基于高頻電磁閥的脈寬調制變量噴頭噴霧特性

李龍龍,何雄奎※,宋堅利,仲崇山(.中國農業大學理學院,北京0093;.中國農業大學信息與電氣工程學院,北京00083)

?

基于高頻電磁閥的脈寬調制變量噴頭噴霧特性

李龍龍1,何雄奎1※,宋堅利1,仲崇山2

(1.中國農業大學理學院,北京100193;2.中國農業大學信息與電氣工程學院,北京100083)

摘要:為探究基于高頻電磁閥的變量噴霧特性,該研究采用高頻、對信號快速響應的電磁閥設計了高于20 Hz的脈寬調制(pulse width moderation, PWM)變量噴霧系統;針對農業施藥作業上常用ST標準扇形和IDK防飄噴頭,測試了不同頻率和占空比對流量、霧滴粒徑、霧化過程、縱向沉積分布均勻性的影響。結果表明,在高頻下,流量與占空比呈線性關系,隨著頻率的增大,流量線性區間減小,增大壓力和頻率,可以有效增大流量調節倍數,30 Hz時最大可達10倍;PWM噴霧時,瞬間霧滴粒徑發生周期性變化,增大頻率,霧滴體積中值中徑(volume medium diameter,VMD)平均值受占空比的影響變小,占空比增大,VMD有減小的趨勢,對于ST110-02號噴頭各頻率下VMD從占空比20%~100%下降了100 μm;沉積試驗中,頻率和占空比都會影響沉積均勻性,對于IDK120-04號噴頭,占空比為40%時,30 Hz下的C.V(coefficient of variation)值較15 Hz減小了6.07%;15 Hz時,IDK120-02和04號噴頭在占空比40%到100%變異系數分別下降了11.75%和18.31%;30 Hz時,兩噴頭在占空比40%到100%變異系數分別下降8.72%和12.24%,并且,ST噴頭沉積均勻性優于IDK噴頭。該研究為高頻電磁閥在PWM變量施藥系統中的應用及參數選擇提供理論基礎。

關鍵詞:噴霧;農業機械;噴頭;高頻電磁閥;變量施藥;霧化;沉積;流量

李龍龍,何雄奎,宋堅利,仲崇山.基于高頻電磁閥的脈寬調制變量噴頭噴霧特性[J].農業工程學報,2016,32(01):97-103.doi:10.11975/j.issn.1002-6819.2016.01.013 http://www.tcsae.org

Li longlong, He Xiongkui, Song Jianli, Zhong Chongshan.Spray characteristics on pulse-width modulation variable application based on high frequency electromagnetic valve[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2016, 32(01): 97-103.(in Chinese with English abstract)doi:10.11975/j.issn.1002-6819.2016.01.013 http://www.tcsae.org

0 引言

隨著人們對農藥環境污染及食品安全的日益重視,基于按需噴藥的變量施藥技術正在成為植保領域的重點發展方向[1]。目前,變量施藥控制主要有以下3種:壓力調節式、濃度調節式和PWM(pulse width modulation)間歇噴霧流量調節式[2],其中,基于PWM的噴霧流量調節系統由于反應時間短,響應速度快、流量調節范圍大,且使用常規噴頭即可獲得良好的噴霧特性而受到越來越多研究人員的關注[3-5]。1990年Giles等人首次利用電磁閥和一個標準噴頭組合實現變量噴霧并測試了固定頻率下霧滴大小和霧化狀態[3]。隨后的二十多年里,研究人員對PWM在變量施藥技術上的應用做了大量的研究工作,Giles等人在1997年試驗發現通過改變占空比和壓力可以得到固定的霧滴粒徑[6];John研究了在10 Hz頻率下,不同占空比的噴霧質量評價,研究發現在較低的占空比下霧滴中徑的變化最大,并且<100 μm的可飄失霧滴百分比最大[7];Lebeau等人設計了基于噴桿速度變化的PWM變量施藥控制系統,并對此控制系統進行試驗測試,最終選定試驗所用占空比為16 Hz[8-9];Pierce Robert等人研究頻率為16 Hz,不同占空比下的沉積特性,試驗發現縱向沉積變異系數在占空比100%時為10%,25%占空比時為65%[10],說明改變占空比會影響噴霧沉積均勻性。在國內PWM變量施藥研究時間相對較短,隨著人們對現代精準農業的重視,PWM變量施藥研究也日趨增多[11-24]。其中,翟長遠等人設計了PWM變量控制系統,在2~10 Hz頻率下試驗得出了噴頭流量模型,參數檢驗和失擬檢驗表明噴頭流量模型合適[25];鄧巍等人分析討論了PWM間歇式脈動變量噴霧在10Hz頻率以下的霧化特性[26]。這些研究均在低頻條件下進行。

