破碎和均細(xì)化處理方式對胡蘿卜汁中類胡蘿卜素釋放的影響

劉嘉寧,劉 璇,畢金峰,張佰清,易建勇,彭 健

(1. 沈陽農(nóng)業(yè)大學(xué)食品學(xué)院,沈陽 110866;2. 中國農(nóng)業(yè)科學(xué)院農(nóng)產(chǎn)品加工研究所,農(nóng)業(yè)部農(nóng)產(chǎn)品加工綜合性重點實驗室,北京 100193)

破碎和均細(xì)化處理方式對胡蘿卜汁中類胡蘿卜素釋放的影響

劉嘉寧1,2,劉 璇2,畢金峰2,張佰清1※,易建勇2,彭 健2

(1. 沈陽農(nóng)業(yè)大學(xué)食品學(xué)院,沈陽 110866;2. 中國農(nóng)業(yè)科學(xué)院農(nóng)產(chǎn)品加工研究所,農(nóng)業(yè)部農(nóng)產(chǎn)品加工綜合性重點實驗室,北京 100193)

為研究不同破碎和均細(xì)化處理對胡蘿卜汁中類胡蘿卜素釋放途徑的影響,采用打漿﹑膠體磨和高壓均質(zhì)3種破碎和均細(xì)化方式處理胡蘿卜汁。應(yīng)用分光光度法對處理后不同植物組織(大細(xì)胞聚集體﹑小細(xì)胞聚集體和有色體)中類胡蘿卜素含量,游離類胡蘿卜素含量,總類胡蘿卜素含量,油脂可萃取類胡蘿卜素含量進(jìn)行測定。應(yīng)用激光共聚焦掃描顯微鏡觀察不同處理后類胡蘿卜素的分布情況。利用高效液相色譜法對油脂可萃取類胡蘿卜素單體含量進(jìn)行測定。通過顯著性分析確定不同均細(xì)化處理對以上3種植物組織中類胡蘿卜素含量﹑游離類胡蘿卜素含量﹑總類胡蘿卜素釋放率和油脂可萃取總類胡蘿卜素含量及單體含量的影響。結(jié)果表明破碎和均細(xì)化處理后,大細(xì)胞聚集體中類胡蘿卜素所占比例減小(從36.18%減小至15.28%),小細(xì)胞聚集體(從11.11%增加至15.73%)和有色體部分(8.36%增加至30.56%)中類胡蘿卜素所占比例增大,類胡蘿卜素釋放在對其釋放阻礙程度低的組織部分中。經(jīng)過均細(xì)化處理后,激光共聚焦顯微鏡下可見的類胡蘿卜素顆粒減少,處理越均細(xì),可見的類胡蘿卜素顆粒越少。對胡蘿卜汁處理越均細(xì),胡蘿卜汁中類胡蘿卜素釋放率越高,其中膠體磨和高壓均質(zhì)聯(lián)合處理胡蘿卜汁后類胡蘿卜素的釋放率為50.91%。對胡蘿卜汁處理越均細(xì),胡蘿卜汁中油脂可萃取總類胡蘿卜素﹑β-胡蘿卜素和α-胡蘿卜素含量越少。研究結(jié)果對后續(xù)分析如何提高胡蘿卜汁中類胡蘿卜素生物利用率提供依據(jù)。

壓力;溫度;果汁;均細(xì)化處理;高壓均質(zhì);類胡蘿卜素;胡蘿卜汁

0 引 言

類胡蘿卜素通常分為以下兩類:一是不含有氧原子的碳?xì)渥孱惡}卜素,被稱為胡蘿卜素(carotene),主要包括β-胡蘿卜素﹑α-胡蘿卜素和番茄紅素等。另外一種是至少含有一個氧原子的葉黃素類(xanthophylls),主要包括β-隱黃素﹑玉米黃素等[1]。類胡蘿卜素被廣泛熟知和關(guān)注的是其維生素A原活性,特別是β-胡蘿卜素﹑α-和β-隱黃素,由于其具有抗氧化活性,已經(jīng)被證實可以降低許多疾病的發(fā)病率,如心血管疾病﹑老年性黃斑變性﹑癌癥[2]等。胡蘿卜具有很高的營養(yǎng)價值,含有豐富的類胡蘿卜素,是β-胡蘿卜素含量最高的蔬菜之一,每 100 g鮮胡蘿卜中含β-胡蘿卜素1.35~4.3 mg。在胡蘿卜中,類胡蘿卜素主要存在于植物細(xì)胞的有色體中,被細(xì)胞壁和細(xì)胞膜包圍[3]。類胡蘿卜素從食品基質(zhì)中的釋放是其消化吸收的第一步,也是決定其生物利用率的關(guān)鍵步驟[4],而有色體的亞細(xì)胞結(jié)構(gòu)和細(xì)胞壁的存在限制了類胡蘿卜素的釋放,因此鮮食胡蘿卜的類胡蘿卜素生物利用率較低。采用合適機械加工處理,例如榨汁﹑打漿和均質(zhì)等方法破壞細(xì)胞壁并減小其粒徑[5],是提高類胡蘿卜素生物利用率的有效途徑。近年來,國內(nèi)外關(guān)于高壓均質(zhì)處理果蔬汁的研究逐漸增多,主要集中于對果蔬汁殺菌效果[6-8],果蔬汁理化性質(zhì)如流變特性[9-11]﹑穩(wěn)定性(粒徑分布、ζ-電位、色澤)[12-13]﹑營養(yǎng)品質(zhì)[14-15]和果蔬汁類胡蘿卜素生物利用率[16-17]等方面。在高壓均質(zhì)處理后類胡蘿卜素含量變化方面,有研究表明,高壓均質(zhì)處理(100,200和300 MPa)橙汁比熱處理(90℃加熱1 min)橙汁總類胡蘿卜素含量高,不同均質(zhì)壓力對總類胡蘿卜素含量無顯著影響[14]。Svelander等[18]結(jié)果表明高壓均質(zhì)處理后的胡蘿卜乳液中胡蘿卜素含量無明顯變化。在高壓均質(zhì)對類胡蘿卜素生物利用率的影響方面,研究的內(nèi)容主要涉及在口腔咀嚼、胃消化階段和小腸消化吸收階段中類胡蘿卜素含量的變化。而關(guān)于高壓均質(zhì)對類胡蘿卜素等脂溶性物質(zhì)從食品中釋放以及其釋放途徑尚未見報道。

本試驗采用打漿﹑膠體磨和高壓均質(zhì) 3種破碎和均細(xì)化方式處理胡蘿卜汁,以研究破碎和均細(xì)化處理對類胡蘿卜素釋放途徑的影響,對后續(xù)提高胡蘿卜汁中類胡蘿卜素的生物利用率具有指導(dǎo)意義。

1 材料與方法

1.1 材料與試劑

胡蘿卜購于北京市清河小營農(nóng)副產(chǎn)品市場,產(chǎn)地山東;BETIS特級初榨橄欖油,托雷斯和貝雷斯公司;正己烷﹑丙酮﹑無水乙醇﹑氯化鈉,國藥集團化學(xué)試劑有限公司,以上試劑均為分析純;2,6-二叔丁基-4-甲基苯酚(butylated hydroxytoluene,BHT),純度99%,北京依諾凱科技有限公司;用于色譜分析的正己烷﹑甲基叔丁基醚(methyl-t-butyl-ether,MTBE)﹑甲醇均為色譜純,美國Tedia公司;尼羅紅,純度≥95%,上海Aladdin公司;β-胡蘿卜素標(biāo)品﹑α-胡蘿卜素標(biāo)品,色譜級,美國Sigma-Aldrich公司。

