Enhanced Extinction Curve Method for Roll Damping Estimation

FENG Pei-yun,FAN She-ming,b

(a.Science and Technology Laboratory of Water-jet Propulsion;b.Shanghai Key Laboratory of Ship Engineering,Marine Design&Research Institute of China,Shanghai 200011,China)

Enhanced Extinction Curve Method for Roll Damping Estimation

FENG Pei-yuana,FAN She-minga,b

(a.Science and Technology Laboratory of Water-jet Propulsion;b.Shanghai Key Laboratory of Ship Engineering,Marine Design&Research Institute of China,Shanghai 200011,China)

Accuracy of roll damping estimation plays a crucial role in ship roll motion predictions.Free-decay test is still so far one of the most useful and popular methods to estimate the roll damping coefficients.The so-called extinction curve method is often used for analyzing the free roll decay data.One shortcoming of this method is that it is derived based on free roll motion equations neglecting nonlinear restoring terms.On the other hand,more sophisticated energy method can take into account this nonlinearity but is relatively complicated to implement.In this paper,an enhanced extinction curve method is proposed,which can take into account the nonlinear restoring terms of ship hulls.The proposed method is in a simple form and is easier to apply than energy method.Numerical experiment proves the validity of the enhanced extinction curve method,and demonstrates its advantages over conventional extinction curve method.

roll damping;free decay test;enhanced extinction curve method;nonlinear restoring moment

0 Introduction

Ship roll motions are featured by highly nonlinear damping moment and restoring moment,which has been widely and intensively investigated by researchers over a long history.One key difficulty lies in the fact that viscous effect is dominant in the case of roll motion,so methods based on potential theory that work well with heave and pitch predictions are no longer applicable,unless the correct roll damping can be accurately estimated.The state of the art assumption is based on a quadratic model,where the linear part of roll damping accounts for the potential wave radiation damping and some frictional effect,while the quadratic part of roll damping accounts for drag forces,flow separation,and other nonlinear effects[1].In practice,the most commonly adopted methods for roll damping estimation can be categorized into three groups:

·Semi-empirical methods can give quick estimations of roll damping but only within a certain applicable range for limited ship types and conditions[2].For unconventional hull forms,there is no guarantee on the estimation accuracy.

·CFD computation based on different Navier Stokes solvers is a promising method[3-6],but the computation burden is very high and its accuracy is still not very reliable at the current stage[1].

·Model testing is so far the most reliable way for roll damping estimation,which can be further categorized into free decay test and forced roll test.By comparison,free decay test is much easier and cheaper to implement.Therefore,it is still so far one of the most useful and popular methods to estimate roll damping coefficients.

This study focuses on the roll damping estimation with free decay test,which is a classical problem already discussed by many researchers[7-10],but still left with several unsolved issues[11].New theories and methods continue to emerge in the recent decades.Ueno et al[12]studied the estimation of nonlinear roll damping for fishing boats by improved energy method and genetic algorithm;Li et al[13]studied the effect of waves on nonlinear roll damping;Oliveira and Fernandes[14]studied the bi-linear behavior of roll damping;Jang et al[15]proposed a new method for detecting non-linear damping and restoring forces in non-linear oscillation systems from transient data;Ma et al[16]adopted an energy method to estimate the roll damping coefficients of amphibious vehicle that can take into account its nonlinear restoring moment.

The contribution of this study is to propose an enhanced extinction curve method for roll damping estimation with free decay test.Compared with conventional extinction curve method which is derived based on free roll motion equations with linear restoring coefficient,the enhanced extinction curve method can further take into account the nonlinear restoring moment of ship hulls.Moreover,the proposed method is in a simple form and very easy to apply.

To introduce this method and demonstrate its validity,this paper is organized as follows:firstly,the energy method is introduced for the purpose of comparison,as well as to help better understand the derivation of enhanced extinction curve method.Then,derivation of the enhanced extinction curve method is elaborated and its validity is proved through numerical experiment,where the results from energy method and conventional extinction curve method are also compared.Finally,some conclusions are drawn.

1 Energy method

Before deriving the enhanced extinction curve method,it is helpful to first follow the derivation of the energy method as elaborated in Ref.

