音圈電機(jī)結(jié)構(gòu)優(yōu)化及應(yīng)用綜述

柴嘉偉 貴獻(xiàn)國(guó)

音圈電機(jī)結(jié)構(gòu)優(yōu)化及應(yīng)用綜述

柴嘉偉 貴獻(xiàn)國(guó)

(哈爾濱工業(yè)大學(xué)電氣工程及自動(dòng)化學(xué)院 哈爾濱 150001)

音圈電機(jī)是一種不需要任何機(jī)械傳動(dòng)環(huán)節(jié),就可以將電能轉(zhuǎn)化為直線運(yùn)動(dòng)機(jī)械能的直線電機(jī)。由于具有結(jié)構(gòu)簡(jiǎn)單、體積小、響應(yīng)速度快、定位精度高、易于控制等優(yōu)點(diǎn),音圈電機(jī)廣泛應(yīng)用于國(guó)民經(jīng)濟(jì)的諸多領(lǐng)域。該文首先簡(jiǎn)述音圈電機(jī)的理論基礎(chǔ),闡述音圈電機(jī)的工作原理、結(jié)構(gòu)分類以及各結(jié)構(gòu)的特點(diǎn);然后,結(jié)合國(guó)內(nèi)外學(xué)者對(duì)音圈電機(jī)的結(jié)構(gòu)優(yōu)化,對(duì)音圈電機(jī)提高力常數(shù)和定位精度的方法進(jìn)行歸納總結(jié);最后,對(duì)音圈電機(jī)的主要應(yīng)用領(lǐng)域進(jìn)行綜述,并對(duì)其發(fā)展趨勢(shì)和研究熱點(diǎn)進(jìn)行討論和展望。

音圈電機(jī) 結(jié)構(gòu)優(yōu)化 力常數(shù) 定位精度

0 引言

音圈電機(jī)是一種直接驅(qū)動(dòng)的無(wú)遲滯設(shè)備[1-2],利用永磁體產(chǎn)生的磁場(chǎng)與通電線圈的相互作用產(chǎn)生驅(qū)動(dòng)力。音圈電機(jī)具有結(jié)構(gòu)簡(jiǎn)單、動(dòng)態(tài)響應(yīng)速度快、無(wú)齒槽轉(zhuǎn)矩、高線性度等優(yōu)點(diǎn),在高精度定位伺服系統(tǒng)中得到廣泛應(yīng)用[3-4]。隨著工業(yè)化不斷升級(jí),快速化、小型化、精密化的電機(jī)已經(jīng)成為各國(guó)研究重點(diǎn),因此音圈電機(jī)得到了廣泛的關(guān)注。

音圈電機(jī)屬于特種直線電機(jī)范疇,沒(méi)有中間傳動(dòng)環(huán)節(jié),極大地簡(jiǎn)化了驅(qū)動(dòng)機(jī)構(gòu),提高系統(tǒng)緊湊性。在直線運(yùn)動(dòng)系統(tǒng)中,直線電機(jī)在效率、推力控制和系統(tǒng)體積等方面比旋轉(zhuǎn)電機(jī)更具優(yōu)勢(shì)[5-6]。相對(duì)于U型直線電機(jī)和平板直線電機(jī),音圈電機(jī)具有更好的高頻響應(yīng)特性,可以實(shí)現(xiàn)高速往復(fù)直線運(yùn)動(dòng),特別適用于定位精度高的短行程伺服控制系統(tǒng)中。但是,音圈電機(jī)作為直線電機(jī)同樣存在推力密度低、端部效應(yīng)、線圈磨損等缺點(diǎn)[7-8]。針對(duì)直線電機(jī)的這些問(wèn)題,國(guó)內(nèi)外研究學(xué)者做了大量研究實(shí)驗(yàn),且取得了一定成果。如采用高磁性材料、使用Halbach磁極陣列代替?zhèn)鹘y(tǒng)磁極結(jié)構(gòu)、將超導(dǎo)材料應(yīng)用于電機(jī)繞組制作、無(wú)線充電等[9-11]。

本文回顧總結(jié)國(guó)內(nèi)外學(xué)者對(duì)音圈電機(jī)的研究成果,對(duì)音圈電機(jī)的技術(shù)概況進(jìn)行總結(jié)歸納。首先,簡(jiǎn)述音圈電機(jī)的工作原理、結(jié)構(gòu)分類以及各結(jié)構(gòu)的特點(diǎn);然后,結(jié)合國(guó)內(nèi)外學(xué)者對(duì)音圈電機(jī)的分析研究,對(duì)音圈電機(jī)存在的輸出力低、端部效應(yīng)等問(wèn)題以及相應(yīng)問(wèn)題的解決方案進(jìn)行歸納總結(jié);最后,對(duì)音圈電機(jī)的應(yīng)用領(lǐng)域進(jìn)行綜述,并對(duì)其發(fā)展前景和研究熱點(diǎn)進(jìn)行討論。

1 理論基礎(chǔ)

1.1 工作原理

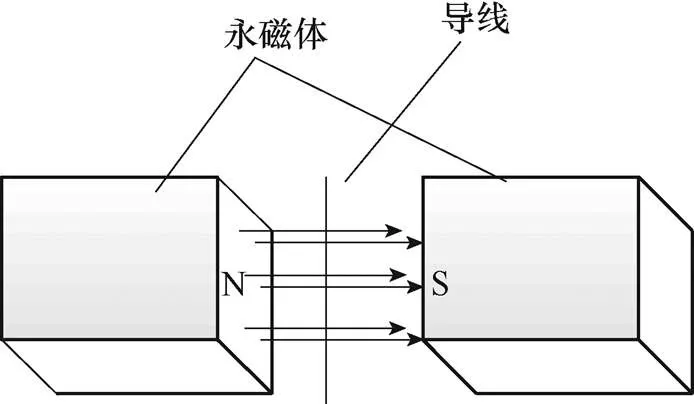

音圈電機(jī)是一種往復(fù)頻率極快的直驅(qū)式電機(jī),一種基于安培力原理而設(shè)計(jì)的直線電機(jī),屬于特種電機(jī)范疇,因其工作原理與揚(yáng)聲器類似而得名[12-13]。安培力原理如圖1所示。

圖1 安培力原理

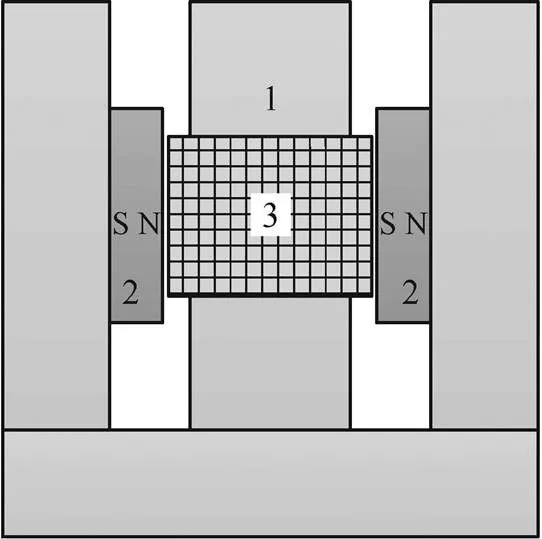

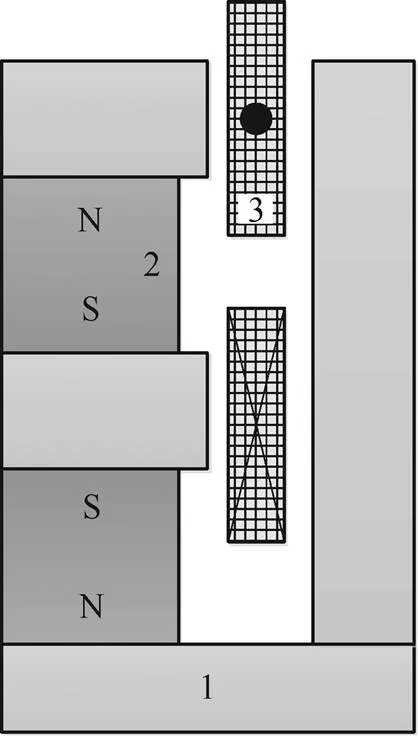

圖2所示為音圈電機(jī)結(jié)構(gòu),音圈電機(jī)主要由線圈、永磁體和磁軛三部分組成。其原理為線圈動(dòng)子在永磁體中通電后,會(huì)受安培力作用并產(chǎn)生垂直于線圈平面方向的運(yùn)動(dòng),可通過(guò)控制線圈電流的方向來(lái)控制線圈運(yùn)動(dòng)的方向,通過(guò)控制線圈通過(guò)電流的大小來(lái)控制線圈所受推力的大小[14]。音圈電機(jī)的磁學(xué)原理、電子學(xué)原理、機(jī)械學(xué)原理及數(shù)學(xué)模型的搭建在相關(guān)文獻(xiàn)中有詳細(xì)講解[15-16]。圖中,1為磁軛,2為永磁體,3為線圈(圖3~圖10中的1, 2, 3同圖2)。

圖2 音圈電機(jī)結(jié)構(gòu)

1.2 結(jié)構(gòu)分類

1.2.1 外磁式與內(nèi)磁式結(jié)構(gòu)

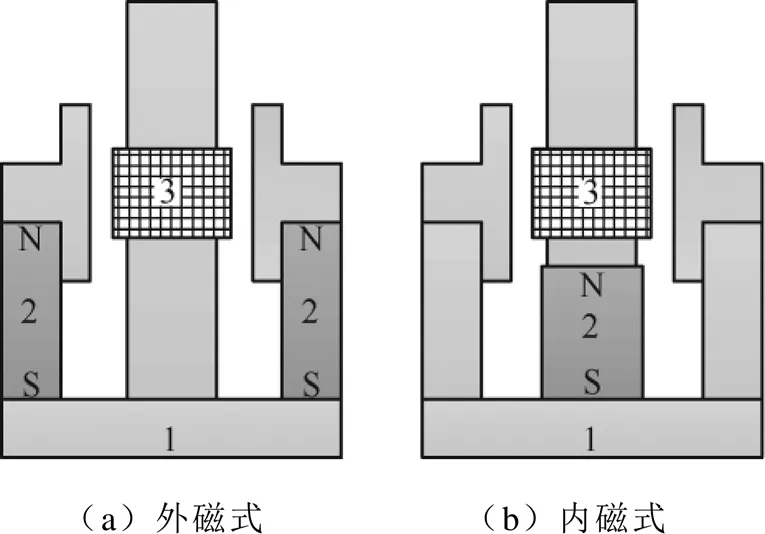

音圈電機(jī)最初應(yīng)用在磁盤磁頭定位機(jī)構(gòu)[17],1970年IBM推出的IBM3330存儲(chǔ)設(shè)備采用外磁式長(zhǎng)音圈電機(jī)作為磁盤定位機(jī)構(gòu),外磁式結(jié)構(gòu)如圖3a所示,永磁體暴露在電機(jī)外部,磁力線向外部發(fā)散,對(duì)外部造成磁干擾,所以外磁式結(jié)構(gòu)需要采用磁屏蔽機(jī)構(gòu)消除漏磁對(duì)磁頭讀寫的影響[18-19]。圖3b為內(nèi)磁式結(jié)構(gòu),利用音圈電機(jī)的外殼作為磁屏蔽,永磁體、氣隙和磁軛形成磁回路,減少漏磁。但是在電機(jī)軸開孔的場(chǎng)合不能使用內(nèi)磁式,如在光刻機(jī)[20-21]中,激光束需要穿過(guò)音圈電機(jī),此時(shí)不能采用內(nèi)磁式結(jié)構(gòu)。