1.2 儀器與設(shè)備

九陽料理機JYL-C51V,九陽股份有限公司;高壓納米均質(zhì)機JN-02HC(含加熱/冷卻循環(huán)系統(tǒng)),廣州聚能生物科技有限公司;膠體磨JM-30A,廊坊市廊通機械有限公司;金屬絲編制網(wǎng)試驗篩,中國航空工業(yè)第五四零廠;超聲高能篩分機USC,上海納維加特機電科技有限公司;紫外/可見光分光光度計UV-1800,日本Shimadzu公司;高速冷凍離心機Sigma 3K15,德國Sigma公司;旋轉(zhuǎn)蒸發(fā)器 RE-3000,上海亞榮生化儀器廠;C30柱,YMC Carotenoid S-5μm(250 mm×4.6 mm);HPLC 設(shè)備(Waters 1525溶劑輸送系統(tǒng)和Waters 2489紫外/可見光檢測器),Waters公司;激光共聚焦掃描顯微鏡LSM 880,德國蔡司公司。

1.3 方法

1.3.1 含有類胡蘿卜素的植物組織部分的分離

參照Palmero等[19]的方法,稍作修改,分離出大細(xì)胞聚集體、小細(xì)胞聚集體和有色體部分,并制備游離類胡蘿卜素。上述4種部分對類胡蘿卜素釋放的阻礙作用由大到小順序為:大細(xì)胞聚集體、小細(xì)胞聚集體、有色體、游離類胡蘿卜素。

1)不同植物組織部分的分離

胡蘿卜經(jīng)過清洗﹑去皮﹑切分后與去離子水1∶1(質(zhì)量比)混合打漿1 min。制得的胡蘿卜漿在超聲高能篩分機下進(jìn)行篩分,大細(xì)胞聚集體采用20目試驗篩進(jìn)行分離,取上層未過篩的部分。小細(xì)胞聚集體采用60目和300目試驗篩分離,60目試驗篩在上層,300目試驗篩在下層,取通過60目試驗篩,并截留于300目試驗篩上的部分。

胡蘿卜經(jīng)過清洗﹑去皮﹑切塊后加入0.05 mol/L的EDTA(1∶1,體積比)打漿5 s,過濾,濾液在10 000×g,4 ℃條件下離心30 min,得到有色體部分[20]。

2)游離類胡蘿卜素的制備

按照1)的方式制得胡蘿卜漿,制得的胡蘿卜漿與橄欖油(5∶1,體積比)充分混合5 h,在9 000×g,4 ℃條件下離心30 min得到游離類胡蘿卜素。

3)不同組織狀態(tài)占胡蘿卜漿的比例

通過以上方法分離得到的部分按照下述公式計算其所占比例:

式中ma為不同組織部分的質(zhì)量(g);mb分別為100g胡蘿卜原料經(jīng)過不同處理后胡蘿卜漿的質(zhì)量(g)。

4)類胡蘿卜素分布比例

類胡蘿卜素在 4種組織部分中的分布比例按下列公式進(jìn)行計算:

式中mc為經(jīng)過不同處理后不同組織部分中類胡蘿卜素總量(μg/g);mt為經(jīng)過不同處理后4種組織部分類胡蘿卜素總量的和(μg/g)。

1.3.2 破碎和均細(xì)化方式

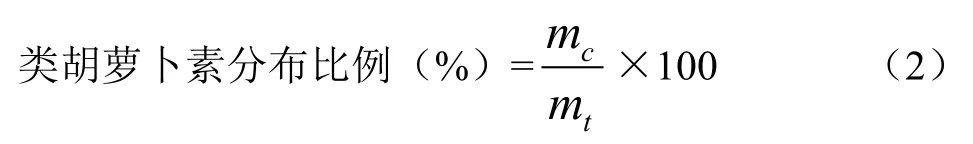

胡蘿卜經(jīng)過清洗﹑去皮和切塊后,與去離子水 1∶1(質(zhì)量比)打漿1 min,過濾得到胡蘿卜汁。得到的胡蘿卜汁分別通過高壓均質(zhì)﹑膠體磨及膠體磨和高壓均質(zhì)串聯(lián)的均細(xì)化方法處理,具體處理條件及編號見表1。

表1 樣品編號和處理條件Table 1 Sample coding and processing conditions

1.3.3 總類胡蘿卜素含量的測定

1)胡蘿卜汁中總類胡蘿卜素含量的測定

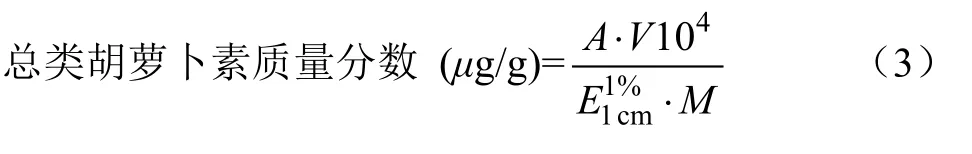

參照 Knockaert等[21]的方法進(jìn)行總類胡蘿卜素含量的測定和計算,取1 g胡蘿卜汁加50 mL提取液(含體積分?jǐn)?shù)為50%的正己烷,25%的丙酮,25%的乙醇,質(zhì)量分?jǐn)?shù)為0.1%的BHT和0.5 g NaCl),攪拌20 min。然后向上述溶液中加入15 mL蒸餾水,攪拌10 min。將混合物放入分液漏斗,收集有機相并定容。在450 nm下測定吸光度,用正己烷加0.1% BHT做空白。

其中A為450 nm處的吸光值,V為提取液總體積(mL),M為胡蘿卜汁質(zhì)量(g),E1cm1%(2 560)為β-胡蘿卜素在正己烷中的消光系數(shù)[22]。整個操作在避光條件下進(jìn)行。

2)原料中總類胡蘿卜素含量的測定

稱0.5 g鮮胡蘿卜于研缽中,用50 mL上述提取液,分?jǐn)?shù)次研磨提取,直到提取液和渣為無色。合并提取液,加入15 mL蒸餾水和0.5 g NaCl攪拌10 min。將混合物放入分液漏斗中,收集有機相并定容,按上述方法測定和計算原料中總類胡蘿卜素含量。

3)釋放率

胡蘿卜汁中總類胡蘿卜素的釋放率用如下公式計算:

式中mj為不同均細(xì)化處理后胡蘿卜汁中總類胡蘿卜素質(zhì)量分?jǐn)?shù)(μg/g);mm為原料中總類胡蘿卜素質(zhì)量分?jǐn)?shù)(μg/g)。

1.3.4 油脂可萃取總類胡蘿卜素含量的測定

胡蘿卜中的類胡蘿卜素由于機械作用初步釋放,因類胡蘿卜素具有親脂性,在胃中與食糜中的油相結(jié)合,隨后在小腸中與油脂、磷脂和膽鹽一起混合轉(zhuǎn)化為水溶性膠束,被小腸上皮細(xì)胞吸收[23]。因此測定均細(xì)化處理后的油脂可萃取類胡蘿卜素含量,可以反映其能夠溶于油脂部分的含量,即可能被人體吸收利用的有效量。參照Palmero等[19]的方法,稍作修改,取不同破碎和均細(xì)化處理的胡蘿卜漿與橄欖油(5∶1,體積比),充分混合5 h。在9 000×g,4 ℃條件下離心30 min得到油脂可萃取類胡蘿卜素,取油脂部分測定油脂可萃取總類胡蘿卜素含量。