[16],where the following nonlinear free roll decay motion equation is considered:

where φ is the roll angle;Ixis the total roll moment of inertia in water;B1and B2are the linear and quadratic parts of damping coefficients,respectively;K1and K3are the linear and nonlinear parts of restoring coefficients,respectively.With some simple manipulation,we can come to the following equation:

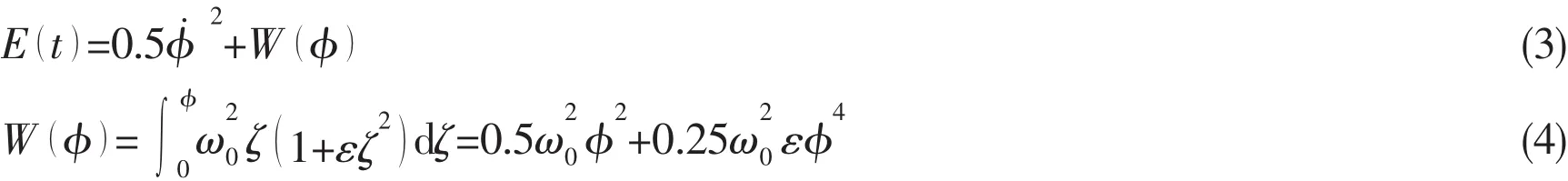

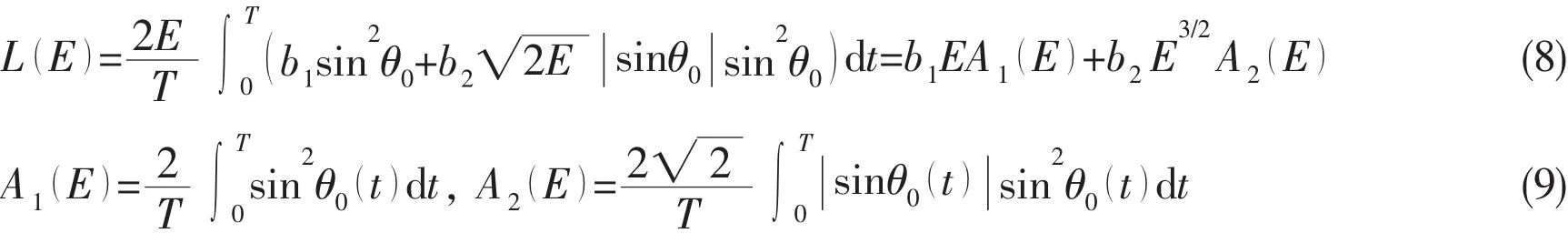

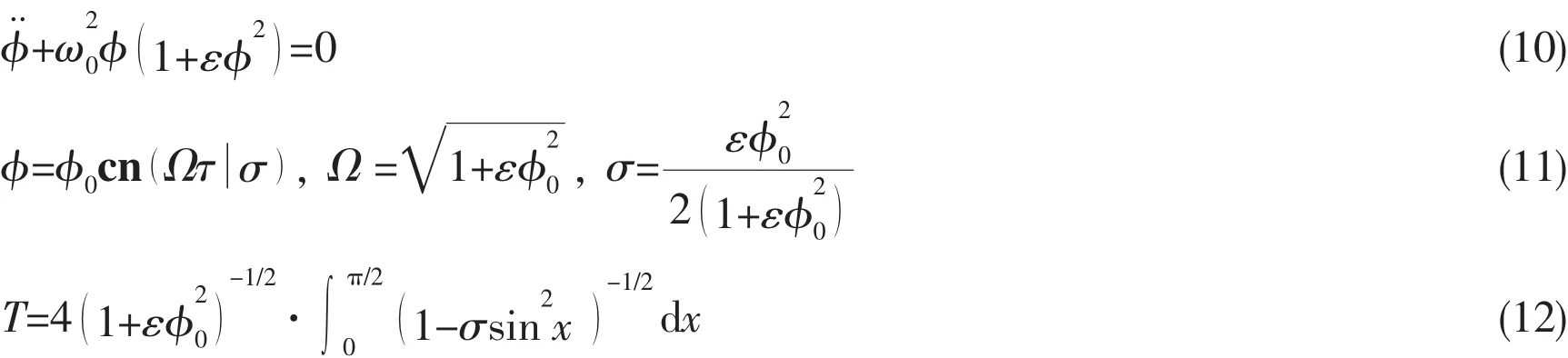

According to energy method,the mechanical energy E corresponding to un-damped free oscillation case,which is the sum of kinetic energy and potential energy W,is as follows:

The key assumption of the energy method is that the decay of E equals to the work done by the damping moment,as shown in Eq.(5).Then,the energy loss function L()E is approximated by averaging over one cycle of oscillation,as shown in Eq.(6).

