 kW with an operating velocity of 4 km/h and a working width of 2 400 mm, resulting in a pure productivity of more than 0.56 hm2/h. The field experiment and measurement results showed that the straw-removing no-tillage planter with an active anti-blocking device had a stable operation that can significantly improve the seeding environment. The number of clear straw was 0, the straw clearance rate was 90.21%, and reduced by 8.29 percentage points compared with the simulated value. This study illustrated that the maize no-tillage planter with active anti-blocking device was suitable for removing the covering straw, cleaning the seedbed, fertilizing, and covering the seedbed with wheat straw. Meanwhile, the research provides a reference for the design and extending of the no-tillage planter for the fields with full coverage of straw.

mechanization; design; computer simulation; straw-removing; discrete element method; straw-cover field; no-tillage seeding; active anti-blocking

10.11975/j.issn.1002-6819.2017.24.002

S224.29

A

1002-6819(2017)-24-0010-08

2017-07-11

2017-11-01

公益性行業(農業)科研專項(201503136);“十三五”國家重點研發計劃課題(2017YFD0300408、2017YFD0301307);研究生創新基金項目(2017yjs-42)

王韋韋,博士生,主要研究方向為保護性耕作技術與機具。Email:wangww0618@163.com

李金才,教授,博士生導師,主要從事作物栽培及秸稈還田理論與技術研究。Email:ljc5122423@126.com

王韋韋,朱存璽,陳黎卿,李兆東,黃 鑫,李金才. 玉米免耕播種機主動式秸稈移位防堵裝置的設計與試驗[J]. 農業工程學報,2017,33(24):10-17. doi:10.11975/j.issn.1002-6819.2017.24.002 http://www.tcsae.org

Wang Weiwei, Zhu Cunxi, Chen Liqing, Li Zhaodong, Huang Xin, Li Jincai. Design and experiment of active straw-removing anti-blocking device for maize no-tillage planter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(24): 10-17. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.24.002 http://www.tcsae.org