圖3 外磁式和內(nèi)磁式音圈電機(jī)結(jié)構(gòu)

1.2.2 短音圈與長(zhǎng)音圈結(jié)構(gòu)

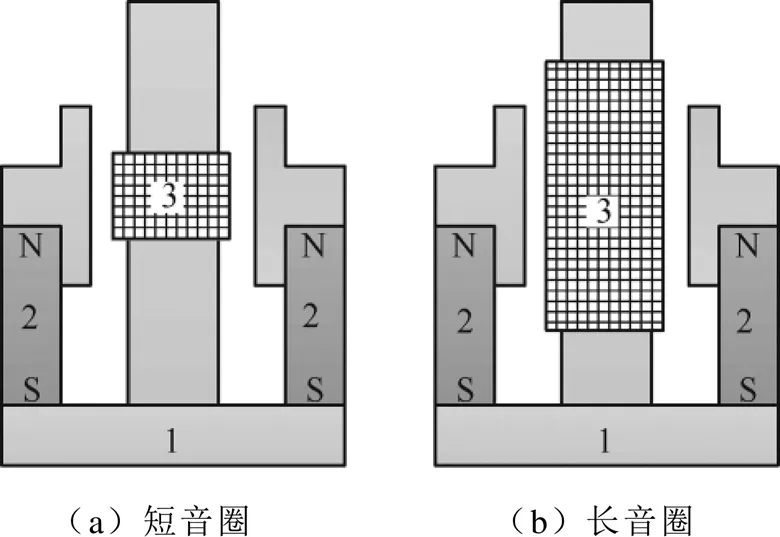

短音圈與長(zhǎng)音圈音圈電機(jī)結(jié)構(gòu)如圖4所示,根據(jù)電機(jī)工作氣隙長(zhǎng)度與音圈長(zhǎng)度的大小關(guān)系,可以將電機(jī)分為短音圈結(jié)構(gòu)和長(zhǎng)音圈結(jié)構(gòu)。長(zhǎng)音圈電機(jī)由于只有一部分線圈在工作氣隙中,電能利用率較低,端部漏磁嚴(yán)重[22-23];優(yōu)點(diǎn)是電機(jī)體積相對(duì)較小。短音圈電機(jī)的動(dòng)子質(zhì)量輕、響應(yīng)速度快,但是鐵磁機(jī)構(gòu)大、成本高。隨著永磁材料的發(fā)展,將稀土永磁材料用于音圈電機(jī)設(shè)計(jì)能夠極大地減小電機(jī)的體積[24-25],在IBM3330之后的IBM3340、IBM3350等產(chǎn)品均采用短音圈結(jié)構(gòu)[19]。

圖4 短音圈與長(zhǎng)音圈音圈電機(jī)結(jié)構(gòu)

1.2.3 動(dòng)圈式與動(dòng)磁式結(jié)構(gòu)

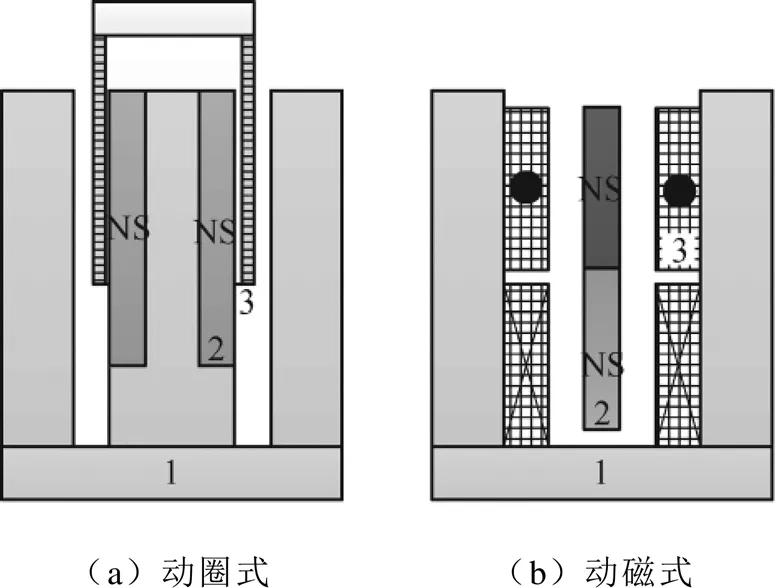

動(dòng)圈式與動(dòng)磁式音圈電機(jī)結(jié)構(gòu)如圖5所示。在動(dòng)圈式音圈電機(jī)中,固定磁體在線圈行程內(nèi)產(chǎn)生均勻磁場(chǎng),線圈是運(yùn)動(dòng)部件,響應(yīng)速度快,但是存在飛線問(wèn)題且散熱能力差,可靠性較低,一般廣泛應(yīng)用于小功率領(lǐng)域[26-28],不適合于功率要求較高的場(chǎng)合。文獻(xiàn)[7]中提出無(wú)線充電的方法在理論上解決了飛線問(wèn)題。動(dòng)磁式音圈電機(jī)的動(dòng)子是永磁體陣列,電機(jī)結(jié)構(gòu)緊湊、功率密度高,可實(shí)現(xiàn)無(wú)摩擦,但是對(duì)永磁體的體積質(zhì)量和機(jī)械強(qiáng)度有一定限制,且電機(jī)結(jié)構(gòu)復(fù)雜,要考慮磁場(chǎng)耦合、推力非線性和渦流損耗等問(wèn)題[29-30]。

圖5 動(dòng)圈式與動(dòng)磁式音圈電機(jī)結(jié)構(gòu)

1.2.4 平板形弧形與圓筒形結(jié)構(gòu)

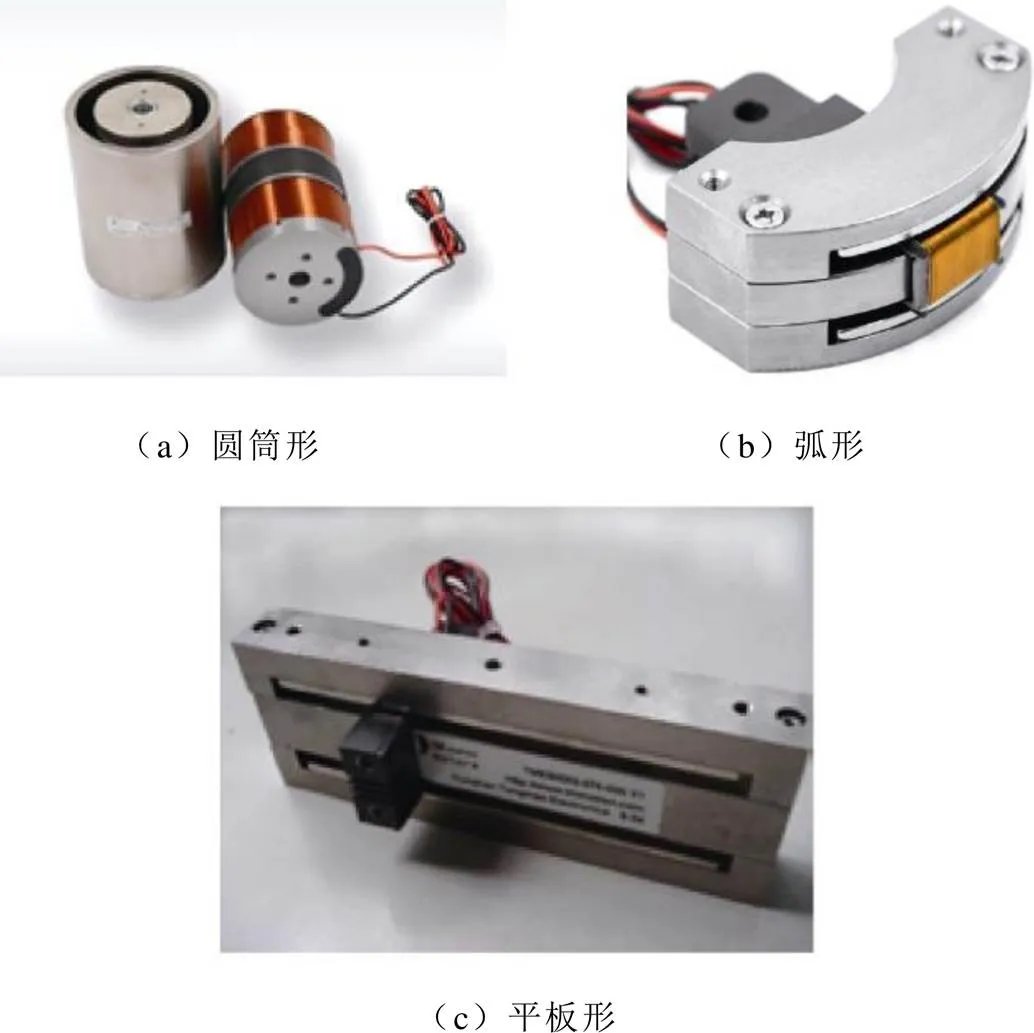

根據(jù)電機(jī)的外形不同,可以將電機(jī)分為圓筒形、弧形和平板形結(jié)構(gòu)。圖6所示為音圈電機(jī)實(shí)物。平板形與弧形結(jié)構(gòu)相對(duì)簡(jiǎn)單,制作工藝成熟,但是漏磁相對(duì)嚴(yán)重,永磁體利用率低,產(chǎn)生的推力較小;圓筒形音圈電機(jī)的永磁材料利用充分,能夠產(chǎn)生較大的推力,但是其環(huán)形結(jié)構(gòu)的永磁陣列充磁成本相對(duì)較高,且其行程低于平板形[31-32]。

圖6 音圈電機(jī)實(shí)物

1.3 總結(jié)

內(nèi)磁式結(jié)構(gòu)有效地解決了外磁式結(jié)構(gòu)存在的磁干擾問(wèn)題,但由于結(jié)構(gòu)限制在特定的場(chǎng)合必須使用帶有屏蔽的外磁式結(jié)構(gòu);隨著永磁材料的發(fā)展,短音圈結(jié)構(gòu)相對(duì)于長(zhǎng)音圈結(jié)構(gòu)的優(yōu)勢(shì)越來(lái)越明顯;動(dòng)圈式結(jié)構(gòu)相對(duì)于動(dòng)磁式結(jié)構(gòu)簡(jiǎn)單,線性推力便于控制,但存在飛線問(wèn)題;平板形和弧形結(jié)構(gòu)簡(jiǎn)單,但是推力較小,圓筒形結(jié)構(gòu)相對(duì)復(fù)雜,但推力較大。

2 高推力音圈電機(jī)

音圈電機(jī)以其優(yōu)秀的動(dòng)態(tài)響應(yīng)和定位精度,使得磁盤存儲(chǔ)技術(shù)得到極大提升,隨著磁盤存儲(chǔ)容量的增加,對(duì)音圈電機(jī)的推力提出新的要求,并且由于音圈電機(jī)的優(yōu)秀性能,在激光、快速反射鏡、引線鍵合機(jī)等需要精密控制領(lǐng)域得到應(yīng)用[32-34]。音圈電機(jī)的有效氣隙較大導(dǎo)致氣隙磁通密度較低,進(jìn)而影響電機(jī)的推力,最初設(shè)計(jì)音圈電機(jī)首要考慮的是提高音圈電機(jī)的出力。由于增大電流會(huì)有損耗、散熱等問(wèn)題,提高力常數(shù)的主要方法是增大氣隙磁通密度。

