基于雙吸肥口的低壓文丘里施肥器設(shè)計(jì)與試驗(yàn)

張建闊,李加念,吳 昊,馬澤宇,Waleed Elnour Babekir Salih,胡赫諶

(昆明理工大學(xué)現(xiàn)代農(nóng)業(yè)工程學(xué)院,昆明 650500)

基于雙吸肥口的低壓文丘里施肥器設(shè)計(jì)與試驗(yàn)

張建闊,李加念※,吳 昊,馬澤宇,Waleed Elnour Babekir Salih,胡赫諶

(昆明理工大學(xué)現(xiàn)代農(nóng)業(yè)工程學(xué)院,昆明 650500)

為降低文丘里施肥器的吸肥臨界進(jìn)口壓力,使之適用于低壓灌溉施肥系統(tǒng),設(shè)計(jì)了一種雙吸肥口文丘里施肥器。選取喉管收縮比、收縮段角度、擴(kuò)散段角度和喉管長(zhǎng)徑比4個(gè)結(jié)構(gòu)參數(shù),采用正交試驗(yàn)設(shè)計(jì)方法,構(gòu)建16種結(jié)構(gòu)參數(shù)組合方案,運(yùn)用CFD模擬技術(shù)對(duì)每種方案的吸肥性能進(jìn)行模擬,以吸肥性能為評(píng)價(jià)指標(biāo)確定最佳結(jié)構(gòu)參數(shù)組合,并根據(jù)最佳結(jié)構(gòu)參數(shù)組合試制文丘里施肥器原型樣品,并在0~0.15 MPa進(jìn)口壓力范圍內(nèi)對(duì)其吸肥性能進(jìn)行分析。結(jié)果表明,最佳結(jié)果參數(shù)為:喉管收縮比為 0.3、收縮段角度為 20°、擴(kuò)散段角度為8°、喉管長(zhǎng)徑比為 1.1。最佳結(jié)構(gòu)文丘里施肥器試制樣品實(shí)測(cè)結(jié)果與模擬分析結(jié)果一致,在相同進(jìn)口壓力下各個(gè)實(shí)測(cè)值均略小于模擬分析值,實(shí)測(cè)與模擬吸肥量、進(jìn)口流量比、肥液濃度和吸肥效率的均方根誤差分別為0.22 L/min、0.96%、0.93%和0.68%。在相同進(jìn)口壓力下,相比于相同結(jié)構(gòu)參數(shù)的單吸肥口文丘里施肥器,模擬得出的吸肥量提高了90%,進(jìn)口流量比提高了85%,肥液濃度提高了80%,吸肥效率提高了 80%,表明雙吸肥口施肥器的吸肥性能比單吸肥口施肥器有較大提高;雙吸肥口施肥器實(shí)測(cè)臨界進(jìn)口壓力為0.007 MPa,當(dāng)進(jìn)口壓力為0.05 MPa時(shí)其吸肥濃度可達(dá)13.6%,與現(xiàn)有文丘里施肥器相比,在獲得同等或更高的吸肥性能時(shí)具有更低的工作進(jìn)口壓力,更適用于低壓滴灌系統(tǒng)。

結(jié)構(gòu); CFD;數(shù)值分析; 文丘里施肥器; 雙吸肥口; 低壓; 吸肥性能

0 引 言

水肥一體化灌溉技術(shù)是現(xiàn)代農(nóng)業(yè)的一個(gè)重要標(biāo)志,既可滿足灌溉的質(zhì)量要求,同時(shí)對(duì)環(huán)境的污染也最小,在發(fā)達(dá)國(guó)家已成為一種標(biāo)準(zhǔn)的作業(yè)方式。低壓滴灌技術(shù)是一種能量?jī)?yōu)化利用的水肥一體化灌溉技術(shù),不僅具備常壓滴灌技術(shù)的所有優(yōu)點(diǎn),還可以降低灌溉系統(tǒng)的建設(shè)成本和運(yùn)行成本,是未來(lái)滴灌技術(shù)發(fā)展的一個(gè)重要方向[1]。施肥裝置是實(shí)現(xiàn)滴灌施肥的重要部件之一,目前國(guó)內(nèi)外常用的施肥裝置主要有自壓式[2]、壓差式[3]、機(jī)械驅(qū)動(dòng)注入式[4]、水力驅(qū)動(dòng)注入式[5]和文丘里吸入式等[6-8]。文丘里施肥器因成本低、結(jié)構(gòu)簡(jiǎn)單、無(wú)需外部動(dòng)力等優(yōu)點(diǎn),在國(guó)內(nèi)外得到了廣泛應(yīng)用,但在實(shí)際應(yīng)用中存在所需進(jìn)口壓力較高,且壓力損失較大(占總水頭10%~30%[9])等問(wèn)題,對(duì)吸肥效率和灌溉施肥均勻性產(chǎn)生重要影響[10],從而難以直接適用于低壓滴灌系統(tǒng),因此有必要進(jìn)一步研究能適用于更低進(jìn)口壓力的文丘里施肥器。由于文丘里施肥器的吸肥性能主要受其結(jié)構(gòu)參數(shù)影響,對(duì)文丘里結(jié)構(gòu)進(jìn)行性能分析與優(yōu)化設(shè)計(jì)是當(dāng)前的研究熱點(diǎn),近年來(lái),為了降低文丘里施肥器進(jìn)口壓力,提高吸肥效率,國(guó)內(nèi)外關(guān)于文丘里施肥器的研究,主要集中于采用理論分析與試驗(yàn)測(cè)試方法[11-18]、計(jì)算流體動(dòng)力學(xué)數(shù)值模擬分析方法[18-23],分析結(jié)構(gòu)參數(shù)與吸肥性能之間的關(guān)系并對(duì)其結(jié)構(gòu)進(jìn)行優(yōu)化設(shè)計(jì)[23-27],以及基于文丘里施肥器為核心執(zhí)行部件的灌溉施肥裝置的設(shè)計(jì)與試驗(yàn)[28-31]。這些研究取得了較好的進(jìn)展,尤其是在結(jié)構(gòu)參數(shù)與吸肥性能的關(guān)系方面積累了較好的研究基礎(chǔ),但對(duì)于低壓范圍內(nèi)的結(jié)構(gòu)設(shè)計(jì)及其參數(shù)優(yōu)化還鮮有涉及。為此,本文面向低壓滴灌系統(tǒng),在兼顧吸肥性能前提下,以降低進(jìn)口工作壓力為目標(biāo),進(jìn)行文丘里施肥器的結(jié)構(gòu)設(shè)計(jì)與參數(shù)優(yōu)化,以期研制出一種適用于低壓滴灌系統(tǒng)的文丘里施肥器。

1 文丘里施肥器設(shè)計(jì)及優(yōu)化

1.1 雙吸肥口施肥器結(jié)構(gòu)設(shè)計(jì)