Through introducing the time varying phase angle θ0,the following relations are obtained:

Substitute Eq.(7)into Eq.(6),we will have

In order to calculate θ0,the following un-damped roll motion equation is considered as shown in Eq.(10).Let τ=ω0t,the analytical solution of φ and its natural roll period can be solved as shown in Eqs.(11)and(12).

where cn is the Jacobian elliptic function;φ0is the roll amplitude.

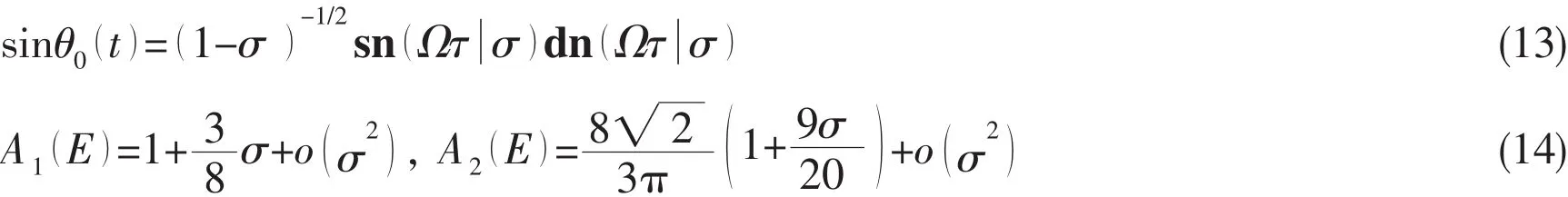

Using Eqs.(4),(7)and(11),sinθ0can be solved;subsequently,the terms A1(E)and A2(E)are obtained as shown in Eq.(13),where sn and dn are the Jacobian elliptic functions.

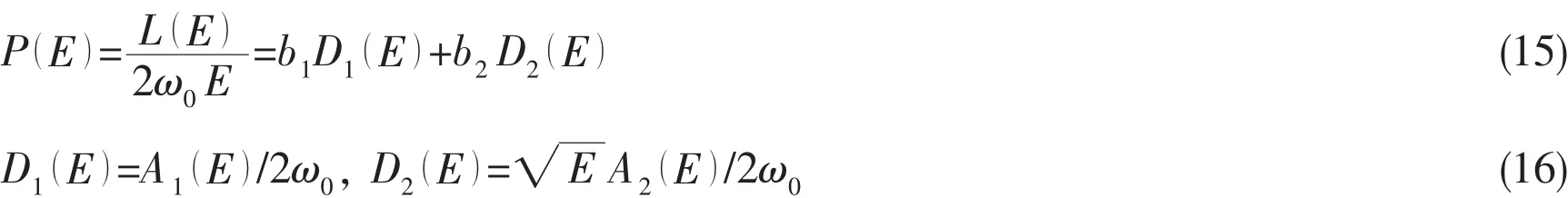

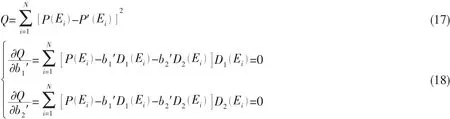

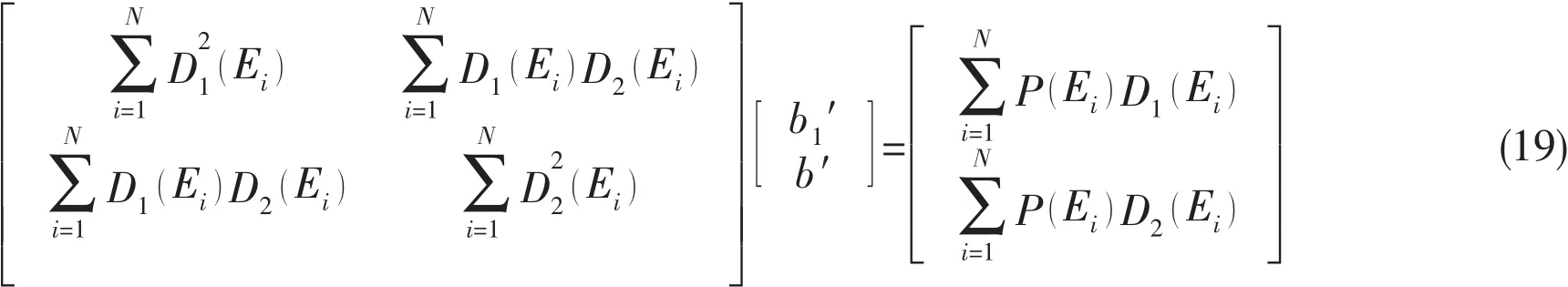

Now that L()E is the linear combination of b1and b2,the least square method can be used.First,define function P()E:

According to least square method,the error Q between estimated P′()E and its experimentally obtained value P()E should be minimized according to the following relationship:

Finally,the estimated roll damping coefficients b1′and b2′can be obtained:

2 Enhanced Extinction Curve Method

Compared with the energy method, the proposed enhanced extinction curve method(EECM)has a simpler form and is easier to implement.Considering the same free roll motion model as discussed in Chap.1,first it is assumed that the roll angle in one oscillation is:

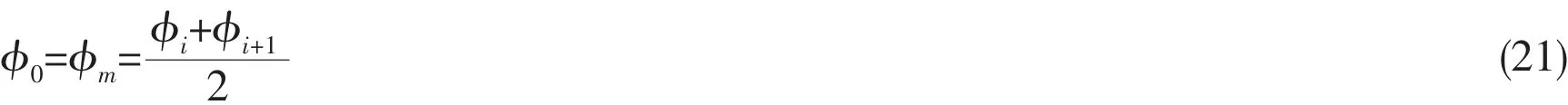

where the roll amplitude φ0is approximated by the mean value of the positive and negative roll amplitudes within half oscillation period:

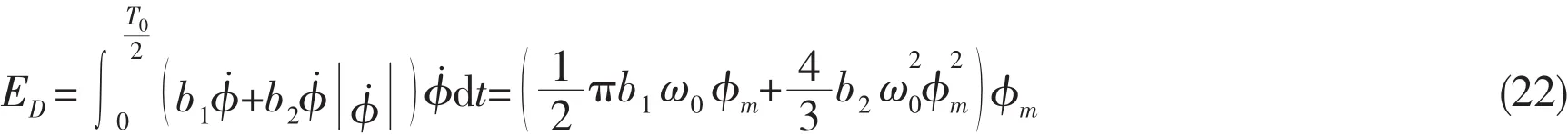

The energy dissipated due to the damping moment in half oscillation period can then be derived as:

The corresponding potential energy variation in half oscillation is:

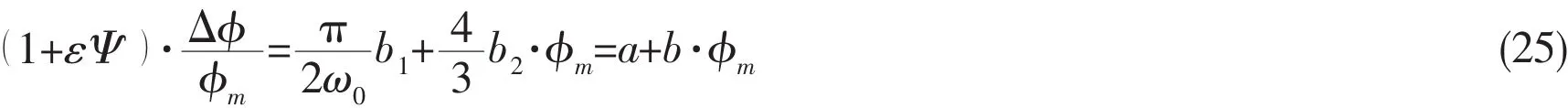

Assuming that the potential energy variation equals to the energy dissipated by the damping moment,i.e.,ED=ER,then we come to the final form of the enhanced extinction curve method:

In the case of ε=0,Eq.(25)becomes the conventional extinction curve method(CECM)that neglects the nonlinear terms of restoring moment.Moreover,the implementation of EECM is almost the same as CECM,except that for each half oscillation period,the term Ψ needs to be evaluated additionally.

3 Numerical experiment

To validate the proposed method,numerical experiment is performed where the ideal roll decay time histories with known coefficients are used as input.Then,the EECM,the energy method and the CECM are adopted to estimate the damping coefficients,respectively.

The tested cases are listed in Tab.1,which are divided into three groups.The control of variable method is used for comparison purpose.In Group A,the nonlinear restoring moment coefficient ε is the changing variable;while in Groups B and C,the damping coefficients b1and b2are varied,respectively.For all tested cases,the initial roll amplitude is 20deg,and ω0=2.0.

