A New Concept of ETLP and Its Hydrodynamic Performance

LIANG Ning,HUANG Wei-ping,GONG Chao,YANG Chao-fan

(Shandong Key Laboratory of Ocean Engineering,Ocean University of China,Qingdao 266100,China)

A New Concept of ETLP and Its Hydrodynamic Performance

LIANG Ning,HUANG Wei-ping,GONG Chao,YANG Chao-fan

(Shandong Key Laboratory of Ocean Engineering,Ocean University of China,Qingdao 266100,China)

In this paper,a new concept of Extended Tension Leg Platform is proposed.It is composed of four square columns and a ring pontoon which is consisted of four box beams.The new platform has less blocks and welds compared to ETLP,so it can be built at a lower cost and in a shorter construction period.Meanwhile,the pontoon extensions in the new platform is part of pontoons,therefore,the fatigue problem in the welds at the root of extensions in ETLP is solved.A hydrodynamic analysis is conducted to prove the structure’s dynamic stabilities.Based on the three-dimensional potential flow theory,the theoretical analysis with numerical calculation is carried out to study the dynamic characteristics of new ETLP in frequency domain.The added mass force and the potential flow of the new platform damping force are calculated.Considering the coupling between the new ETLP and the tension leg system,the nonlinear dynamic response of the new ETLP is calculated in load combination of wind,wave,flow and the effect of tension leg system.The time domain analyses are carried out and the new platform displacement in time history is obtained.The results proved that the new type of ETLP has a reasonable hydrodynamic characteristic.At the same time,the time domain results of the platform in the South China Sea state environment meet the safety requirements.

ETLP;structural design;hydrodynamic analysis;hydrodynamic characteristics

0 Introduction

With the depletion of onshore and offshore shallow water reserves,the exploration and production of oil is advancing into deep water and even ultra-deep water.Therefore continued developments of new types of structures are required in the offshore industry.Many floating structures have already been installed worldwide,such as Tension Leg Platforms(TLP),Spar, Float Production Storage and Offloading(FPSO)and Semi-submersibles[1].TLP is a kind of compliant type offshore platform,consisting of deck,hull,columns and mooring system[2].The mooring system is consisted of vertical tendons,which restrain the heave motion and make dry trees possible on a TLP[3].

The first commercial application of this structure and the first dry tree completion from a floating platform was the Conoco Hutton TLP installed in the UK sector of the North Sea in 1984[4]and the second(Jolliet TLWP)in the Gulf of Mexico 1989[5].In design of TLP,oneimportant challenge is to keep the natural period of heave and pitch below the range of significant wave period. These can be reduced by increasing wall thickness of the pipes in tendons and placing the tendons on a wide spacing to increase restoring effort.However,it may induce the deck structure with large spans.Therefore,the Extended Tension Leg Platform(ETLP)was introduced(Fig.1).The ETLP consists of three or four columns,on a closer spacing than normal,connected underwater by pontoons and pontoon extensions[6].The extensions increase the restoring effect of the tendons effectively while reducing the column spacing and deck structure steel weight.But the construction period may be increased due to building four more pontoon extensions and the relative welds,and fatigue damage and structural failure may be induced by the weld connection between extensions and columns.

A new ETLP which is proposed in this paper has less blocks and welds compared to ETLP,so it can be built at a lower cost and in a shorter construction period.Meanwhile,the extensions in the new design are parts of the pontoons instead of welded to the columns as the ETLP.Therefore,the fatigue problem in the welds at the root of extended beam in ETLP will not be a consideration in the design.Afterwards,a hydrodynamic analysis is carried out.The results show that the new concept of platform has a reasonable hydrodynamic characteristic.