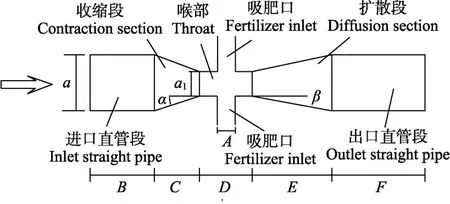

文丘里施肥器根據(jù)引射原理利用文丘里管進(jìn)行吸肥,其吸肥量取決于文丘里管進(jìn)出口壓差。實(shí)際應(yīng)用中,文丘里施肥器出口多為自然出流狀態(tài)或出口壓力為某一固定值,其吸肥量主要取決于入口壓力。有研究表明,相同進(jìn)出口壓力下,適當(dāng)增加引射口(對(duì)應(yīng)于文丘里施肥器則為吸肥口)可以提高文丘里管的引射能力[32]。因此,為滿足低壓灌溉應(yīng)用的需求,降低文丘里管工作壓力,采用雙吸肥口結(jié)構(gòu)設(shè)計(jì)文丘里施肥器,如圖1所示,其主要結(jié)構(gòu)由進(jìn)口直管段、收縮段、喉部、擴(kuò)散段、出口直管段和吸肥口6部分組成。其中,2個(gè)相同的吸肥口在水平方向上對(duì)稱分布于喉管兩側(cè),并且連接于喉管中部;由于同等條件下吸肥管與喉管直徑相同時(shí)其吸肥量可達(dá)到最大[22],故設(shè)計(jì)吸肥口直徑A等于喉管直徑a1;進(jìn)口和出口直管段直徑相同;進(jìn)出口直管段長(zhǎng)度B和F均為20 mm,收縮段長(zhǎng)度C、擴(kuò)散段長(zhǎng)度E、喉管長(zhǎng)度D由文丘里管結(jié)構(gòu)參數(shù)決定。

圖1 文丘里管結(jié)構(gòu)示意圖Fig.1 Structural diagram of Venturi injector

1.2 施肥器最佳結(jié)構(gòu)參數(shù)的確定方法

1.2.1 待定結(jié)構(gòu)參數(shù)選擇

表征文丘里施肥器結(jié)構(gòu)的主要參數(shù)有 7個(gè):進(jìn)口直管段直徑a、喉管直徑a1、喉管收縮比γ、收縮段角度α、擴(kuò)散段角度β、喉管長(zhǎng)徑比λ和吸肥口直徑A,其中γ=a1/a、λ=D/a1。由圖1可知,對(duì)于某一進(jìn)口直徑的文丘里施肥器,只需喉管收縮比γ、收縮段角度α、擴(kuò)散段角度β、喉管長(zhǎng)徑比λ這4個(gè)參數(shù)即可表征其整體結(jié)構(gòu)。

以a為25 mm的文丘里施肥器為例,根據(jù)前人研究結(jié)果優(yōu)選各參數(shù)的取值,即α和β選取范圍分別為15°~30°和4°~10°[22]、γ和λ取值范圍分別為0.3~0.45和1.1~1.4[20]。

1.2.2 CFD數(shù)值模擬

1)模擬方法建立

為降低數(shù)值分析與模擬計(jì)算的運(yùn)算量,進(jìn)行4因素4水平正交設(shè)計(jì)L16(44),采用CFD模擬方法,分析16種結(jié)構(gòu)參數(shù)組合在不同進(jìn)口壓力下的吸肥性能。用正交試驗(yàn)設(shè)計(jì)方法對(duì)4個(gè)結(jié)構(gòu)參數(shù)進(jìn)行組合。進(jìn)行模擬前,對(duì)每種參數(shù)組合采用Solidworks2015軟件建立文丘里施肥器三維模型,并采用Gambit2.4.6軟件以0.7 mm劃分六面體結(jié)構(gòu)化網(wǎng)格,然后采用CFD軟件Fluent 16.2.0進(jìn)行模擬分析。模擬分析過(guò)程中,采用標(biāo)準(zhǔn)k?ε湍流模型進(jìn)行數(shù)值模擬,采用二階迎風(fēng)差分格式和壓力基求解器 SIMPLE算法對(duì)離散方程組求解,收斂標(biāo)準(zhǔn)均取各因變量相鄰 2次迭代殘差<10–4。

2)模擬方法驗(yàn)證

為驗(yàn)證數(shù)值計(jì)算方法和條件設(shè)置的正確性,選取一款 DN25文丘里施肥器(喉管收縮比為 0.35,收縮角為25°,擴(kuò)散角為10°,喉管長(zhǎng)徑比為1.1),應(yīng)用上述方法構(gòu)建文丘里施肥器三維模型并對(duì)其吸肥性能進(jìn)行數(shù)值模擬分析,然后在相同條件下通過(guò)試驗(yàn)實(shí)測(cè)其吸肥性能并與模擬分析結(jié)果對(duì)比。其中,模擬工況設(shè)置為:進(jìn)口壓力為0.06 MPa,吸肥口壓力為 -5×103Pa,出口壓力為0。結(jié)果表明:數(shù)值模擬得到的出口肥液濃度為10.8%,試驗(yàn)實(shí)測(cè)得到的出口肥液濃度為10.3%,其相對(duì)誤差為4.9%,表明所建立的方法用于模擬文丘里施肥器吸肥性能的可靠性。

3)模擬參數(shù)設(shè)置

運(yùn)用 Fluent軟件模擬分析時(shí),進(jìn)口壓力分別設(shè)置為0.03、0.06、0.09、0.12和0.15 MPa;出口壓力設(shè)置為0,即出口為自流狀態(tài);由于文丘里施肥器臨界入口壓力與吸肥液面密切相關(guān),并考慮到實(shí)際應(yīng)用中的常用吸肥液面高度,將吸肥液面高度設(shè)為500 mm,即吸肥管入口壓力設(shè)置為–0.005 MPa。

1.2.3 吸肥性能指標(biāo)計(jì)算

施肥器吸肥性能采用進(jìn)口流量比M、吸肥效率η和肥液濃度θ這3個(gè)指標(biāo)進(jìn)行衡量。

式中q、Q分別為吸肥量和進(jìn)口流量,kg/s;P1,P2和P3分別為施肥器進(jìn)口、出口和吸肥口壓力,MPa;M為施肥器進(jìn)口流量比,用于反映文丘里施肥器的吸肥能力,%;η為吸肥效率,用于反映文丘里施肥器的綜合吸肥性能,%;θ為水肥混合后的肥液濃度,能直觀反映文丘里施肥器性能優(yōu)劣,%。