2.1 磁路優(yōu)化

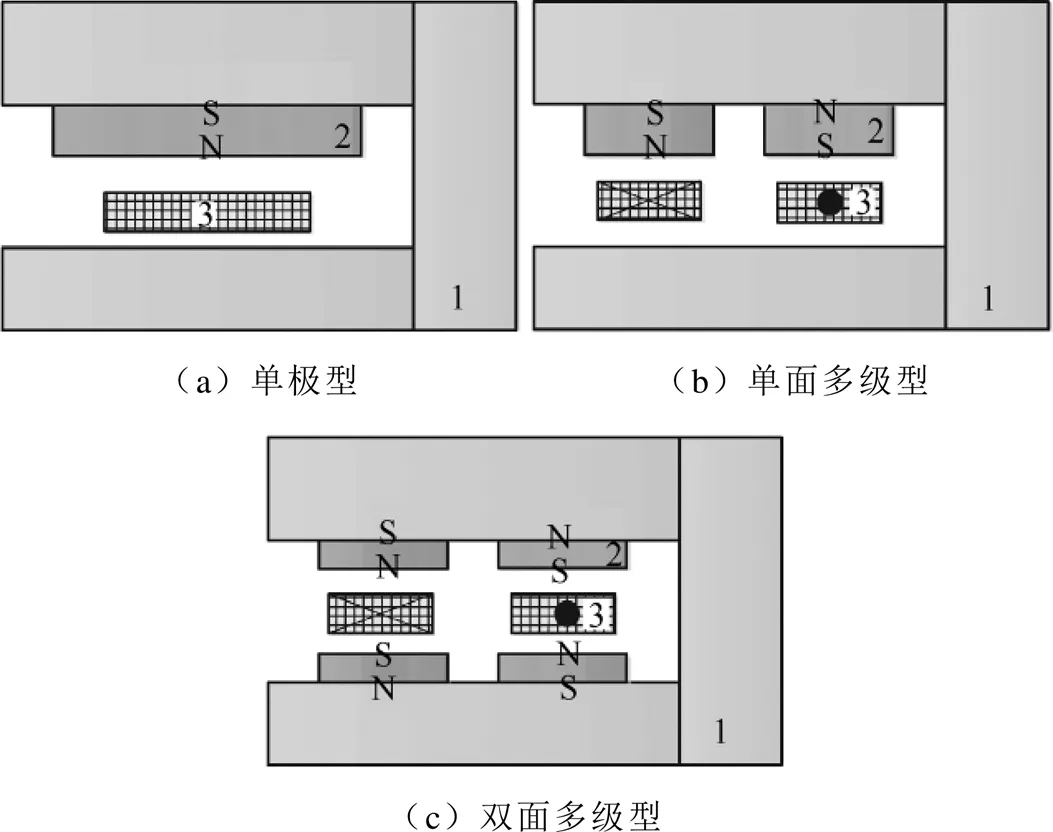

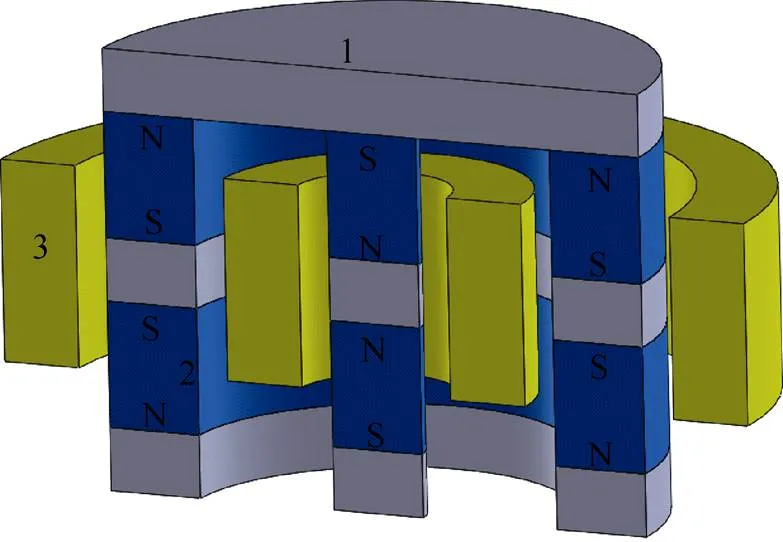

在文獻(xiàn)[35-39]中,對(duì)如圖7所示的傳統(tǒng)單極型、單面多級(jí)型和雙面多極型三種磁極結(jié)構(gòu)進(jìn)行分析對(duì)比。在傳統(tǒng)單極型結(jié)構(gòu)中,由于一段磁軛的存在導(dǎo)致電機(jī)的左右磁路不對(duì)稱,容易產(chǎn)生偏心問(wèn)題。采用差動(dòng)式結(jié)構(gòu),減小繞組電感和電樞反應(yīng),抑制不平衡推力。采用多級(jí)型磁極結(jié)構(gòu)不僅能夠改善偏心問(wèn)題,在相同體積和永磁材料下,多面多級(jí)型磁極結(jié)構(gòu)能夠在一定程度上提高氣隙磁通密度,改善電機(jī)推力。但是由于電機(jī)磁軛底部的飽和問(wèn)題,增加徑向充磁磁鋼厚度,氣隙磁通密度不是呈線性提升,且磁通密度提升有限,永磁體利用率較低。

圖7 磁路結(jié)構(gòu)

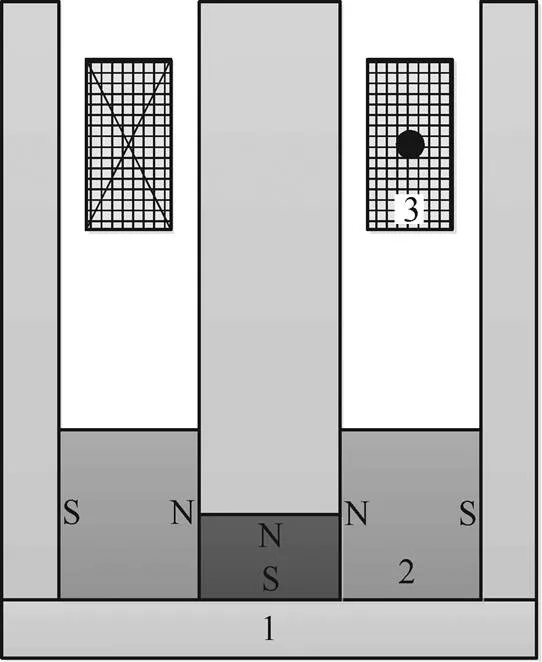

文獻(xiàn)[40-42]提出在音圈電機(jī)中采用軸向充磁結(jié)構(gòu),如圖8所示,推導(dǎo)出軸向充磁圓筒形永磁動(dòng)圈式直線電機(jī)的氣隙磁場(chǎng)解析計(jì)算公式,將徑向充磁與軸向充磁分析比對(duì),證明了在采用相同永磁材料的前提下,軸向充磁能夠產(chǎn)生更高的磁通密度,具有明顯的聚磁效果。文獻(xiàn)[43]在采用軸向充磁的基礎(chǔ)上,在音圈電機(jī)的中央放置一個(gè)磁心以增加徑向磁通,電機(jī)磁路結(jié)構(gòu)如圖9所示。該結(jié)構(gòu)使得內(nèi)外線圈有效地利用徑向磁通來(lái)產(chǎn)生軸向力,進(jìn)一步提高了電機(jī)的輸出力,使其能夠快速驅(qū)動(dòng)大直徑的反射鏡。

文獻(xiàn)[44-46]對(duì)非常規(guī)的磁極形狀和充磁方向的磁極結(jié)構(gòu)對(duì)氣隙磁通密度的影響進(jìn)行分析,結(jié)果發(fā)現(xiàn),采用非常規(guī)方向充磁和非矩形的磁極結(jié)構(gòu)可能對(duì)氣隙磁通密度有著極大的改善,對(duì)于形狀不規(guī)則的磁極,其制造和加工燒結(jié)方式存在一定困難,故文獻(xiàn)[46]中,提出一種粘接式的磁極結(jié)構(gòu)。文獻(xiàn)[47-48]采用徑向軸向混合的磁極陣列,制作了一臺(tái)應(yīng)用于快速掃描鏡的集中通量式音圈電機(jī),如圖10所示。該電機(jī)內(nèi)部中心有一個(gè)圓柱形磁體,中心外部有一環(huán)形磁體,有助于減小漏磁。

圖8 軸向充磁結(jié)構(gòu)

圖9 電機(jī)磁路結(jié)構(gòu)

圖10 集中通量式音圈電機(jī)

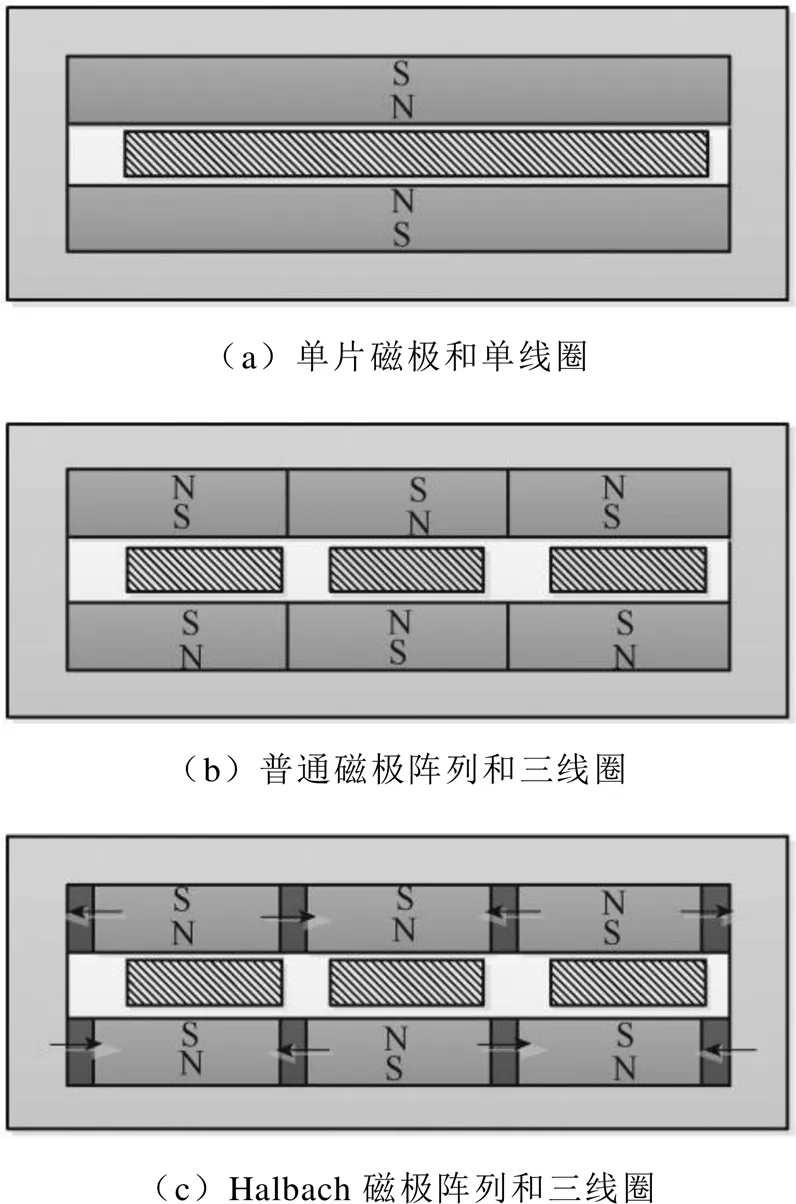

文獻(xiàn)[52-55]中,對(duì)單片磁極和單線圈、普通磁極陣列和三線圈、Halbach磁極陣列和三線圈三種結(jié)構(gòu)的音圈電機(jī)進(jìn)行性能比較,采用Halbach磁極陣列和三線圈結(jié)構(gòu)的音圈電機(jī)具有最大的推力和最小的力矩波動(dòng),磁極結(jié)構(gòu)如圖12所示。采用開槽的動(dòng)圈支架,有助于抑制渦流損耗。從而制作出能夠應(yīng)用于納米精確定位裝置的音圈電機(jī)。

