短程分子蒸餾技術精制巨尾桉葉精油工藝優化

胡雪芳,田志清,裴海生,張志民,王士奎

?

短程分子蒸餾技術精制巨尾桉葉精油工藝優化

胡雪芳,田志清,裴海生,張志民,王士奎※

(1. 農業部規劃設計研究院農產品加工工程研究所,北京 100125;2. 農業部農產品產后處理重點實驗室,北京 100121)

為了優化巨尾桉葉精油精制工藝,采用短程分子蒸餾,對初級桉葉精油中1,8-桉葉素和-蒎烯進行精制,研究不同溫度和壓力條件下2種物質分離特性。以巨尾桉葉為試驗材料,依次采用超臨界CO2萃取和分子蒸餾對其進行桉葉油樹脂提取和純化得到初級桉葉精油,采用二因素五水平的響應面優化試驗,將餾出物得率、餾出物中1,8-桉葉油素質量分數及-蒎烯質量分數、餾余物中1,8-桉葉油素質量分數及-蒎烯質量分數作為試驗指標,對分子蒸餾精制桉葉精油工藝進行優化研究。最優純化工藝條件:以餾出物為目標產物,蒸餾溫度38 ℃,蒸餾壓力41 Pa,餾出物中1,8-桉葉油素和-蒎烯的質量分數分別約為60.80%和31.58%,餾出物的得率為82.06%。分子蒸餾能夠對桉葉精油進行有效的純化精制,桉葉初級精油經過二級分子蒸餾精制后,1,8-桉葉油素和-蒎烯的質量分數分別提高了77.62%和56.72%。蒸餾溫度和蒸餾壓力對1,8-桉葉油素質量分數的影響均較-蒎烯明顯,同時,對于1,8-桉葉油素,蒸餾壓力的變化對其質量分數的影響較蒸餾溫度明顯,相反的,對于-蒎烯,蒸餾溫度對其質量分數影響更為顯著(<0.05),該研究結果可為分離提純2種物質提供技術參考。

蒸餾;壓力;溫度;桉葉精油;1,8-桉葉油素;-蒎烯;工藝優化

0 引 言

桉樹是中國最重要的經濟樹種之一,在中國廣西、廣東、云南等20多個省、市、自治區均有種植,面積已超過360萬hm2[1]。在桉樹種植區,大量桉葉作為木材生產的主要廢棄物幾乎未被加工利用,造成優質生物質資源的極大浪費。桉葉油是桉樹葉油腺細胞分泌出來的芳香精油,主要為萜品烯類化合物、芳香族類化合物和脂肪族類[2-5],是世界上十大精油品種之一。桉葉油具有抑菌消炎[6-7]、抗氧化[8-10]、抗腫瘤抗病毒[11-12]、殺蟲等活性[13-15],在食品、化工、醫藥、環境和能源等領域有廣泛應用[16-17]。

目前國內外對植物精油分離提取的方式主要有水蒸氣蒸餾法[18]、超聲波(微波)輔助提取法[19-21]、有機溶劑萃取法、超臨界提取法[22-24]和分子蒸餾等[25-30]。水蒸氣蒸餾法是最常用的方法,具有設備簡單、成本低等優點,但是由于需要較高的溫度,可能會使熱敏性成分發生熱分解,降低了精油產品質量;溶劑提取法具有操作簡單、產率高等特點,但是此方法由于溶劑殘留難以完全除去,一般適用于精油粗品提取;超臨界萃取法作為一種新型綠色的氣體-液分離技術,萃取速度快、效率高、能耗少,但設備投資較大,操作要求高,用簡單的超臨界萃取方法無法生產高純度的產品,還應考慮與其他分離、純化技術相結合[31-33]。中國作為世界桉葉油的主要供應國和出口國,開發新型高效桉葉油分離純化技術,提高其產品附加值有著重要意義。分子蒸餾(molecular distillation,MD)又稱為短程蒸餾(short path distillation, SPD),是隨著真空技術及真空蒸餾技術的發展而逐漸發展起來的一種特殊的液-液分離技術,它的原理是在高真空度條件下操作,依據分子運動平均自由程的差別,具有蒸餾壓力低、操作溫度低、受熱時間短、分離效率高等優點,特別適用于高分子量、高沸點、高粘度、熱敏性及易氧化物系的分離[34-37]。中國對于分子蒸餾技術的研究起步較晚,近年來作為精制、純化、除蠟手段在植物精油提取領域的研究成為熱點,在但是關于蒸餾參數對分餾物組分影響尚缺乏深入研究,在桉葉精油分離提取方面的應用研究甚少,1,8-桉葉油素和-蒎烯是桉葉精油的主要組分,在醫藥化工領域有著重要的應用。本文運用分子蒸餾技術對這2種物質進行分餾純化,探究不同操作參數下餾出物和餾余物中餾分組成的變化,并且以精油得率、1,8-桉葉素和-蒎烯質量分數作為指標,對工藝參數進行優化,旨在為桉葉精油的精制提供新的工藝思路和參考。

1 材料與方法

1.1 試驗材料

巨尾桉桉葉,由桂林集琦生化有限公司提供;正己烷(色譜級);1,8-桉葉素標準品(1,8-cineole,純度≥98%);-蒎烯標準品(-Pinene,純度≥98%),正十二烷標準品(Dodecane),購于美國Sigma-Aldrich公司。

1.2 儀器與試劑

2英寸刮膜式分子蒸餾器(美國Pope科學公司),安捷倫GC-7890A氣相色譜儀(美國安捷倫公司),BSA124S-CW電子天平(量程:120 g,精度:0.1 mg,德國Satorious公司),二氧化碳流體萃取裝置(大連卓爾高科技有限公司)。

1.3 試驗方法

1.3.1 桉葉初級精油的制備

桉葉油樹脂由超臨界二氧化碳流體萃取裝置,從巨尾桉桉葉中提取。CO2純度:99.99%。超臨界流體萃取條件如下:40 MPa萃取壓力、溫度50 ℃,60目粉碎粒度、CO2流速30 kg/h,分離壓力:8 MPa,分離溫度:60 ℃、提取時間2.5 h。桉葉油提取率為15.47%。初級分子蒸餾純化過程:量取桉葉油樹脂500 mL,加入進料瓶中,打開排氣閥,關閉進料閥,打開真空泵,將系統壓力設置為40 Pa,對物料進行脫氣工序。脫氣完成后,設置蒸餾溫度50 ℃,蒸餾壓力90 Pa,刮膜速度250~300 r/min,進料速度1滴/s,冷卻水溫度10 ℃,進料溫度35 ℃,所得桉葉精油得率為39.43%,1,8-桉葉素和-蒎烯質量分數分別為34.23%和20.15%。

1.3.2 定量測定方法

1,8-桉葉素和-蒎烯質量分數用氣相色譜儀測定,色譜柱選取DB-5毛細管柱(30.0 m×0.25 mm×0.25m),氣譜條件為:載氣高純度氮氣(99%),流速1.0 mL/min,進樣口溫度250 ℃,采用FID檢測器,檢測器溫度290 ℃,空氣流速為300 mL/min,氫氣流速30 mL/min。采用內標標準曲線法,以1,8-桉葉油素、-蒎烯與內標物的質量濃度比為縱坐標(),峰面積比為橫坐標(),進行性回歸分析計算結果。

1.3.3 中心旋轉復合設計

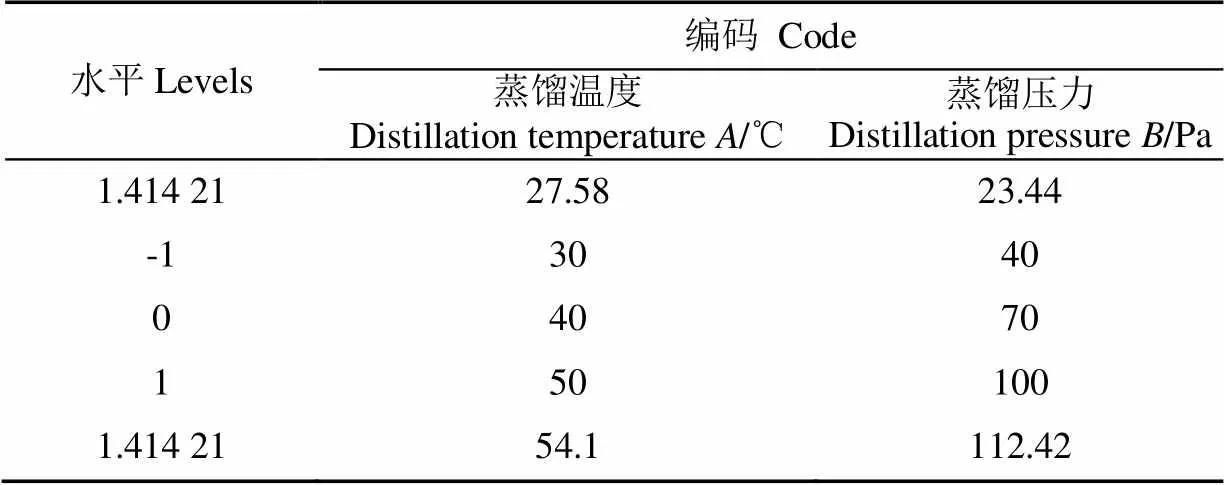

采用中心旋轉復合設計(central composite rotating design, CCRD)對分子蒸餾精制桉葉精油工藝進行優化研究。將餾出物得率(1)、餾出物中1,8-桉葉油素質量分數(2)及-蒎烯質量分數(3)、1,8-桉葉油素質量分數(4)及-蒎烯質量分數(5)作為試驗指標,考察蒸餾溫度與蒸餾壓力在試驗過程中對各試驗指標的影響,以得到最佳的工藝條件,分子蒸餾工藝其他試驗參數:刮膜速度250 r/min,進料速度1~2滴/s(3~4 mL/min),冷卻水溫度5 ℃,進料溫度30 ℃。因素水平編碼見表1。