Fig.1 Extended Tension Leg Platform

1 Concept of the new ETLP

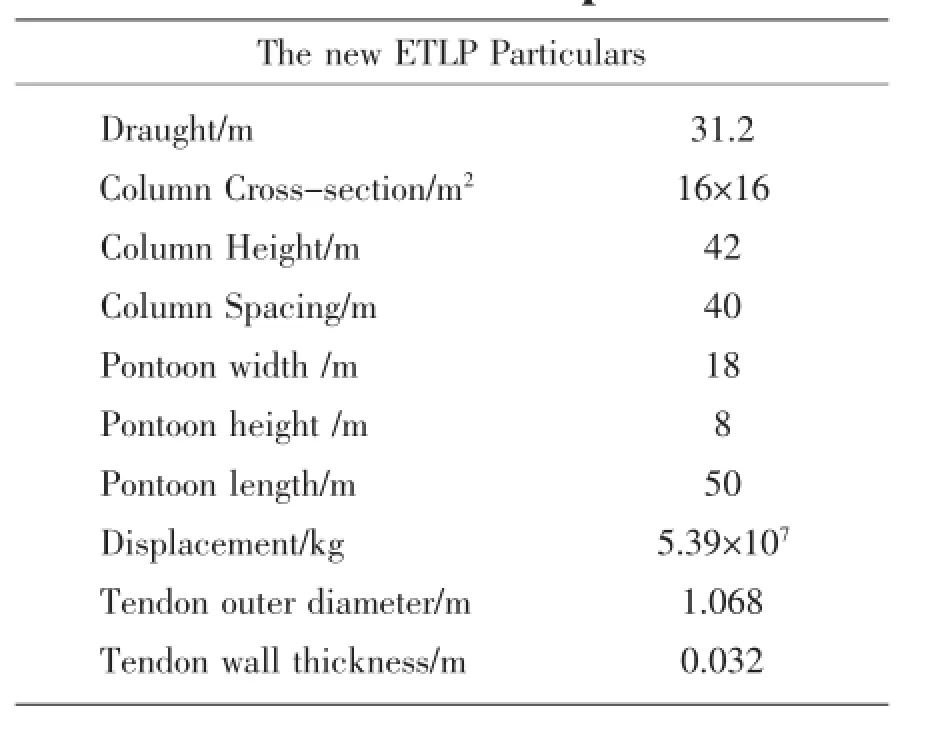

The new Extended Tension Leg Platform(the new ETLP),illustrated in Fig.2,is consisted of deck structure,hull and tendon system which is referred to as the traditional ETLP.The hull of the new ETLP is consisted of four columns and a ring pontoon.Four columns are chosen based on the environmental conditions and the weight of deck structure.Four box beams are welded to each other and form a ring pontoon.Square columns are used and it is more of a fabrication choice with some hydrodynamic implications.Large corner radius (r≈D/4)on square column achieves most of the hydrodynamic benefits of round columns.What will influence this issue the most is the structural design joining the pontoons with the columns as well as tendon connections[7].The new ETLP is moored by 12 tendons;three tendons per free end of the box beams.Principal dimensions of the platform are listed in Tab.1.

Fig.2 New Extended Tension Leg Platform

The traditional ETLP is consisted of four circular columns,four pontoons and four pontoon extensions andeach part is all built as independent blocks[8]. While,in the new ETLP,pontoon extensions are parts of the pontoons,so the total blocks of the hull structure are four blocks less than the traditional ETLP,and the construction cost will be decreased.In traditional ETLP,the total number of welds is forty-eight,including twelve flat weld seams,twenty-four vertical weld seams and twelve overhead weld seams in the final block assembly.While in the new ETLP,the connections of columns and pontoons can be fulfilled with only twenty-four flat weld seams.The connections of box beams,can be fulfilled with eight flat weld seams and eight vertical weld seams.Compared with the traditional ETLP, the ETLP needs less weld seams in the final block assembly and the proportion of flat weld seams is increased.With less blocks and weld seams,the new ETLP reduces the construction period and cost of the platform.

Meanwhile,in traditional ETLP,as the platform is permanently moored by tendons which connected with pontoon extensions,pontoon extensions will withstand great tensions[9].The function of pontoon extensions is like a cantilever beam with great shear forces and bending moments acting on their fixed ends.As a result,this may induces fatigue damage and structural failure.In the new ETLP,a ring pontoon is connected with four box beams,with each end of the box beams extending outwards a little.These extensions have pontoon extensions’function but do not need be welded together,because they are parts of the ring pontoon.Therefore the structure strength and fatigue reliability of the platform are improved compared with the traditional ETLP.

2 Calculation methods

2.1 Potential theory

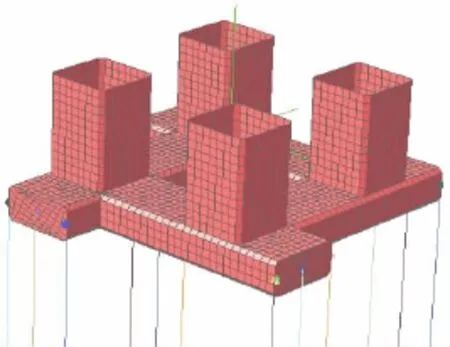

The potential theory is applied in SEASAM to calculate first order radiation and diffraction effects.The 3D panel method is used to evaluate velocity potentials and hydrodynamic coefficients,the panel model of hull structure and free surface model are given in Fig.2.The free surface condition is linearized in the first order potential theory.The radiation and diffraction velocity potentials are derived from the solution of an integral equation obtained by using Green theorem with regarding the free surface source potentials as the Green functions.