1.3 施肥器最佳結(jié)構(gòu)參數(shù)分析結(jié)果

1.3.1 不同組合吸肥性能分析

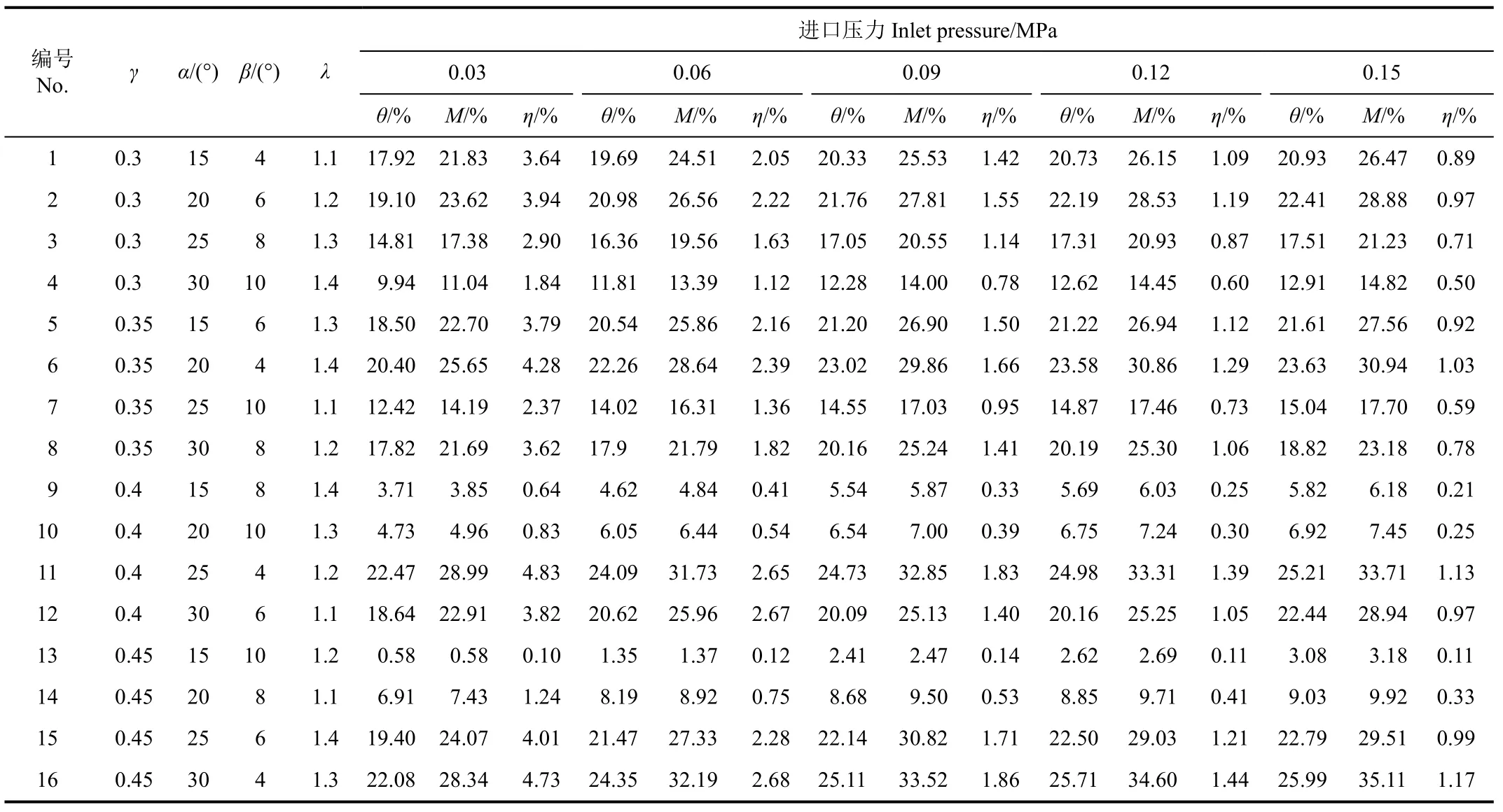

16種結(jié)構(gòu)參數(shù)組合方案在各進(jìn)口壓力下的吸肥性能模擬結(jié)果如表1所示。表1表明,對(duì)于某一特定組合,θ和M均隨進(jìn)口壓力增加而增大,吸肥效率η隨進(jìn)口壓力增加而減小。已有研究[15,21]將出口壓力設(shè)置為某個(gè)大于0的定值,而本文設(shè)置出口壓力為 0以便獲得低壓條件下文丘里施肥器的吸肥性能,這導(dǎo)致η偏低。在實(shí)際應(yīng)用中,可適當(dāng)調(diào)整。

表1 文丘里施肥器不同結(jié)構(gòu)參數(shù)組合的吸肥性能模擬結(jié)果Table 1 Fertilizer absorption performance simulation results of different structure parameters combinations of Venturi injector

1.3.2 最佳組合參數(shù)確定

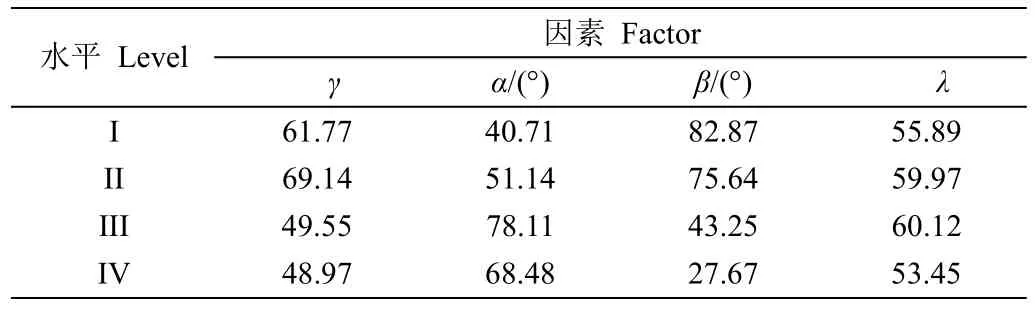

由式(1)~(3)知,η、θ均是M的函數(shù),且θ僅決定于M,則η和M亦可表示為θ的函數(shù)。由于本文目的是探尋一種能滿足低壓灌溉的文丘里施肥器,以θ為主要研究對(duì)象,對(duì)表1中低壓0.03 MPa情況下的θ模擬結(jié)果進(jìn)行正交分析,如表2所示。

表2 進(jìn)口壓力為0.03 MPa時(shí)吸肥濃度模擬值正交分析結(jié)果Table 2 Orthogonal analysis results of simulated fertilizer concentration at input pressure 0.03 MPa

由表2可知,當(dāng)γ為水平II、α為水平III、β為水平I、λ為水平III時(shí),即γ為0.35、α為25°、β為4°、λ為1.3時(shí),肥液濃度達(dá)到最大。此參數(shù)組合為理想狀態(tài)下的理論值,還需考慮低進(jìn)口壓力的實(shí)際情況進(jìn)行綜合取值。在實(shí)際灌溉施肥中,α過(guò)大會(huì)引起收縮段局部水頭損失增大,β過(guò)小且擴(kuò)大段長(zhǎng)度過(guò)長(zhǎng)會(huì)導(dǎo)致沿程水頭損失增加,同時(shí)考慮到相同條件下沿程水頭損失隨λ增大而增大,θ隨γ的增加而呈下降趨勢(shì)[20],故以盡可能減小收縮段角度α、增大擴(kuò)散段角度β為基礎(chǔ),并在滿足吸肥濃度大于10%[33]的前提下,以有效降低進(jìn)口壓力為目標(biāo),將進(jìn)口直徑為 25 mm的文丘里施肥器的最佳結(jié)構(gòu)參數(shù)組合確定為:喉管收縮比γ為0.3、收縮段角度α為20°、擴(kuò)散段角度β為8°、喉管長(zhǎng)徑比λ為1.1。該參數(shù)組合的文丘里施肥器通過(guò) CFD數(shù)值模擬得出在進(jìn)口壓力為 0.05 MPa的條件下,肥液濃度θ達(dá)到14.4%,滿足低壓條件下肥液濃度的要求。

2 文丘里施肥器吸肥性能分析

2.1 材料與方法

從以下3個(gè)方面分析文丘里施肥器的吸肥性能:1)根據(jù)所確定的最佳結(jié)構(gòu)參數(shù),采用3D打印技術(shù)制出文丘里施肥器原型樣品,進(jìn)行試驗(yàn),驗(yàn)證CFD模擬結(jié)果的可靠性;2)采用 CFD數(shù)值模擬分析方法,比較雙吸肥口文丘里施肥器與相同結(jié)構(gòu)參數(shù)的單吸肥口文丘里施肥器吸肥性能;3)將實(shí)測(cè)試驗(yàn)得出的雙吸肥口施肥器吸肥性能與現(xiàn)有研究或文丘里施肥器產(chǎn)品進(jìn)行對(duì)比分析。