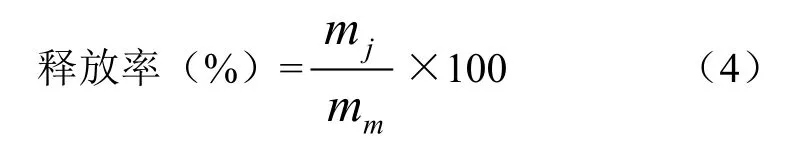

1.3.5 油脂可萃取類胡蘿卜素單體含量測定

取不同破碎和均細(xì)化處理的胡蘿卜漿與橄欖油(5∶1,體積比),充分混合5 h。在9 000 ×g,4 ℃條件下離心30 min得到油脂可萃取類胡蘿卜素,得到的部分加入50 mL上述提取液,并攪拌20 min。然后加入15 mL蒸餾水,攪拌10 min。將混合物放入分液漏斗,收集有機相于旋轉(zhuǎn)蒸發(fā)儀,在(40±2) ℃的條件下蒸至近干。用正己烷溶解殘渣并轉(zhuǎn)移至容量瓶中定容,用0.45μm濾膜過濾,在-18 ℃條件下冷藏備用。采用高效液相色譜法,反相C30柱加紫外可見光檢測器。流動相A:甲醇:甲基叔丁基醚(MTBE)∶水=81∶15∶4,流動相B:甲醇∶MTBE∶水=6∶90∶4;梯度洗脫條件:100% A在45 min內(nèi)降至44%;流速:1.0 mL/min;檢測波長:450 nm;進(jìn)樣量:10μL;柱溫:30 ℃[24]。采用外標(biāo)法計算樣品中β-胡蘿卜素和α-胡蘿卜素含量。圖1為油脂可萃取類胡蘿卜素的HPLC圖,由圖1可知油脂可萃取類胡蘿卜素中主要為β-胡蘿卜素和α-胡蘿卜素。類胡蘿卜素化學(xué)結(jié)構(gòu)的中心部分含有交替排列的雙鍵與單鍵的聚烯烴鏈,因此類胡蘿卜素通常有高度的疏水性,尤其是不含有任何氧原子的類胡蘿卜素,例如β-胡蘿卜素和α-胡蘿卜素,因此測定油脂可萃取β-胡蘿卜素和α-胡蘿卜素可以充分反映其可以溶于油部分的含量。

1.3.6 類胡蘿卜素的分布圖

參照Low[25],Liu[26]的方法稍作修改,將尼羅紅溶解于正己烷中,配置成0.25 g/L尼羅紅,對胡蘿卜汁染色30 min后,在10倍物鏡,激發(fā)波長561 nm,激光功率密度2 mW條件下觀察。采用Zen(Black)軟件處理圖片。

圖1 油脂可萃取類胡蘿卜素的HPLC圖Fig.1 HPLC chromatogram of oil-extracted carotenoids

1.4 數(shù)據(jù)處理

試驗設(shè)計均采用平均值±標(biāo)準(zhǔn)差(Mean±SD)表示。數(shù)據(jù)分析采用SPSS 19.0統(tǒng)計分析軟件的ANOVA及LSD多重比較分析顯著性差異(P<0.05),試驗分析圖采用Excel 2010軟件繪制。

2 結(jié)果與分析

2.1 均細(xì)化處理對不同組織中類胡蘿卜素分布的影響

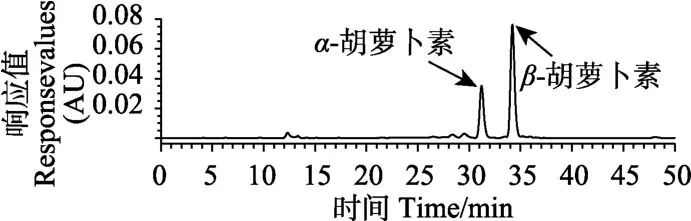

不同組織狀態(tài)占胡蘿卜漿的比例見圖2,由圖2可知,游離類胡蘿卜素,有色體和小細(xì)胞聚集體部分所占比例在均質(zhì)前后無顯著差異(P>0.05),均質(zhì)后大細(xì)胞聚集體所占比例顯著低于未均質(zhì)時大細(xì)胞聚集體所占比例(P<0.05)。均質(zhì)前后有色體部分所占比例都在90%以上,這是因為離心后有色體部分存在于上清液中,所以這一部分質(zhì)量包含水的質(zhì)量,因此所占比例很高。測定不同組織狀態(tài)的比例主要目的是對比均質(zhì)前后每一部分的質(zhì)量占比差異。

圖2 不同組織狀態(tài)占胡蘿卜漿的比例Fig.2 Proportion of different organizational state in carrot puree