The total velocity potential of fluid consists of

where φ0is incident potential and φsis scattering potential.The characteristics of idea fluid allows its velocity potential φ that satisfies the Laplace equation

Tab.1 The new ETLP specifications

φ0is incident potential which has determined of direction and frequency.In infinite-depth,

where ω,g,A,k and α represent the frequency of the incident wave,the acceleration of gravity,the amplitude of the incident wave,the wave number and the direction of the incident wave.

The radiation potential and the diffraction potential can be obtained by controlling equation and the definite condition.Then by establishing the integral equation between the velocity potential and the Green’s function,we can solve the velocity potential of the node.

2.2 Frequency domain analysis

The motion complex vector X ω,()

βcan be expressed as:

where,M,A(ω),B(ω)pand Bvrepresent the inertia matrix,the frequency dependent added mass matrix,the frequency dependent potential damping matrix and the linearized viscous damping matrix,respectively.C,Ceand F( ω,β)represent the hydrostatic restoring matrix, the external restoring matrix and the complex exciting force vector for frequency ω and incident wave heading angle β,respectively.All the factors are all calculated by using the methods in the Seasam user manual-Wadam-wave analysis by diffraction and Morison theory. The viscous item of the Morison equation can be expressed as:

where V,Vmaxand CDare the relational velocity of water particle and platform,the amplitude of the relative velocity and drag coefficient which is dependent on many parameters such as the shape of the body,Reynolds number and Keulegan-Carpenter number,etc.In estimating the viscous damping of the platform,the drag coefficients are chosen to be equal to 2.05 suggested by Li Yucheng and Tengbin[10].

Fig.3 Model used in the frequency domain analysis

Fig.4 Model used in time domain analysis

2.3 Time domain analysis

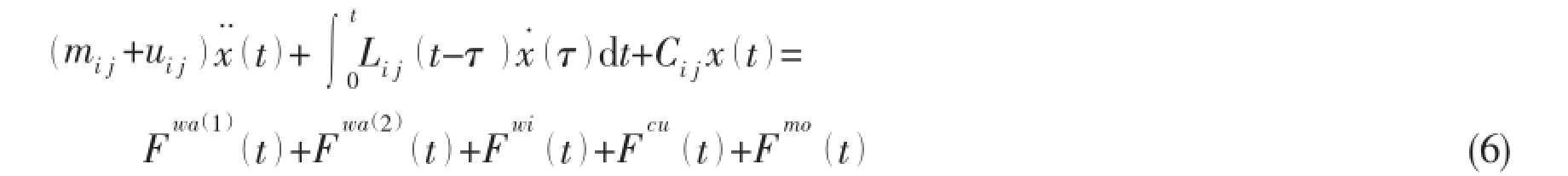

Considering the wind,wave,current and tension leg mooring system’s effect,the timedomain equations of platform’s movement can be expressed as:

Platform under the nonlinear transient wave forces component in a certain direction can be expressed as:

3 Numerical analysis

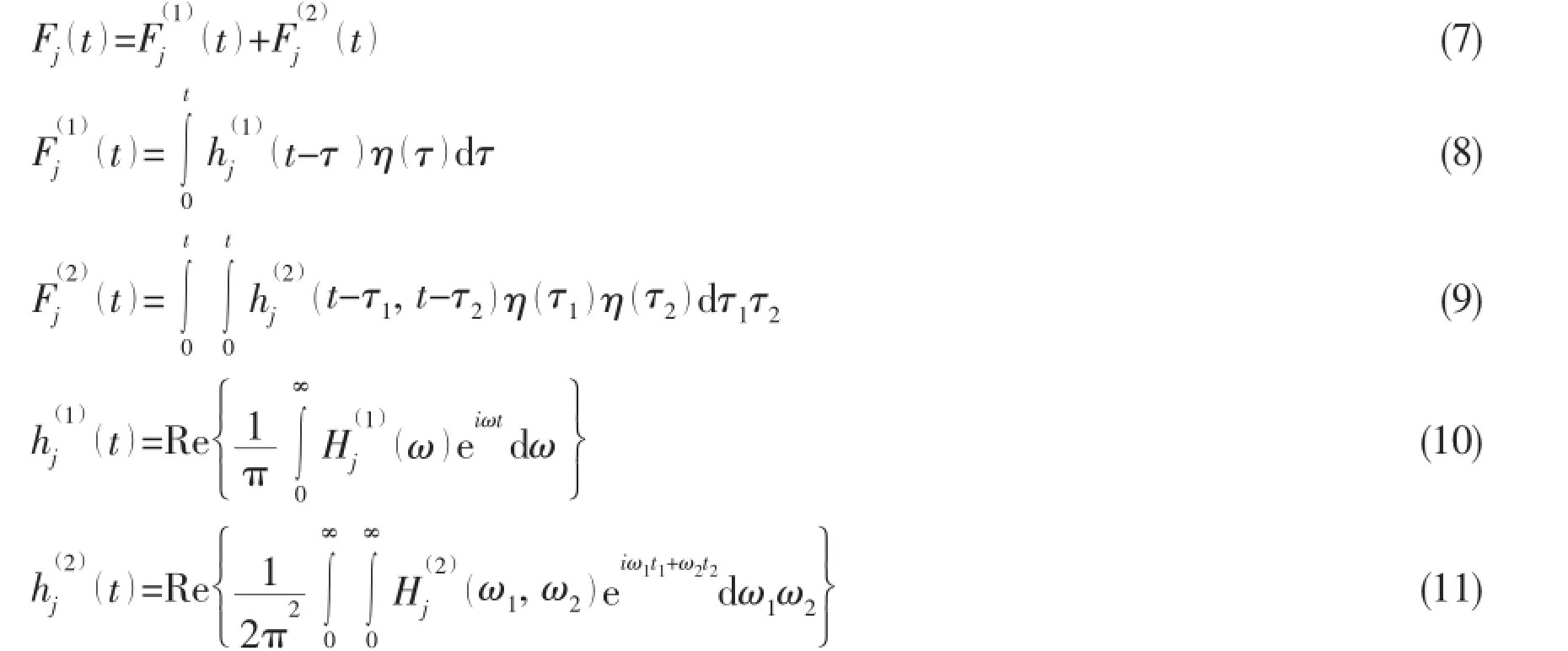

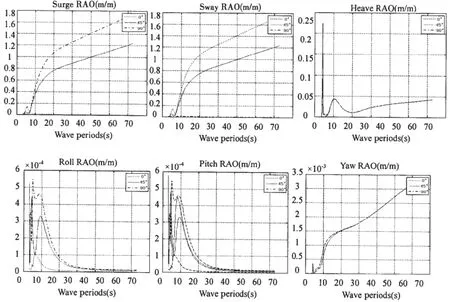

The new ETLP is designed for water of which the depth is 1 500 m.The motion of the platform is calculated by the commercial software SEASAM.A panel model is created to calculate the added mass and potential damping of the new ETLP and a mass model is created to simulate the distribution of mass.In order to study the hydrodynamic performance of the new ETLP,regular wave is used,with frequency range of 0.1 to 2.0 rad/s,with 0.1 rad/s frequency interval,to calculate the motion response of platform in frequency domain.The wave incident angle varies from 0°,45°to 90°.In time domain analysis,environmental load is defined as ahundred-year return period in the South China Sea in Tab.2 and the calculation time is 10 800seconds with 1 s interval.The final frequency calculation results include added mass,total damping and motion response amplitude operator.And the final time domain calculation results include the time domain response of platform in six degrees of freedom.