圖11 環(huán)形磁鋼充磁方向

圖12 磁極結(jié)構(gòu)

2.2 音圈電機(jī)線圈優(yōu)化設(shè)計(jì)

音圈電機(jī)是無(wú)槽電機(jī),音圈厚度不僅影響電機(jī)繞組的安培匝數(shù),還影響氣隙磁通密度。而電機(jī)的輸出與這兩項(xiàng)的乘積成正比,因此存在一個(gè)使電機(jī)輸出最大化的最佳厚度。通過(guò)有限元優(yōu)化繞組厚度得到最優(yōu)的繞組結(jié)構(gòu)[56-57]。

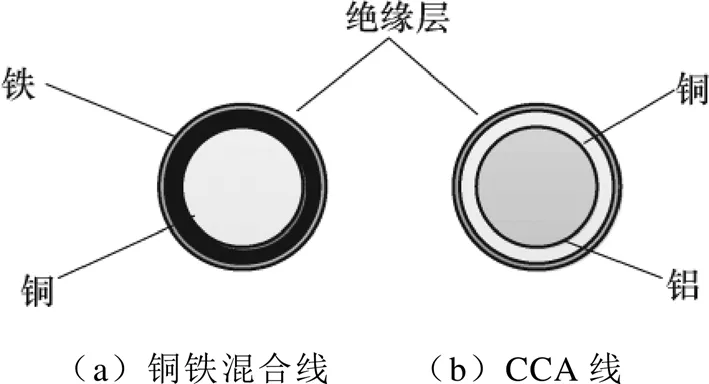

導(dǎo)線組成如圖13所示。文獻(xiàn)[58-60]針對(duì)線圈材料對(duì)電機(jī)性能的影響進(jìn)行分析,在電機(jī)體積不變的前提下,分別采用銅鐵混合線和銅包鋁(Copper Clad Aluminum, CCA)線作為線圈,銅鐵混合線減小磁阻,增大氣隙磁通密度,在導(dǎo)線電阻相差不多的前提下,CCA線的質(zhì)量是銅線質(zhì)量的40%左右,降低了動(dòng)子的質(zhì)量。文獻(xiàn)[61]表明,在線圈體積一定的前提下,改變線圈匝數(shù),不會(huì)改變推力。

圖13 導(dǎo)線組成

2.3 總結(jié)

提高音圈電機(jī)推力的優(yōu)化主要分為兩種:一種為磁路優(yōu)化,即采用多面多磁極結(jié)構(gòu)、聚磁磁極結(jié)構(gòu)和Halbach磁極結(jié)構(gòu)等磁極陣列,在相同的永磁材料用量下,提高氣隙磁通密度,進(jìn)而實(shí)現(xiàn)電機(jī)的大推力;另一種為線圈優(yōu)化,即采用銅鐵或銅鋁混合線,減小氣隙磁阻或動(dòng)子質(zhì)量,實(shí)現(xiàn)推力的提高,但會(huì)增大繞組損耗,故音圈電機(jī)高推力的研究主要集中在磁路優(yōu)化方面。

3 提高音圈電機(jī)定位精度

隨著裝備制造高精尖發(fā)展,在滿足推力的基礎(chǔ)上對(duì)音圈電機(jī)的定位精度的要求越來(lái)越高,如何提高定位精度是研究的熱點(diǎn)之一。

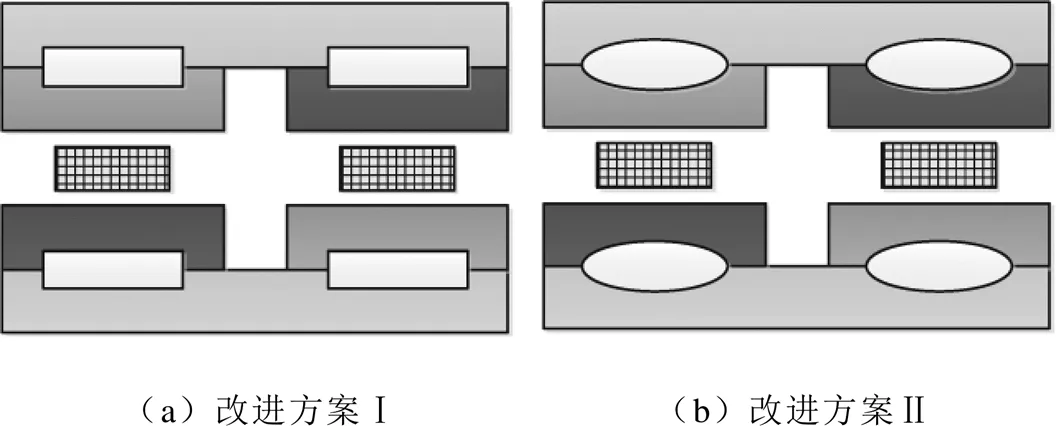

3.1 均勻磁通密度方案

根據(jù)音圈電機(jī)的基本公式=,磁通密度越平穩(wěn),力矩波動(dòng)越小。在電機(jī)動(dòng)子行程范圍內(nèi),獲得相對(duì)平穩(wěn)均勻的氣隙磁通密度,能夠有效地減小波動(dòng)。文獻(xiàn)[44-46]通過(guò)調(diào)整磁極的形狀和充磁方向,得到符合幅值和均勻性的磁通密度波形。文獻(xiàn)[62-63]對(duì)音圈電機(jī)的永磁體和磁軛進(jìn)行優(yōu)化,提出兩種永磁體和磁軛的改進(jìn)方案,其結(jié)構(gòu)如圖14所示。通過(guò)改進(jìn)音圈電機(jī)結(jié)構(gòu)中的永磁體和磁軛,使其內(nèi)部垂直峰值磁通密度大大降低。但是,電機(jī)輸出力會(huì)減小,且對(duì)永磁體的加工和機(jī)械強(qiáng)度有一定要求。高磁通密度與低轉(zhuǎn)矩波動(dòng)是相反的,要根據(jù)實(shí)際情況進(jìn)行選擇。

圖14 永磁體和磁軛結(jié)構(gòu)

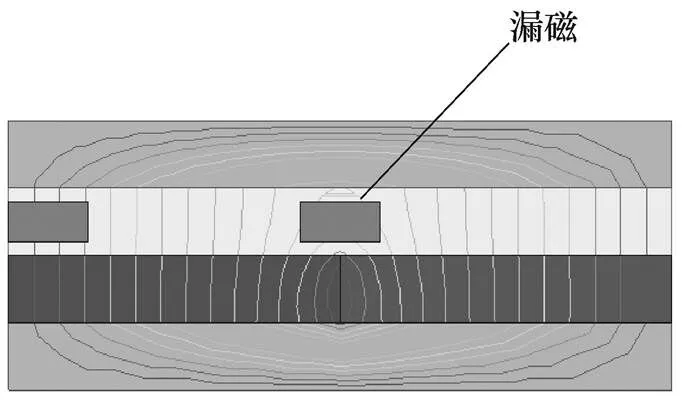

文獻(xiàn)[64-65]對(duì)漏磁進(jìn)行分析,磁力線云圖如圖15所示,永磁體產(chǎn)生的大量磁通通過(guò)磁軛中部,磁軛中部的磁通密度很大。磁軛中部高度飽和,此處氣隙磁通密度分布不均勻,會(huì)造成推力波動(dòng)的現(xiàn)象。而且,當(dāng)載流導(dǎo)線運(yùn)動(dòng)到磁軛中部時(shí),通電導(dǎo)線在漏磁通的作用下,會(huì)產(chǎn)生一個(gè)向上的力,將線圈推向磁軛,造成線圈運(yùn)行的不穩(wěn)定,因此提出了將永磁體分塊或調(diào)整永磁體之間的間隙,增大磁極間磁阻達(dá)到較少漏磁的目的。

圖15 磁力線云圖

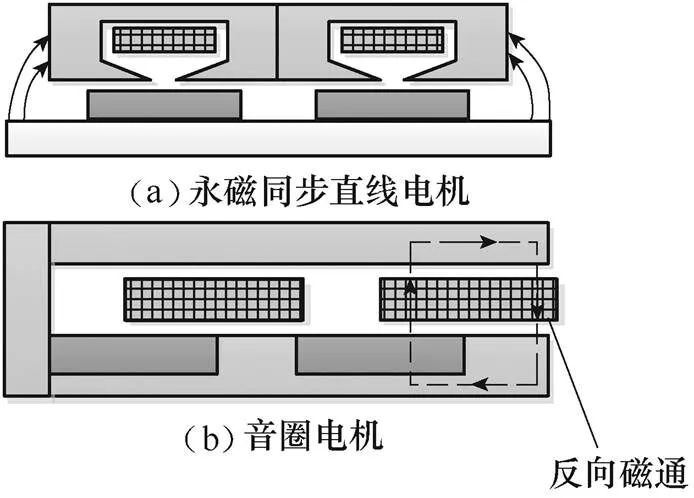

3.2 端部效應(yīng)與渦流損耗抑制

端部效應(yīng)是直線電機(jī)的固有特性,但是音圈電機(jī)與永磁同步直線電機(jī)的端部效應(yīng)是不同的。端部效應(yīng)如圖16所示,永磁同步電機(jī)的端部力是由于電機(jī)鐵心端部與永磁體磁場(chǎng)相互作用而產(chǎn)生的磁阻力。音圈電機(jī)的端部效應(yīng)是由于載流線圈移動(dòng)出磁軛端部時(shí)會(huì)受到一個(gè)反向力降低推力[66],因此永磁同步電機(jī)端部效應(yīng)的抑制方法不適用于音圈電機(jī)。由渦流阻尼器的思想可知,適當(dāng)?shù)臏u流阻尼可以減弱電機(jī)的振動(dòng),提高音圈電機(jī)的穩(wěn)定性和控制精 度[67-68],當(dāng)渦流損耗過(guò)大時(shí)會(huì)對(duì)電機(jī)的動(dòng)態(tài)性能造成一定影響。關(guān)于音圈電機(jī)本體設(shè)計(jì)的大部分文獻(xiàn)研究重點(diǎn)都是重塑磁場(chǎng),提高推力常數(shù)。近年來(lái),重慶大學(xué)Luo Ciyong等在抑制音圈電機(jī)端部效應(yīng)和渦流損耗方面做了相關(guān)研究[69-71],認(rèn)為減小端部磁阻和引導(dǎo)端部反向磁通對(duì)于抑制端部效應(yīng)有著重要作用。

心理壓力又稱心理應(yīng)激、心理緊張,是個(gè)體在生活適應(yīng)過(guò)程中的一種身心緊張狀態(tài)。由環(huán)境要求和自身應(yīng)對(duì)能力不平衡而產(chǎn)生,這種緊張狀態(tài)傾向于通過(guò)非特異的心理和生理反應(yīng)表現(xiàn)出來(lái)。它是個(gè)體“察覺(jué)”到環(huán)境刺激對(duì)生理、心理和社會(huì)系統(tǒng)負(fù)擔(dān)過(guò)重時(shí)出現(xiàn)的整體現(xiàn)象所引起的反應(yīng)[1]。