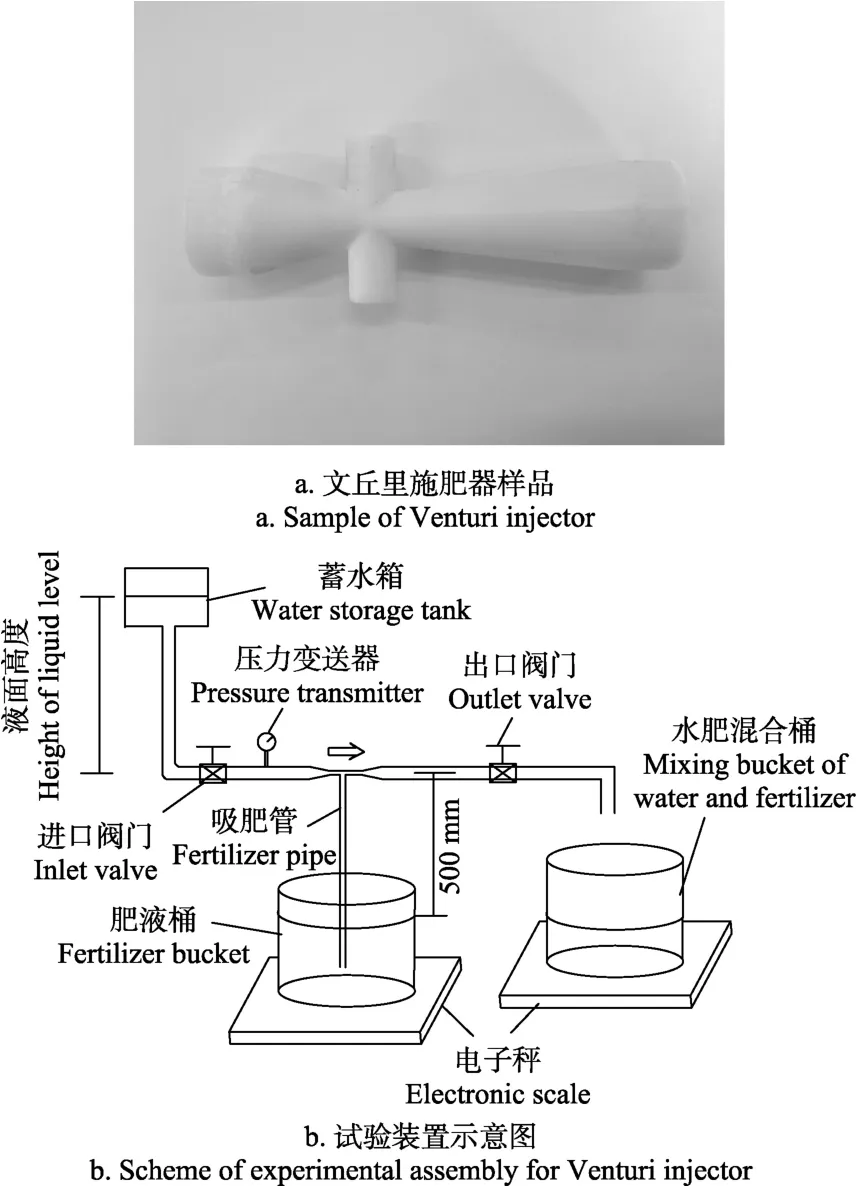

利用制成的文丘里施肥器樣品(如圖2a所示)在昆明理工大學(xué)現(xiàn)代農(nóng)業(yè)工程學(xué)院樓梯間進(jìn)行試驗(yàn)。試驗(yàn)裝置如圖2b所示,安裝文丘里施肥器時(shí),確保2個(gè)吸肥口水平放置且進(jìn)口、出口、吸肥口三者軸心在一個(gè)水平面上,肥液液面與吸肥口的垂直距離(即吸肥液面高度)為500 mm;文丘里施肥器進(jìn)口水源由蓄水桶提供,肥液(試驗(yàn)過(guò)程中采用常溫清水代替)由肥液桶提供,出口為自然出流狀態(tài);進(jìn)口水壓通過(guò)調(diào)節(jié)儲(chǔ)水桶與文丘里施肥器之間的高度差實(shí)現(xiàn)在0~0.15 MPa之間變化(蓄水桶高度調(diào)節(jié)范圍在0~15 m之間),并采用壓力變送器(量程0.2 MPa,精度等級(jí)為0.5)測(cè)定其進(jìn)口水壓,分別將進(jìn)口水壓調(diào)節(jié)為0.01、0.03、0.05、0.07、0.09、0.11、0.13和0.15 MPa進(jìn)行試驗(yàn);試驗(yàn)過(guò)程中,為保證入口水壓穩(wěn)定,通過(guò)補(bǔ)水使蓄水桶始終處于滿水位狀態(tài),而且每次測(cè)量數(shù)據(jù)前使吸肥液面高度為500 mm。試驗(yàn)采用稱質(zhì)量法計(jì)算吸肥量和肥液濃度,即:待施肥器運(yùn)行穩(wěn)定3 min后開(kāi)始計(jì)時(shí)60 s,并利用電子稱(型號(hào)為英橫YHW-L01,量程為30 kg,精度為0.5 g)分別測(cè)量肥液桶和水肥混合桶計(jì)時(shí)前后的質(zhì)量,吸肥量為肥液桶計(jì)時(shí)前后的質(zhì)量差,水肥混合量為水肥混合桶計(jì)時(shí)前后的質(zhì)量差,進(jìn)口量為水肥混合量與吸肥量的差值,吸肥流量、水肥混合流量、入口流量分別為其60 s的均值,肥液濃度為吸肥流量與水肥混合流量的比值。對(duì)于每個(gè)進(jìn)口壓力點(diǎn)重復(fù)進(jìn)行試驗(yàn)10次并取其均值作為結(jié)果。

圖2 文丘里施肥器樣品及吸肥性能試驗(yàn)裝置Fig.2 Venturi injector sample and fertilizer absorption performance test device

2.2 結(jié)果與分析

2.2.1 吸肥性能實(shí)測(cè)驗(yàn)證試驗(yàn)