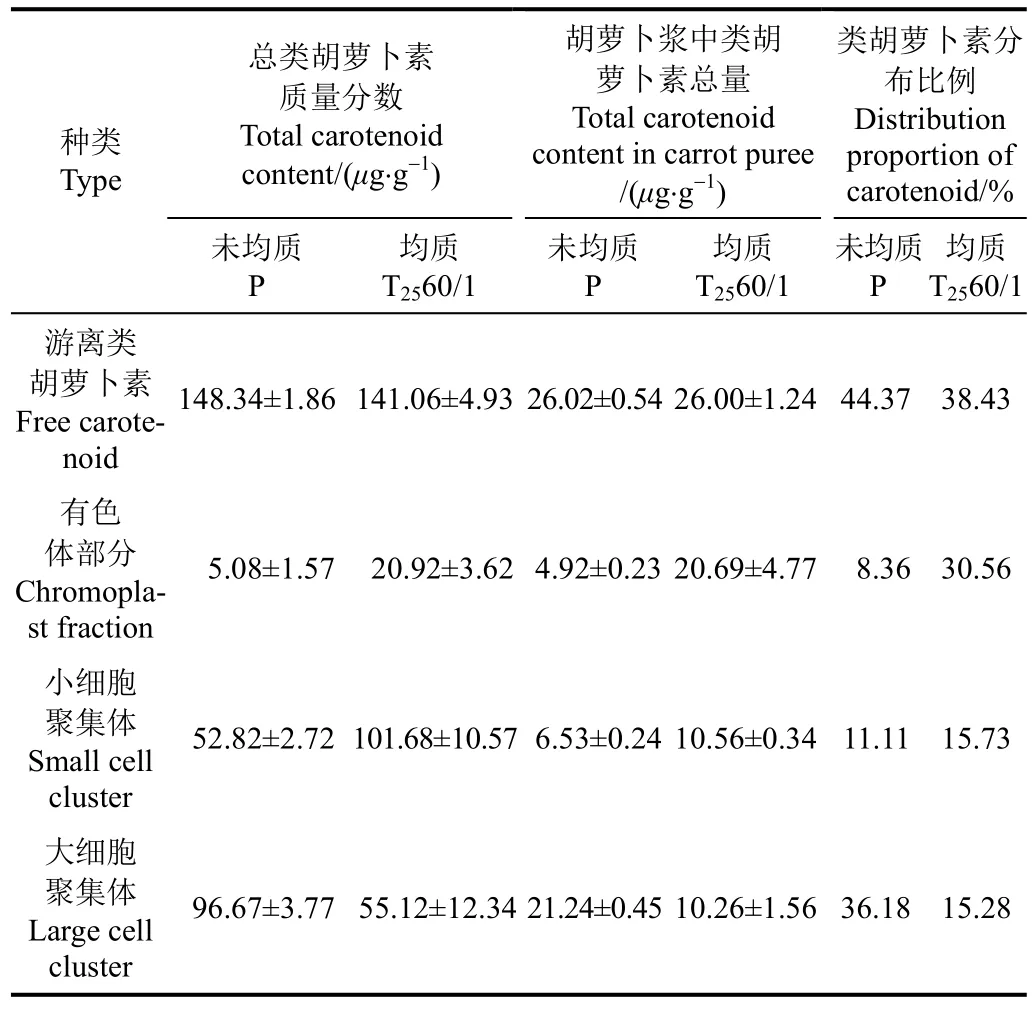

表 2為均細(xì)化處理對類胡蘿卜素在不同組織分布的影響,由表 2可知,對于總類胡蘿卜素質(zhì)量分?jǐn)?shù),未均質(zhì)時,胡蘿卜漿中游離類胡蘿卜素含量最高,其次是大細(xì)胞聚集體、小細(xì)胞聚集體和有色體。游離類胡蘿卜素作為對類胡蘿卜素釋放沒有阻礙的部分,類胡蘿卜素含量最高。大細(xì)胞聚集體中類胡蘿卜素含量較高,作為對類胡蘿卜素釋放含有最多屏障的部分,這一部分如果經(jīng)過合適的機械處理,可以釋放較多類胡蘿卜素。而有色體部分類胡蘿卜素含量很少,這可能是由于未均質(zhì)的胡蘿卜漿中有色體的完整性破壞程度低,因此有色體部分類胡蘿卜素未完全釋放。均質(zhì)后,胡蘿卜漿中游離類胡蘿卜素含量與未均質(zhì)相比無顯著差異(P>0.05),均質(zhì)后的有色體部分的類胡蘿卜素含量是未均質(zhì)的 4倍左右(P<0.05),均質(zhì)后的小細(xì)胞聚集體中的類胡蘿卜素含量顯著高于未均質(zhì)的小細(xì)胞聚集體中的類胡蘿卜素含量(P<0.05),均質(zhì)后的大細(xì)胞聚集體中類胡蘿卜素含量顯著低于未均質(zhì)的大細(xì)胞聚集體中類胡蘿卜素含量(P<0.05)。因此可以看出均質(zhì)后,類胡蘿卜素更多的釋放在對其釋放阻礙程度低的組織部分中。

表2 均細(xì)化處理對不同組織中類胡蘿卜素分布的影響Table 2 Effects of refining treatment on carotenoid distribution in different organizational state

對于類胡蘿卜素總量,未均質(zhì)的胡蘿卜漿中游離類胡蘿卜素總量最高,其次是大細(xì)胞聚集體、小細(xì)胞聚集體和有色體。由于小細(xì)胞聚集體所占比例比較少,因此其類胡蘿卜素總量相對較低。以上 4部分的類胡蘿卜素總量在均質(zhì)前后呈現(xiàn)以下規(guī)律:均質(zhì)前后游離類胡蘿卜素總量無顯著差異(P>0.05),均質(zhì)后有色體中類胡蘿卜素總量是未均質(zhì)的 4倍左右(P<0.05),均質(zhì)后小細(xì)胞聚集體中類胡蘿卜素總量是未均質(zhì)2倍左右(P<0.05),而均質(zhì)后大細(xì)胞聚集體中類胡蘿卜素含量顯著減少(P<0.05),是未均質(zhì)的1/2左右。對于類胡蘿卜素分布比例,未均質(zhì)胡蘿卜漿中,游離類胡蘿卜素所占比例最高,其次是大細(xì)胞聚集體,占比例較小的是小細(xì)胞聚集體和有色體部分,而均質(zhì)后游離類胡蘿卜素所占比例最高,其次是有色體部分。均質(zhì)后大細(xì)胞聚集體中類胡蘿卜素所占比例減小,小細(xì)胞聚集體和有色體部分中類胡蘿卜素所占比例增大,游離類胡蘿卜素所占比例減少,但是減小程度不大,由此可以看出,類胡蘿卜素更多的釋放在對其阻礙程度低的組織部分中,這是由于均質(zhì)處理破壞細(xì)胞壁和細(xì)胞膜,促進(jìn)類胡蘿卜素的釋放,更多的類胡蘿卜素從大細(xì)胞中釋放出,進(jìn)入其他組織部分。Palmero等[19]從胡蘿卜中分離出上述4部分,得出的結(jié)論為對其釋放阻礙程度越低的組織中的類胡蘿卜素生物利用率越高。Svelander等[18]報道高壓均質(zhì)可以提高胡蘿卜乳液中類胡蘿卜素生物利用率。因此,高壓均質(zhì)可能通過使類胡蘿卜素更多的釋放在對其釋放阻礙程度低的組織部分中,從而提高胡蘿卜中類胡蘿卜素生物利用率,而這一假設(shè)有待于進(jìn)一步試驗的證明。

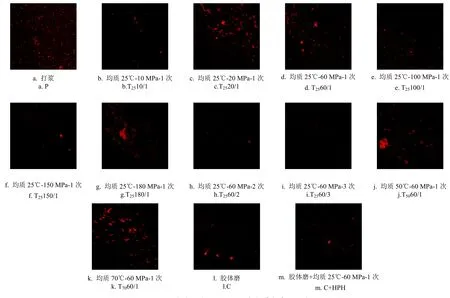

2.2 不同破碎和均細(xì)化處理后類胡蘿卜素在細(xì)胞組織中的分布圖

在胡蘿卜中,有色體主要以晶體形態(tài)存在,其中主要含有的類胡蘿卜素是β-胡蘿卜素[27-28],晶體形態(tài)有色體在機械作用下容易受到破壞[16]。由圖 3可知,均質(zhì)和膠體磨處理相對于打漿處理,可見的類胡蘿卜素顆粒減少,膠體磨與均質(zhì)串聯(lián)處理與單獨膠體磨處理相比,類胡蘿卜素顆粒也會減少。Croak等[29]發(fā)現(xiàn)橙汁的ζ-電位隨pH值的變化規(guī)律與果膠分子在此pH范圍內(nèi)帶電性變化規(guī)律一致,因此橙汁中帶負(fù)電的果膠可能包裹在小顆粒周圍,形成保護(hù)層。結(jié)合本試驗結(jié)果,可推測類胡蘿卜素顆粒減小可能是由于均細(xì)化處理后,細(xì)胞壁受到較嚴(yán)重的破壞,而處理越均細(xì),細(xì)胞壁破壞的程度越嚴(yán)重,從而使細(xì)胞壁中的果膠等物質(zhì)釋放出來,包裹在類胡蘿卜素周圍。均質(zhì)壓力范圍為100 MPa~150 MPa(25 ℃,均質(zhì)1次)與均質(zhì)壓力為10 MPa~60 MPa(25 ℃,均質(zhì)1次)相比,可觀察到的類胡蘿卜素減少,這是由于均質(zhì)壓力升高后,產(chǎn)生了更高的速度梯度,增加了湍流作用和空穴作用等[30],對細(xì)胞壁結(jié)構(gòu)的破壞增強[31],從而使細(xì)胞壁中更多的果膠物質(zhì)釋放出來,因此果膠對類胡蘿卜素的包裹程度增高。當(dāng)均質(zhì)壓力為180 MPa(25 ℃,均質(zhì) 1次)時,類胡蘿卜素傾向于形成聚集體,這可能是由于壓力較高的情況下,破壞果膠等物質(zhì)與類胡蘿卜素分子的結(jié)合作用,類胡蘿卜素釋放出來。在均質(zhì)壓力為60 MPa和進(jìn)料溫度為25 ℃的條件下,隨著均質(zhì)次數(shù)的增加,類胡蘿卜素顆粒減小,這可能是由于處理越均細(xì),對細(xì)胞壁的破壞程度越大,有越多的果膠等物質(zhì)釋放出來,包裹類胡蘿卜素。在均質(zhì)壓力為60 MPa和均質(zhì)1次的條件下,隨著進(jìn)料溫度的增加,類胡蘿卜素發(fā)生聚集,可能是由于溫度的升高,細(xì)胞結(jié)構(gòu)變得松散[32],果膠與類胡蘿卜素結(jié)合作用減弱,因此類胡蘿卜素釋放出來。