1.4 數據處理

用Design expert(8.0.6,.,MN,USA)軟件對試驗數據進行擬合與統計分析,利用Duncan新復極差法對差異顯著性進行分析。

表1 中心組合設計各因素水平

2 結果與分析

2.1 試驗結果

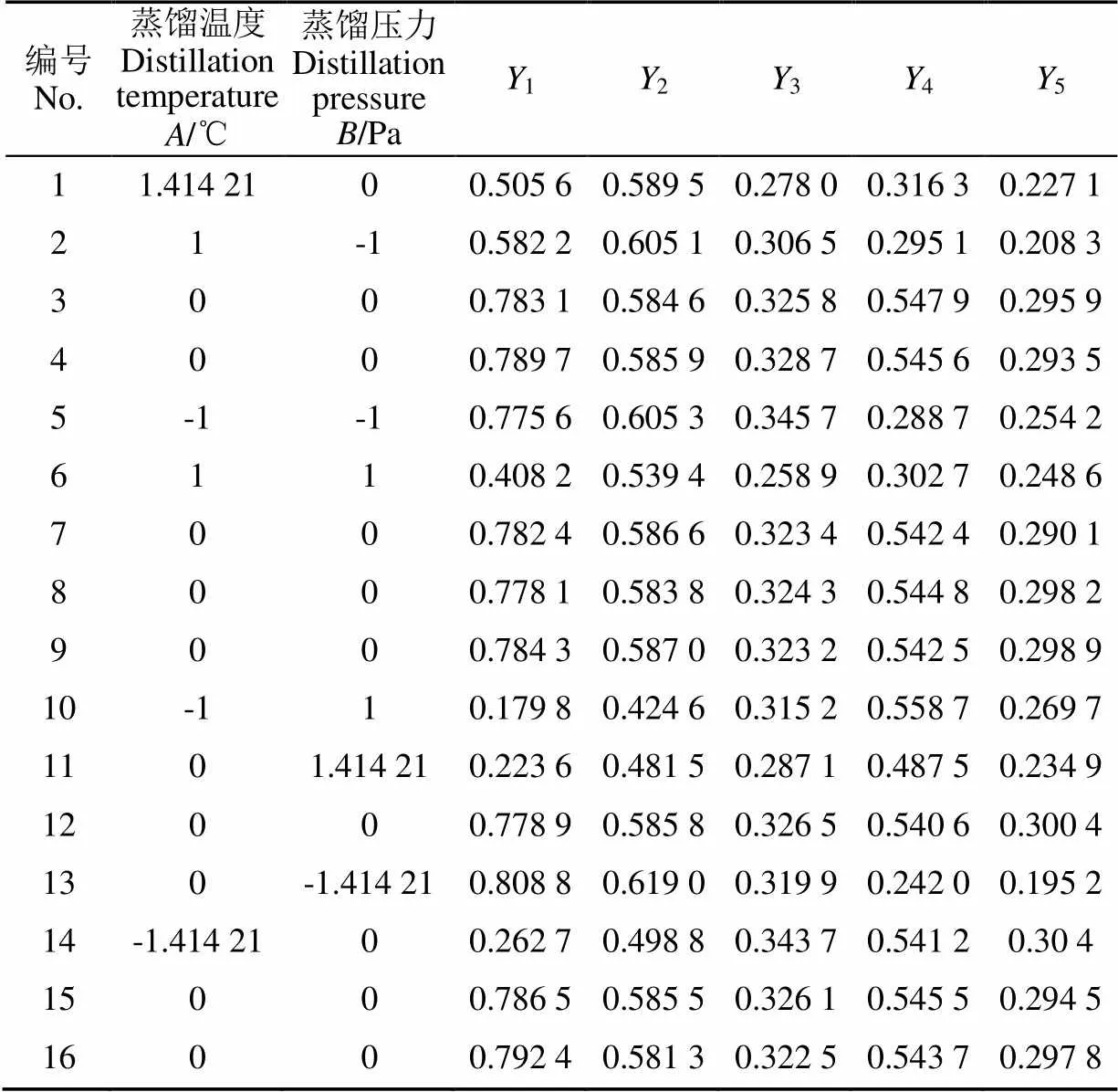

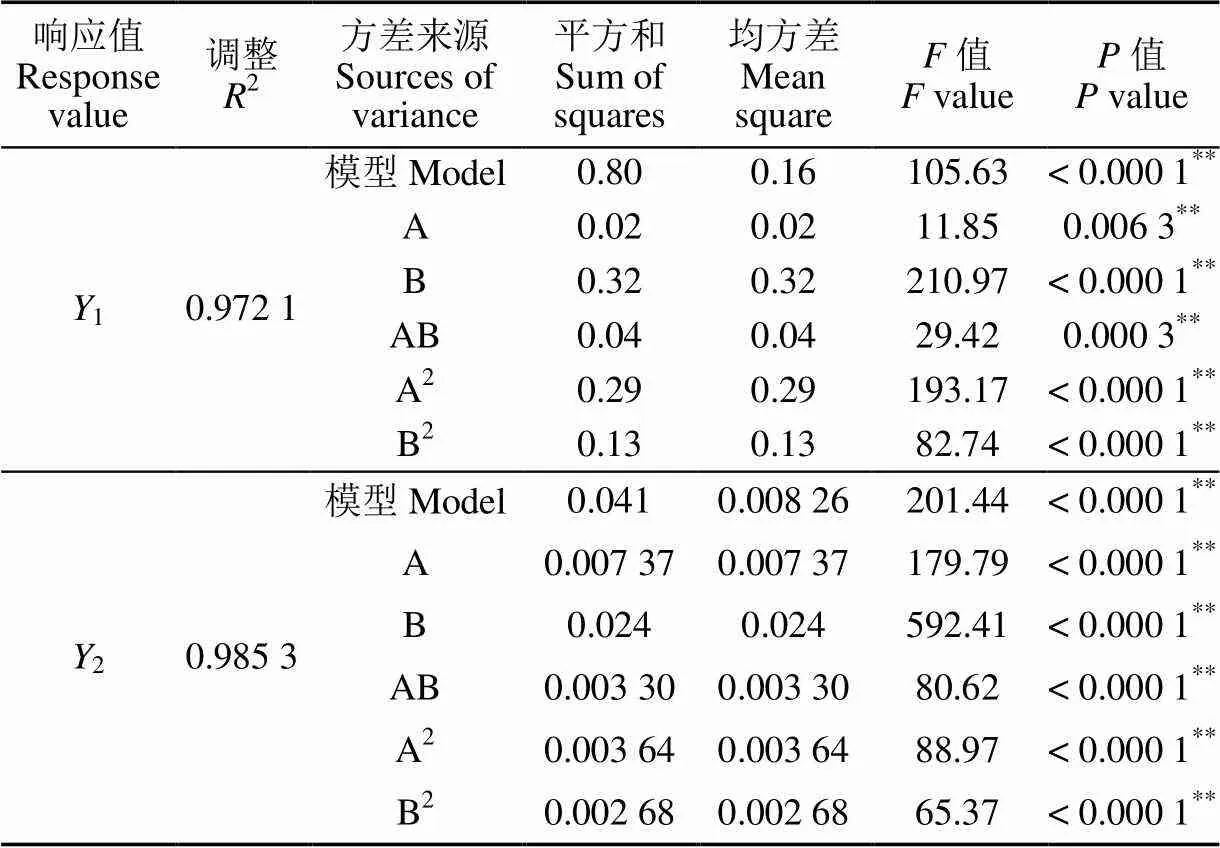

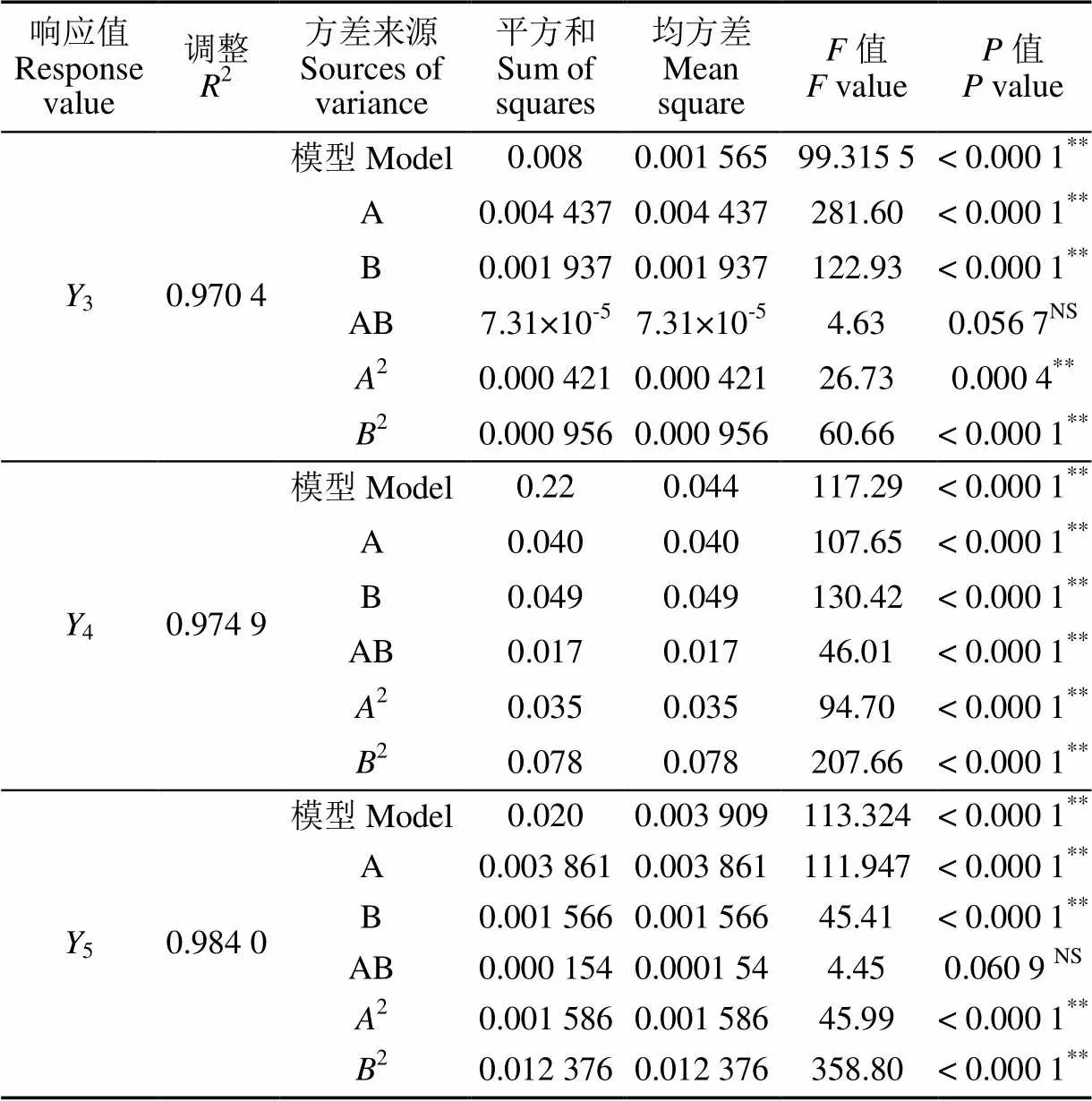

優化試驗結果如表2所示,所有試驗數據平行測定3次取平均值。蒸餾溫度及蒸餾壓力對各個響應值影響的方差分析及預測模型的回歸分析結果分別見表3。

表2試驗結果

Table 2 Experiment results

注:1、2、3、4與5分別為餾出物得率,餾出物中1,8-桉葉油素質量分數,-蒎烯質量分數,1,8-桉葉油素質量分數,-蒎烯質量分數。

表3 蒸餾溫度(A)與壓力(B)對各響應值影響的方差分析

續表

注:**代表<0.01,*代表0.01<<0.05,NS代表不顯著。

Note: ** means<0.01, * means 0.01<<0.05, NS means not significant.