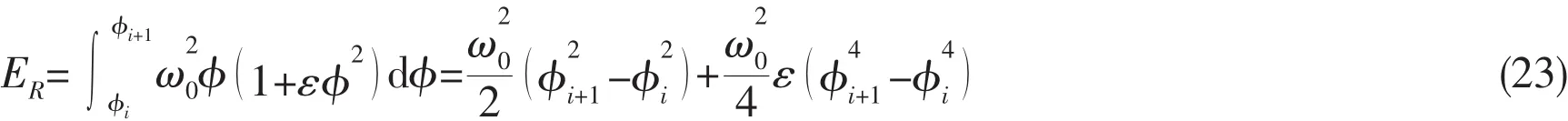

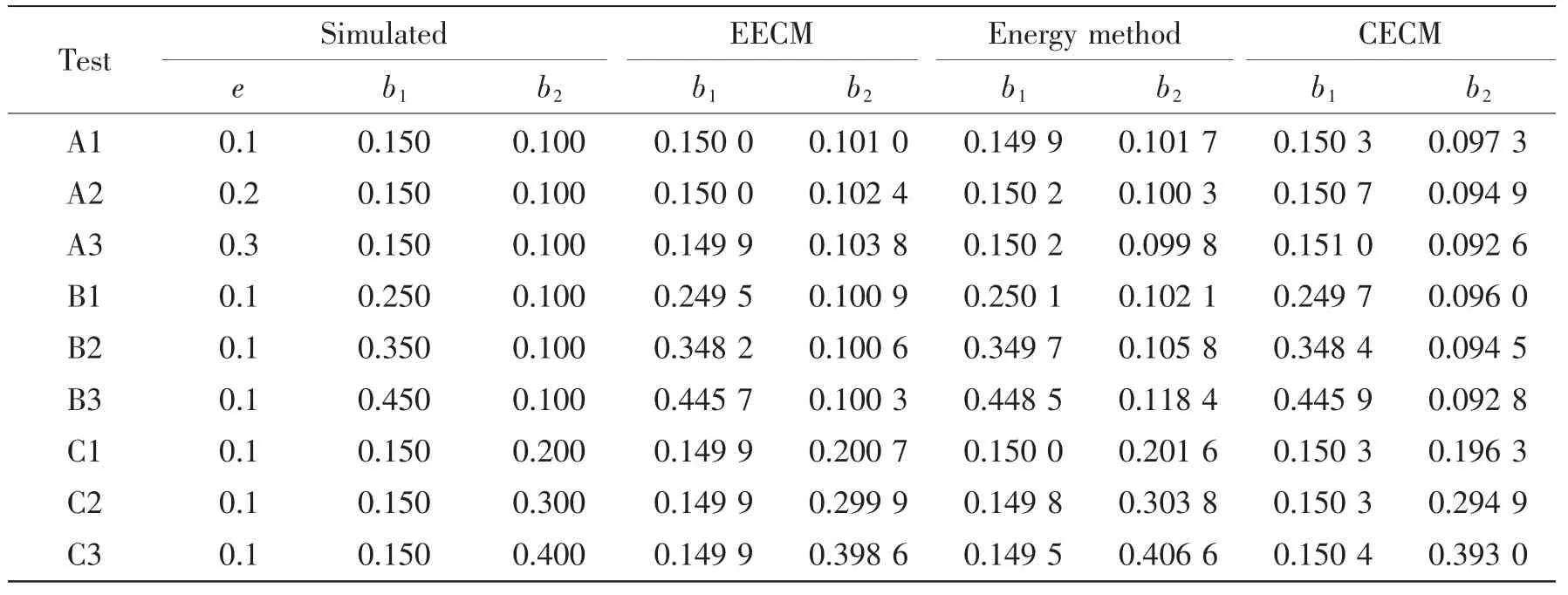

Tab.1 Numerical experiment result

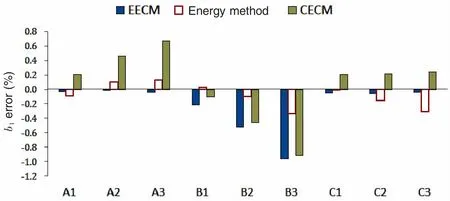

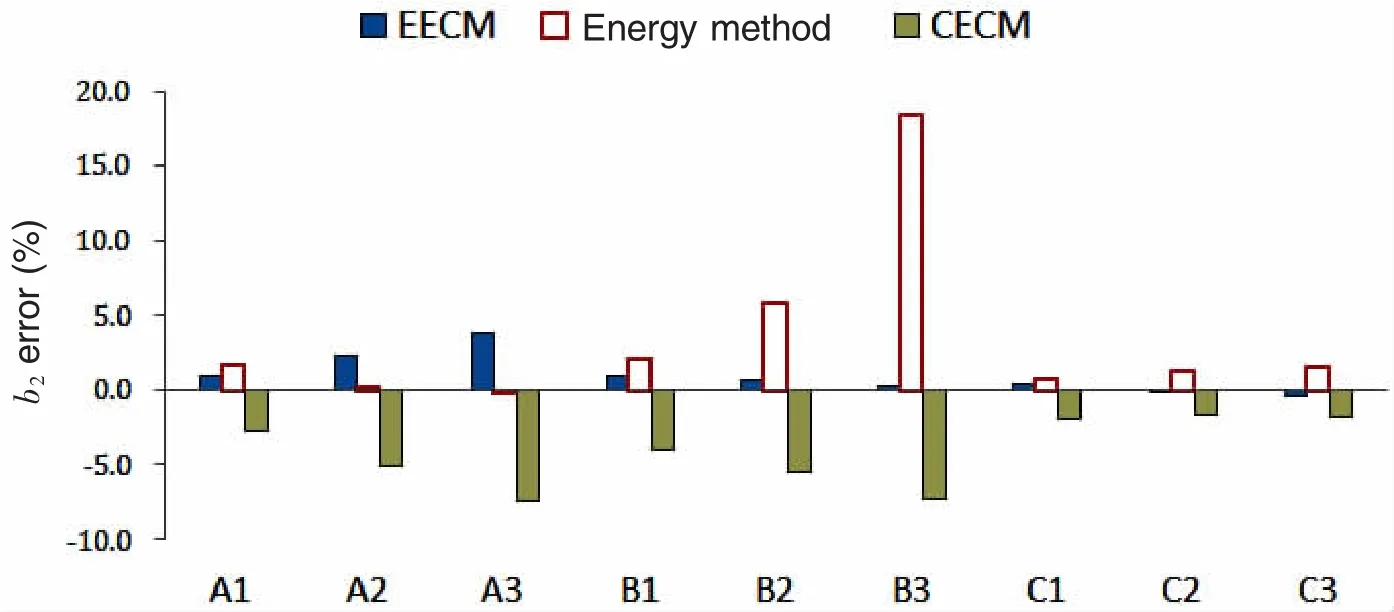

The results of all three methods are listed in Tab.1.To compare the three methods in a more intuitive way,the errors of b1and b2are presented in Fig.1 and Fig.2,respectively.The following points can be observed:

·All three methods can give fairly accurate estimation of b1,the maximum error of all cases is within 1%;however,the accuracy of b2estimation is not guaranteed,the maximum error can be up to 18%.

·From the results of Group A,it is clearly demonstrated that with the increasing of ε,the errors using CECM also keep growing.The EECM has the highest estimation accuracy of b1,and can help improve the estimation accuracy of b2,but not as effective as the energy method.

·From the results of Group B,it is shown that with the increasing of b1,the energy method can give the most accurate estimation of b1,but very poor estimation of b2.On the contrary,EECM can give the most accurate estimation of b2,and slightly poorer estimation of b1.

·From the results of Group C,it is shown that the increase of b2alone will not influence the estimation accuracy very much.All three methods can give fairly good result with EECM being the best among them.