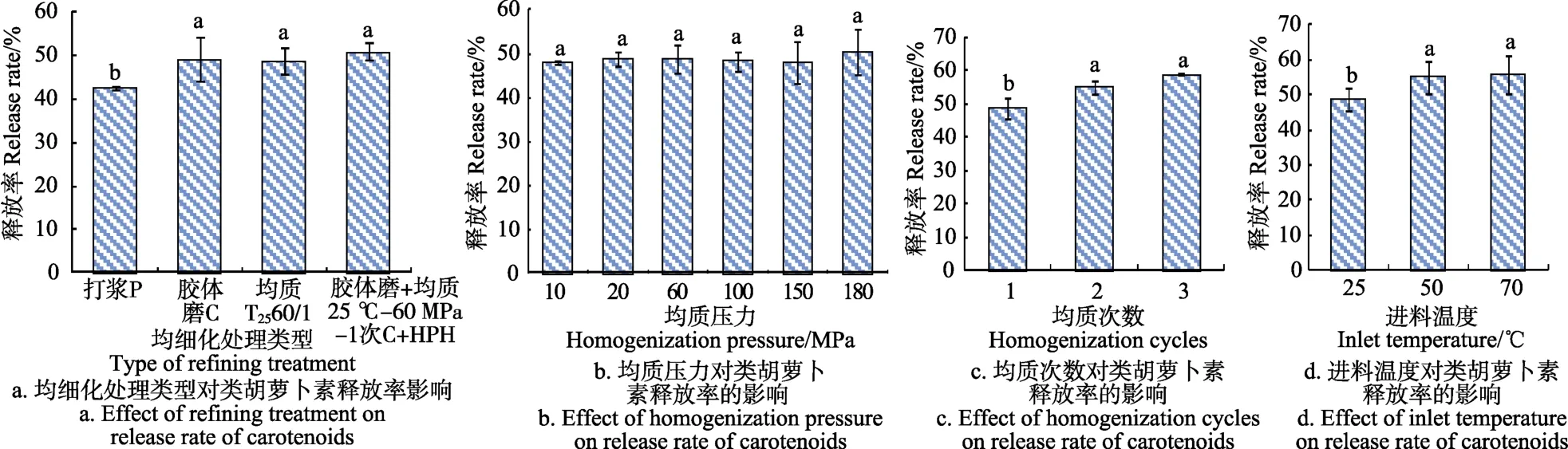

2.3 不同破碎和均細(xì)化處理對類胡蘿卜素釋放率的影響

由圖4a可以看出均質(zhì)(48.82%)﹑膠體磨(49.16%)和膠體磨與均質(zhì)串聯(lián)(50.91%)這 3種處理方式相對于打漿(42.69%)處理可以顯著提高類胡蘿卜素的釋放率(P<0.05),處理越均細(xì),類胡蘿卜素釋放率越高。這是因為均細(xì)化處理對細(xì)胞壁起到進(jìn)一步破壞的作用,從而促進(jìn)類胡蘿卜素的釋放。由圖4b可以看出,在高壓均質(zhì)處理中,不同均質(zhì)壓力對類胡蘿卜素含量沒有顯著影響(P>0.05),這可能是由于胡蘿卜汁中顆粒本身就很小,因此不同均質(zhì)壓力產(chǎn)生的擠壓和剪切作用對胡蘿卜汁中顆粒的影響較小,該結(jié)果與Velázquez-Estrada等的研究結(jié)果一致,不同均質(zhì)壓力對橙汁中總類胡蘿卜素含量無顯著影響[14]。由圖4c可以看出,均質(zhì)次數(shù)的增加可以顯著提高類胡蘿卜素的釋放率(P<0.05),這可能是由于均質(zhì)次數(shù)的增加可以使果肉顆粒變得更小更均勻[9],從而使更多類胡蘿卜素釋放在胡蘿卜汁中,提高胡蘿卜汁中類胡蘿卜素的含量,該結(jié)果與吳亦兵[33]報道的研究結(jié)果一致。由圖4d可以看出,進(jìn)料溫度越高,類胡蘿卜素的釋放率越高,可能是因為加熱后細(xì)胞結(jié)構(gòu)變得松散[32],從而促進(jìn)類胡蘿卜素釋放到胡蘿卜汁中。結(jié)合圖 3可以看出,均細(xì)化處理在破壞細(xì)胞方面作用效果好,可有效促進(jìn)類胡蘿卜素釋放到胡蘿卜汁中,而且均細(xì)化處理可以使胡蘿卜果肉顆粒更細(xì)小,更多地懸浮在果汁中,間接提高類胡蘿卜素含量。

圖3 不同破碎和均細(xì)化處理后類胡蘿卜素的分布圖Fig.3 Micrograph of carotenoid distribution by different crushing and refining treatment

圖4 不同均細(xì)化處理參數(shù)對類胡蘿卜素釋放率的影響Fig.4 Effects of different crushing and refining treatment on release rate of carotenoids

