高壓線束支架多工位連續模設計

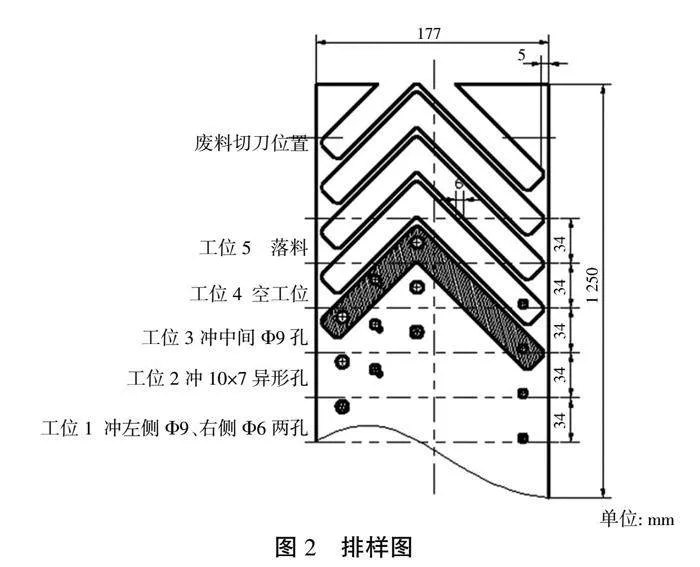

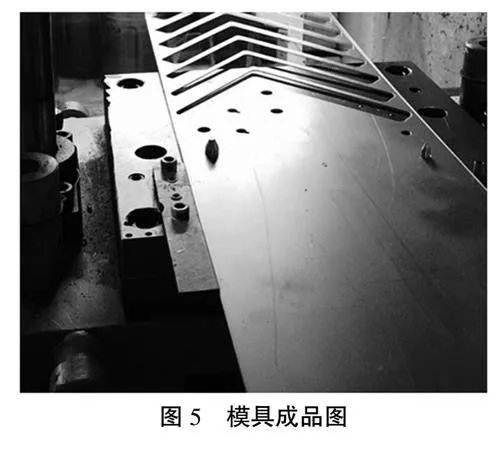

摘 "要:該文分析高壓線束支架的沖壓成形工藝及排樣方法,闡述該連續沖裁模的結構及工作零件的加工方法,凹模采用鑲拼結構,節約模具鋼,零件加工難度降低,制造成本降低。實踐證明,該模具結構合理,沖件質量穩定,較好地滿足沖件精度和批量生產的要求。

關鍵詞:沖壓工藝;排樣;連續模;直通式;高壓線束支架

中圖分類號:TG385 " " "文獻標志碼:A " " " " "文章編號:2095-2945(2024)20-0127-04

Abstract: The stamping forming technology and layout method of the high voltage wire harness bracket are analyzed, and the structure of the continuous blanking die and the processing method of the working parts are described. The die adopts the insert structure, which saves the die steel and parts processing difficulty and the manufacturing cost. The practice shows that the structure of the die is reasonable, the quality of the stamping parts is stable, and meets the requirements of stamping precision and mass production.

Keywords: stamping process; layout; continuous die; straight-through type; high voltage wire harness bracket

汽車的高壓線是通過點火線圈傳輸電能以供火花塞點火作用,從而讓發動機做功的一種帶有“絕緣”裝置的“導線”,能在較高、低溫度下有良好的絕緣性和內部傳輸與導電功能。高壓線束支架屬汽車內部零件,主要用來固定高壓線束,結構比較簡單。要求外觀無毛刺,剛性強、孔距精度高。本文就該產品的形狀特點和成形性進行分析,確保產品質量,并對其沖壓工藝性、排樣設計及模具結構設計作了剖解。

1 "零件沖壓工藝性分析

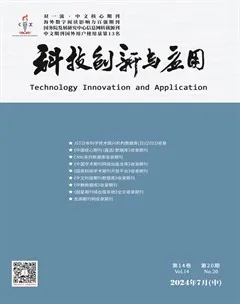

圖1為高壓線束支架,材料為BLC沖壓用冷軋鋼,料厚2 mm,年產量6萬件。材料抗拉強度大于等于270 MPa,屈服強度140~270 MPa,斷后伸長率大于等于36%,含碳量小于等于10%,沖壓成形性能好。該零件形狀為L形,左側有Φ9 mm孔2個,異形孔10 mm×7 mm1個,右側有Φ6 mm孔1個,孔與孔之間距離的尺寸公差為IT7級,其余為未注尺寸公差,合適采用沖壓加工。該沖件如采用單工序生產至少需要2副模具,設備占用率高,生產效率低,而且基于該零件的特殊形狀,還存在沖件定位難度增加,沖件精度不高,操作麻煩、不夠安全等問題;如采用復合模則存在凸凹模強度不足的問題。……