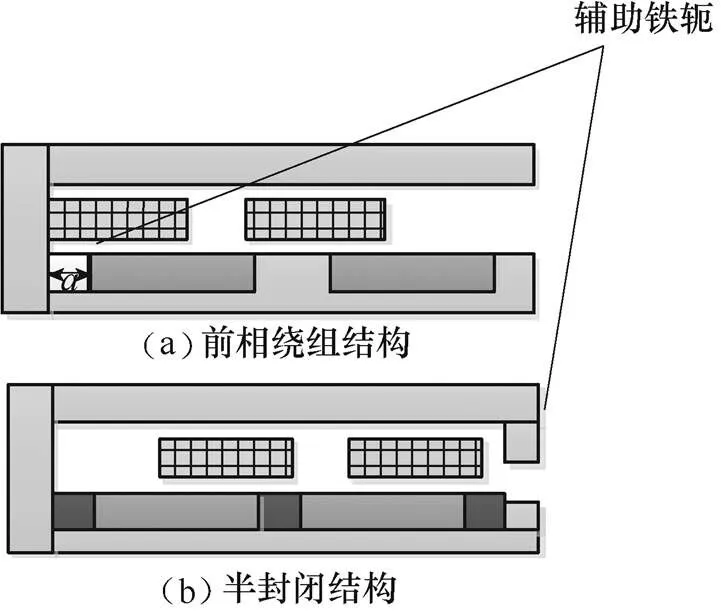

2017年Luo Ciyong提出在音圈電機(jī)底部增加一塊長(zhǎng)度為的輔助鐵軛形成前相繞組,如圖17a所示[69],由于線圈被運(yùn)動(dòng)軌道上的磁軛所覆蓋,在一定程度上有助于減弱電機(jī)的端部效應(yīng),增加輔助鐵軛導(dǎo)致電機(jī)體積增加,通過(guò)改變(鐵軛長(zhǎng)度),推力特性曲線右移,曲線變寬,則平均推力增加,因此選取最優(yōu)值能夠得到最優(yōu)的推力密度。該方法雖然使音圈電機(jī)具有較小的端部反向磁通并改善了推力的特性,但端部氣隙磁阻仍然占磁路主磁阻相當(dāng)大一部分,2019年Luo Ciyong提出一種半封閉結(jié)構(gòu)的音圈電機(jī),如圖17b所示[70],在前向繞組的基礎(chǔ)上,采用Halbach永磁陣列來(lái)提高推力密度,并且在音圈電機(jī)端部增加一塊輔助鐵軛,引導(dǎo)端部磁通減小端部磁阻,達(dá)到抑制端部效應(yīng)的目的。

圖16 端部效應(yīng)

圖17 輔助軛鐵音圈電機(jī)

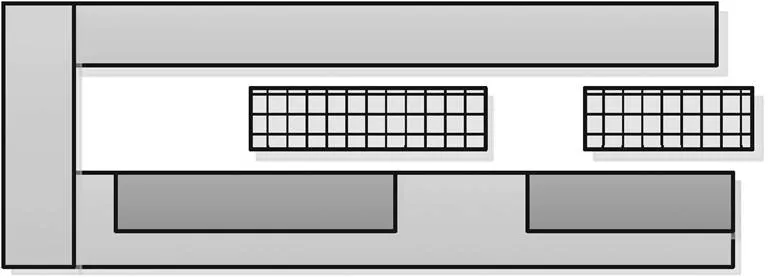

2020年Luo Ciyong提出一種新的無(wú)端鐵音圈電機(jī),如圖18所示[71],通過(guò)取消端鐵,增大端部氣隙磁阻減少反向磁通來(lái)抑制端部效應(yīng),且通過(guò)有限元分析得出最佳永磁體長(zhǎng)度比。

圖18 無(wú)端鐵音圈電機(jī)

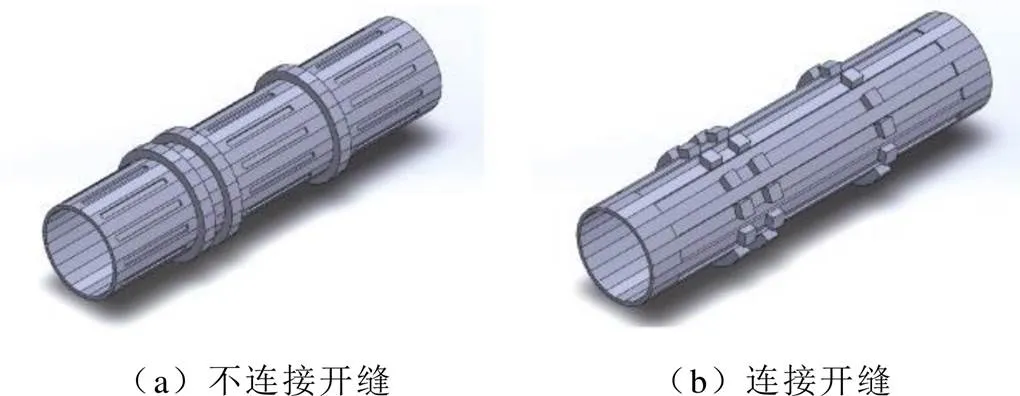

根據(jù)在傳統(tǒng)永磁同步電機(jī)中可以通過(guò)疊片磁心和套管開孔的方式減少渦流損耗[72-73],提出了三種有利于減弱渦流損耗的鋁管結(jié)構(gòu)如圖19所示[74],經(jīng)過(guò)分析對(duì)比得出,加勁肋并連接開縫的方法對(duì)渦流損耗的抑制最顯著。

3.3 多自由度音圈電機(jī)

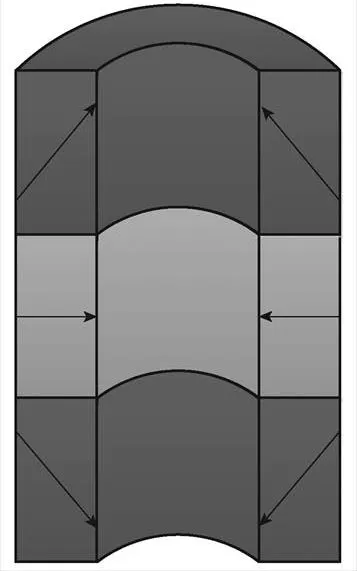

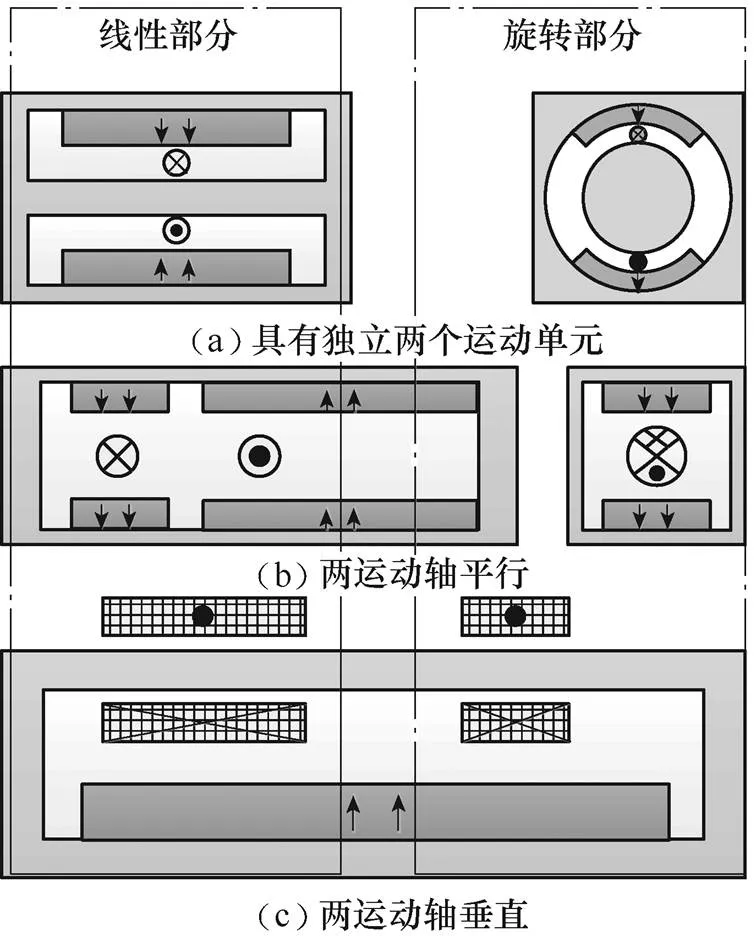

通過(guò)多個(gè)電機(jī)實(shí)現(xiàn)多自由度運(yùn)動(dòng)存在誤差疊加的問(wèn)題,隨著精密加工技術(shù)的發(fā)展,滿足多維精密加工系統(tǒng)的高精度、高動(dòng)態(tài)速度的電機(jī)成為研究的熱點(diǎn)。文獻(xiàn)[75-79]提出了三種結(jié)構(gòu)簡(jiǎn)單、體積小的新型二自由度旋轉(zhuǎn)直線音圈電機(jī)作為多維精密運(yùn)動(dòng)平臺(tái)的末端執(zhí)行器。電機(jī)的磁路結(jié)構(gòu)如圖20所示,經(jīng)過(guò)實(shí)驗(yàn)測(cè)試三種電機(jī)結(jié)構(gòu)均滿足要求。

圖20 兩自由度的音圈電機(jī)磁路

具有兩個(gè)運(yùn)動(dòng)單元的電機(jī)結(jié)構(gòu)具有良好的可控性;運(yùn)動(dòng)軸平行的電機(jī)結(jié)構(gòu)具有最高的平均直線推力;運(yùn)動(dòng)軸垂直的電機(jī)結(jié)構(gòu)具有最低的推力脈動(dòng)和最高的平均旋轉(zhuǎn)力矩。本文還探究了電樞反應(yīng)對(duì)電機(jī)性能的影響,實(shí)驗(yàn)表明,通過(guò)優(yōu)化電機(jī)的電樞反應(yīng),能夠進(jìn)一步提高電機(jī)的推力密度、降低紋波。

3.4 總結(jié)

對(duì)音圈電機(jī)的永磁體、鐵軛和端部等結(jié)構(gòu)進(jìn)行優(yōu)化,達(dá)到均勻動(dòng)子行程內(nèi)的磁通密度、抑制音圈電機(jī)的端部效應(yīng)和渦流損耗的目的,都有助于提高電機(jī)的定位精度。設(shè)計(jì)制造多自由度的音圈電機(jī)可以減少多個(gè)電機(jī)以實(shí)現(xiàn)多自由度運(yùn)動(dòng)時(shí)誤差疊加,有利于實(shí)現(xiàn)加工系統(tǒng)的高精度。