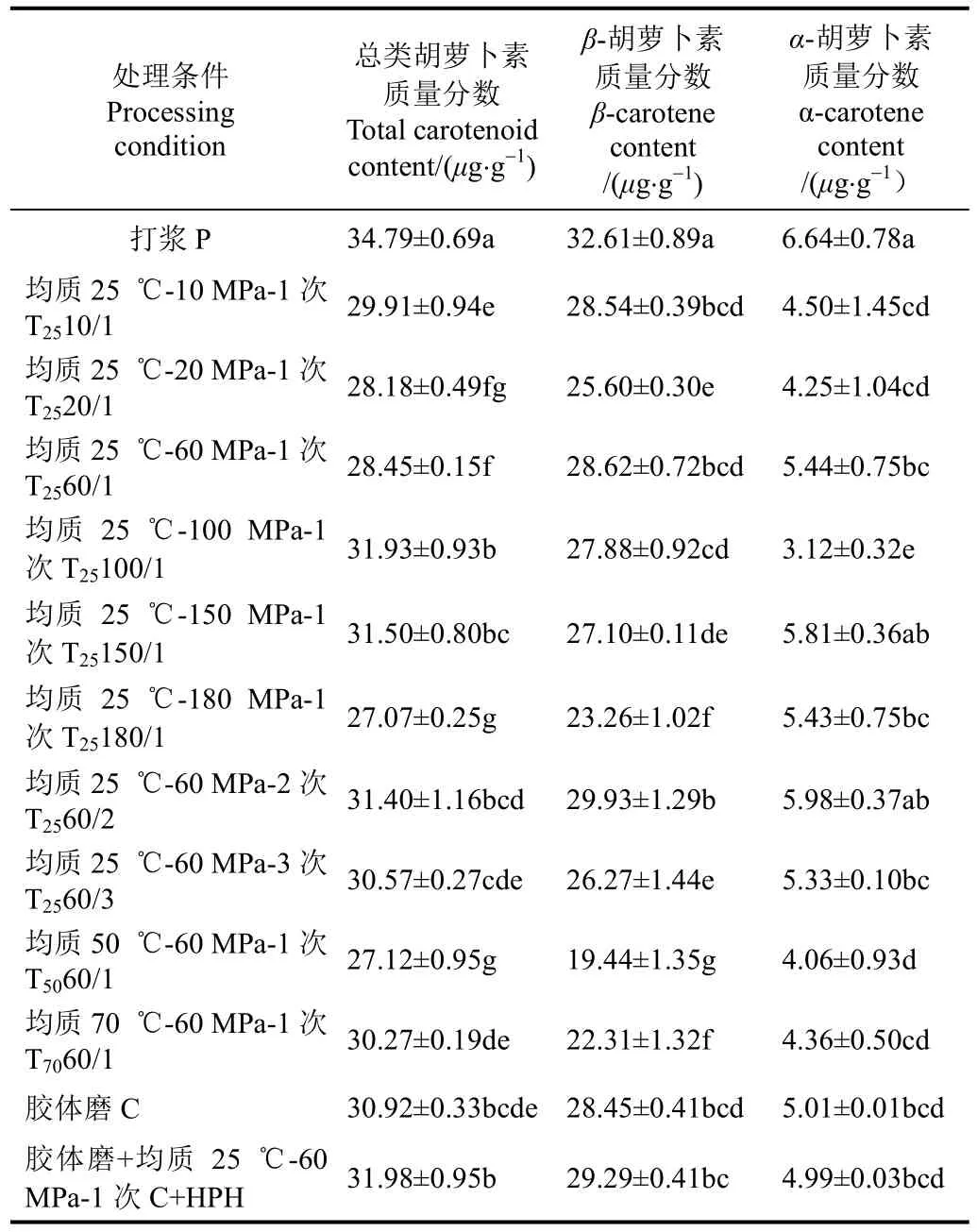

2.4 不同破碎和均細(xì)化處理對油脂可萃取總類胡蘿卜素含量的影響

從表 3可以看出,打漿處理總類胡蘿卜素含量最高(P<0.05),而均質(zhì)﹑膠體磨以及膠體磨和均質(zhì)串聯(lián)處理相對于打漿處理會顯著降低總類胡蘿卜素含量(P<0.05)。均質(zhì)壓力從10 MPa升高到180 MPa(25 ℃,均質(zhì) 1次)時,總類胡蘿卜素含量先減少后增加又減小,在100 MPa和150 MPa達(dá)到較高水平,在壓力為180 MPa時降低。均質(zhì)次數(shù)從1次增加到2次(25 ℃,60 MPa)可以顯著增加總類胡蘿卜素含量(P<0.05),而再增加次數(shù)不會顯著影響總類胡蘿卜素含量(P>0.05),這可能是由于對細(xì)胞壁的破碎程度增高,增加細(xì)胞壁果膠等的溶出,從而影響總類胡蘿卜素含量。Beysseriat等報道[34]膳食纖維可以吸附在乳化的脂滴表面,形成一層保護(hù)層。結(jié)合本試驗結(jié)果,可推測高壓均質(zhì)促進(jìn)胡蘿卜中內(nèi)源果膠的釋放,而其形成的保護(hù)層可能會影響油脂中總類胡蘿卜素的釋放。進(jìn)料溫度為 70 ℃比進(jìn)料溫度為50 ℃和25 ℃(60 MPa,均質(zhì)1次)時總類胡蘿卜素含量高(P<0.05),由此可以看出當(dāng)進(jìn)料溫度較高時,才可以提高油脂可萃取總類胡蘿卜素的含量,這可能是由于溫度較高時,加速對細(xì)胞壁和細(xì)胞膜的破壞,果膠發(fā)生β-消除反應(yīng),從而使細(xì)胞結(jié)構(gòu)軟化,減弱與類胡蘿卜素結(jié)合的物質(zhì)對其釋放的阻礙作用,使更多類胡蘿卜素釋放到油脂中。

表3 不同破碎和均細(xì)化處理方式對胡蘿卜汁中油脂可萃取總類胡蘿卜素和類胡蘿卜素單體含量的影響Table 3 Effects of different crushing and refining treatments on contents of total oil-extracted carotenoid, oil-extracted β-carotene and α-carotene in carrot juice

2.5 不同破碎和均細(xì)化處理對油脂可萃取類胡蘿卜素單體含量的影響

由表3可知,打漿處理后β-胡蘿卜素和α-胡蘿卜素含量最高(P<0.05),均質(zhì)﹑膠體磨和均質(zhì)膠體磨串聯(lián)處理相對于打漿處理會顯著降低β-胡蘿卜素和α-胡蘿卜素含量(P<0.05),這與總類胡蘿卜素含量變化規(guī)律一致,因此可推測高壓均質(zhì)促進(jìn)胡蘿卜中內(nèi)源果膠的釋放,而其形成的保護(hù)層可能會影響油脂中總類胡蘿卜素的釋放。對于β-胡蘿卜素,均質(zhì)壓力從10 MPa升到20 MPa(25 ℃,均質(zhì) 1 次),β-胡蘿卜素含量顯著降低(P<0.05),在壓力為60 MPa~150 MPa時(25 ℃,均質(zhì)1次),β-胡蘿卜素含量無顯著差異(P>0.05),當(dāng)壓力為180 MPa(25 ℃,均質(zhì)1次)時,含量顯著降低(P<0.05)。這一現(xiàn)象可能是由于不同均質(zhì)壓力對果膠結(jié)構(gòu)產(chǎn)生影響[35],引起果膠解聚,從而影響果膠對類胡蘿卜素的包裹作用,引起類胡蘿卜素含量變化。進(jìn)料溫度較低時,β-胡蘿卜素含量較高,進(jìn)料溫度為50 ℃和70 ℃,與25 ℃時相比均顯著降低β-胡蘿卜素含量(P<0.05),這可能是由于熱對β-胡蘿卜素氧化的降解作用引起的[36]。對于α-胡蘿卜素,均質(zhì)壓力在10 MPa~60 MPa(25 ℃,均質(zhì)1次)時,α-胡蘿卜素含量無顯著差異(P>0.05),當(dāng)壓力為100 MPa時,α-胡蘿卜素含量顯著降低(P<0.05),壓力升高到150 MPa~180 MPa(25 ℃,均質(zhì)1次)時,α-胡蘿卜素含量又顯著增加(P<0.05)。進(jìn)料溫度為50 ℃和 70 ℃,與 25 ℃時相比均顯著降低α-胡蘿卜素含量(P<0.05),這可能是由于熱對α-胡蘿卜素氧化的降解作用引起的。β-胡蘿卜素和α-胡蘿卜素在不同均質(zhì)壓力條件下,含量變化趨勢不同,這可能是由于兩者結(jié)構(gòu)不同,溶于油脂的能力不同,因此含量變化趨勢不同。

3 結(jié) 論

1)均質(zhì)處理后,大細(xì)胞聚集體中類胡蘿卜素總量所占比例減小(從 36.18%減小至 15.28%),小細(xì)胞聚集體(從11.11%增加至15.73%)和有色體部分(從8.36%增加至30.56%)中類胡蘿卜素總量所占比例增大,類胡蘿卜素更多的釋放在對其釋放阻礙程度低的組織中。

2)破碎和均細(xì)化處理后,細(xì)胞壁受到破壞,激光共聚焦顯微鏡下可見的類胡蘿卜素顆粒減小,處理越均細(xì),可見的類胡蘿卜素顆粒越小,類胡蘿卜素被包裹的程度越高。均質(zhì)壓力為100 MPa~150 MPa和其他壓力相比,激光共聚焦顯微鏡下可見的類胡蘿卜素顆粒較小,類胡蘿卜素被包裹程度較高。均質(zhì)壓力達(dá)到180 MPa時,類胡蘿卜素傾向于形成聚集體。隨著均質(zhì)次數(shù)的增加,可見的顆粒越小,而隨著進(jìn)料溫度的增加,類胡蘿卜素傾向于形成聚集體。

3)對胡蘿卜汁的處理越均細(xì),類胡蘿卜素釋放率越高,膠體磨和高壓均質(zhì)聯(lián)合處理胡蘿卜汁后類胡蘿卜素的釋放率為50.91%。不同壓力處理對類胡蘿卜素釋放率無顯著影響(P>0.05),均質(zhì)次數(shù)增加可以顯著提高類胡蘿卜素釋放率(P<0.05),進(jìn)料溫度越高,類胡蘿卜素釋放率越高。對胡蘿卜汁的處理越均細(xì),胡蘿卜汁中油脂可萃取總類胡蘿卜素﹑β-胡蘿卜素和α-胡蘿卜素含量越低。

由于均細(xì)化處理對胡蘿卜細(xì)胞壁的破壞作用,導(dǎo)致細(xì)胞壁中釋放出蛋白質(zhì)和多糖例如果膠等,包裹在類胡蘿卜周圍或與類胡蘿卜素結(jié)合從而影響類胡蘿卜素的釋放,因此高壓均質(zhì)后胡蘿卜汁中內(nèi)源果膠與類胡蘿卜素交互作用有待于進(jìn)一步研究。

[1] Yonekura L, Nagao A. Intestinal absorption of dietary carotenoids[J]. Molecular nutrition & food research, 2007,51(1): 107-115.