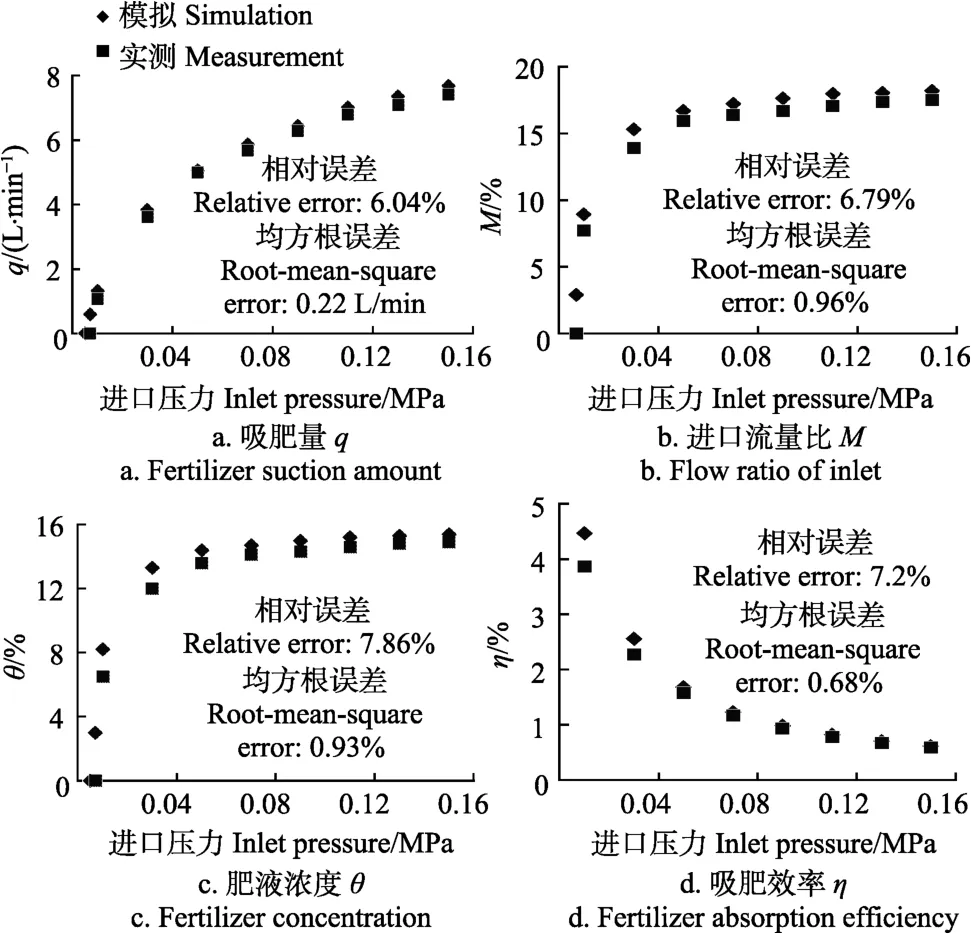

對(duì)比于CFD數(shù)值模擬分析結(jié)果,雙吸肥口文丘里施肥器原型樣品在 0~0.15 MPa進(jìn)口壓力下的吸肥性能驗(yàn)證試驗(yàn)結(jié)果如圖 3所示,施肥器原型樣品實(shí)測(cè)的吸肥量性能隨進(jìn)口壓力的變化均與數(shù)值模擬分析結(jié)果一致,實(shí)測(cè)與模擬吸肥量、進(jìn)口流量比、肥液濃度和吸肥效率的均方根誤差分別為0.22 L/min、0.96%、0.93%和0.68%。這表明施肥器原型樣品可以在較低工作壓力下獲得良好的吸肥性能,也證實(shí)了采用CFD數(shù)值模擬方法分析文丘里施肥器結(jié)構(gòu)的可靠性。

如圖3a~圖3c可知,施肥器實(shí)測(cè)的臨界吸肥進(jìn)口壓力為0.007 MPa,略大于模擬分析得出的0.005 MPa,當(dāng)進(jìn)口壓力從0.007 MPa增至0.05 MPa時(shí),實(shí)測(cè)吸肥量、進(jìn)口流量比和肥液濃度分別從0快速單調(diào)遞增至4.99 L/min、15.95%和13.6%,當(dāng)進(jìn)口壓力逐漸增至0.15 MPa時(shí),實(shí)測(cè)吸肥量、進(jìn)口流量比和肥液濃度分別平緩地單調(diào)遞增至7.42 L/min、17.51%和14.9%;如圖3d可知,當(dāng)進(jìn)口壓力從0.007 MPa增加至0.05 MPa時(shí),實(shí)測(cè)吸肥效率從3.87%快速單調(diào)遞減至1.58%,當(dāng)進(jìn)口壓力逐漸增至0.15 MPa時(shí),實(shí)測(cè)吸肥效率平緩地單調(diào)遞減至0.59%。

圖3 模擬與實(shí)測(cè)吸肥性能對(duì)比Fig.3 Comparison of simulated and measured fertilizer absorption performance

2.2.2 與單吸肥口文丘里施肥器的吸肥性能對(duì)比

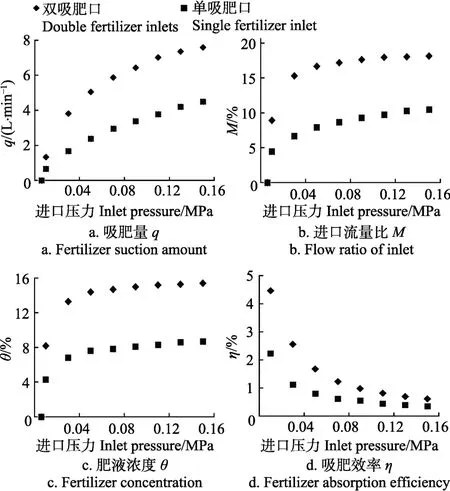

分別基于單吸肥口和雙吸肥口,建立 2個(gè)結(jié)構(gòu)參數(shù)完全相同的文丘里施肥器模型,采用CFD數(shù)值模擬方法,在0~0.15 MPa進(jìn)口壓力范圍內(nèi)對(duì)比分析了2種施肥器的吸肥性能,結(jié)果如圖4所示,雙吸肥口施肥器的吸肥量、進(jìn)口流量比、肥液濃度和吸肥效率隨進(jìn)口壓力的變化均與單吸肥口一致,但相同進(jìn)口壓力下雙吸肥口吸肥性能遠(yuǎn)遠(yuǎn)高于單吸肥口。由圖4a可知,單/雙吸肥口2種文丘里施肥器的臨界吸肥進(jìn)口壓力均為 0.005 MPa,進(jìn)口壓力在0.005~0.05 MPa范圍內(nèi)吸肥量增加較快,雙吸肥口施肥器的吸肥量從0快速增至5.1 L/min,在0.05~0.15 MPa范圍內(nèi)變化趨勢(shì)逐漸趨于平緩,其吸肥量從5.1 L/min增至7.6 L/min,在相同進(jìn)口壓力下,相比于單吸肥口文丘里施肥器,雙吸肥口文丘里施肥器的吸肥量提高 90%以上;由圖4b和4c可知,雙吸肥口施肥器進(jìn)口流量比和肥液濃度在進(jìn)口壓力 0.005~0.05 MPa范圍內(nèi)快速增至16.7%和14.4%,進(jìn)口壓力繼續(xù)增加其進(jìn)口流量比和肥液濃度增加平緩,當(dāng)進(jìn)口壓力為0.15 MPa時(shí),其進(jìn)口流量比和肥液濃度為18.2%和15.4%;由圖4d可知,雙吸肥口文丘里施肥器進(jìn)口壓力0.005~0.05 MPa范圍內(nèi)增加,其吸肥效率從4.5%快速減至1.6%,當(dāng)進(jìn)口壓力增至0.15 MPa時(shí),其吸肥效率為0.6%。在相同進(jìn)口壓力下,相比于單吸肥口文丘里施肥器,雙吸肥口文丘里施肥器的吸肥量提高了90%,進(jìn)口流量比提高了85%,肥液濃度提高了80%,吸肥效率提高了80%。這表明雙吸肥口施肥器與單吸肥口具有相同的工作原理,但由于雙吸肥口增加了吸肥過(guò)流面積,其引射能力得到增強(qiáng),使得雙吸肥口施肥器的吸肥性能大大優(yōu)于具有相同結(jié)構(gòu)參數(shù)的單吸肥口施肥器。

圖4 單雙吸肥口文丘里施肥器吸肥性能對(duì)比Fig.4 Comparison of fertilizer absorption performance of single and double fertilizer inlets