Fig.1 Comparison of b1estimation errors

Fig.2 Comparison of b2estimation errors

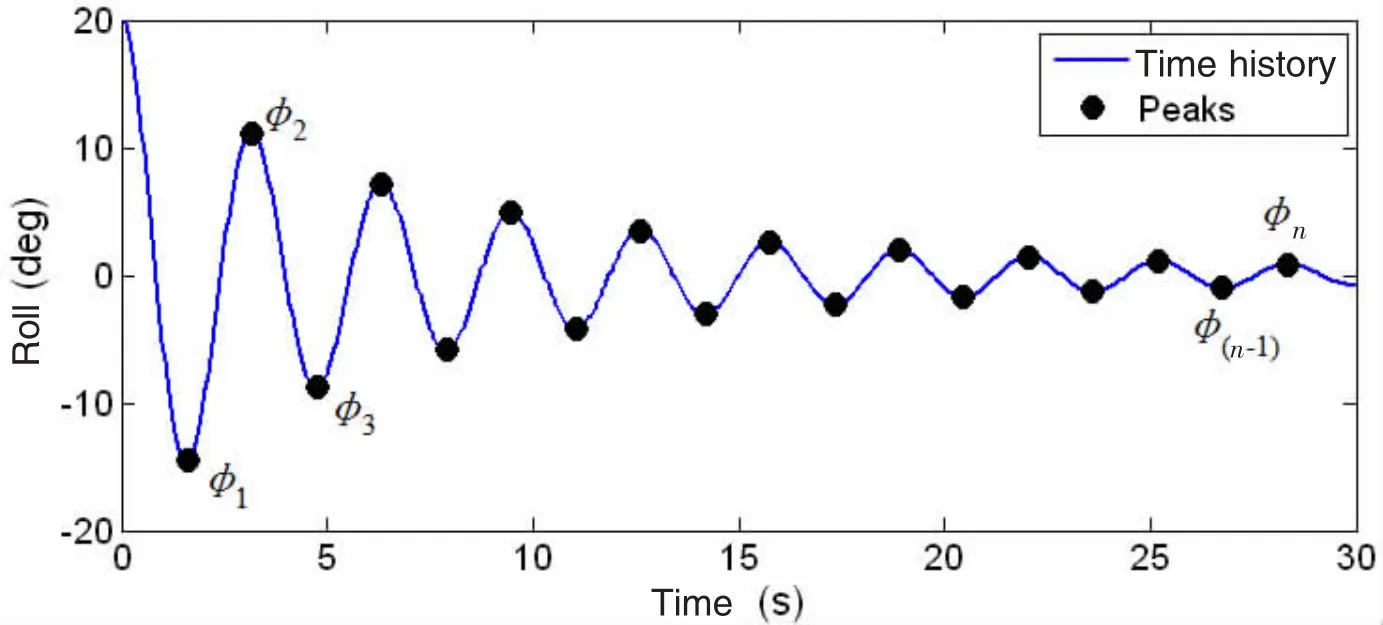

Fig.3 Roll decay time history

Overall speaking,EECM has the best perform among the three methods,and effectively improves the estimation accuracy over CECM.

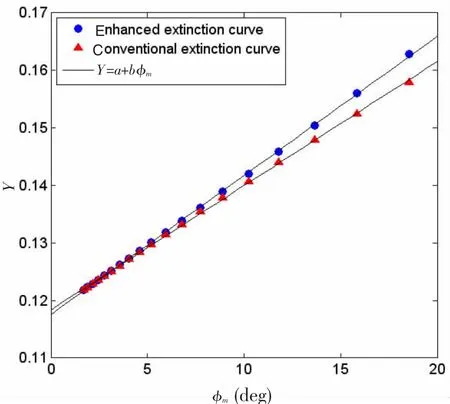

To further investigate the difference between EECM and CECM,the roll decay time history of test case A3,as shown in Fig.3,is used for the analysis.The resulting extinction curves according to EECM and CECM are illustrated in Fig.4.It is shown that the key difference between EECM and CECM is that the Y value is corrected according to Eq.(25),with respect to the value of ε,so as to obtain more accurate estimation of b1and b2.

4 Conclusions

An enhanced extinction curve method is proposed,which can take into account the nonlinear restoring terms of ship hulls.The proposed method is in a simple form and is easier to apply than energy method.Numerical experiment proves the validity of the enhanced extinction curve method,and demonstrates its advantages over conventional extinction curve method.The following conclusions can be drawn:

(1)With the increasing of ε,the EECM has the highest estimation accuracy of b1,and can help improve the estimation accuracy of b2,but not as effective as the energy method.

(2)With the increasing of b1,the energy method can give the most accurate estimation of b1,but very poor estimation of b2.On the contrary,EECM can give the most accurate estimation of b2,and slightly poorer estimation of b1.

(3)The increase of b2alone will not influence the roll damping estimation accuracy very much.All three methods can give fairly good result with EECM being the best among them.

[1]Orozco J M,Raposo C V,Malenica S.A practical procedure for the evaluation of the roll motions of FPSO’s including the non potential damping[C]//Offshore Technology Conference.Houston,Texas,USA,2002.

[2]Ikeda Y.Prediction methods of roll damping of ships and their application to determine optimum stabilization devices[J].Marine Technology,2004,41(2):89-93.

[3]Wilson R V,Carrica P M,Stern F.Unsteady RANS method for ship motions with application to roll for a surface combatant[J].Computational Fluids,2006,35:501-524.

[4]Xie N,Vassalos D,Lee B S.Prediction of roll hydrodynamics of cylinders fitted with bilge keels with RANS[J].Journal of Ship Mechanics,2007,11(6):839-847.

[5]Huang H,Guo H Q,Zhu R C,Miao G P.Computations of ship roll damping in viscous flow[J].Journal of Ship Mechanics,2008,12(4):568-573.