2.2 餾出物得率響應面分析

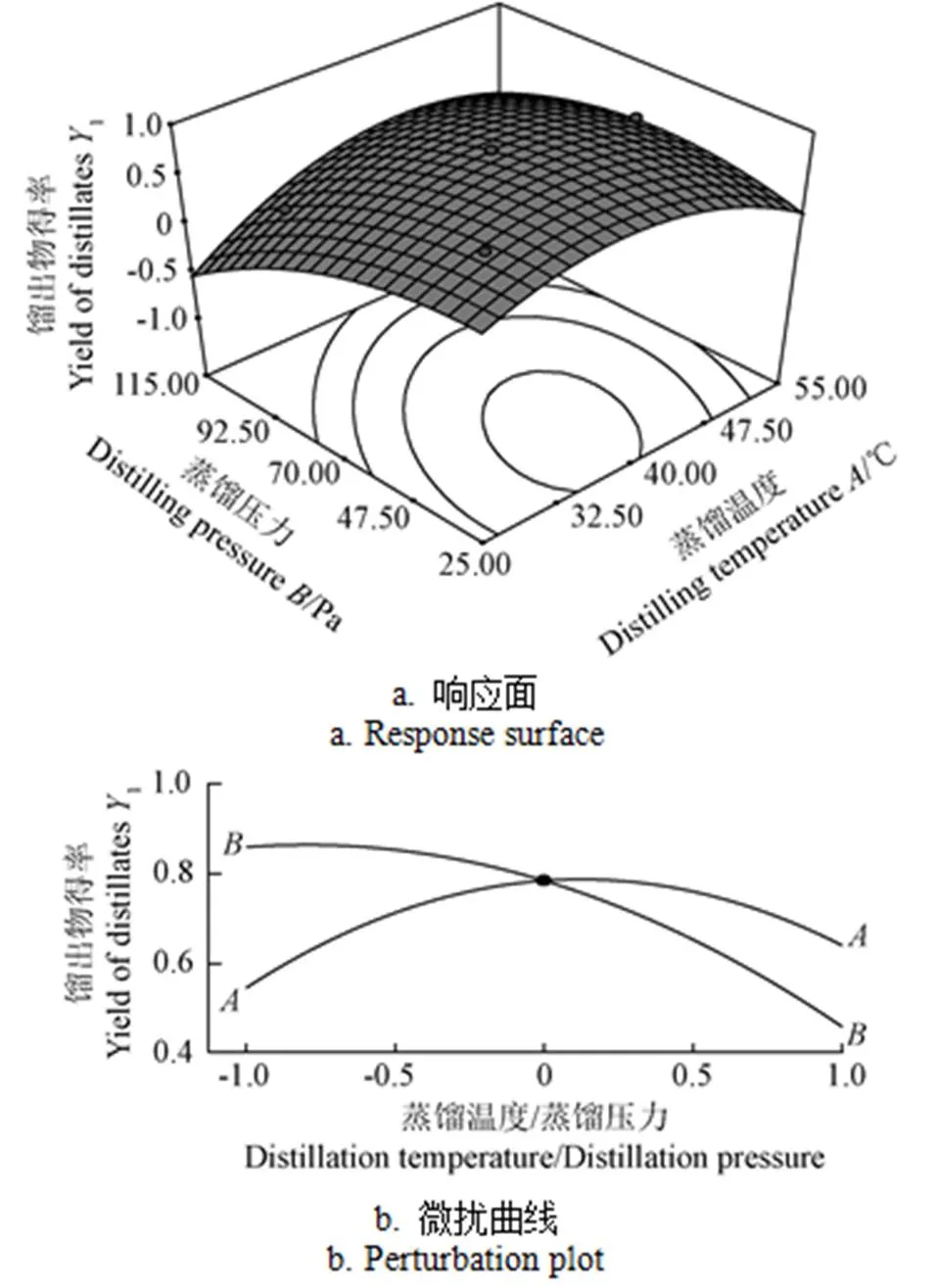

圖1a是蒸餾壓力、蒸餾溫度及其交互作用對餾出物得率影響的響應面模型圖。

圖1 蒸餾溫度和蒸餾壓力對精油得率影響的響應面和微擾曲線分析

從圖1a可以看出,在蒸餾溫度35 ℃、蒸餾壓力30 Pa左右餾出物得率最高。通過微擾曲線分析,進一步探討了自變量對響應值影響的變化規律(圖1b),參考點為優化設計空間的中點(T=40 ℃,P=70 Pa),由曲線可以看出,餾出物得率隨著溫度升高呈現先上升后下降的趨勢,這是由于隨著溫度的升高,大量的輕分子組分因為得到足夠的能量,其分子平均自由程變長,從而被冷凝器收集而進入餾出物中。相反的,當溫度繼續升高(>40℃)的時候,一部分分子由于碰撞頻繁和激烈,在冷凝面和蒸發面之間做無規則運動,無法及時被冷凝面收集,另外其質量分數在蒸餾體系內達到過飽和狀態,通過薄膜蒸發進入外置冷凝器中,導致餾出物得率的下降。由曲線可以看出,餾出物得率隨著蒸餾壓力的增加而下降,這是因為隨著壓力的不斷升高,物質分子的平均自由程迅速降低,越來越多的組分無法被冷凝器捕集到,使餾出物的得率變小[38]。由表3可以看出,蒸餾溫度及其平方項、蒸餾壓力及其平方項、以及兩者的交叉項對餾出物得率的影響都達到極顯著水平。

餾出物得率的二次回歸模型為(編碼水平)

1=+0.78+0.047?0.20+0.11?0.192?0.132(3)

方程的矯正2為0.97,說明該方程模擬良好。

2.3 蒸餾溫度及蒸餾壓力對1,8-桉葉油素和α-蒎烯質量分數的影響分析

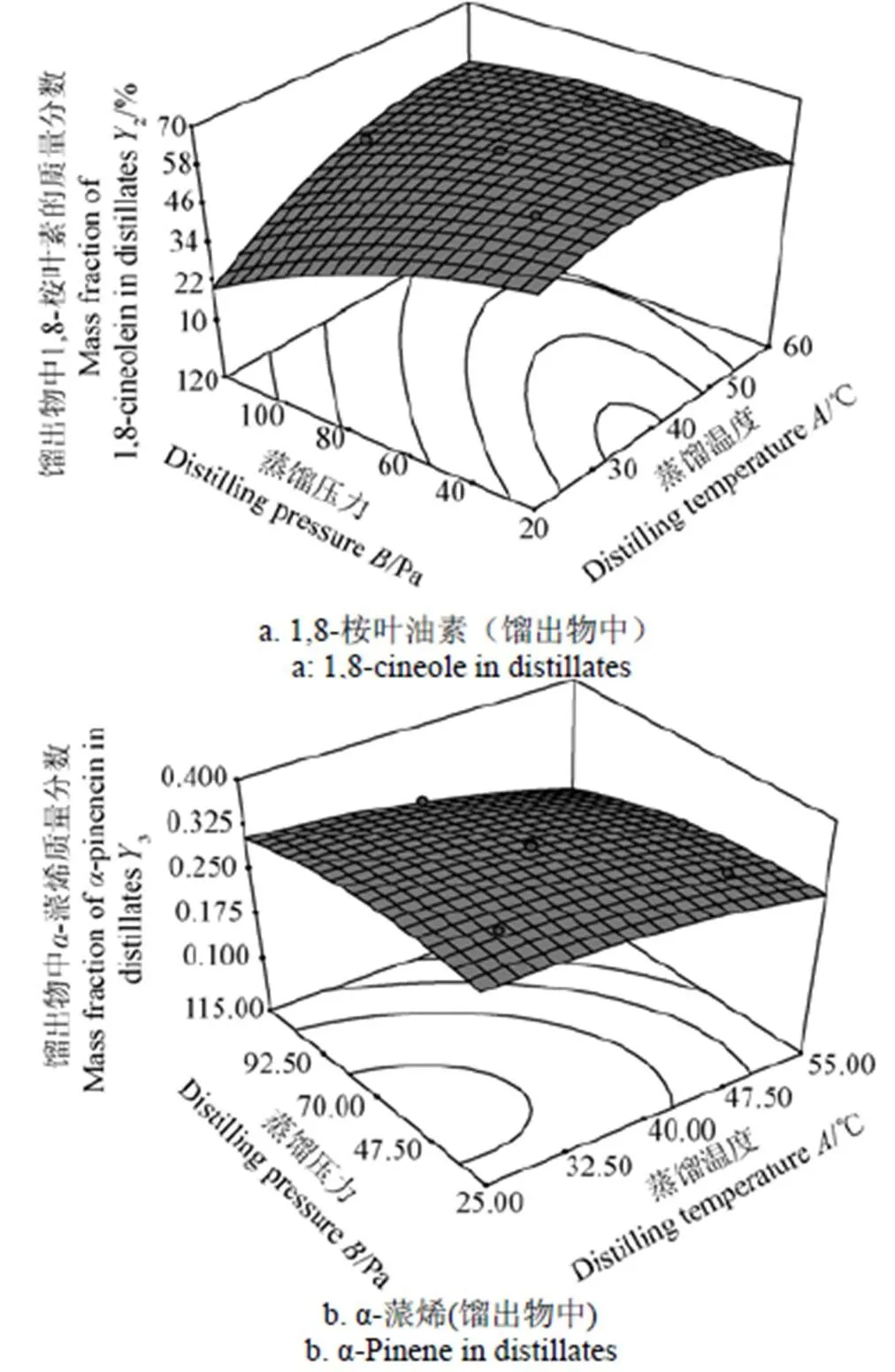

2.3.1 餾出物中1,8-桉葉油素和-蒎烯質量分數響應面分析

根據試驗結果,得出餾出物中1,8-桉葉油素質量分數與各因素之間關系的二階回歸方程(編碼水平)如下。

2=+0.59+0.030?0.055+0.029?0.0212?0.0182(4)

3=+0.33?0.024?0.016?7.256×10-32?0.0112(5)