2.2.3 與現(xiàn)有文丘里施肥器的性能對(duì)比

現(xiàn)廣泛研究的文丘里施肥器主要有進(jìn)出口直徑相同、進(jìn)出口直徑互異這2種:

1)對(duì)于進(jìn)出口直徑相同的國(guó)內(nèi)文丘里施肥器,其試制樣品開(kāi)始吸肥時(shí)的進(jìn)口壓力可低至0.03 MPa,但其吸肥濃度較小,當(dāng)進(jìn)口壓力上升至0.1 MPa時(shí)肥液濃度才達(dá)最大值10%[8],而本研究雙吸肥口文丘里施肥器實(shí)測(cè)結(jié)果表明,其吸肥時(shí)進(jìn)口壓力為0.007 MPa,且進(jìn)口壓力在0.05 MPa時(shí),肥液濃度可達(dá) 13.6%;與進(jìn)出口直徑相同的以色列文丘里施肥器相比,在較低進(jìn)口壓力下其肥液濃度均能滿足灌溉要求,但在獲得相同吸肥量時(shí)雙吸肥口文丘里施肥器具有更低的進(jìn)口壓力,當(dāng)吸肥量為5 L/min時(shí),以色列文丘里施肥器的進(jìn)口壓力為0.06 MPa[18],而本文雙吸肥口文丘里施肥器的進(jìn)口壓力為0.05 MPa,與之相比降低了0.01 MPa,因而更適用于低壓灌溉系統(tǒng)。

2)對(duì)于進(jìn)出口直徑互異的文丘里施肥器,其進(jìn)口流量比最大可達(dá)11%,且進(jìn)口壓力在0.15 MPa時(shí),最大吸肥量為2.7 L/min[23],而本文雙吸肥口施肥器進(jìn)口壓力在0.05 MPa時(shí),進(jìn)口流量比15.95%,吸肥量5 L/min,可在較低的進(jìn)口壓力下獲得更高的進(jìn)口流量比和吸肥量。

上述以色列文丘里施肥器與進(jìn)出口直徑互異的文丘里施肥器大多采用喉部環(huán)繞式結(jié)構(gòu),該結(jié)構(gòu)的設(shè)計(jì)原理與雙吸肥口文丘里施肥器相同,均可在一定程度上提高喉部負(fù)壓的利用效率、增強(qiáng)文丘里施肥器的性能;由于雙吸肥口文丘里施肥器具有2個(gè)肥液入口,比只有1個(gè)肥液入口的喉部環(huán)繞式文丘里施肥器具有更大的吸肥過(guò)流面積,因而在相同進(jìn)口壓力下可較大幅度地提高其吸肥量,從而在獲得相同吸肥量時(shí)可工作于更低進(jìn)口壓力下,而且與喉部環(huán)繞式文丘里施肥器相比,其加工制造工藝較為簡(jiǎn)單,成本較低。市面上常見(jiàn)文丘里施肥器(首沃S02、華維8210等),其最小工作壓力為0.07 MPa,最大肥液濃度約為12%。本文所設(shè)計(jì)的雙吸肥口施肥器,其臨界進(jìn)口壓力為0.007 MPa,當(dāng)進(jìn)口壓力為0.05 MPa時(shí)其吸肥濃度可達(dá)13.6%,這完全滿足實(shí)際農(nóng)業(yè)生產(chǎn)中灌溉施肥的濃度要求。相比之下,在獲得等同于或高于現(xiàn)有文丘里施肥器的吸肥性能時(shí),雙吸肥口文丘里施肥器具有更低的工作壓力,更適用于低壓滴灌系統(tǒng)。

3 結(jié) 論

1)本文設(shè)計(jì)了一種雙吸肥口文丘里施肥器,采用CFD數(shù)值模擬方法確定其最佳結(jié)構(gòu)參數(shù)為喉管收縮比為0.3、收縮段角度為 20°、擴(kuò)散段角度為 8°、喉管長(zhǎng)徑比為1.1,并試制出其原型樣品。

2)雙吸肥口文丘里施肥器原型樣品的吸肥性能試驗(yàn)結(jié)果與CFD模擬分析結(jié)果吻合,相比于模擬分析結(jié)果,實(shí)測(cè)吸肥量、進(jìn)口流量比、肥液濃度和吸肥效率的均方根誤差分別為0.22 L/min、0.96%、0.93%和0.68%,可見(jiàn)模擬結(jié)果的可靠性。

3)采用 CFD數(shù)值模擬方法對(duì)比分析了具有相同結(jié)構(gòu)參數(shù)的單/雙吸肥口2種文丘里施肥器,結(jié)果表明二者吸肥性能隨進(jìn)口壓力的變化規(guī)律一致,但雙吸肥口文丘里施肥器的吸肥量、進(jìn)口流量比、肥液濃度和吸肥效率均較單吸肥口施肥器提高了80%以上。

4)所設(shè)計(jì)的雙吸肥口施肥器進(jìn)口壓力在 0.05 MPa時(shí)其吸肥濃度可達(dá)13.6%,在滿足灌溉要求的前提下,其進(jìn)口壓力更低,適用于低壓滴灌系統(tǒng)。下一步將對(duì)設(shè)計(jì)的文丘里施肥器進(jìn)行實(shí)際應(yīng)用,驗(yàn)證其性能,并根據(jù)應(yīng)用結(jié)果對(duì)產(chǎn)品進(jìn)行完善。

[1] 牛文全,吳普特,范興科. 低壓滴灌系統(tǒng)研究[J]. 節(jié)水灌溉,2005(2):29-30,32.Niu Wenquan, Wu Pute, Fan Xingke. Low-pressure drip irrigation system[J]. Water Saving Irrigation, 2005(2): 29-30, 32. (in Chinese with English abstract)

[2] 郭彥彪,李社新,鄧蘭生,等. 自壓微灌系統(tǒng)施肥裝置[J].水土保持研究,2008,15(1):261-262.Guo Yanbiao, Li Shexin, Deng Lansheng, et al. Fertilizing equipment of self-press micro-irrigation system[J]. Research of Soil and Water Conservation, 2008, 15(1): 261-262. (in Chinese with English abstract)

[3] 孟一斌,李久生,李蓓. 微灌系統(tǒng)壓差式施肥罐施肥性能試驗(yàn)研究[J]. 農(nóng)業(yè)工程學(xué)報(bào),2007,23(3):41-45.Meng Yibin, Li Jiusheng, Li Bei. Fertilization performance of the pressure differential tank in micro-irrigation system[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2007, 23(3): 41-45. (in Chinese with English abstract)

[4] 朱志堅(jiān),盧秉恒,趙萬(wàn)華,等. 機(jī)械注入式施肥裝置研制與應(yīng)用[J]. 節(jié)水灌溉,2005(2):21-22.Zhu Zhijian, Lu Binheng, Zhao Wanhua, et al. Development and application of mechanical injecting fertigation device[J].Water Saving Irrigation, 2005(2): 21-22. (in Chinese with English abstract)

[5] 李百軍,王曉寧. 水動(dòng)施肥裝置的設(shè)計(jì)與試驗(yàn)[J]. 江蘇大學(xué)學(xué)報(bào)(自然科學(xué)版),2002,23(2):9-12.Li Baijun, Wang Xiaoning. Design and experiment on hydrodynamic fertilizer injection unit[J]. Journal of Jiangsu University: Natural Science, 2002, 23(2): 9-12. (in Chinese with English abstract)

[6] 韓啟彪,馮紹元,黃修橋,等. 我國(guó)節(jié)水灌溉施肥裝置研究現(xiàn)狀[J]. 節(jié)水灌溉,2014(12):76-79,83.Han Qibiao, Feng Shaoyuan, Huang Xiuqiao, et al. Research on fertilizer injection units in saving-water irrigation in China[J]. Water Saving Irrigation, 2014(12): 76-79,83. (in Chinese with English abstract)

[7] Villalobos Roberto, Montoya Emmy, Nomogramas paraensambley Uso, et al. Inyectora Unidrench? de dispositivo Venturi operation setting nomograms for Unidrench? Venturi injector[J].Agronomía Colombiana, 2010, 28(2): 303-318.