Tab.2 A once-in-a-century environment parameters selection

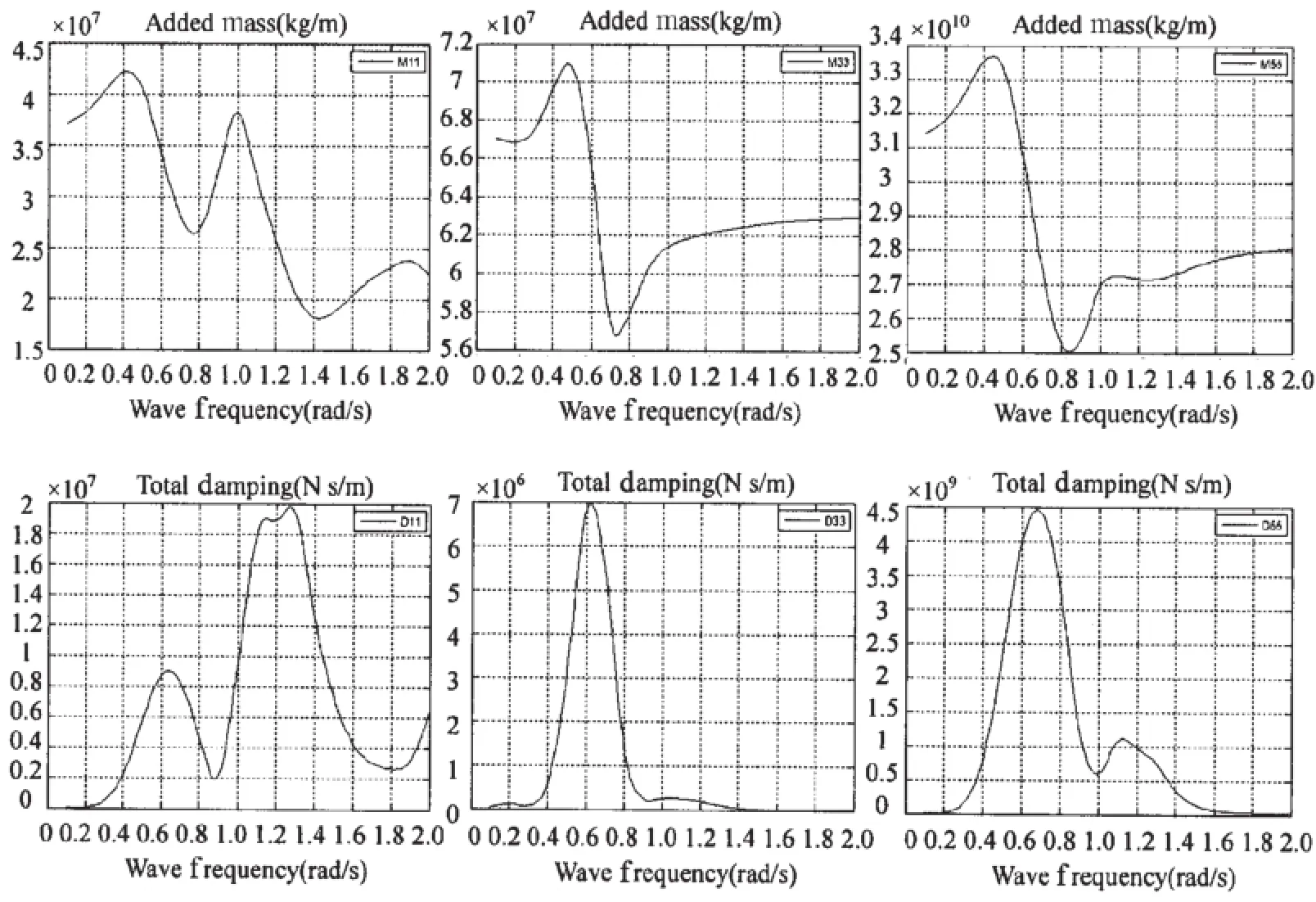

The hydrodynamic characters of the new ETLP include mass,damping and hydrodynamic coefficients which determine the response of motion.Three principal diagonal elements of added mass and total damping of the new ETLP are respectively shown in Fig.5.TLP should be designed for the surge,sway,and yaw frequencies are below the wind and wave frequencies while the heave,pitch,and roll frequencies are above the wind and wave frequencies[11].The motion response amplitude operators(RAOs)of six degree of freedom are shown in Fig.6.As shown in Fig.6,the nature periods of heave,pitch and roll are below the significant wave energy,and the nature periods of surge,sway and yaw are much larger than the significant wave energy.

