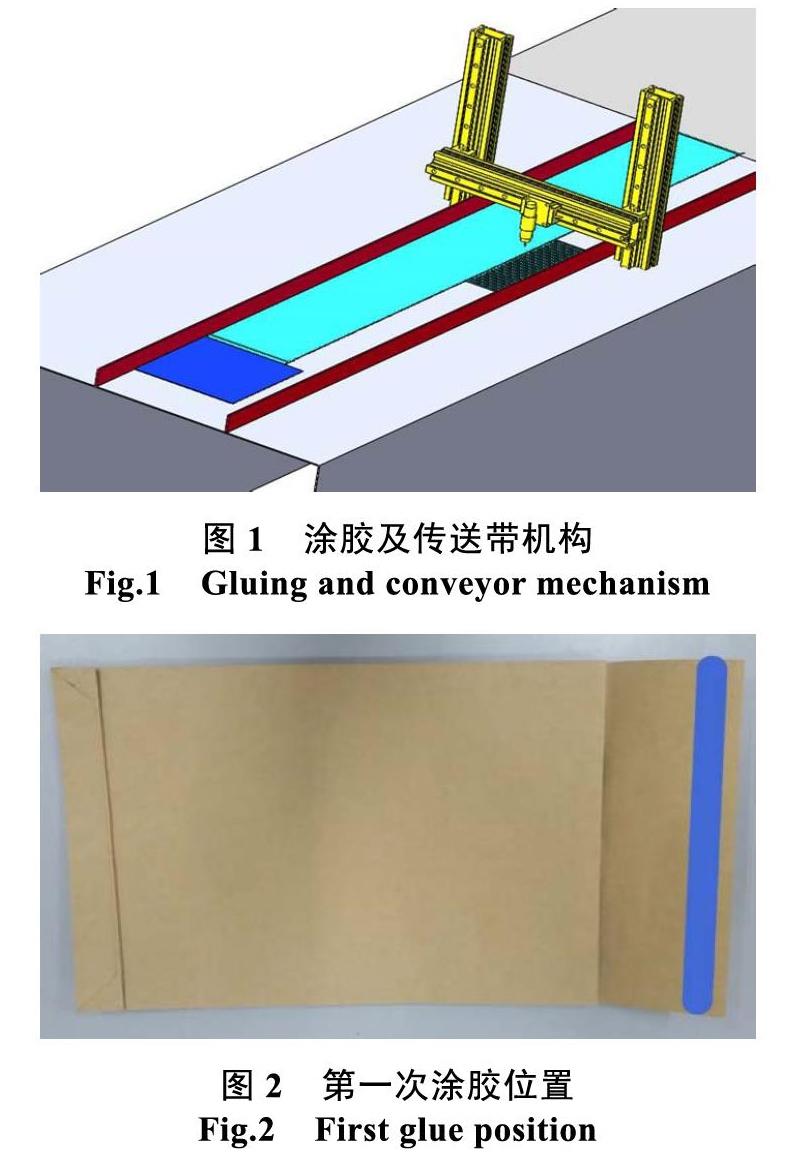

試卷袋密封及自動施膠控制流程研究

蔣銳,何邦貴,王巖,王超,姚傳紅

摘 ?要: 針對目前試卷袋手工封口和手工施膠入闈時間長、效率低、可靠性差等缺點,對具體的生產工藝過程、控制需求和控制元件進行了分析,并對控制方案進行選擇,確定以PLC控制作為最佳的控制方案,進行了PLC與伺服系統的連接和PLC與HMI通信連接,為進一步的具體控制實現,軟硬件的選型和編程提供了參考,為后續試卷袋密封及自動施膠自動化的實現打下了基礎。

關鍵詞: 試卷袋;封口;施膠;PLC

中圖分類號: TP273 ? ?文獻標識碼: A ? ?DOI:10.3969/j.issn.1003-6970.2019.12.017

本文著錄格式:蔣銳,何邦貴,王巖,等. 試卷袋密封及自動施膠控制流程研究[J]. 軟件,2019,40(12):7376

Research on Test Bag Sealing and Automatic Sizing Control Process

JIANG Rui1, HE Bang-gui1, WANG Yan1, WANG Chao2, YAO Chuan-hong3

(1. Kunming University of Science and Technology, Kunming 650500, China; 2. Yunnan Institute of Printing Technology,

Kunming 650231, China; 3. Yunnan Xinhua Fifth Printing Plant, Kunming 650224, China)

【Abstract】: In view of the shortcomings of manual sealing and manual sizing of the test bag, such as long time, low efficiency and poor reliability, the specific production process, control requirements and control components were analyzed, and the control scheme was selected to determine PLC control. The best control scheme, the connection between PLC and servo system and PLC and HMI communication connection, provide reference for further specific control implementation, software and hardware selection and programming, for subsequent test bag sealing and automatic glue automation. The realization laid the foundation.

【Key words】: Test bag; Sealing; Sizing; PLC

0 ?引言

試卷印制是一個復雜的技術過程,除了要保證傳統的印刷質量外,更重要的是在整個生產過程中的安全、保密以及試卷的時效性[1]。由于試卷產品的多變性和多樣性,導致對試卷袋密封和施膠工作長期停留在手工作業上,整個試卷的生產效率不高。而且未實現對試卷內容的保密,試卷印制企業需要對能接觸到試卷內容印、裝、封各環節工人進行大量時間的入闈管理[2]。傳統的手工生產越來越難以滿足社會考試的需求,因此,急需研發試卷袋密封等關鍵技術以及集成創新形成的自動化生產設備,來提高企業試卷的保密性和生產效率。隨著PLC(可編程邏輯控制器)的出現[3],運用PLC來實現在試卷袋密封及自動施膠流程的控制,將實現試卷袋生產自動化,減少試卷印制企業員入闈數量,提高試卷生產效率和可靠性。……