[8] 金永奎,夏春華,方部玲. 文丘里施肥器系列的研制[J]. 中國(guó)農(nóng)村水利水電,2006(5):14-16,20.Jin Yongkui, Xia Chunhua, Fang Buling. Research and development of venturi fertilizer applicator series[J]. China Rural Water and Hydropower, 2006(5): 14-16, 20. (in Chinese with English abstract)

[9] Cooperative Extension Service College of Agriculture and Home Economics. Drip irrigation system for row crops[R].New Mexico: New Mexico State University, 2001.

[10] Neto L E L, Porto R D M. Performance of low-cost ejectors[J]. Journal of Irrigation and Drainage Engineering,2004, 130(2): 122-128.

[11] 韓啟彪,黃興法,劉洪祿,等. 6種文丘里施肥器吸肥性能比較分析[J]. 農(nóng)業(yè)機(jī)械學(xué)報(bào),2013,44(4):113-117,136.Han Qibiao, Huang Xingfa, Liu Honglu, et al. Comparative anylysis on fertilization performance of six venture injectors[J].Transaction of the Chinese Society for Agricultural Machinery,2013, 44(4): 113-117, 136. (in Chinese with English abstract)

[12] 嚴(yán)海軍,初曉一,王敏,等. 微灌系統(tǒng)文丘里施肥器吸肥性能試驗(yàn)[J]. 排灌機(jī)械工程學(xué)報(bào),2010,28(3):251-255,264.Yan Haijun, Chu Xiaoyi, Wang Min, et al. Injection performance of venturi injector in micro-irrigation system[J]. Journal of Drainage and Irrigation Machinery Engineering, 2010, 28(3):251-255, 264. (in Chinese with English abstract)

[13] 馮瑞玨,洪添勝,李加念,等. 文丘里施肥器控制性能試驗(yàn)分析[J]. 灌溉排水學(xué)報(bào),2011,30(6):11-14,56.Feng Ruijue, Hong Tiansheng, Li Jianian, et al. Experiment and analysis on control performance of venturi injector[J].Journal of Irrigation and Drainage, 2011, 30(6): 11-14, 56.(in Chinese with English abstract)

[14] 孔令陽(yáng),范興科. 文丘里施肥器喉部負(fù)壓的影響因素分析[J]. 干旱地區(qū)農(nóng)業(yè)研究,2013,31(6):78-82,89.Kong Lingyang, Fan Xingke. Analysis on the influencing factors of throat negative pressure for Venturi injector[J].Agricultural Research in the Arid Areas, 2013, 31(6): 78-82,89. (in Chinese with English abstract)

[15] 范興科,孔令陽(yáng). 文丘里施肥器能量轉(zhuǎn)化關(guān)系[J]. 排灌機(jī)械工程學(xué)報(bào),2013,31(6):528-533.Fan Xingke, Kong Lingyang. Relationship of energy conversion for Venturi injector[J]. Journal of Drainage and Irrigation Machinery Engineering, 2013, 31(6): 528-533. (in Chinese with English abstract)

[16] Xu Yuncheng, Chen Yan, He Jianqiang, et al. Detection of cavitation in a Venturi injector with a combined method of strain gauges and numerical simulation[J]. Journal of Fluids Engineering Transactions of the ASME, 2014, 136(8):081302.

[17] 嚴(yán)海軍,陳燕,徐云成,等. 文丘里施肥器的空化特性試驗(yàn)研究[J]. 排灌機(jī)械工程學(xué)報(bào),2013,31(8):724-728.Yan Haijun, Chen Yan, Xu Yuncheng, et al. Experimental investigation on cavitation characteristics of Venturi injector[J].Journal of Drainage and Irrigation Machinery Engineering,2013, 31(8): 724-728. (in Chinese with English abstract)

[18] 孔令陽(yáng),范興科. 文丘里施肥器吸肥性能試驗(yàn)研究[J]. 節(jié)水灌溉,2013(7):4-6.Kong Lingyang, Fan Xingke. Experimental study on fertilizer suction performance of Venturi injector[J]. Water Saving Irrigation, 2013(7): 4-6. (in Chinese with English abstract)

[19] 王淼,黃興法,李光永. 文丘里施肥器性能數(shù)值模擬研究[J]. 農(nóng)業(yè)工程學(xué)報(bào),2006,22(7):27-31.Wang Miao, Huang Xingfa, Li Guangyong. Numerical simulation of characteristics of venturi injector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2006, 22(7): 27-31. (in Chinese with English abstract)

[20] 孫艷琦,牛文全. 文丘里管結(jié)構(gòu)參數(shù)對(duì)其水力性能的影響[J]. 西北農(nóng)林科技大學(xué)學(xué)報(bào),2010,38(2):211-218.Sun Yanqi, Niu Wenquan. Effects of Venturi structural parameters on the hydraulic performance[J]. Journal of Northwest A&F University, 2010, 38(2): 211-218. (in Chinese with English abstract)

[21] 嚴(yán)海軍,初曉一. 喉管直徑對(duì)文丘里施肥器性能影響的數(shù)值模擬[J]. 排灌機(jī)械工程學(xué)報(bào),2011,29(4):359-363.Yan Haijun, Chu Xiaoyi. Numerical simulation of influence of diameter of throat on Venturi injector performance[J].Journal of Drainage and Irrigation Machinery Engineering,2011, 29(4): 359-363. (in Chinese with English abstract)

[22] 邱振宇,鮑安紅. 施肥器結(jié)構(gòu)參數(shù)對(duì)施肥濃度影響的數(shù)值研究—基于并聯(lián)式文丘里施肥器[J]. 農(nóng)機(jī)化研究,2012,34(4):42-45.Qiu Zhenyu, Bao Anhong. Fertilization numerical studies on the impact of structure parameters on fertilizer concentration[J].Journal of Agricultural Mechanization Research, 2012, 34(4):42-45. (in Chinese with English abstract)

[23] 嚴(yán)海軍,陳燕,初曉一,等. 文丘里施肥器結(jié)構(gòu)參數(shù)優(yōu)化對(duì)吸肥性能的影響[J]. 排灌機(jī)械工程學(xué)報(bào),2013,31(2):162-166.Yan Haijun, Chen Yan, Chu Xiaoyi, et al. Influence of optimization of structural parameters on injection performance of Venturi injector[J]. Journal of Drainage and Irrigation Machinery Engineering, 2013, 31(2): 162-166. (in Chinese with English abstract)

[24] Manzano J, de Azevedo BM, do Bomfim GV, et al. Design and prediction performance of Venturi injectors in drip irrigation[J]. Revista Brasileira de Engenharia Agricola E Ambiental, 2014, 18(12): 1209-1217.