[6]Yang C L,Zhu R C,Miao G P,Fan J.A roll damping prediction method of three-dimensional ships based on CFD computation[J].Journal of Shanghai Jiaotong University,2012,46(8):1190-1195.

[7]Roberts J B.Estimation of nonlinear ship roll damping from free-decay data[J].Journal of Ship Research,1985,29(2):127-138.

[8]Bass D W,Haddara M R.Non-linear models of ship roll damping[J].International Shipbuilding Progress,1988,(35):5-24.

[9]Roberts J B,Kountzeris A,Gawthrop P J.Parametric identification techniques for roll decrement data[J].International Shipbuilding Progress,1991(38):271-293.

[10]Chan H S Y,Xu Z,Huang W L.Estimation of nonlinear damping coefficients from large amplitude ship rolling motions[J].Applied Ocean Research,1995(17):217-224.

[11]Fernandes C,Oliveira C.The roll damping assessment via decay model testing[J].Journal of Marine Science and Application,2009,8:144-150.

[12]Ueno K,Kimura N,Amagai K.Estimation of coefficients of the equation of nonlinear roll motion for fishing boats by improved energy method and genetic algorithm[J].Japan Journal of Industrial and Applied Mathematics,2003,20:155-192.

[13]Li Y L,Wu J M,Wang D J.Effect of waves on nonlinear rolling damping of ship[J].Ship Engineering,2003,25(2):21-24.

[14]Oliveira A C,Fernandes A C.The bi-linear behavior for FPSO rolling motions[C]//Proceedings of the 9th International Conference on Stability of Ships and Ocean Vehicles.Rio de Janeiro,Brazil,2006.

[15]Jang T S,Choi H S,Han S L.A new method for detecting non-linear damping and restoring forces in non-linear oscillation systems from transient data[J].International Journal of Non-Linear Mechanics,2009,44:801-808.

[16]Ma X M,Pan Y T,Chang L Z.Estimated nonlinear damping coefficients of amphibious vehicle roll motion[J].Journal of Ship Mechanics,2013,17(5):488-493.

基于改進型消滅曲線法的橫搖阻尼估算

封培元a, 范佘明a,b

(中國船舶及海洋工程設計研究院a.噴水推進技術重點實驗室;b.上海市船舶工程重點實驗室,上海200011)

自由衰減試驗仍是目前最為有效且常用的估算橫搖阻尼系數的方法。橫搖阻尼系數的估算精度對于船舶橫搖運動的預報起著至關重要的作用。通常采用所謂的消滅曲線法來分析自由橫搖衰減數據。該方法的一個不足之處在于其推導是基于忽略了非線性恢復力項的自由橫搖運動方程。另一方面,考慮更多非線性成分的能量法能夠納入該因素影響但在實施過程中較為復雜。文中提出了一種改進型的消滅曲線法,能夠納入船體非線性恢復力項的影響。所提出的方法形式簡單且相比能量法更易于實施。數值試驗證明了改進型消滅曲線法的正確性,并展現了其相對傳統消滅曲線法所具有的優勢。

橫搖阻尼;自由衰減試驗;改進型消滅曲線法;非線性恢復力項

U661.31

A

封培元(1987-),男,博士,中國船舶及海洋工程設計研究院,E-mail:pyfeng23@163.com;

范佘明(1963-),男,博士,中國船舶及海洋工程設計研究院教授/博士生導師。

U661.31 Document code:A

10.3969/j.issn.1007-7294.2017.12.005

date:2017-06-17

National Natural Science Foundation of China(Grant Nos.51709240 and 51579144)

Biography:FENG Pei-yuan(1987-),male,Ph.D.,E-mail:pyfeng23@163.com;

FAN She-ming(1963-),male,Ph.D.,professor/tutor.

1007-7294(2017)12-1489-08

- 船舶力學的其它文章

- A New Method for Fast Estimation of Collision Dissipated Energy and Its Application in Ship-Platform Collision Accident

- Optimization of Composites Shell Subjected to Hydrostatic Pressure to Maximize Design Pressure Factor

- Experimental Study on Strength and Fatigue of Sandwich Composite L-joint under Bending

- Fatigue Analysis for Welded Joints of Offshore Wind Turbine under Three Wind Loads

- Algorithm Simulation of Ship Dynamic Positioning Using Adaptive Fading Memory Filter

- Numerical Predictions of the PPTC Propeller Tip Vortex Cavitation in Uniform Flow