1,8-桉葉油素模型矯正2=0.985 3,-蒎烯模型矯正2=0.964 0,回歸方程與響應值具有高度的擬合性。從表3的方差分析可以看出,蒸餾溫度及其平方項,蒸餾壓力及其平方項以及蒸餾溫度與蒸餾壓力的交互項對1,8-桉葉油素質量分數的影響均達到極顯著水平(<0.01),蒸餾溫度、蒸餾壓力及其平方項對-蒎烯質量分數的影響達到極顯著水平,而溫度的平方項、溫度及壓力的交互項對其影響不顯著。

由圖2a響應曲面圖可以看出,1,8-桉葉油素質量分數隨著蒸餾壓升高逐漸降低,隨著蒸餾溫度的升高呈現先升高后降低的趨勢,在試驗設計空間內,蒸餾溫度30~40℃和蒸餾壓力30~40 Pa的區域內,1,8-桉葉油素的質量分數達到最高值。由圖2b可看出,-蒎烯隨著蒸餾溫度及壓力的升高均呈現下降趨勢,因此,低溫低壓的蒸餾體系更有利于提取-蒎烯。

2.3.2 餾余物中1,8-桉葉油素和-蒎烯質量分數響應面分析

餾余物中1,8-桉葉油素質量分數與各因素之間關系的二階回歸方程如下

4=+0.74?0.055+0.064?0.051?0.0512?0.0782(6)

5=+0.30?0.021+0.014?0.0142?0.0392(7)

餾余物中1,8-桉葉油素和-蒎烯模型矯正2值均大于97%,表示響應值中97%以上變異可以由自變量來解釋,兩個模型可以準確測定1,8-桉葉油素和-蒎烯的質量分數。由表3的方差分析得出,蒸餾溫度,蒸餾壓力以及兩者的平方項和交互項對餾余物中1,8-桉葉油素和-蒎烯質量分數的影響都達到極顯著水平(<0.01)。

由圖2c,2d可看出,低溫高壓條件下更有利用餾余物中1,8-桉葉油素、-的的富集。在溫度35℃、壓力93 Pa左右餾余物中1,8-桉葉油素質量分數達到最大值,-蒎烯質量分數在30℃和75 Pa左右參數條件下達到最大。

2.4 分子蒸餾過程中1,8-桉葉油素與α-蒎烯分子分離特性研究

微擾曲線(perturbation plot)可在響應優化曲面特定區域比較各自變量對響應值的影響[39],本文將參考點設為優化設計空間的中點(T=40℃,P=70 Pa),進一步探討了蒸餾溫度與蒸餾壓力對兩種物質分子分離特性的影響。