[2] Fraser P D, BramLey P M. The biosynthesis and nutritional uses of carotenoids[J]. Progress in Lipid Research, 2004,43(3): 228-265.

[3] Hornero-Méndez D, Mínguez-Mosquera M I. Bioaccessibility of carotenes from carrots: Effect of cooking and addition of oil[J]. Innovative Food Science & Emerging Technologies,2007, 8(3): 407-412.

[4] Palmero P, Panozzo A, Colle I, et al. Role of structural barriers for carotenoid bioaccessibility upon high pressure homogenization[J]. Food Chemistry, 2016, 199: 423-432.

[5] Lemmens L, van Buggenhout S, van Loey A M, et al.Particle size reduction leading to cell wall rupture is more important for the β-carotene bioaccessibility of raw compared to thermally processed carrots[J]. Journal of Agricultural and Food Chemistry, 2010, 58(24): 12769-12776.

[6] Maresca P, Donsì F, Ferrari G. Application of a multi-pass high-pressure homogenization treatment for the pasteurization of fruit juices[J]. Journal of Food Engineering, 2011, 104(3):364-372.

[7] Suárez-Jacobo á, Gervilla R, Guamis B, et al. Effect of UHPH on indigenous microbiota of apple juice: a preliminary study of microbial shelf-life[J]. International Journal of Food Microbiology, 2010, 136(3): 261-267.

[8] Bevilacqua A, Corbo M R, Sinigaglia M. Use of natural antimicrobials and high pressure homogenization to control the growth of Saccharomyces bayanus in apple juice[J]. Food Control, 2012, 24(1): 109-115.

[9] Tan J, Kerr W L. Rheological properties and microstructure of tomato puree subject to continuous high pressure homogenization[J]. Journal of Food Engineering, 2015,166(4): 45-54.

[10] Augusto P E D, Ibarz A, Cristianini M. Effect of high pressure homogenization (HPH) on the rheological properties of tomato juice: Time-dependent and steady-state shear[J].Journal of Food Engineering, 2012, 111(4): 570-579.

[11] Augusto P E D, Ibarz A, Cristianini M. Effect of high pressure homogenization (HPH) on the rheological properties of tomato juice: Creep and recovery behaviours[J]. Food Research International, 2013, 54(1): 169-176.

[12] Leite T S, Augusto P E D, Cristianini M. Using high pressure homogenization (HPH) to change the physical properties of cashew apple juice[J]. Food Biophysics, 2015, 10(2): 169-180.[13] van Buggenhout S, Wallecan J, Christiaens S, et al. Influence of high-pressure homogenization on functional properties of orange pulp[J]. Innovative Food Science & Emerging Technologies, 2015, 30: 51-60.

[14] Velázquez-Estrada R M, Hernández-Herrero M M, Rüfer C E,et al. Influence of ultra high pressure homogenization processing on bioactive compounds and antioxidant activity of orange juice[J]. Innovative Food Science & Emerging Technologies, 2013, 18: 89-94.

[15] Suárez-Jacobo á, Rüfer C E, Gervilla R, et al. Influence of ultra-high pressure homogenisation on antioxidant capacity,polyphenol and vitamin content of clear apple juice[J]. Food Chemistry, 2011, 127(2): 447-454.

[16] Panozzo A, Lemmens L, van Loey A, et al. Microstructure and bioaccessibility of different carotenoid species as affected by high pressure homogenisation: A case study on differently coloured tomatoes[J]. Food Chemistry, 2013,141(4): 4094-4100.

[17] Colle I, van Buggenhout S, van Loey A, et al. High pressure homogenization followed by thermal processing of tomato pulp: Influence on microstructure and lycopene in vitro bioaccessibility[J]. Food Research International, 2010, 43(8):2193-2200.

[18] Svelander C A, Lopez‐Sanchez P, Pudney P D A, et al.High Pressure Homogenization Increases the In Vitro Bioaccessibility ofα-andβ-Carotene in Carrot Emulsions But Not of Lycopene in Tomato Emulsions[J]. Journal of Food Science, 2011, 76(9): H215-H225.

[19] Palmero P, Lemmens L, Ribas-Agustí A, et al. Novel targeted approach to better understand how natural structural barriers govern carotenoid in vitro bioaccessibility in vegetable-based systems[J]. Food Chemistry, 2013, 141(3):2036-2043.

[20] Hansen L U, Chiu M C M. Isolation and composition of chromoplasts from tomatoes[J]. Journal of Agricultural and Food Chemistry, 2005, 53(17): 6678-6682.

[21] Knockaert G, Lemmens L, van Buggenhout S, et al. Changes in β-carotene bioaccessibility and concentration during processing of carrot puree[J]. Food Chemistry, 2012, 133(1):60-67.

[22] Hart D J, Scott K J. Development and evaluation of an HPLC method for the analysis of carotenoids in foods, and the measurement of the carotenoid content of vegetables and fruits commonly consumed in the UK[J]. Food Chemistry,1995, 54(1): 101-111.

[23] Mutsokoti L, Panozzo A, Musabe E T, et al. Carotenoid transfer to oil upon high pressure homogenisation of tomato and carrot based matrices[J]. Journal of Functional Foods,2015, 19: 775-785.

[24] 劉鳳霞. 基于超高壓技術(shù)芒果汁加工工藝與品質(zhì)研究[D].北京:中國農(nóng)業(yè)大學(xué),2014.Liu Fengxia. Effect of High Hydrostatic Pressure on Processing and Qualities of Mango Juice[D]. Beijing: China Agricultural University, 2014. (in Chinese with English abstract)

[25] Low D Y, D’Arcy B, Gidley M J. Mastication effects on carotenoid bioaccessibility from mango fruit tissue[J]. Food Research International, 2015, 67: 238-246.

[26] Liu Xuan, Bi Jinfeng, Xiao Hang, et al. Increasing carotenoid bioaccessibility from yellow peppers using excipient emulsions: Impact of lipid type and thermal processing[J].Journal of Agricultural and Food Chemistry, 2015, 63(38):8534-8543.

[27] Schweiggert R M, Mezger D, Schimpf F, et al. Influence of chromoplast morphology on carotenoid bioaccessibility of carrot, mango, papaya, and tomato[J]. Food Chemistry, 2012,135(4): 2736-2742.

[28] Kim J E, Rensing K H, Douglas C J, et al. Chromoplasts ultrastructure and estimated carotene content in root secondary phloem of different carrot varieties[J]. Planta,2010, 231(3): 549-558.

[29] Croak S, Corredig M. The role of pectin in orange juice stabilization: Effect of pectin methylesterase and pectinase activity on the size of cloud particles[J]. Food Hydrocolloids,2006, 20(7): 961-965.

[30] Floury J, Bellettre J, Legrand J, et al. Analysis of a new type of high pressure homogeniser. A study of the flow pattern [J].Chemical Engineering Science, 2004, 59(4): 843-853.