實際上,較高的PWM頻率是噴霧覆蓋連續性的保證[8],可以提高縱向沉積分布均勻性,尤其在高速作業的情況下。因此,本文在高頻電磁閥的基礎上設計了PWM變量控制系統,

可根據工況需求改變頻率和占空比,通過開展流量、霧滴粒徑、霧化過程、沉積分布均勻性與頻率、占空比的關系諸方面的研究,了解高頻電磁閥在PWM變量噴霧中的霧化特性,分析高頻電磁閥在PWM變量施藥中的適用性,以期為高頻電磁閥在PWM變量施藥系統中的應用提供理論基礎。

1 材料與方法

1.1PWM變量噴霧系統

PWM變量噴霧系統由12 V電源、驅動、單片機、電磁閥、噴頭體、計算機、串口通信模塊組成,利用計算機實時改變頻率和占空比,從而達到變量施藥的目的,控制界面如圖1a。計算機模擬信號發生器,通過USB轉RS232轉換線與單片機連接,計算機發出指令后通過單片機將信號傳輸給電磁閥。變量噴霧系統中使用的電磁閥為壓縮天然氣(compressed natural gas,CNG)高頻電磁閥,電磁閥的性能如表1所示,噴霧試驗系統如圖1b。

圖1 PWM變量控制噴霧系統Fig.1 PWM variable spray control system

表1 高頻電磁閥參數Table 1 Parameters of high-frequency electromagnetic valve

1.2流量測試

理論上講,噴霧壓力和頻率一定時,噴頭流量與占空比成正相關。為了驗證試驗中所用高頻電磁閥是否符合這一規律,在0.2~0.5 MPa噴霧壓力、不同頻率和占空比工況下測量不同噴頭的流量。

試驗用噴頭為德國Lechler公司生產的標準扇形霧噴頭ST110-02,ST110-03,ST120-04,頻率范圍為12~37 Hz,占空比范圍為20%~100%。試驗用自來水作為試驗液體。每次測量中,秒表記錄噴霧時間(30 s),萬分之一天平測量30 s內液體重量,進而算得噴頭流量(L/min),每次試驗重復五次,最后得到測試條件下的流量平均值并根據公式(1)求得流量調節倍數P。

式中P為流量調節倍數;qx=100為占空比100%時的噴頭流量,L/min;qx=20為占空比20%時的噴頭流量,L/min。

1.3霧滴粒徑測試

采用英國Malvern公司生產的Spraytec霧滴粒徑分析儀定點測量霧化區的霧滴粒徑,將噴頭置于霧滴粒徑分析儀的正上方50 cm處,該儀器可測試連續一定時間段(比如10 s)的粒徑,也可每秒0~500 Hz斷續測量某一間隔時間內的霧滴粒徑。由于PWM變量噴霧為斷續噴霧,因此采用連續(10 s)和間斷(100 Hz)兩種測量模式探究霧滴粒徑與PWM參數(頻率和占空比)的關系,本文采用體積中值中徑(volume medium diameter, VMD)計量霧滴粒徑。

將Spraytec分析儀的測量模式設為連續測量10 s,試驗壓力定為0.3 MPa,分別測量ST110-02,ST110-03,ST120-04 3種噴頭的霧滴粒徑,PWM噴霧系統頻率分別為15、20、25、30、35 Hz,占空比從20%~100%每隔5%做一個設置。每個測試重復3次,得到VMD平均值。非連續間斷測量試驗中,將Spraytec分析儀設為間斷測量模式,測量頻率設為100 Hz,即每秒鐘測量100次,其他試驗參數與連續測量一致。

