汽車(chē)試制管理過(guò)程中數(shù)字化技術(shù)的應(yīng)用

吳志軒 吳展慧 岳雙成

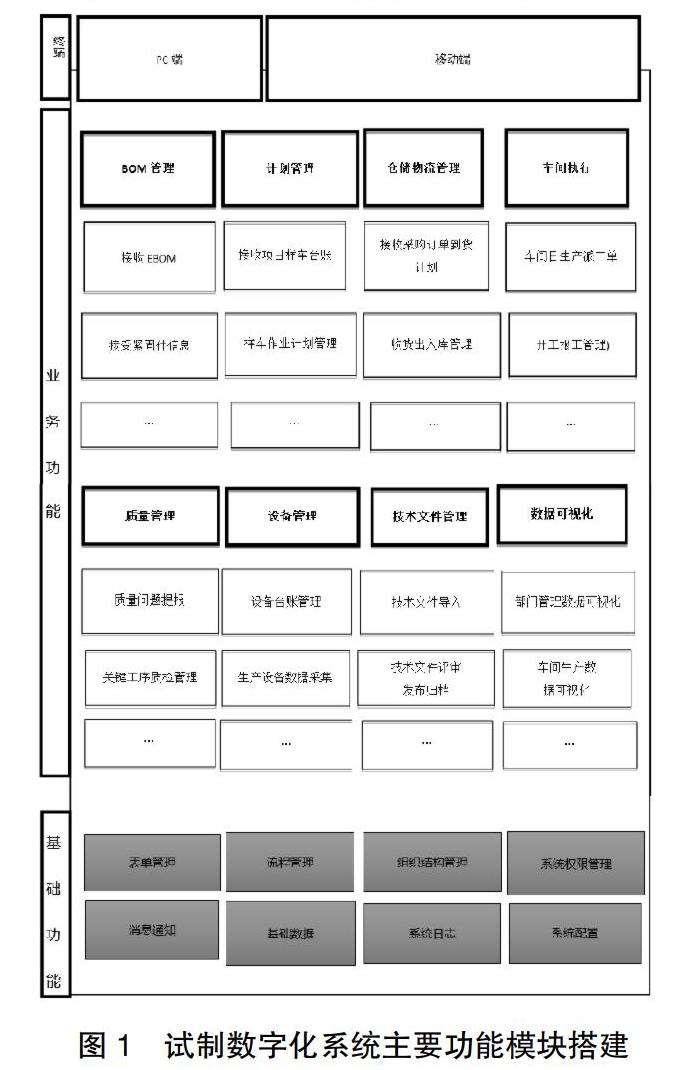

摘 要:文章介紹了在汽車(chē)研發(fā)過(guò)程中,對(duì)樣車(chē)試制階段應(yīng)用數(shù)字化技術(shù)提升其試制生產(chǎn)效率,消除試制信息孤島,對(duì)樣車(chē)研發(fā)試制各環(huán)節(jié)的實(shí)時(shí)數(shù)據(jù)監(jiān)控和生產(chǎn)管理。從系統(tǒng)角度應(yīng)用業(yè)務(wù)模塊化的管理理念,將試制全流程進(jìn)行模塊化管理,建設(shè)基于各模塊的樣車(chē)試制管理系統(tǒng)。在系統(tǒng)整合試制各業(yè)務(wù)模塊數(shù)據(jù)信息基礎(chǔ)上,開(kāi)發(fā)多款定制APP、前端數(shù)據(jù)可視化界面,并將其部署于移動(dòng)端、可視化拼接大屏、現(xiàn)場(chǎng)顯示終端等設(shè)備,最終實(shí)現(xiàn)對(duì)樣車(chē)試制全方位、各領(lǐng)域業(yè)務(wù)流程的數(shù)字化系統(tǒng)管理。

關(guān)鍵詞:數(shù)字化;管理系統(tǒng);試制;信息孤島

中圖分類(lèi)號(hào):U461.99? 文獻(xiàn)標(biāo)識(shí)碼:A? 文章編號(hào):1671-7988(2020)17-228-03

Application of Digital Technology in the Process of Automobile Trial

Production Management

Wu Zhixuan, Wu Zhanhui, Yue Shuangcheng

( Guangzhou Automobile Group Co., Automotive Engineering Institute, Guangdong Guangzhou 511434 )

Abstract: This article introduces the application of digital methods to the prototype production stage in the automobile R & D process to improve its production efficiency, eliminate the information island of the trial production, and real-time data monitoring and production management of all aspects of the prototype development. From the perspective of the system, the business modular management concept is applied, the entire process of trial production is modularly managed, and a prototype production trial management system based on each module is constructed. On the basis of system integration and trial production of various business module data information, develop a variety of customized APPs, front-end data visualization interfaces, and deploy them on mobile devices, visual splicing large screens, on-site display terminals and other equipment, and finally achieve a full range of prototype car trial production 3. Digital system management of business processes in various fields.

Keywords: Digital; Management system; Trial production; Information island

CLC NO.: U461.99? Document Code: A? Article ID: 1671-7988(2020)17-228-03

引言

近年來(lái),我國(guó)的汽車(chē)行業(yè)快速發(fā)展,與之而來(lái)的在汽車(chē)研發(fā)領(lǐng)域,越來(lái)越多的研發(fā)車(chē)型與數(shù)量,同時(shí)伴隨著研發(fā)周期的進(jìn)一步壓縮,對(duì)汽車(chē)研發(fā)企業(yè)制造試制樣車(chē)的要求也越來(lái)越高。樣車(chē)試制過(guò)程中信息的及時(shí)共享與業(yè)務(wù)流程管理成為提升試制水平和研發(fā)效率的關(guān)鍵指標(biāo)。在試制過(guò)程中由于試制的不確定性及個(gè)性化需求特點(diǎn)的限制,試制方法及管理手段基本以人力為基礎(chǔ),信息溝通交互基本依靠研發(fā)人員的線(xiàn)下聯(lián)系,以及人工整理現(xiàn)場(chǎng)各類(lèi)圖表的方式進(jìn)行。而在現(xiàn)階段各行各業(yè)應(yīng)用信息化、數(shù)字化等的先進(jìn)管理手段大幅提升效率的背景下,汽車(chē)研發(fā)試制領(lǐng)域亟需進(jìn)行一次先進(jìn)管理手段的更新升級(jí)。

數(shù)字化管理手段作為管理模式的前沿水平[1],主要是借助計(jì)算機(jī)和網(wǎng)絡(luò)技術(shù)的發(fā)展,將管理工作從粗放的事務(wù)型向精細(xì)的數(shù)據(jù)型量化、精準(zhǔn)化管理轉(zhuǎn)變的有效手段,通過(guò)大數(shù)據(jù)的分析去發(fā)現(xiàn)問(wèn)題,提供決策參考,大幅提升管理效能。……