2.4.1 蒸餾溫度對2種物質質量分數變化的影響

從圖3a,3b,3c和3d中的曲線可以看出,在餾出物和餾余物中,蒸餾溫度對2種物質的質量分數的影響都呈負相關。在餾出物中,1,8-桉葉油素質量分數隨著溫度的升高而升高,在餾余物中,隨著蒸餾溫度的升高,1,8-桉葉油素質量分數呈逐漸下降趨勢,這是因為隨著溫度的增加,1,8-桉葉油素分子因為獲得足夠的熱量而被冷凝器捕集進入餾出物。-蒎烯質量分數的變化則較為復雜,由圖3b、圖3d可以看出-蒎烯質量分數隨著溫度的升高均呈下降趨勢。究其原因,由于-蒎烯其分子的易揮發特性,蒸餾過程中,隨著溫度升高會有一部分通過薄膜蒸發進入外置冷凝器中,同時蒸發溫度的升高,使得蒸汽分子到達冷凝面冷凝時釋放大量的冷凝熱,使冷凝液膜表面溫度上升,導致冷凝面的液膜表面分子再蒸發速率增大[40],降低了-蒎烯的富集效率,越來越多-蒎烯分子從餾余物中逸出,在蒸發面和冷凝面之間的氣相空間內做無規則的分子碰撞,無法被冷凝面有效富集,造成了餾出物中-蒎烯質量分數的下降。

2.4.2 蒸餾壓力對2種物質質量分數變化的影響

從圖3a,3b,3c和3d中的曲線可以看出可以看出,在餾出物與餾余物中,蒸餾壓力對2種物質的質量分數的影響呈正相關。在餾出物中,隨著蒸餾壓力的升高兩種物質的質量分數均下降。在餾余物中,2種物質的質量分數隨著壓力的升高而不斷升高,在90 Pa左右達到峰值,而后呈下降趨勢。這是由于隨著系統壓力的上升,2種物質的產率迅速下降,越來越多的1,8-桉葉油素和-蒎烯分子因為分子平均自由程太小無法被冷凝面捕集,而停留在餾余物中。而當蒸餾壓力超過90 Pa的時候,很多小分子物質也開始無法充分到達冷凝面而被富集在餾出物中,降低分餾效果,導致1,8-桉葉油素質量分數和-蒎烯質量分數同時下降。

另外,從圖3a、3b、3c、3d的、曲線弧度、以及表3方差分析中的值大小可以看出,在餾出物及餾余物中,蒸餾溫度和蒸餾壓力對1,8-桉葉油素質量分數的影響均較-蒎烯明顯,同時,對于1,8-桉葉油素,蒸餾壓力的變化對其質量分數的影響較蒸餾溫度明顯,相反的,對于-蒎烯,蒸餾溫度對其質量分數影響更為顯著,且溫度與壓力的交互作用對-蒎烯質量分數的影響不顯著,這可為分離提純2種物質提供了一定的技術參考。

圖3 蒸餾溫度和蒸餾壓力對餾出物、餾余物中1,8-桉葉油素、α-蒎烯質量分數影響的微擾分析

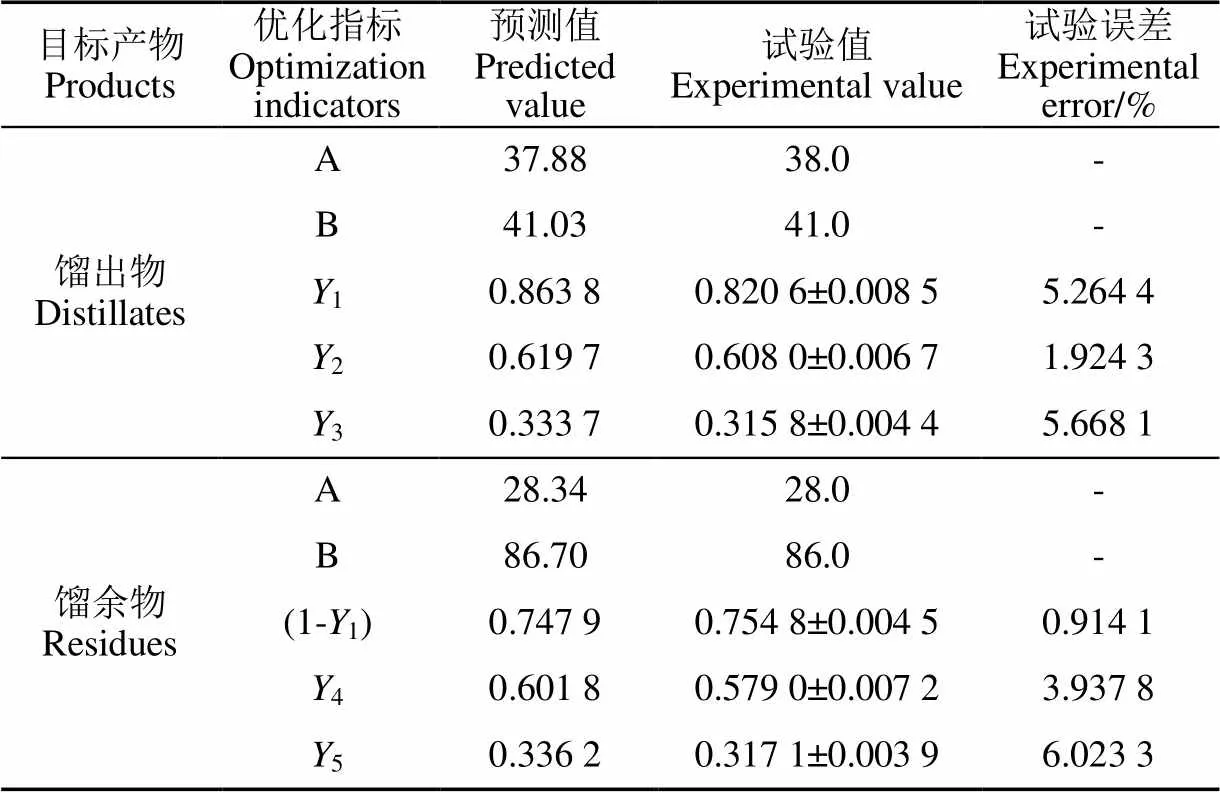

2.5 最終優化與驗證

采用Design Export7.0中多響應值優化數據處理系統對蒸餾溫度和蒸餾壓力進行了優化,分別以餾出物和餾余物作為目標產物,以獲最高的1,8-桉葉油素質量分數和-蒎烯質量分數,并兼顧純化產品得率較高作為優化指標,進行優化設計和驗證試驗。由表4可以看出,方案一:以餾出物為目標產物,以獲高質量分數1,8-桉葉油素和-蒎烯(2、3),高得率餾出物(1)作為優化指標、得到最佳的操作參數為:蒸餾溫度38 ℃,蒸餾壓力41 Pa,在此條件下,餾出物中1,8-桉葉油素和-蒎烯的質量分數分別為60.80%±0.67%和31.58%±0.44%,餾出物的得率為82.06%±0.85%,1,8-桉葉油素和-蒎烯質量分數分別提高了77.62%和56.72%;方案二:以餾余物為目標產物,以獲最高質量分數1,8-桉葉油素和-蒎烯(3、5),高得率餾余物(1-1)作為優化指標,得到最佳的操作參數為:蒸餾溫度28℃,蒸餾壓力86 Pa,餾余物中1,8-桉葉油素和-蒎烯的質量分數分別為57.90%±0.72%和31.71%±0.39%,餾余物的得率為75.48%±0.45%。其中,方案一所得優化產物中1,8-桉葉油素和精油得率分別比方案二高出2.90%、6.58%,-蒎烯質量分數相當,因此就產品純度及得率來講,方案一工藝條件優于方案二,但方案一所需蒸餾溫度高于方案二10℃、蒸餾壓力低于方案二45 Pa(真空度高于方案二45 Pa),因此從節能方面、對設備的保護性以及操作便易性方面考慮,方案二略有優勢。本試驗中選取方案一作為最終優化方案。

表4 最優工藝參數及驗證試驗結果

注:驗證試驗重復3次。

Note: Verification testing data were mean values of triplicate determinations.