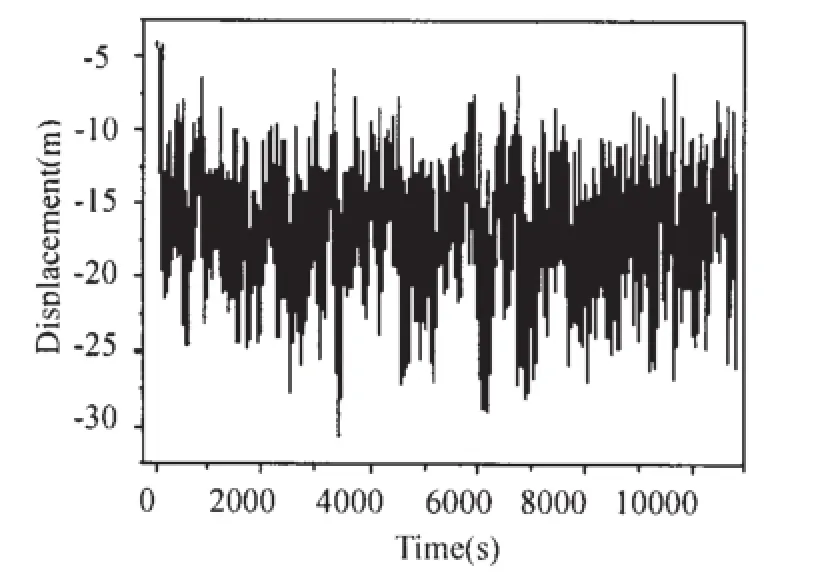

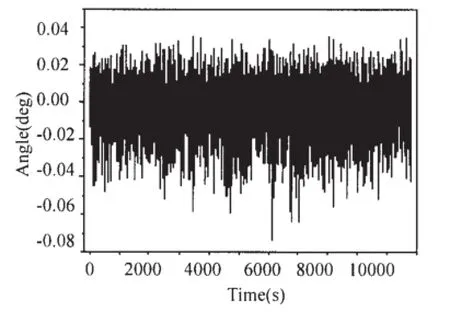

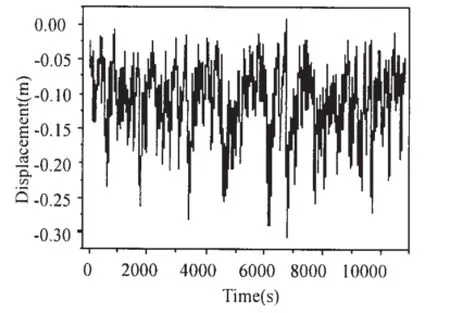

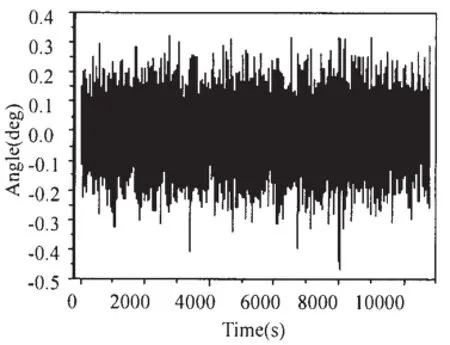

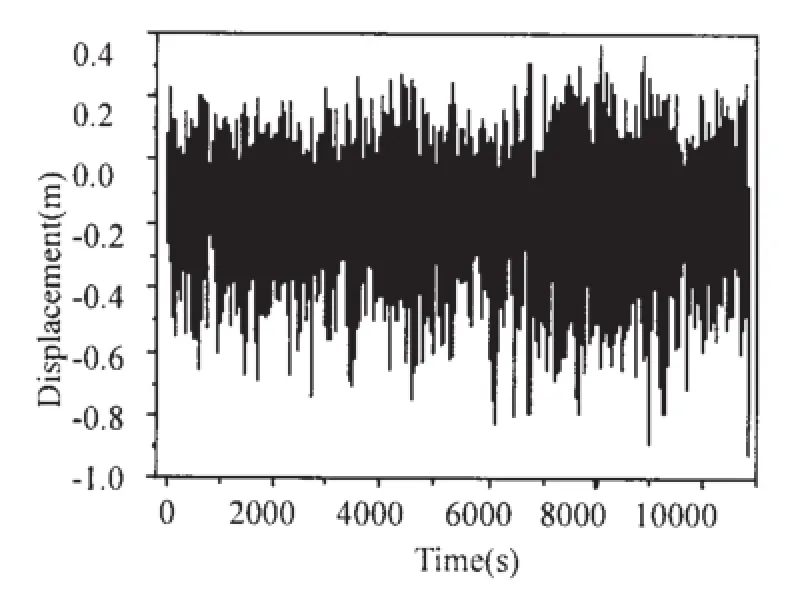

According to time history response curves in Figs.7~12,the extreme offset of platform in horizontal appeared in the surge results.In the 3 400 s,the extreme value of 30.45 m,which was 2.03%of the water depth.The extreme swing angle of the platform appeared in the pitch results.In the 8 000 s,the extreme value was 0.44°.The extreme heave appeared in the 9 000 s,the value was 0.89 m which less than 1m of specification requirements.