1.4噴頭霧化區的可視化研究

為了進一步研究PWM變量噴霧的霧化特性,壓力0.3 MPa下,使用高速攝影儀對噴頭霧化區進行整體動態視頻拍攝并保存。高速攝影儀拍攝幀數為3000FPS,快門速度1/4 000 s;PWM控制系統頻率為15、25和30 Hz,占空比為25%、50%和75%。試驗噴頭為ST110-02,ST110-03 和ST120-04,利用文獻[27]中介紹的方法進行拍攝,拍攝完成后將保存的視頻轉換成圖像,不同工況下觀察PWM變量噴霧霧化特性,試驗用中國農業大學飲水系統中自來水作為試驗液體。

1.5縱向沉積測試

1.5.1測試平臺

為了測試和分析基于高頻電磁閥的PWM變量施藥的沉積特性,在中國農業大學藥械與施藥技術實驗室設計了基于噴霧天車的PWM噴霧沉積測試平臺,如圖2所示,裝有噴頭的噴桿固定在天車上,噴頭正下方放一霧滴收集臺用以放置霧滴收集器,噴頭與收集臺的垂直距離為0.5 m,試驗中用直徑35 mm的塑料培養皿作為霧滴收集器,平行放置5列,相鄰間隔12 cm,每一列緊密排列16個培養皿(0.56 m),第3列放置于噴頭X軸正下方。

1.5.2沉積測試

3‰檸檬黃溶液作為示蹤劑,測試結束后迅速蓋上培養皿蓋,將培養皿放置于黑箱內,防止光照引起檸檬黃分解。試驗選取15 Hz和30 Hz 2個頻率,占空比分別設置為40%、70%、和100%,天車運行速度為2 m/s,噴霧壓力為0.3 MPa,試驗所用噴頭為常規扇形霧噴頭ST110-02,ST120-04和防飄噴頭IDK120-02,IDK120-04。每個試驗重復3次。試驗結束后,培養皿內加3.5 mL去離子水洗脫、震蕩,最后用分光光度計測量吸光度,利用文獻[28]中介紹的方法求得沉積量(mL/cm2),最終根據沉積量求得縱向平均變異系數(coefficient of variation,C.V)值。

圖2 PWM噴霧沉積測試平臺Fig.2 Platform for spray deposition test

2 結果與討論

2.1噴頭流量

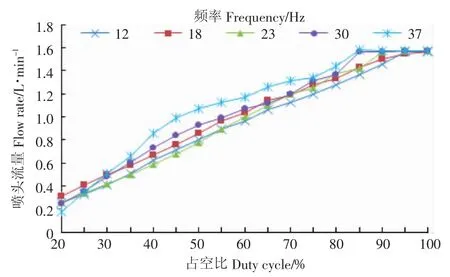

通過3種噴頭的流量測試顯示,基于高頻電磁閥的PWM變量噴霧的噴頭流量與頻率和占空比有關,在一定的壓力和頻率下,流量開始隨著占空比成線性正相關,達到一定占空比之后流量不再增長,噴頭流量與占空比的關系為q=a·x+b,q為噴頭流量(L/min);a,b為常數,x為占空比。圖3是ST120-04號噴頭在各工況下的流量變化。

圖3 0.3 MPa壓力下ST120-04噴頭流量與頻率和占空比的關系Fig.3 Relationship between flow rate and frequency and duct cycle under pressure of 0.3 MPa