3 討 論

不同桉樹品種揮發油質量分數及成分存在很大差異[41]。比如,窿緣桉和尾葉桉揮發油主要化學成分(>10%)為-蒎烯和1,8-桉葉油素[42-43],檸檬桉葉油的化學成分主要是香茅醛[5]、藍桉葉油主要化學成分為1,8-桉葉油素,本研究采用的巨尾桉,其桉葉揮發油主要成分為1,8-桉葉油素和-蒎烯,與周莉君等測定結果一致[44,2]。國內外對于桉葉揮發油主成分提純的研究集中在對1,8-桉葉油素的提純,王健英等[45-47]利用水蒸氣蒸餾法提純1,8-桉葉油素,但由于桉葉油對熱、氧較敏感,長時間與水共沸易引起氧化、聚合等變性反應,很難保持揮發油原有品質。應安國等[48]采用間歇真空精餾技術對桉葉油粗品進行多步驟分離得到的1,8-桉葉油素質量分數在99%上,但其采用的桉葉油為多次精餾后的產品,初始濃度高達75.48%,因此其間歇精餾效果有待考究。張廣求等[49-50]利用減壓蒸饋法和熔融結晶法串聯將1,8-桉葉油質量分數分別提高了45.0%和58.41%,以上研究涉及兩種單元操作,工藝耗時長,且結晶的效果較差;欒國顏等[51]通過添加第3組分提純-蒎烯,此方法涉及外來組分的添加,為后續純化帶來一定麻煩。郭文生等[52]利用包結物晶析法純化辛夷揮發油中的1,8-桉葉油素,得到質量分數>98%的1,8-桉葉油素,但是過程操作繁瑣,一次只能處理3 g辛夷揮發油,效率較低。劉文婷[53]等利用低溫控溫結晶法分離提純1,8-桉葉油素,將原料由63.24%提升至了89.63%,但產品收率僅為4.13%。且對于桉葉精油的分離與純化,其過程通常占生產成本的50%~70%,甚至高達90%[54],步驟多、耗時長,往往成為制約生產的瓶頸。

本研究主要應用分子自由程理論,從響應值的變化趨勢初步探討了蒸餾溫度與蒸餾壓力對1,8-桉葉油素和-蒎烯的分離特性。由于關于分子蒸餾過程的基礎理論研究很少,分子蒸餾過程研究涉及到流體的流動、傳熱、傳質等很多問題,而刮膜式分子蒸餾器內的流體流動及傳熱傳質過程非常復雜,進料速度、刮膜速度、物料組成與性質對蒸餾效率及蒸餾過程中桉葉精油中各組分在體系中的分配都有著不同程度的影響[55-56],且關于應用分子蒸餾技術純化分離1,8-桉葉油素和-蒎烯的研究較少,利用分子蒸餾進一步分離1,8-桉葉油素和-蒎烯研究有待進一步探討。

4 結 論

本試驗以提高1,8-桉葉油素和-蒎烯純度作為雙指標,采用分子蒸餾對桉葉初級精油進行了進一步精制,綜合考察了蒸餾溫度與蒸餾壓力對餾出物得率,餾出物中1,8-桉葉油素質量分數和-蒎烯質量分數,餾余物中1,8-桉葉油素質量分數和-蒎烯質量分數的影響,得到最優精制工藝條件:以餾出物為目標產物,蒸餾溫度38 ℃,蒸餾壓力41 Pa,在此條件下,餾出物的得率為82.06%,餾出物中1,8-桉葉油素和-蒎烯的質量分數分別約為60.80%和31.58%,較一級分子蒸餾所得初級桉葉精油中質量分數分別提高了77.62%和56.72%。在工藝方面,分子蒸餾法與傳統分離方法相比,可最大限度保持物料純天然特性,操作簡單,可明顯降低能耗,節約時間,提高分離效率。

[1] 黃承標,楊錦仁,魏國余,等. 桉樹林地枯枝落葉層的水文恃性及養分貯量[J]. 福建林學院學報,2011,31(4):289-294.

Huang Chengbiao, Yang Jinren, Wei Guoyu, et al. Hydrological characteristics and nutrient storage of litterfall in Eucalyptus sp. plantation[J]. Journal of Fujian College of Forestry, 2011, 31(4): 289-294. (in Chinese with English abstract)

[2] 黃增. 巨尾桉有效成分的提取分離及其生物活性研究[D]. 南寧:廣西大學,2012.

Huang Zeng. Study on the Extraction, Separation Technology and Bioactivity of Effective Components From Eucalyptus GrandisE.urophylla[D]. Nanning: Guangxi University, 2012. (in Chinese with English abstract)

[3] Macedo I T, Bevilaqua C M, De Oliveira L, et al. Anthelmintic effect of eucalyptus staigeriana essential oil against goat gastrointestinal nematodes[J]. Veterinary Parasitology, 2010, 173(1): 93-98.

[4] Elaissi A, Salah K H, Mabrouk S, et al. Antibacterial activity and chemical composition of 20 eucalyptus species’ essential oils[J]. Food Chemistry, 2011, 129: 1427-1434.

[5] 田玉紅,劉雄民,周永紅,等. 檸檬桉葉揮發油成分的提取及成分分析[J]. 色譜,2005,23(6):651-653.

Tian Yuhong, Liu Xiongmin, Zhou Yonghong, et al. Extraction and determination of volatile constituents in leaves of eucalyptus citriodora[J]. Chinese Journal of Chromatography, 2005, 23(6): 651-653. (in Chinese with English abstract)

[6] Ramezani H, Singh H, Batish D, et al. Antifungal activity of the volatile oil of eucalyptus citriodora[J]. Fitoterapia, 2002, 73(3): 261-262.

[7] Merih S, Resat D. Investigation of effect of 1,8-cineole on antimicrobial activity of chlorhexidine gluconate[J]. Pharmacognosy Res, 2017, 9(3): 234-237

[8] Singh H P, Kaur S, Negi K, et al. Assessment of in vitro antioxidant activity of essential oil of Eucalyptus citriodora (lemon-scented eucalypt; myrtaceae) and its major constituents[J]. Food Science and Technology, 2012, 48(2): 237-241.

[9] 陳運嬌,李偉,陳洪璋,等. 桉葉抗氧化物分離純化及其抗氧化活性的研究[J]. 桉樹科技,2016,33(2):25-32.

Chen Yunqiao, Li Wei, Chen Hongzhang, et al. The isolation and purification of compounds from Eucalyptus Leaves and their antioxidant activity[J]. Eucalypt Science & Technology, 2016, 33(2): 25-32. (in Chinese with English abstract)

[10] 黃增,劉雄民,黃麗葵,等. 巨尾桉葉中皂苷的提取分離及其抗氧化活性研究[J]. 天然產物研究與開發,2012,24(8):1113-1117.

Huang Zeng, Liu Xiongmin, Huang Likui, et al. Extraction, separation and antioxidant activity of saponins from[J]. Natural Product Research and Development, 2012, 24(8): 1113-1117. (in Chinese with English abstract)

[11] 葉奎川,殷中瓊,魏琴,等. 油樟葉揮發油及其主要成分的體外抗肝癌活性[J]. 解剖學報,2012,43(3):381-386.

Ye Kuichuan, Yin Zhongqiong, Wei Qin, et al. Anticancer activity of the essential oil from cinnamomum longepaniculatum leaves and its major components against human[J]. Acta Anatomica Sinica, 2012, 43(3): 381-386. (in Chinese with English abstract)

[12] 劉小香,陳秋波,王真輝. 巨尾桉揮發油對真菌和昆蟲的化感作用[J]. 生態學雜志,2007,26(6):835-839.

Liu Xiaoxiang, Chen Qiubo, Wang Zhenhui. Allelopathic effects of essential oil fromon pathogenic fungi and pest insect[J]. Chinese Journal of Ecology, 2007, 26(6): 835-839. (in Chinese with English abstract)

[13] 張海燕,鄧永學,王進軍. 幾種植物精油對長角扁谷盜成蟲的熏蒸作用[J]. 植物保護,2005,31(2):62-63.

Zhang Haiyan, Deng Yongxue, Wang Jinjun. Fumigant activity of several kinds of plant essential oils against Cryptolestes pusi llus Sch?nherr[J].Plant Protection, 2005, 31(2): 62-63. (in Chinese with English abstract)

[14] 嚴敖金,譚青安. 桉葉精油對三種天牛的忌避效果[J]. 南京林業大學學報,1998,22(1):87-90.

Yan Aojin, Tan Qing’an. Replellency effects of essential oil derived from eucalyptus leaf against three species of sawyers[J]. Journal of Nanjing Forestry University, 1998, 22(1): 87-90. (in Chinese with English abstract)

[15] Bachir R Q, Benali M. Antibacterial activity of the essential oils from the leaves of eucalyptus globulus against Escherichia coli and lococcus aureus[J]. Asian Pacific Journal of Tropical Biomedicine, 2012, 2(9): 739-742. (in Chinese with English abstract)

[16] 桉葉油歷史發展與行業分析[J]. 國內外香化信息,2015(6):2-4.

[17] 曹子英,成云龍. 重慶發展桉葉油產業的優勢、機遇和路徑[J]. 重慶工貿職業技術學院學報,2016,12(2):14-17. Cao Ziying, Cheng Yunlong. The advantages and opportunities of eucalyptus oil industry in chongqing and its development paths[J]. Journal of Chongqing Industry & Trade Polytechnic, 2016, 12(2): 14-17. (in Chinese with English abstract)

[18] 陳耕夫. 水蒸氣提取與超臨界萃取丁香化學成分的研究[J]. 海南醫學院學報,2002,8(2):65-67.