Fig.5 Added mass and total damping of the new ETLP

Fig.6 RAO of the new ETLP

Fig.7 Surge time domain result

Fig.8 Sway time domain result

Fig.9 Heave time domain result

Fig.10 Roll time domain result

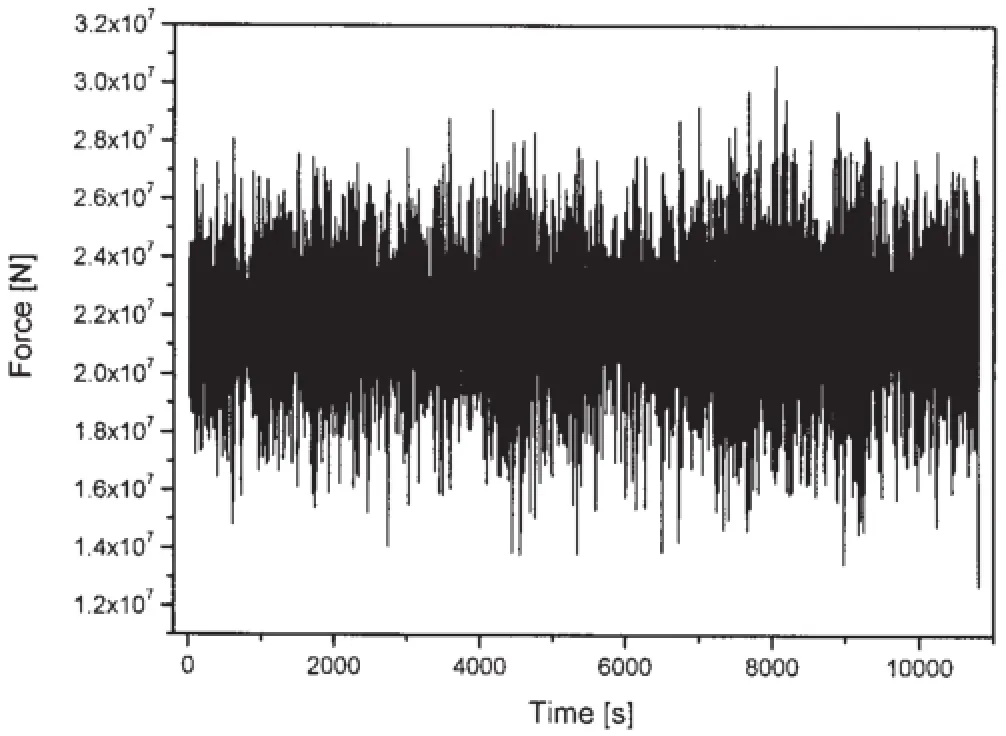

Tension stress time history curve of the 12 roots tendon is obtained by time domain coupling analysis.By comparing that the maximum tension force occurred at tendon No.4.Its tension force curve is shown at Fig.13.Steel type for the tendon is NV-32 which yield strength is 315 MPa.It can be obtained from the figure that the maximum tension force is 3.06×107 Nwhich occurred at 8 000 s.Then the stress of the tendon is 259.93 MPa which is less than the allowable stress 283.5 MPa.Therefore the tendon’s strength meets the safety requirements.Finally, the action of the platform motion response and tendon’s strength under oncein-a-century environment load condition meet the specification’s requirements.

Fig.11 Pitch time domain result

4 Conclusions

Extended Tension Leg Platform(ETLP)is a kind of offshore structure which is suitable for oil and gas exploration in deep water.Compared with the traditional TLP,ETLP can reduce the column space and deck span,but the construction period may increase due to building four more pontoon extensions and relative welds.Fatigue damage and structural failure may be induced by the weld connection between pontoon extensions and columns.The new ETLP consisted of four columns and a ring pontoon.A ring pontoon with four box beams is used in the new platform in order to reduce the total blocks and avoid welded connections of hull structure and make pontoon extensions to be parts of the ring pontoon.The new ETLP can carry on the advantages of ETLP and overcome its shortcomings.Afterwards,a hydrodynamic analysis is carried out to prove the structure’s dynamic stability.The results show that the new design Extended Tension Leg Platform has a reasonable hydrodynamic characteristic.At the same time,the time domain results of the platform in the South China Sea state environment meet the safety requirements.