[31] Kubo M T K, Augusto P E D, Cristianini M. Effect of high pressure homogenization (HPH) on the physical stability of tomato juice[J]. Food Research International, 2013, 51(1):170-179.

[32] Sila D N, Smout C, Elliot F, et al. Non-enzymatic depolymerization of carrot pectin: Toward a better understanding of carrot texture during thermal processing[J].Journal of Food Science, 2006, 71(1): E1-E9.

[33] 吳奕兵. 超高壓均質(zhì)對胡蘿卜汁理化性質(zhì)及酶和微生物的影響[D]. 南京:南京農(nóng)業(yè)大學(xué), 2009.Wu Yibing. Effects of Ultra High Homogenization on Physicochemical Properties of Carrot Juice and Effects on Enzyme and Microorganism in Carrot Juice[D]. Nanjing:Nanjing Agricultural University, 2009. (in Chinese with English abstract)

[34] Beysseriat M, Decker E A, McClements D J. Preliminary study of the influence of dietary fiber on the properties of oil-in-water emulsions passing through an in vitro human digestion model[J]. Food Hydrocolloids, 2006, 20(6): 800-809.

[35] Shpigelman A, Kyomugasho C, Christiaens S, et al. The effect of high pressure homogenization on pectin: Importance of pectin source and pH[J]. Food Hydrocolloids, 2015, 43:189-198.

[36] Rodriguez-Amaya D B. Carotenoids and food preparation:the retention of provitamin A carotenoids in prepared,processed and stored foods[M]. Arlington, VA: John Snow Incorporated/OMNI Project, 1997.

Effects of different crushing and refining treatments on release of carotenoids in carrot juice

Liu Jianing1,2, Liu Xuan2, Bi Jinfeng2, Zhang Baiqing1※, Yi Jianyong2, Peng Jian2

(1.College of Food Science, Shenyang Agricultural University, Shenyang110866,China;2.Key Laboratory of Agro-products Processing, Ministry of Agriculture, Institute of Food Science and Technology,Chinese Academy of Agricultural Sciences, Beijing100193,China)

Carotenoids have

special attention owing to their health-related characteristics, including pro-vitamin A activity, antioxidant properties and prevention organisms against certain types of cancer. In carrot, the existence of chromoplast substructure and cell wall limit the release of carotenoids, thus adopting appropriate mechanical processing to destroy the cell wall and decrease the particle size is an effective way to improve carotenoid bioaccessibility. As the first step of digestion, the release of carotenoids from raw materials plays a crucial role in determining carotenoid bioaccessibility. The objective of this study was to investigate the effects of different crushing and refining treatments on release pathway of carotenoids in carrot juice. Pulping, colloid mill, and high pressure homogenization with different homogenization pressures,homogenization cycles and inlet temperatures were applied as crushing and refining treatments. After different crushing and refining treatments, carotenoid content in different organizational states (large cell clusters, small cell clusters and chromoplast fraction), free carotenoid content, micrograph of carotenoid distribution, release rate of carotenoids, as well as contents of oil-extracted carotenoids,β-carotene and α-carotene were investigated, respectively. Total carotenoid content was determined spectrophotometrically.β-carotene and α-carotene content were measured by HPLC. Micrograph of carotenoid distribution was observed by confocal laser scanning microscopy. The results demonstrated that after crushing treatment, carotenoid content of above-mentioned four fractions was in a decreasing order: free carotenoid, large cell clusters, small cell clusters and chromoplast fraction. After homogenization, there was almost no difference in free carotenoid content, however, there were about fourfold increase in carotenoid content for chromoplast fraction, twofold increase in carotenoid content for small cell clusters, and twofold decrease for large cell clusters. The proportion of carotenoid content decreased from 36.18% to 15.28%in large cell clusters, increased from 8.36% to 30.56% in chromoplast fraction and increased from 11.11% to 15.73% in small cell clusters. Therefore, an enhancement of carotenoid content could be observed with the decreasing level of bioencapsulation. After refining treatments, the visible carotenoid particles under laser scanning confocal microscopy decreased in size. As the homogenization pressure increased up to 100 MPa and 150 MPa, confocal micrographs showed that visible carotenoid particles became smaller than the ones treated by other homogenization pressures. When the pressure reached 180 MPa,carotenoid tended to aggregate. The visible particle became smaller with the increase of homogenization cycle. Increasing inlet temperature contributed to aggregation of carotenoid particles. The value of carotenoid release rate was 50.91% for joint processing of colloid mill and high pressure homogenization. However, different levels of homogenization pressure had no significant (P>0.05) effect on carotenoid release rate. Higher carotenoid release rate could be observed with an increment of homogenization cycle and inlet temperature. Therefore, suitable refining treatment can be found and applied to damage the cell wall and effectively promote the release of carotenoids in carrot juice. As lipophilic pigment, carotenoid must first be released from the food matrix, solubilized in the lipid phase followed by transferring into mixed micelles in the small intestine before the uptake by intestinal epithelium. Therefore, oil-extracted carotenoid content reflects the available dose that may be absorbed by human body. The highest oil-extracted carotenoid content in carrot juice was 34.79μg/g treated by pulping. When the pressure increased from 10 MPa to 180 MPa, the content of oil-extracted carotenoids decreased at first and then increased. The value of oil-extracted carotenoid content reached 31.93μg/g for 100 MPa and 31.5μg/g for 150 MPa, respectively. Contrarily,the value was 27.07μg/g for homogenization at 180 MPa. The highest contents of oil-extractedβ-carotene andα-carotene were 32.61μg/g and 6.64μg/g, respectively. Under the different conditions of homogenization, the content ofβ-carotene andα-carotene changed differently due to structural differentiation. This study has significance on subsequent analysis about how to improve carotenoid bioaccessibility in carrot juice. After refining treatment, polysaccharides such as pectin may be released from the cell wall, wrap around the carotenoid and affect the release of the carotenoid. Therefore, further research is needed to study the interaction between carotenoid and endogenous pectin in carrot juice after high homogenization.

pressure; temperature; fruit juices; refining treatments; high pressure homogenization; carotenoid; carrot juice

10.11975/j.issn.1002-6819.2017.14.041

TS255.5

A

1002-6819(2017)-14-0307-08

劉嘉寧,劉 璇,畢金峰,張佰清,易建勇,彭 健. 破碎和均細(xì)化處理方式對胡蘿卜汁中類胡蘿卜素釋放的影響[J]. 農(nóng)業(yè)工程學(xué)報,2017,33(14):307-314.

10.11975/j.issn.1002-6819.2017.14.041 http://www.tcsae.org

Liu Jianing, Liu Xuan, Bi Jinfeng, Zhang Baiqing, Yi Jianyong, Peng Jian. Effects of different crushing and refining treatments on release of carotenoids in carrot juice[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(14): 307-314. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.14.041 http://www.tcsae.org

2017-03-01

2017-05-21

國家自然科學(xué)基金項目資助(31671868);“十三五”國家重點研發(fā)計劃項目:食品非熱加工新技術(shù)研究與裝備開發(fā)(2016YFD0400302)

劉嘉寧,女,遼寧大連人,研究方向農(nóng)產(chǎn)品加工技術(shù)及裝備。沈陽 沈陽農(nóng)業(yè)大學(xué)食品學(xué)院,110866。Email:jianingliutracy@163.com

※通信作者:張佰清,男,黑龍江拜泉縣人,博士,教授,博士生導(dǎo)師,研究方向為農(nóng)產(chǎn)品加工。沈陽 沈陽農(nóng)業(yè)大學(xué)食品學(xué)院,110866。

Email:sybaiqingxl@sina.com