4 音圈電機(jī)的應(yīng)用

4.1 攝像頭

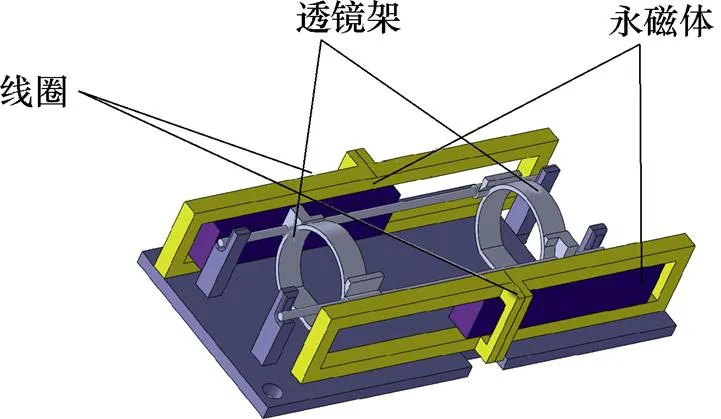

在智能手機(jī)攝像模塊中,相比于步進(jìn)電機(jī)和壓電材料,音圈電機(jī)更具優(yōu)勢(shì),多數(shù)攝像頭采用音圈電機(jī),通過(guò)控制音圈電機(jī)的電流來(lái)實(shí)現(xiàn)手機(jī)鏡頭的自動(dòng)對(duì)焦功能。開環(huán)音圈電機(jī)控制需要簧片提供復(fù)位力,存在振鈴問(wèn)題。對(duì)此,文獻(xiàn)[80]提出攝像頭的音圈電機(jī)閉環(huán)控制,霍爾傳感器判斷動(dòng)子位置,鏡頭控制采用閉環(huán),無(wú)需使用簧片。目前,由于手機(jī)體積限制以及音圈電機(jī)行程,大部分手機(jī)僅有自動(dòng)對(duì)焦功能[81],無(wú)法實(shí)現(xiàn)光學(xué)變焦。文獻(xiàn)[82]設(shè)計(jì)如圖21所示的音圈電機(jī)結(jié)構(gòu),采取L形繞組,有助于實(shí)現(xiàn)大行程。

圖21 L形繞組音圈電機(jī)結(jié)構(gòu)

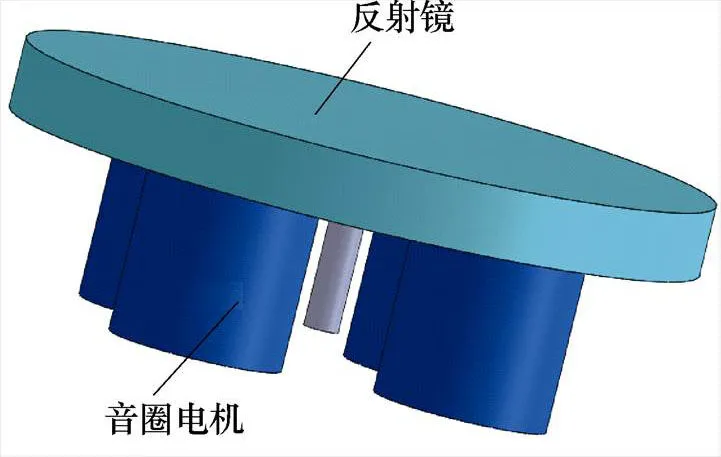

4.2 快速反射鏡

快速反射鏡用來(lái)改變光源與目標(biāo)之間光束指向的裝置,需要對(duì)光傳播方向進(jìn)行高精度、高動(dòng)態(tài)的控制,實(shí)現(xiàn)光束在所需轉(zhuǎn)角范圍內(nèi)的快速精確指向,對(duì)系統(tǒng)的環(huán)境適應(yīng)性等也有很高要求[43]。當(dāng)前快速反射鏡平臺(tái)根據(jù)驅(qū)動(dòng)方式的不同分為壓電陶瓷驅(qū)動(dòng)和音圈電機(jī)驅(qū)動(dòng)兩大類。壓電陶瓷驅(qū)動(dòng)器的行程相對(duì)較小,一般只有幾十mm,用于快速反射鏡中無(wú)法實(shí)現(xiàn)較大轉(zhuǎn)角范圍。采用音圈電機(jī)驅(qū)動(dòng),可使快速反射鏡系統(tǒng)轉(zhuǎn)角范圍大、承載能力強(qiáng),且對(duì)振動(dòng)、沖擊等工作環(huán)境具有較強(qiáng)的適應(yīng)性。在國(guó)防軍工等行程要求較高、反射鏡口徑較大的系統(tǒng)中,大多采用音圈電機(jī)驅(qū)動(dòng)的快速反射鏡,如圖22所示。

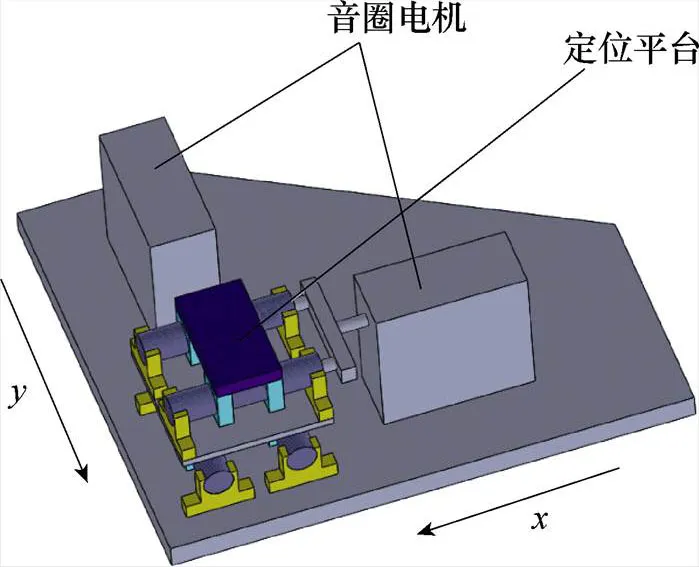

4.3 精密運(yùn)動(dòng)平臺(tái)

XY精密工作平臺(tái)如圖23所示,是光刻機(jī)、引線鍵合機(jī)、PCB鉆孔等半導(dǎo)體器件制造和封裝儀器的核心部件,工作臺(tái)對(duì)驅(qū)動(dòng)設(shè)備的速度和精度要求極高[83],音圈電機(jī)具有響應(yīng)速度快和精度高的優(yōu)點(diǎn),在有關(guān)半導(dǎo)體制作的領(lǐng)域得到了廣泛應(yīng)用[84]。光刻機(jī)和引線鍵合機(jī)是芯片、半導(dǎo)體制作封裝的核心設(shè)備,我國(guó)與西方國(guó)家有著較大差距,因此也有著較大的提升空間。目前最好的光刻機(jī)是荷蘭的AMSL,能夠刻出5nm的電路,而國(guó)產(chǎn)光刻機(jī)要在28nm以上。

圖22 快速反射鏡

圖23 精密工作平臺(tái)

5 音圈電機(jī)研究熱點(diǎn)與未來(lái)發(fā)展

隨著我國(guó)裝備制造向著高、精、尖發(fā)展,對(duì)于音圈電機(jī)有著大量的需求,如光刻機(jī)、引線鍵合機(jī)等芯片、半導(dǎo)體加工制造裝備。隨著智能手機(jī)逐步引入多攝像頭、光學(xué)變焦等技術(shù),也會(huì)增大音圈電機(jī)的需求,因此音圈電機(jī)具有廣泛的應(yīng)用前景。目前,音圈電機(jī)的研究熱點(diǎn)有如下幾個(gè)方面:

1)提高音圈電機(jī)的推力。隨著稀土材料加工研制工藝的進(jìn)步,將高性能的永磁材料以及Halbach陣列和多面多磁極等結(jié)構(gòu)應(yīng)用到音圈電機(jī)的設(shè)計(jì)中,初步解決音圈電機(jī)推力低的問(wèn)題,但電機(jī)的推力依然有著巨大的提升空間,新型拓?fù)浣Y(jié)構(gòu)的構(gòu)建和高性能材料的應(yīng)用,都將有助于進(jìn)一步提高音圈電機(jī)的推力。

2)提高音圈電機(jī)的定位精度。音圈電機(jī)主要應(yīng)用于高精度領(lǐng)域,提高電機(jī)的定位精度是一個(gè)永久課題,如優(yōu)化拓?fù)浣Y(jié)構(gòu)以均勻磁通密度、抑制端部效應(yīng)和渦流損耗,研制多自由度電機(jī)解決誤差積累問(wèn)題等。音圈電機(jī)在理論上具有無(wú)限的控制精度,但在實(shí)際使用中會(huì)受到外部干擾,進(jìn)一步深化對(duì)音圈電機(jī)控制的研究有重要價(jià)值。

3)減小音圈電機(jī)的體積。在推力不變的前提下,減小電機(jī)的體積有利于節(jié)省電機(jī)的制造材料,同時(shí)可間接減小如手機(jī)、工作臺(tái)等設(shè)備的體積,節(jié)省設(shè)備的制造成本,與國(guó)家的“去成本”政策相契合。并且,對(duì)于精密醫(yī)療儀器如掃描儀,航空設(shè)備如反射鏡平臺(tái)等設(shè)備的體積有著嚴(yán)格限制,音圈電機(jī)的小型化研究有重要的實(shí)用價(jià)值。

因此,音圈電機(jī)將朝著高推力、高精度和小型化方向發(fā)展。

6 結(jié)論

本文結(jié)合國(guó)內(nèi)外對(duì)音圈電機(jī)本體結(jié)構(gòu)的研究,對(duì)音圈電機(jī)的技術(shù)概況進(jìn)行綜述。本文分別對(duì)外磁式和內(nèi)磁式、短音圈和長(zhǎng)音圈、動(dòng)圈式和動(dòng)磁式、平板形弧形和圓筒形的結(jié)構(gòu)以相應(yīng)的特點(diǎn)進(jìn)行全面闡述,對(duì)如何提高音圈電機(jī)輸出力常數(shù)和定位精度的方法進(jìn)行歸納總結(jié),對(duì)音圈電機(jī)的應(yīng)用前景和熱點(diǎn)問(wèn)題進(jìn)行分析討論。音圈電機(jī)發(fā)展至今,以其結(jié)構(gòu)簡(jiǎn)單、響應(yīng)速度快、精度高等優(yōu)越性能得到廣泛應(yīng)用,特別在手機(jī)變焦、精密工作臺(tái)等高精密領(lǐng)域具有突出優(yōu)勢(shì),相信隨著研究的不斷深入,音圈電機(jī)將會(huì)得到更進(jìn)一步的發(fā)展。

[1] Chen S Y, Lin Heru, Yang Mengchen, et al. Fractional- order fuzzy PID contouring control for a VCMs- based x-y motion stage[C]//International Conference on Control, Automation and Robotics, Singapore, 2020: 236-241.

[2] Chen S Y, Lee C Y. Digital signal processor based intelligent fractional-order sliding-mode control for a linear voice coil actuator[J]. IET Control Theory & Applications, 2017, 11(8): 282-1292.

[3] Cao Yu, Wang Haitao, Lü Tao, et al. Research on large caliber FSM digital control system based on voice coil motor[C]//IEEE Advanced Information Technology, Electronic and Automation Control Conference, Chengdu, China, 2019: 2778-2781.

[4] Wang Baochao, Liu Cheng, Wu Zhiwei, et al. LCL filter design and implementation for improving transient position tracking control performance of voice coil motor[J]. IEEE Access, 2020, 8: 4963- 4971.

[5] 凌志健, 趙文祥, 吉敬華. 高推力永磁直線作動(dòng)器及其關(guān)鍵技術(shù)綜述[J]. 電工技術(shù)學(xué)報(bào), 2020, 35(5): 1022-1035.

Ling Zhijian, Zhao Wenxiang, Ji Jinghua. Overview of high force density permanent magnet linear actuator and its key technology[J]. Transactions of China Electrotechnical Society, 2020, 35(5): 1022- 1035.

[6] 張春雷, 張輝, 葉佩青, 等. 兩相圓筒型永磁同步直線電機(jī)無(wú)傳感算法[J]. 電工技術(shù)學(xué)報(bào), 2019, 34(23): 4901-4908.

Zhang Chunlei, Zhang Hui, Ye Peiqing, et al. Research on sensorless algorithm of two phase tubular permanent magnet synchronous linear motor[J]. Transactions of China Electrotechnical Society, 2019, 34(23): 4901-4908.