[25] Li Jiusheng, Meng Yibin, Li Bei. Field evaluation of fertigation uniformity as affected by injector type and manufacturing variability of emitters[J]. Irrigation Science, 2007, 25(2): 117-125.

[26] Bracy R P, Parish R L, Rosendale R M. Fertigation uniformity affected by injector type[J]. Horttechnology, 2003, 13(1): 103-105.

[27] Yan Haijun, Chen Yan, Chu Xiaoyi, et al. Effect of structural optimization on performance of Venturi injector[C]//26th IAHR Symposium on Hydraulic Machinery and Systems., ,Bristol, England: IOP Publishing Ltd, 2012:072014.doi:10.1088/1755-1315/15/7/072014.

[28] 周亮亮,柯建宏. 基于模糊控制的溫室灌溉施肥控制系統(tǒng)[J]. 浙江農(nóng)業(yè)科學(xué),2012(12):1648-1652.

[29] Coates R, Delwiche M, Evans R, et al. Adjustable-rate fertigation system for container nurseries[J]. Applied Engineering in Agriculture, 2014, 30(6): 987-994.

[30] 李加念,洪添勝,馮瑞玨,等. 基于脈寬調(diào)制的文丘里變量施肥裝置設(shè)計(jì)與試驗(yàn)[J]. 農(nóng)業(yè)工程學(xué)報(bào),2012,28(8):105-110.Li Jianian, Hong Tiansheng, Feng Ruiyue, et al. Design and experiment of Venturi variable fertilizer apparatus based on pulse width modulation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2012, 28(8): 105-110. (in Chinese with English abstract)

[31] 李加念,洪添勝,馮瑞玨,等. 基于模糊控制的肥液自動(dòng)混合裝置設(shè)計(jì)與試驗(yàn)[J]. 農(nóng)業(yè)工程學(xué)報(bào),2013,29(16):22-30.Li Jianian, Hong Tiansheng, Feng Ruijue, et al. Design and experiment of automatic mixing apparatus for liquid fertilizer based on fuzzy control[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2013, 29(16): 22-30. (in Chinese with English abstract)

[32] 楊帥,劉牮,常國(guó)峰,等. 引射式EGR系統(tǒng)文丘里管內(nèi)流動(dòng)數(shù)值模擬分析[J]. 內(nèi)燃機(jī)工程,2011,32(3):64-67.Yan Shuai, Liu Jian, Chang Guofeng, et al. Numerical simulation on flow in Venturi tube of EGR system for turbocharged diesel engine[J]. Chinese Internal Combustion Engine Engineering, 2011, 32(3): 64-67. (in Chinese with English abstract)

[33] 李加念. 橘園水肥一體化滴灌的自動(dòng)控制系統(tǒng)[D]. 廣州:華南農(nóng)業(yè)大學(xué),2012.Li Jianian. Automatic Control System of Drip Irrigation and Fertigation for Citrus Orchard[D]. Guangzhou: South China Agricultural University, 2012. (in Chinese with English abstract)

Design and experiment of low pressure Venturi injector based on double fertilizer inlets

Zhang Jiankuo, Li Jianian※, Wu Hao, Ma Zeyu, Waleed Elnour Babekir Salih, Hu Hechen

(College of Modern Agricultural Engineering, Kunming University of Science and Technology, Kunming650500,China)

Venturi injector has been widely used in the integrated irrigation system of water and fertilizer because of its advantages of low cost, simple structure, no external power and so on. In order to reduce the critical inlet pressure of the Venturi injector and make it suitable for low pressure irrigation and fertilization system, a kind of Venturi injector with double fertilizer inlets was designed. The design was based on the study results that increasing the numbers of fertilizer inlets can improve fertilizer absorption capability of Venturi tube. A total of 4 structural parameters (throat contraction ratio, contraction angle, diffusion angle and ratio of throat length and diameter) were required to be determined for the Venturi injector. A total of 16 combinations with the 4 structural parameters were designed by using the orthogonal method. The CFD simulation was used to simulate the fertilizer absorption performance of each scheme. According to the simulation results, the optimum combination of structural parameters was throat contraction ratio 0.3, contraction angle 20o, diffusion angle 8oand ratio of throat length and diameter 1.1. According to the optimum combination of structural parameters, a prototype of Venturi injector was manufactured by the 3D print technique for an experiment. The experiment was carried out in College of Modern Agricultural Engineering of Kunming University of Science and Technology, China. The water inlet pressure from 0 to 0.15 MPa was realized by adjusting the difference in height between the bucket and the Venturi injector and there were 8 points chosen from 0 to 0.15 MPa. The vertical distance between the liquid level and the fertilizer inlets was set to 500 mm. During the experiment, the fertilizer concentration was calculated. The experimental results showed that the measured values agreed well with the simulated values with the root-mean-square error of 0.22 L/min for fertilizer suction amount, 0.96% for flow ratio of inlet, 0.93% for fertilizer concentration, and 0.68% for fertilizer absorption efficiency. The change in measured and simulated fertilizer absorption performance with the inlet pressure was similar. The CFD simulation was used for compare single and double inlets injector with the same structural parameters and the results showed that under the same inlet pressure,fertilizer suction amount, flow ratio of inlet, fertilizer concentration and fertilizer absorption efficiency of the double inlets increased by 90%, 85%, 80% and 80%, respectively, compared to single fertilizer inlet. The measured critical inlet pressure was 0.007 MPa for the double inlets injector. When the inlet pressure was 0.05 MPa, the fertilizer concentration was 13.6%.Compared with the existing Venturi injector, the Venturi injector with double fertilizer inlets need much lower water inlet pressure to obtain the equal or higher fertilizer absorption performance and it is more suitable for low pressure irrigation system.

structures; computational fluid dynamics; numerical analysis; Venturi injector; double fertilizer inlets; low pressure; fertilizer absorption performance

10.11975/j.issn.1002-6819.2017.14.016

S224.2

A

1002-6819(2017)-14-0115-07

張建闊,李加念,吳 昊,馬澤宇,Waleed Elnour Babekir Salih,胡赫諶. 基于雙吸肥口的低壓文丘里施肥器設(shè)計(jì)與試驗(yàn)[J]. 農(nóng)業(yè)工程學(xué)報(bào),2017,33(14):115-121.

10.11975/j.issn.1002-6819.2017.14.016 http://www.tcsae.org

Zhang Jiankuo, Li Jianian, Wu Hao, Ma Zeyu, Waleed Elnour Babekir Salih, Hu Hechen. Design and experiment of low pressure Venturi injector based on double fertilizer inlets[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(14): 115-121. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.14.016 http://www.tcsae.org

2017-04-04

2017-07-10

國(guó)家自然科學(xué)基金(51509121);云南省高校工程研究中心建設(shè)計(jì)劃資助項(xiàng)目

張建闊,男,河北邯鄲人,主要從事電子信息技術(shù)及測(cè)控技術(shù)應(yīng)用研究。昆明 昆明理工大學(xué)現(xiàn)代農(nóng)業(yè)工程學(xué)院,650500。

Email:763519823@qq.com

※通信作者:李加念,男,湖南道縣人,博士,副教授,主要從事農(nóng)業(yè)測(cè)控技術(shù)應(yīng)用研究。昆明 昆明理工大學(xué)現(xiàn)代農(nóng)業(yè)工程學(xué)院,650500。

Email:ljn825@163.com