Chen Gengfu. Research on chemical constituents of flos cryophhylli extracted by the steam distillation and SFE method[J]. Journal of Hainan Medical University, 2002, 8(2): 65-67. (in Chinese with English abstract)

[19] 張婷婷,楊玉紅,王世強,等. 丁香花精油提取工藝及不同花期香氣成分分析[J]. 湖南農業學報,2011(1):97-100.

Zhang Tingting, Yang Yuhong, Wang Shiqiang, et al. Extraction technologies for essential oil of syringa oblata lindl and aroma constituents analysis of syringa oblata lindl at different flowering period[J]. Hunan Agricultural Sciences, 2011(1): 97-100. (in Chinese with English abstract)

[20] Chinnarasu C, Montes A, Fernandez–Ponce M T, et al. Natural antioxidant fine particles recovery from Eucalyptus globulusleaves using supercritical carbon dioxide assisted processes[J]. The Journal of Supercritical Fluids, 2015(101): 161-169.

[21] Sereshti H, Rohanifar A, Bakhtiari S, et al. Bifunctional ultrasound assisted extraction and determination of Elettaria cardamomum Maton essential oil[J]. Journal of Chromatography A, 2012, 1238(10): 46-53.

[22] 李衛民,高英,曾建青. 香附CO2超臨界萃取物的化學成分研究[J]. 中草藥,2000,31(10):734-735.

[23] Cao Hui, Xiao JianBo, Xu Ming. Comparison of volatile components of Marchantia convoluta obtained by super critical carbon dioxide extraction and petrol ether extraction[J]. Journal of Food Composition and Analysis, 2007, 20(1): 45-51.

[24] 張忠義,王鵬,雷正杰,等. 超臨界CO2萃取–分子蒸餾技術對白術揮發油的提取分離和GC-MS分析[J]. 分析測試學報,2003,22(4):61-64.

Zhang Zhongyi, Wang Peng, Lei Zhengjie, et al. Analysis of essential oil from rhizoma atractylodis macrocephalae by GC-MS with supercritical CO2extraction and molecular distillation[J]. Journal of Instrumental Analysis, 2003, 22(4): 61-64. (in Chinese with English abstract)

[25] 劉克海,陳秋林,謝晶,等. 分子蒸餾法富集甜橙油特征香氣成分[J]. 食品科學,2012,33(10):200-203

Liu Kehai, Chen Qiulin, Xie Jing, et al. Enrichment of characteristic aroma compounds in sweet orange oil by molecular distillation[J]. Food Science, 2012, 33(10): 200-203. (in Chinese with English abstract)

[26] 胡雪芳,甘芝霖,李淑燕,等. 響應面法優化分子蒸餾技術純化孜然精油工藝[J]. 食品科學,2011,32(12):139-144.

Hu Xuefang, Gan Zhilin, Li Shuyan, et al. Optimization of purification process for essential oil from cumin oleoresin by molecular distillation[J]. Food Science, 2011, 32(12): 139-144. (in Chinese with English abstract)

[27] 王琴,蔣林,溫其標,等. 分子蒸餾純化八角精油的工藝研究[J]. 林產化學與工業,2007,27(3):77-80.

Wang Qin, Jiang Lin, Wen Qibiao, et al. Study on technology of molecular distillation for purification of star anise essential oil[J]. Chemistry and Industry of Forest Product, 2007, 27(3): 77-80. (in Chinese with English abstract)

[28] 于童童,范剛,任婧楠,等. 分子蒸餾分離濃縮甜橙精油及對賦香性能的影響[J]. 黑龍江大學自然科學學報,2013,30(6):802-808.

Yu Tongtong, Fan Gang, Ren Jingnan, et al. Deterpenation of orange essential oil and effects on aroma–giving capability by molecular distillation[J]. Journal of Natural Science of Heilongjiang University, 2013, 30(6): 802-808. (in Chinese with English abstract)

[29] 楊瑩,劉麗芬,黃星,等. 迷迭香精油的分子蒸餾精制及其在卷煙中的應用[J]. 精細化工,2013,30(5):534-538.

Yang Ying, Liu Lifen, Huang Xin, et al. A study on the rosemary essential oil refined by molecular distillation technology and its application in cigarette[J]. Fine Chemicals, 2013, 30(5): 534-538. (in Chinese with English abstract)

[30] 任艷奎,許松林,欒禮俠. 應用分子蒸餾技術分離提純玫瑰精油[J]. 應用化工,2005,34(8):58-61.

Ren Yankui, Xu Songlin, Luan Lixia. Refining rose oil by molecular distillation technology[J]. Applied Chemical Industry, 2005, 34(8): 58-61. (in Chinese with English abstract)

[31] 李權,楊明杰,陳林碧,等. 植物精油的主要提取技術、應用及研究進展[J]. 林業實用技術,2014(6):60-63.

[32] 楊君,張獻忠,高宏建,等. 天然植物精油提取方法研究進展[J]. 中國食物與營養,2012,18(9):31-35.

Yang Jun, Zhang Xianzhong, Gao Hongjian, et al. Research progress of natural plant essential oil extraction methods [J]. Food and Nutrition in China, 2012, 18(9): 31-35. (in Chinese with English abstract)

[33] 蔡基智,林杰. 植物精油提取新技術的研究進展[J]. 精細與專用化學品,2012,20(1):14-16.

Cai Jizhi, Lin Jie. Research development of the new extraction techniques of plant essential oil[J]. Fine and Specialty Chemicals, 2012, 20(1): 14-16. (in Chinese with English abstract)

[34] 吳鵬,張東明,張慶波. 短程蒸餾原理及工業應用[J]. 化工進展,2000,19(1):49-52.

Wu Peng, Zhang Dongming, Zhang Qingbo. Principles and industrial applications of short path distillation[J]. Chemical Industry and Engineering Progress, 2000, 19(1): 49-52. (in Chinese with English abstract)

[35] 馮武文,楊村,于宏奇. 分子蒸餾技術及其應用[J]. 化工進展,1998,17(6):26-29.

Feng Wuwen, Yang Cun, Yu Hongqi. Molecular distillation technology and its application[J]. Chemical Industry and Engineering Progress, 1998, 17(6): 26-29. (in Chinese with English abstract)

[36] 白宇,張炳南,高昌保,等. 分子蒸餾過程技術研究及其應用進展[J]. 化工裝備技術,2009,30(1):9-12.

[37] 郭麗,朱林,杜先鋒. 微膠囊雙水相提取柑橘精油的工藝優化[J]. 農業工程學報,2007,23(1):229-233.

Guo Li, Zhu Lin, Du Xianfeng. Optimization of the technology for the extraction of citrus essential oil by micro capsule and aqueous two-phase system[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2007, 23(1): 229-233. (in Chinese with English abstract)

[38] 陳芳,廖小軍,汪政富,等. 分子蒸餾工藝參數對高碳脂肪醇提取物精制效果的研究[J]. 農業工程學報,2005,21(11):197-199.

Chen Fang, Liao Xiaojun, Wang Zhengfu, et al. Effect of process parameters on the refining of higher fatty alcohol extracts during molecular distillation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2005, 21(11): 197-199. (in Chinese with English abstract)

[39] Mason R L, Gunst R F, Hess J L. Statistical Design and Analysis of Experiments: with Applications to Engineering and Science[M]. New York: Wiley, 2003.

[40] 王德喜,陸峰,鄒慧芬. 真空蒸餾[M],北京:化學工業出版社,2014.

[41] 田玉紅,張祥民,黃泰松,等. 桉葉油的研究進展[J]. 食品與發酵工業,2007,33(10):139-143.

Tian Yuhong, Zhang Xiangmin, Huang Qinsong, et al. Research advances on the essential oils from leaves of eucalyptus[J]. Food and Fermentation Industries, 2007, 33(10): 139-143. (in Chinese with English abstract)

[42] 馬麗,藍亮美,郭占京,等. 兩種桉葉揮發油含量和化學成分周年變化[J]. 精細化工,2015,32(3):300-303.

Ma Li, Lan Liangmei, Guo Zhanjing, et al. Annual change of contents and chemical compositions of essential oils from leaves of E. exserta and E. urophylla [J]. Fine Chemicals, 2015, 32(3): 300-303. (in Chinese with English abstract)

[43] 黃瑤,田玉紅,劉雄民,等. 尾葉桉葉精油的成分分析及抑菌效果初探[J]. 北方園藝,2010(6):26-28.