[7] Huang Weikang, Cao Li, Huang Wenxin, et al. Research on voice coil motor for a new construction with wireless power supply[C]//International Con- ference on Electrical Machines and Systems, Harbin, China, 2019: 1-6.

[8] 陳曉, 趙文祥, 吉敬華, 等. 考慮邊端效應(yīng)的雙邊直線永磁游標(biāo)電機(jī)模型預(yù)測(cè)電流控制[J]. 電工技術(shù)學(xué)報(bào), 2019, 34(1): 49-57.

Chen Xiao, Zhao Wenxiang, Ji Jinghua, et al. Model predictive current control of double-side linear vernier permanent magnet machines considering end effect[J]. Transactions of China Electrotechnical Society, 2019, 34(1): 49-57.

[9] 秦偉, 范瑜, 徐洪澤, 等. 高溫超導(dǎo)運(yùn)動(dòng)磁場(chǎng)電磁Halbach初級(jí)結(jié)構(gòu)直線感應(yīng)磁懸浮電機(jī)[J]. 電工技術(shù)學(xué)報(bào), 2018, 33(23): 5427-5434.

Qin Wei, Fan Yu, Xu Hongze, et al. A linear induction maglev motor with HTS traveling magnetic electromagnetic Halbach array[J]. Transactions of China Electrotechnical Society, 2018, 33(23): 5427- 5434.

[10] 許孝卓, 孫震, 汪旭東, 等. Halbach交替極永磁同步直線電機(jī)特性分析[J]. 電工技術(shù)學(xué)報(bào), 2019, 34(9): 1825-1833.

Xu Xiaozhuo, Sun Zhen, Wang Xudong, et al. Characteristic of a novel permanent magnet linear synchronous motor with Halbach array consequent- pole[J]. Transactions of China Electrotechnical Society, 2019, 34(9): 1825-1833.

[11] Ma Guangtong, Gong Tianyong, Zhang Han, et al. Experiment and simulation of REBCO conductor coils for an HTS linear synchronous motor[J]. IEEE Transactions on Applied Superconductivity, 2017, 27(4): 1-5.

[12] 楊光. 基于三維磁場(chǎng)計(jì)算的永磁音圈電機(jī)結(jié)構(gòu)優(yōu)化設(shè)計(jì)[D]. 天津: 天津大學(xué), 2004.

[13] 常雪峰, 陳幼平, 艾武, 等. 音圈直線電動(dòng)機(jī)設(shè)計(jì)、控制及應(yīng)用綜述[J]. 微電機(jī), 2008, 41(11): 66-69.

Chang Xuefeng, Chen Youping, Ai Wu, et al. Design and control application of voice coil linear motors[J]. Micromotors, 2008, 41(11): 66-69.

[14] 張陽(yáng), 周惠興, 曹榮敏, 等. 基于有限元分析的弧形音圈電機(jī)綜合優(yōu)化設(shè)計(jì)[J]. 微電機(jī), 2010, 43(11): 28-33.

Zhang Yang, Zhou Huixing, Cao Rongmin, et al. Comprehensive optimization design of a rotary VCM based on FEM[J]. Micromotors, 2010, 43(11): 28-33.

[15] 興連國(guó), 周惠興, 侯書林, 等. 音圈電機(jī)研究及應(yīng)用綜述[J]. 微電機(jī), 2011, 44(8): 82-87.

Xing Lianguo, Zhou Huixing, Hou Shulin, et al. Research and application of voice coil motor[J]. MicroMotors, 2011, 44(8): 82-87.

[16] 張大衛(wèi), 馮曉梅. 音圈電機(jī)的技術(shù)原理[J]. 中北大學(xué)學(xué)報(bào): 自然科學(xué)版, 2006, 27(3): 224-228.

Zhang David, Feng Xiaomei. Technical principles of voice coil motor[J]. Journal of North University of China: Natural Science Edition, 2006, 27(3): 224- 228.

[17] 王曉遠(yuǎn), 楊光, 閆杰. 兩種結(jié)構(gòu)的光盤驅(qū)動(dòng)器音圈電機(jī)性能分析[J]. 微電機(jī), 2005, 38(2): 7-9.

Wang Xiaoyuan, Yang Guang, Yan Jie. Performance analysis of two voice coils motors wiyt different kinds of structure for disk driver[J]. Micromotors, 2005, 38(2): 7-9.

[18] 王道生. 高速高精度磁頭定位機(jī)構(gòu)的設(shè)計(jì)[J]. 電子計(jì)算機(jī)參考資料, 1978(7): 58-76.

Wang Daosheng. Design of high speed and high precision magnetic head positioning mechanism[J]. Computer Engineering and Applications, 1978(7): 58-76.

[19] 何松波, 顧鴻祥. 自屏蔽式音圈電機(jī)[J]. 計(jì)算機(jī)研究與發(fā)展, 1984(4): 27-34.

He Songbo, Gu Hongxiang. Self-shielded voice coil motor[J]. Journal of Computer Research and Deve- lopment, 1984(4): 27-34.

[20] Gong Zhean, Zhang Zhishen, Zhang Longlong, et al. Reliability enhancement test of vertical voice-coil motor on wafer stage of lithography machine[C]// International Conference on Quality, Chengdu, China, 2013: 991-995.

[21] 羅敢, 王岳環(huán), 張彪. 光刻機(jī)光頭調(diào)焦音圈電機(jī)的結(jié)構(gòu)設(shè)計(jì)[J]. 微電機(jī), 1998, 31(6): 7-11.

Luo Gan, Wang Yuehuan, Zhang Biao. VCM structure design for optical-head focusing in optical pre- etching machine[J]. Micromotors, 1998, 31(6): 7-11.

[22] 張寶銘, 王春茹. 高精度音圈電動(dòng)機(jī)[J]. 微電機(jī), 1995, 28(1): 50-51.

Zhang Baoming, Wang Chunru. High-precision voice coil motor[J]. Micromotors, 1995, 28(1): 50-51.

[23] 馮勝東. 大量程觸針式儀器測(cè)力控制系統(tǒng)研究[D]. 武漢: 華中科技大學(xué), 2015.

[24] Rashidi A S, 楊媛霞. 用希土磁鋼改善音圈電機(jī)性能[J]. 電子計(jì)算機(jī)動(dòng)態(tài), 1979(2): 40-42.

Rashidi A S, Yang Yuanxia. Improving the per- formance of voice coil motors with rare earth magnets[J]. Journal of Computer Research and Development, 1979(2): 40-42.

[25] 鄭大材, 呂輝. 短音圈電機(jī)設(shè)計(jì)要求及使用[J]. 西北電訊工程學(xué)院學(xué)報(bào), 1979, 6(3): 113-123.

Zheng Dacai, Lü Hui. Design requirements and use of short voice coil motors[J]. Journal of Xidian University, 1979, 6(3): 113-123.

[26] Lee D J, Woo K S, Park N C, et al. Design and optimization of a linear actuator for subminiature optical storage devices[J]. IEEE Transactions on Magnetics, 2005, 41(2): 1055-1057.

[27] Chou P C, Lin Yucheng, Cheng S. A novel seesaw swivel actuator design and fabrication[J]. IEEE Transactions on Magnetics, 2010, 46(7): 2603-2610.

[28] Djamari D W, Ong C J, Yap F F. An investigation into the use of four-bar linkage mechanism as actuator for hard-disk drive[J]. IEEE Transactions on Magnetics, 2013, 49(6): 2466-2472.

[29] 周惠興, 黃燦, 王磊, 等. 大功率動(dòng)磁式音圈電機(jī)優(yōu)化及試驗(yàn)研究[J]. 北京信息科技大學(xué)學(xué)報(bào), 2014, 29(3): 1-4.

Zhou Huixing, Huang Can, Wang Lei, et al. Opti- mization and experimental research for a high-power moving magnet voice coil motor[J]. Journal of Beijing Information Science & Technology University, 2014, 29(3): 1-4.

[30] 凌金福. 動(dòng)圈式直線電機(jī)的研制和應(yīng)用[J]. 電工電能新技術(shù), 1983, 2(3): 44-49.

Ling Jinfu. Development and application of moving coil linear motor[J]. Advanced Technology of Electrical Engineering and Energy, 1983, 2(3): 44-49.

[31] 王曉偉. 高推力密度圓筒型音圈電機(jī)的結(jié)構(gòu)設(shè)計(jì)研究[D]. 重慶: 重慶大學(xué), 2018.

[32] 夏瑞陽(yáng). 圓柱形音圈電機(jī)結(jié)構(gòu)的設(shè)計(jì)及優(yōu)化[D]. 洛陽(yáng): 河南科技大學(xué), 2012.

[33] 陳國(guó)真, 徐斯強(qiáng), 劉品寬, 等. 大行程快速反射鏡的結(jié)構(gòu)設(shè)計(jì)及帶寬特性[J]. 光學(xué)精密工程, 2020, 28(1): 90-101.

Chen Guozhen, Xu Siqiang, Liu Pinkuan, et al. Structural design and bandwidth characteristic of a fast steering mirror with large travel range[J]. Optics and Precision Engineering, 2020, 28(1): 90-101.

[34] Lou Yunjiang, Yang Xiansheng, Li Ke, et al. Design and optimization of a linear voice coil motor for LED die bonders[C]//IEEE International Conference on Information and Automation, Yinchuan, China, 2013: 1011-1016.

[35] Peng Bo, Quan JianZhou, Yin Zhouping, et al. The analysis and control of pick-and-place process in flip-chip[C]//International Conference on Mechanical and Electronics Engineering, Kyoto, Japan, 2010: 404-408.

[36] Kim D H, Lee D Y, Jung C G, et al. Improvement of operating characteristics for MC-LOA taking account of permanent magnet arrangement[J]. IEEE Transa- ctions on Magnetics, 2004, 40(4): 2038-2040.

[37] 凌金福, 李世毅, 楊媛霞. 雙磁體音圈電機(jī)氣隙磁場(chǎng)的分析[J]. 電工技術(shù)雜志, 1984, 5(6): 25-29.

Ling Jinfu, Li Shiyi, Yang Yuanxia. Analysis of air gap magnetic field of dual magnet voice coil motor[J]. Electrotechnical Application, 1984, 5(6): 25-29.

[38] Guo Hong, Wang Dayu, Xu Jinquan. Research on a high-frequency response direct drive valve system based on voice coil motor[J]. IEEE Transactions on Power Electronics, 2013, 28(5): 2483-2492.

[39] Wu Shuai, Jiao Zongxia, Yan Liang, et al. Deve- lopment of a direct-drive servo valve with high- frequency voice coil motor and advanced digital controller[J]. IEEE/ASME Transactions on Mechatro- nics, 2014, 19(3): 932-942.

[40] 凌志鵬, 李晉川, 黃學(xué)進(jìn), 等. 改進(jìn)型音圈式直線電動(dòng)機(jī)有限元優(yōu)化設(shè)計(jì)[J]. 微電機(jī), 2007, 40(10): 18-20.

Ling Zhipeng, Li Jinchuan, Huang Xuejin, et al. Finite element optimal design of improved linear motor of voice coil type[J]. Micromotors, 2007, 40(10): 18-20.

[41] 王淑紅, 熊光煜. 新型筒型永磁動(dòng)圈式直線電動(dòng)機(jī)氣隙磁場(chǎng)解析分析[J]. 電工技術(shù)學(xué)報(bào), 2007, 20(5): 40-44.

Wang Shuhong, Xiong Guangyu. Analysis of air-gap field in a new tubular linear PM motor with moving coil[J]. Transactions of China Electrotechnical Society, 2007, 20(5): 40-44.