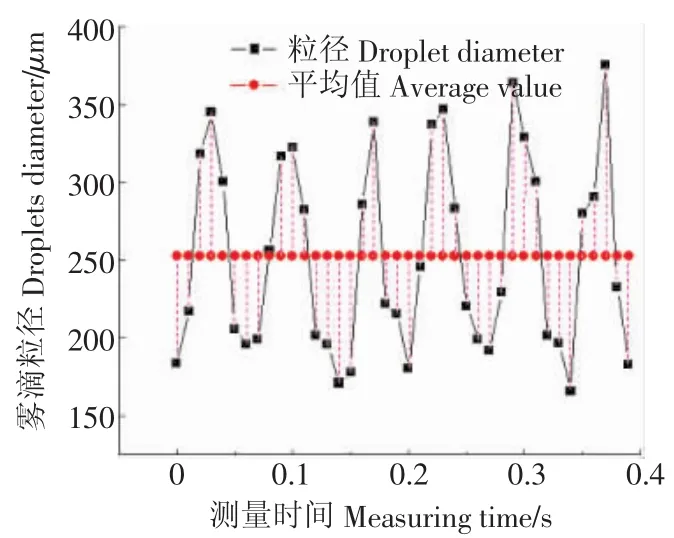

將試驗得到的流量數據進行擬合,圖4a、4b分別為ST120-04號噴頭在30 Hz頻率和0.3 MPa噴霧壓力下流量擬合直線斜率、R2、線性區間(線性區間為流量與占空比成正相關關系的占空比范圍,如占空比在20%~80%時噴頭流量成線性正相關則線性區間為0.6的變化。可以看出壓力和頻率變化對流量變化擬合度影響較小;與頻率變化相比,噴霧壓力變化能夠更有效的調節噴頭流量,且線性區間變化相對較小。

圖4 作業參數和擬合直線斜率、R2、線性區間的關系Fig.4 Relationship between working parameter and slope, R2and interval linear

根據公式(1)求得ST120-04號噴頭的流量調節倍數,如圖5。壓力一定時,流量調節倍數隨著頻率的增大呈現增大的趨勢,這種趨勢在壓力大時比較明顯,30 Hz、0.5 MPa工況下流量倍數可達10,流量調節范圍對實際作業有指導性意義,根據流量調節倍數和作業需要,選取合適的頻率和噴霧壓力來達到作業要求。

圖5 作業參數與流量調節倍數關系Fig.5 Relationship between working conditions and flow regulation

2.2霧滴粒徑

圖6分別為3種噴頭不同壓力,連續10 s測量霧滴粒徑隨頻率和占空比的變化關系。從圖中可以看出,3種噴頭霧化區的霧滴粒徑總體上隨占空比的增大而減小,占空比達到60%后,各頻率下的粒徑曲線幾乎趨于一致。ST110-03和ST120-04號噴頭的粒徑在占空比較小時先增大,最后出現和ST110-02號噴頭相同的變化趨勢,這是由于03和04號噴頭形成霧化區所需的流量較大,在較小占空比時,由于流量較小不能形成完整的霧化區而產生大霧滴。

圖6 連續測量模式下3種噴頭霧滴粒徑與占空比、頻率的關系Fig.6 Relationship between particle diameter and duty cycle and frequency of three species of nozzles in continuous measurement mode