Fig.13 No.4 tendon’s tension time domain result

[1]Zhang D G,Chen Y J and Zhang T Y.Floating production platforms and their applications in the development of oil and gas fields in the south china sea[J].Journal of Marine Science and Application,2014,13:67-75.

[2]Gu J Y.Study on the complex dynamic response and vortex-induced motion characteristics of tension leg platform[D]. Shanghai:Shanghai Jiao Tong University,2013:60-61.

[3]Wang X G.Coupled dynamic analysis of deepwater floating structure and the mooring system[D].Dalian:Dalian University of Technology,2011:53-55.

[4]Mercier J A,Leverette S J,Bliault A.Evaluation of hutton TLP response to environmental loads[C].Proc.OTC,1982, OTC 4429:585-601.

[5]Hunter A F,et al.Designing the TLWP[C].Proc.OTC,OTC 6330,1990:147-158.

[6]Huang E,Bhat S,Luo Y,Zou J.Evaluation of dry tree platform concepts[C].Proceedings of Offshore Technology Conference,2002,OTC 11899.

[7]Subrata K,Chakrabarti.Handbook of Offshore Engineering[M].Elsevier Ltd,2005:19.

[8]Yan G W,Ou J P.The conceptual design of new type separating self-balance minimum-offshore-surface extended mooring TLP(SSME TLP)[J].Science Technology and Engineering,2012,12(8):1724-1732.

[9]Meng Z B,Li M,Yang S G.The analysis and research of TLP’s motion performance[J].China Offshore Platform,2013,28 (2):28-34.

[10]Li Y C,Teng B.Wave action on maritime structures[M].Beijing:Ocean Press,2002:266.

[11]Seon M H,Haym B.Nonlinear and stochastic dynamics of compliant offshore structures[M].Kluwer Academic Publishers, 2002:4.

一種新型延展式張力腿平臺及其水動力性能

梁寧,黃維平,鞏超,楊超凡

(山東省海洋工程重點實驗室,中國海洋大學,山東青島266100)

文章提出了一種由四個立柱和一個環形浮箱(四個方型截面梁組成)組成的新型延展式張力腿平臺。與傳統延展式張力腿平臺相比,新型延展式張力腿平臺有更少的組塊和組塊間焊縫,因此它的建造成本更低、建造周期更短。新型延展式張力腿平臺將延展式結構改進為浮箱的一部分,這就解決了傳統平臺的延展式結構與浮箱連接處焊縫疲勞損傷問題。文中對結構進行了水動力性能分析以證明其動態響應可靠性。基于三維勢流理論對新型平臺進行頻域內的數值模擬,得到了新型平臺的附加質量和勢流阻尼。考慮新型平臺和張力筋腱系統的耦合作用,分析了新型平臺在風、浪、流聯合作用下的非線性動態響應。時域分析得到了新型平臺在時域內的位移響應。水動力分析結果證明了新型延展式張力腿平臺有可靠的水動力性能,并且滿足在南海環境條件下的安全要求。

延展式張力腿平臺;結構設計;水動力分析;水動力性能

P751

:A

梁寧(1990-),男,中國海洋大學碩士研究生,E-mail:liangningouc@163.com;

1007-7294(2015)12-1498-09

P751

:A

10.3969/j.issn.1007-7294.2015.12.006

黃維平(1954-),男,中國海洋大學教授,博士生導師,通訊作者,E-mail:wphuang@ouc.edu.cn;

鞏超(1987-),男,中國海洋大學碩士研究生;

楊超凡(1989-),男,中國海洋大學碩士研究生。

Received date:2015-07-01

Foundation item:Supported by the National Natural Science Foundation of China(No.51239008,51179179)

Biography:LIANG Ning(1990-),male,master student of Ocean University of China;corresponding author:HUANG Wei-ping(1954-),male,Ph.D.,professor of Ocean University of China,E-mail:wphuang@ouc.edu.cn.

- 船舶力學的其它文章

- Active Control of Low-Frequency Sinusoidal Vibration Transmission of Ship Machinery

- An Analytical Model of Ballistic Impact on Light Ceramic/Metal Lightweight Armours

- Analysis on Factors Influencing Strains of Unbonded Flexible Risers Under Pressures

- Tensile Fatigue Test Method for Typical Stiffened Panel

- Theoretical and Numerical Research on CTOD for Ship Plate under Cyclic Loading Considering Accumulative Plastic Strain

- Study on the Dynamic Response and Tension Characteristics of a TLP with One Tendon Broken