[42] Lu Haiwei, Zhu Jianguo, Lin Zhiwei, et al. A miniature short stroke linear actuator-design and analysis[J]. IEEE Transactions on Magnetics, 2008, 44(4): 497-504.

[43] Shinshi T, Shimizu D, Kodeki K, et al. A fast steering mirror driven by voice coil motors and supported by magnetic suspension[C]//International Conference on Mechatronics Technology, Salerno, Italy, 2019: 1-4.

[44] Meessen K J, Gysen B L J, Paulides J J H, et al. Halbach permanent magnet shape selection for slotless tubular actuators[J]. IEEE Transactions on Magnetics, 2008, 44(11): 4305-4308.

[45] Remy M, Lemarquand G, Castagnede B, et al. Ironless and leakage free voice-coil motor made of bonded magnets[J]. IEEE Transactions on Magnetics, 2008, 44(11): 4289-4292.

[46] Li Liyi, Huang Xuzhen, Pan Donghua, et al. Magnetic field of a tubular linear motor with special permanent magnet[J]. IEEE Transactions on Plasma Science, 2011, 39(1): 83-86.

[47] 石本義, 陳四海, 吳鑫, 等. 基于遺傳算法的音圈電機(jī)的優(yōu)化設(shè)計(jì)[C]//先進(jìn)光學(xué)技術(shù)及其應(yīng)用研討會(huì)論文集, 杭州, 中國(guó), 2009: 137-141.

[48] Yu Bin, Fu Hongwei, Wang Li. Electromagnetic field analysis and calculation of voice coil motor with a concentrated magnetic structure[C]//International Conference on Electrical Machines and Systems, Harbin, China, 2019: 1-4.

[49] Lemarquand V, Ravaud R, Lemarquand G. A new linear voice-coil motor for ironless loudspeakers: analytical study[C]//International Conference on Electrical Machines, Rome, Italy, 2010: 1-5.

[50] Xu Zhaoping, Chang Siqin. Improved moving coil electric machine for internal combustion linear generator[J]. IEEE Transactions on Energy Con- version, 2010, 25(2): 281-286.

[51] Li Liyi, Pan Donghua, Tang Yongbin, et al. Analysis of flat voice coil motor for precision positioning system[C]//International Conference on Electrical Machines and Systems, Beijing, China, 2011: 1-4.

[52] Wu Shuai, Jiao Zongxia, Yan Liang, et al. Deve- lopment of a direct-drive servo valve with high- frequency voice coil motor and advanced digital controller[J]. IEEE/ASME Transactions on Mechatronics, 2014, 19(3): 932-942.

[53] Dong Liang, Chen Jinhua, Zhang Chi, et al. A novel voice coil motor used in nano-positioning device[C]// International Conference on Electrical Machines and Systems, Pattaya, Thailand, 2015: 1997-2002.

[54] Dong Liang, Chen Jinhua, Zhang Chi, et al. Design and comparison of three-type VCMs for nano- positioning system[C]//IEEE 11th Conference on Industrial Electronics and Applications, Hefei, China, 2016: 656-1660.

[55] Yan Liang, Zhang Lei, Jiao Zongxia, et al. Armature reaction field and inductance of coreless moving-coil tubular linear machine[J]. IEEE Transactions on Industrial Electronics, 2014, 61(12): 6956-6965.

[56] Yu Bin, Fu Hongwei, Wang Li. Electromagnetic field analysis and calculation of voice coil motor with a concentrated magnetic structure[C]//International Conference on Electrical Machines and Systems, Harbin, China, 2019: 1-4.

[57] Luo Ciyong, Sun Jun, Liao Yong, et al. Analysis and design of ironless toroidal winding of tubular linear voice coil motor for minimum copper loss[J]. IEEE Transactions on Plasma Science, 2019, 47(5): 2369- 2375.

[58] Sanada M, Morimoto S. Experimental verification of thrust improvement in voice coil linear actuator using combined wire of copper and iron[C]//IEEE Industry Applications Annual Meeting, New Orlearns, USA, 2007: 490-494.

[59] Cakal G, Zeinali R, Keysan O. Design and optimi- zation of reduced torque ripple rotary voice coil motor[C]//International Conference on Electrical Machines, Alexandroupoli, Greece, 2018: 663-669.

[60] Guo Hong, Wang Dayu, Xu Jinquan. Research on a high-frequency response direct drive valve system based on voice coil motor[J]. IEEE Transactions on Power Electronics, 2013, 28(5): 2483-2492.

[61] 林兼. 音圈電機(jī)的型式和性能[J]. 電子計(jì)算機(jī)動(dòng)態(tài), 1978(7): 62-68.

Lin Jian. Type and performance of voice coil motor[J]. Journal of Computer Research and Deve- lopment, 1978(7): 62-68.

[62] Chi Feng, Wu Liwei, Yang Xiaofeng. Optimum design of voice coil motor using for nano-stage in lithographic equipment[C]//Proceeding of the 11th World Congress on Intelligent Control and Auto- mation, Shenyang, China, 2014: 2540-2543.

[63] Kim C, Kim Y. Design and analysis of linear voice coil motor for automatic transmission[C]//International Conference on Electrical Machines and Systems, Chiba, Japan, 2016: 1-5.

[64] Liu Yu, Zhang Ming, Zhu Yu, et al. Optimization of voice coil motor to enhance dynamic response based on an improved magnetic equivalent circuit model[J]. IEEE Transactions on Magnetics, 2011, 47(9): 2247- 2251.

[65] Smith K J, Graham D J, Neasham J A. Design and optimization of a voice coil motor with a rotary actuator for an ultrasound scanner[J]. IEEE Transa- ctions on Industrial Electronics, 2015, 62(11): 7073- 7078.

[66] 張弛, 湯廷孝, 鄧益民. 設(shè)計(jì)輔助齒抑制永磁同步直線電機(jī)端部效應(yīng)[J]. 機(jī)械制造, 2018, 56(11): 45-49.

Zhang Chi, Tang Tingxiao, Deng Yimin. Design auxiliary teeth to suppress the end effect of permanent magnet synchronous linear motor[J]. Machinery, 2018, 56(11): 45-49.

[67] Lee S G, Kim S A, Saha S, et al. Optimal structure design for minimizing detent force of PMLSM for a ropeless elevator[J]. IEEE Transactions on Magnetics, 2014, 50(1): 1-4.

[68] Kim Y, Sohn B, Youm W, et al. Voice coil motor nano stage with an eddy current damper[C]// International Conference on Control, Automation, Robotics and Vision, Hanoi, Vietnam, 2008: 1714- 1717.

[69] Luo Ciyong, Sun Jun, Wang Xiaowei, et al. Design of voice coil motor with the forward winding for linear vibro-impact systems[J]. IEEE Transactions on Magnetics, 2017, 53(8): 1-9.

[70] Luo Ciyong, Lin Zhonglan, Sun Jun. Design of linear voice coil motor with semi-closed structure[J]. IET Electric Power Applications, 2019, 13(10): 1574- 1579.

[71] Luo Ciyong, Li Xingwang, Liao Yong, et al. Design of end-iron-free voice coil motor with appropriate PM length ratio[J]. IEEE Transactions on Energy Conversion, 2020, 35(2): 1139-1146.

[72] Jun H W, Seol H S, Lee J. Effect of pole-slot combination on eddy-current formation in PMSM rotor assembly including retaining plate structure[J]. IEEE Transactions on Magnetics, 2017, 53(11): 1-5.

[73] Jun H W, Lee J, Lee H W, et al. Study on the optimal rotor retaining sleeve structure for the reduction of eddy-current loss in high-speed SPMSM[J]. IEEE Transactions on Magnetics, 2015, 51(3): 1-4.

[74] Luo Ciyong, Zhao Rui. Analysis and restraining of eddy current damping effect in linear voice coil motor[J]. IET Electric Power Applications, 2019, 14(5): 837-842.

[75] Zhang Zijiao, Zhou Haibo, Duan Jian, et al. Design and analysis of two-degree-of-freedom voice coil motors for linear-rotary motion[C]//International Conference on Electrical Machines and Systems, Chiba, Japan, 2016: 1-6.

[76] Luo Meizhu, Zhou Haibo, Duan Jian, et al. Design and analysis of a servo control system for a novel linear-rotary voice coil motor[C]//International Con- ference on Electrical Machines and Systems, Chiba, Japan, 2016: 13-16.

[77] Zhang Zijiao, Zhou Haibo, Duan Jian. Design and analysis of a high acceleration rotary-linear voice coil motor[J]. IEEE Transactions on Magnetics, 2017, 53(7): 1-9.

[78] Zhang Zijiao, Luo Meizhu, Zhou Haibo, et al. Design and analysis of a novel two-degree-of-freedom voice coil motor[J]. IEEE/ASME Transactions on Mechatronics, 2019, 24(6): 2908-2918.

[79] Luo Meizhu, Zhang Zijiao, Luo Chaoqun. Analysis and optimization on armature reaction of a rotary- linear voice coil motor[C]//International Conference on Electrical Machines and Systems, Harbin, China, 2019: 1-4.

[80] Liu C S, Ko S S, Lin P D. Experimental characteri- zation of high-performance miniature auto-focusing VCM actuator[J]. IEEE Transactions on Magnetics, 2011, 47(4): 738-745.

[81] Lai L K, Tsai C L, Liu T S. Design of compact linear electromagnetic actuator for auto-focusing in phone camera[J]. IEEE Transactions on Magnetics, 2011, 47(12): 4740-4744.

[82] Hsieh C L, Liu C S. Design of a voice coil motor actuator with l-shape coils for optical zooming smartphone cameras[J]. IEEE Access, 2020, 8: 20884-20891.

[83] Jeong J, Jo J, Park K. Characteristic analysis and improvement of VCM/PZT driven xy nanostage for atomic force microscope[C]//International Conference on Control, Automation and Systems, Gwangju, South Korea, 2013: 1381-1383.

[84] Bang Y B, Lee C H, Cho S Y, et al. Design of a high-speed, short-stroke xy-stage with counter- balance mechanisms[C]//International Conference on Control, Automation and Systems, Busan, South Korea, 2015: 123-125.

Overview of Structure Optimization and Application of Voice Coil Motor

(School of Electrical Engineering and Automation Harbin Institute of Technology Harbin 150001 China)

Voice coil motor is a linear motor that can convert electrical energy into linear motion mechanical energy without any mechanical transmission. Due to the advantages of simple structure, small size, fast response speed, high positioning accuracy and easy control, voice coil motors are widely used in many electrical fields. This paper briefly described the theoretical basis of the voice coil motor, and explained the working principle, structural classification and characteristics of each structure of voice coil motor. Besides, based on the research of domestic and foreign scholars on the structure optimization of voice coil motor, this paper summarized the methods of improving the force constant and positioning accuracy of voice coil motor. Furthermore, the main application fields of voice coil motor were summarized, and their development trends and research hotspots were discussed and prospected.

Voice coil motor, structure optimization, force constant, positioning accuracy

TM359.9

10.19595/j.cnki.1000-6753.tces.200725

國(guó)家科技重大專項(xiàng)資助項(xiàng)目(2012ZX04001051)。

2020-06-30

2020-12-02

柴嘉偉 男,1994年生,碩士,研究方向?yàn)橛来烹姍C(jī)多目標(biāo)優(yōu)化。E-mail: 2482572585@qq.com(通信作者)

貴獻(xiàn)國(guó) 男,1972年生,博士,副教授,研究方向?yàn)樘胤N電機(jī)多物理場(chǎng)耦合優(yōu)化設(shè)計(jì)、永磁電機(jī)驅(qū)動(dòng)與控制。E-mail: xianggui@hit.edu.cn

(編輯 陳 誠(chéng))