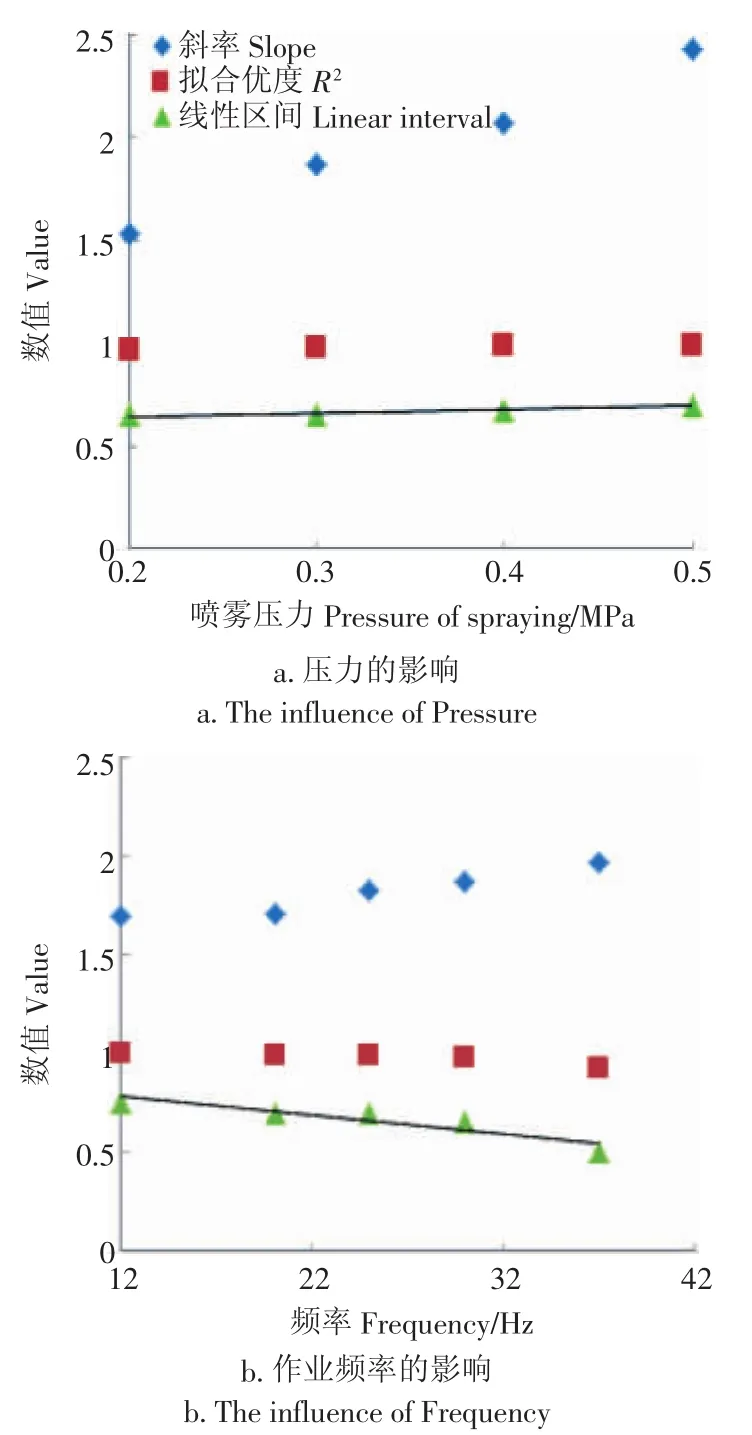

0.3MPa壓力下ST120-04號噴頭在非連續測量模式下的測試結果如圖7所示,測試時的PWM參數為頻率15 Hz,占空比50%,測試時間為0.4 s,正好對應6個PWM周期。從圖中可以看出,霧滴粒徑隨著PWM的變化呈現周期性變化,在平均值252 μm上下不斷變化,這說明PWM噴霧過程中霧滴粒徑會發生明顯的改變。造成這種現象的原因是電磁閥快速開閉造成的湍流和壓力不穩定。為了進一步探究頻率和占空比對霧滴粒徑的影響,在100 Hz測量模式下分別測量15 Hz和30 Hz下3個占空比的霧滴粒徑,試驗結果如表2所示,用方差表示每個工況下的霧滴粒徑的變化浮動。進一步研究發現,增大頻率和占空比可以減小霧滴粒徑的變化,并且各個工況下的霧滴粒徑平均值與連續測量模式下的試驗結果一致。

圖7 100 Hz測量模式下ST120-04號噴頭霧滴粒徑與測量時間關系Fig.7 Relationship between particle diameter and measure time of ST120-04 nozzle in measure mode of 100 Hz

表2 不同工況下霧滴粒徑的變化Table 2 Changes of particle diameter under different working condition