Huang Yao, Tian Yuhong, Liu Xiongmin, et al. Study on the composition and its antimicrobial effects of essential oils from leaves of eucalyptus urophylla [J]. Northern Horticulture, 2010(6): 26-28. (in Chinese with English abstract)

[44] 周莉君,丁濤,楊志榮,等. 巨尾桉不同樹齡及染蟲狀態桉葉油的成分分析[J]. 天然產物研究與開發,2016,28(11):1747-1751.

Zhou Lijun, Ding Tao, Yan Zhirong, et al. Chemical constituents of essential oil from the leaves of eucalyptus grandis E.urophylla in different years old and insect infection status[J]. Natural Product Research and Development, 2016, 28(11): 1747-1751. (in Chinese with English abstract)

[45] 王健英. 1,8-桉葉油素的提取與提純[D]. 天津:天津大學,2004.

Wang Jianying. The Extraction and Purify of 1,8-Cineole[D]. Tianjin: Tianjin University, 2004. (in Chinese with English abstract)

[46] 吳青業,關業枝,張清民,等. 兩種方法提取桉樹葉揮發油成分的比較研究[J]. 中藥材,2010,33(8):1346-1349.

[47] Basma A A, Asrar A H, Badoor M. K. Extraction of oil from eucalyptus camadulensis using water distillation method[J]. Iraqi Journal of Chemical and Petroleum Engineering, 2013, 14(2): 7-12.

[48] 應安國,許松林,徐世民. 間歇真空精餾提純桉葉油的研究[J]. 林產工業,2005,32(2):29-31.

Ying Anguo, Xu Songlin, Xu Shimin. Purification of 1,8-cineol by vacuum batch distillation[J]. China Forest Products Industry, 2005, 32(2): 29-31. (in Chinese with English abstract)

[49] 張廣求,王炯,袁永華. 桉葉素精制工藝初步研究[J]. 云南民族大學學報,2012,21(2):107-108.

Zhang Guangqiu, Wang Jiong, Yuan Yonghua. a preliminary Study on the refining of cineole[J]. Journal of Yunnan Nationalities University, 2012, 21(2): 107-108. (in Chinese with English abstract)

[50] 王石,靳林溪,謝建春,等. 從桉葉油母液中間歇減壓精餾純化1,8-桉葉油素[J]. 食品科學,2013,34(8):21-26.

Wang Shi, Jin Linxi, Xie Jianchun, et al. Purification of 1,8-cineole from stock solution of eucalyptus oil by batch vacuum distillation[J]. Food Science, 2013, 34(8): 21-26. (in Chinese with English abstract)

[51] 欒國顏,閻麗萍,高維平. 松節油中提取-蒎烯與-蒎烯的分離研究[J]. 吉林化工學院學報,1998,15(2):11-16.

Luan Guoyan, Yan Liping, Gao Weiping. On the separation process of-pinene and-pinene from turpentine[J]. Journal of Jilin Institute of Chemical Technology, 1998, 15(2): 11-16. (in Chinese with English abstract)

[52] 郭文生,郭放,侮健,等. 包結物晶析法選擇分離辛夷揮發油中1,8-桉葉素[J]. 高等學校化學學報,2005,26(5):883-885.

Guo Wensheng, Guo Fang, Wu Jian, et al. Selective isolation of 1,8-cineole from volatile oil of flos magnoliae (Xin Yi) via inclusion crystalline[J]. Chemical Journal of Chinese Universities, 2005, 26(5): 883-885. (in Chinese with English abstract)

[53] 劉文婷,顧麗莉,萬紅焱,等. 低溫控溫結晶法分離提純1,8-桉葉油素的工藝[J]. 化工進展,2016,35(2):570-574.

Liu Wenting, Gu Lili, Wan Hongyan, et al. Technique of low temperature control crystallization for separating and purifying 1,8-cineole[J]. Chemical Industry and Engineering Progress, 2016, 35(2): 570-574. (in Chinese with English abstract)

[54] 徐懷德. 天然產物提取工藝學[M]. 北京:中國輕工業出版社,2006.

[55] 盧星河,佘鴻燕,張廣清,等. 分子蒸餾法提純1,8–桉葉油素的工藝研究[J]. 現代化工,2008, 28(增刊1):108-110.

Lu Xinghe, She Hongyan, Zhang Guangqing, et al. Study on purifying techniques of molecular distillation for 1, 8-cineole[J]. Modern Chemical Industry, 2008, 28(Supp.1): 108-110. (in Chinese with English abstract)

[56] Chen F, Wang Z F, Zhao G H, et al. Puri?cation process of octacosanol extracts from rice bran wax by molecular distillation[J]. Journal of Food Engineering. 2007 (79) : 63-68.

Optimization of short-path molecular distillation technology for refining essential oil fromleaves

Hu Xuefang, Tian Zhiqing, Pei Haisheng, Zhang Zhimin, Wang Shikui※

(1. Chinese Academy of Agricultural Engineering, Beijing 100125, China; 2. Key Laboratory of Agro-Products Postharvest Handling, Ministry of Agriculture, Beijing 100121, China)

1,8-cineole and-pinene are the main constituents of eucalyptus essential oil and important medicine and chemical raw materials. The primary eucalyptus essential oil was refined by short-range molecular distillation, and the separation characteristics of 1,8-cineole and-pinene of substances under different temperature and pressure conditions were studied, so as to provide technical method for the fractionation and application of eucalyptus essential oil. Using eucalyptus grandis leaves as material, the primary eucalyptus essential oil was extracted and purified by supercritical CO2extraction and molecular distillation method respectively. Taking the distillate yield, the content of 1,8-cineole and the content of-pinene in the distillates, the content of 1,8-cineole and the content of-pinene in the residues as experimental indices, two-stage molecular distillation purification was carried out. Response surface methodology (RSM) based on a two-variable and five-level center composite rotation design (CCRD) was employed to evaluate the purification effects. Using the free path theory, the effects of different distillation temperatures and distillation pressures on the content of 1,8-cineole and-pinene in distillates and residues were investigated. The optimization of the process of eucalyptus essential oil refining by molecular distillation was studied. The distillation temperature and distillation pressure had significant influence on the effect of 1,8-cineole and-pinene fractionation, and the experimental results were optimized by the optimization method of multi response values. Taking distillate as the target product, the optimum conditions were as follows: distillation temperature 38 ℃, distillation pressure 41 Pa, and 1,8-cineole and-pinene content in distillates of 60.80% and 31.58%, respectively, and the yield of the distillates was 82.06%, which were well matched with the predicated values 61.97%, 33.37% and 86.38% obtained from the models. The smaller error between experimental and predicted values indicated the optimization experiment was successful. The results of variance analysis showed that the regression equations and models were reliable to predict the influences of factors on the distillate yield, and the content of 1,8-cineole and-pinene in distillates and residues. Molecular distillation purification can effectively purify the eucalyptus oil. The CCRD is suitable for the process optimization of molecular distillation of eucalyptus essential oil. The experimental process did not introduce any organic solvents, and was carried out in low temperature environment, protecting the material composition and characteristics of the structure. The contents of 1,8-cineole and-pinene were increased by 77.62% and 56.72% respectively after the secondary molecular distillation. Through the investigation of the change of the content of 1,8-cineole and-pinene with the distillation temperature and the distillation pressure, the effects of distillation temperature and distillation pressure on the content of 1,8-cineole were significantly higher than those of-pinene. Meanwhile, the effect of distillation pressure on the content of 1,8-cineole oil was higher than that of distillation temperature. In contrast, for-pinene, the effect of distillation temperature on its content was more significant, and the interaction of temperature and pressure had no significant effect on the content of-pinene. The result provides a technical reference for the separation and purification of 1, 8-cineole and-pinene.

distillation; pressure; temperature; Eucalyptus essential oil; 1,8-cineole;-pinene; process optimization

10.11975/j.issn.1002-6819.2018.02.041

TS201.2

A

1002-6819(2018)-02-0299-09

2017-09-05

2017-12-26

國家自然科學基金資助項目(21576142)

胡雪芳,工程師,主要從事天然產物提取與開發,農業廢棄物生物質多糖資源綜合利用。Email:xuefang1022@126.com

王士奎,研究員,主要從事海洋及陸地生物質多糖資源綜合利用研究。Email:wosk1963@shou.com

胡雪芳,田志清,裴海生,張志民,王士奎. 短程分子蒸餾技術精制巨尾桉葉精油工藝優化[J]. 農業工程學報,2018,34(2):299-307. doi:10.11975/j.issn.1002-6819.2018.02.041 http://www.tcsae.org

Hu Xuefang, Tian Zhiqing, Pei Haisheng, Zhang Zhimin, Wang Shikui. Optimization of short-path molecular distillation technology for refining essential oil fromleaves[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(2): 299-307. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.02.041 http://www.tcsae.org