2.3噴頭霧化區的可視化分析

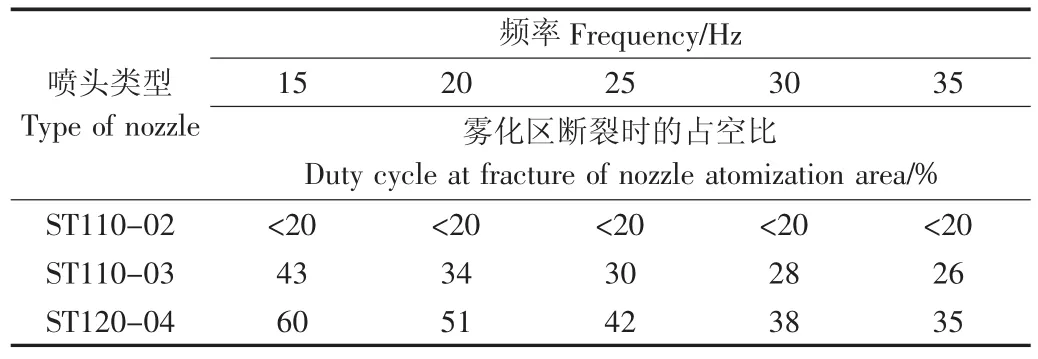

為了進一步探究試驗2.2中霧滴粒徑的變化,利用文獻[24]的方法對噴頭霧化區進行高速攝影分析,發現PWM變量噴霧過程中由于電磁閥瞬間開閉會導致霧化帶斷裂,表3給出的是不同頻率下噴頭霧化帶斷裂時最大占空比,對于ST110-02號噴頭,各個工況下霧化帶斷裂時占空比均小于20%;ST120-04號噴頭的斷裂占空比最大,這是由于該型號噴頭流量最大,因此霧化帶斷裂時的最大占空比也較大。此外,通過圖片發現噴頭霧化區斷裂瞬間,噴嘴下方50 cm處會產生大霧滴,這也解釋了連續測量模式下各個噴嘴霧滴粒徑曲線變化的原因,由于較小占空比時流量較小,ST110-03和ST120-04號噴頭霧化帶斷裂導致大霧滴產生,因此霧滴粒徑有先增大后平緩減小的趨勢。

表3 不同噴頭霧化帶斷裂時的占空比Table 3 Duty cycle at fracture of nozzle atomization area

2.4縱向沉積特性

圖8為0.3 MPa壓力下,IDK-04號噴頭在15 Hz,占空比40%、70%和100%下縱向沉積變化,從圖中看出縱向沉積量呈現出周期性的變化規律。表4是15 Hz時3個占空比下流量和沉積量,流量平均值(40%∶70%∶100%)=1∶1.73∶2.29,沉積量平均值(40%∶70%∶100%)=1∶1.43∶1.76。

圖8 IDK-04號噴頭在行駛方向上沉積量變化示意圖Fig.8 Schematic of deposition quantity on travelinging direction of IDK-04

表4 IDK-04號噴頭在不同占空比下的流量與沉積量Table 4 Flow rate and deposition quantity in different duty cycle of IDK-04

圖9分別為ST110-02和04、IDK120-02和04噴頭在15 Hz和30 Hz,各占空比的C.V值,從圖中可以看出,PWM變量噴霧的沉積受頻率和占空比的影響,同一占空比,高頻下的縱向C.V值比低頻下的小,對于IDK120-04號噴頭,占空比為40%下,15 Hz時的C.V值為28.31%,30 Hz時的C.V值為22.24%,減小了6.07%;相同頻率下,隨著占空比的增大,C.V值有減小的趨勢,15 Hz時,IDK-02和04號噴頭從占空比40%到100%分別下降了11.75%和18.31%;30 Hz時,IDK-02和04號噴頭從占空比40%到100%分別下降了8.72%和12.24%。因此在PWM變量噴霧系統中,高頻是沉積均勻性的保證,不僅要考慮流量的變化范圍,也要考慮到占空比的選擇范圍,低占空比時會增大沉積不均勻性的幾率。

相比于IDK噴頭,ST噴頭的縱向沉積均勻性相對較好,C.V值都在10%左右,隨頻率和占空比的影響較小。但也呈現出和IDK噴頭一樣的趨勢,頻率大的沉積均勻性較低頻的好,隨著占空比增大,沉積均勻性有變好的趨勢,C.V值變化相對平緩。

圖9 4種噴嘴在不同工況下的C.V值Fig.9 C.V-value in different working condition of four nozzles

3 結論

1)基于高頻電磁閥的PWM變量噴霧,對于標準扇形霧噴頭,在壓力和頻率一定時,流量和占空比呈線性關系,線性區間隨頻率增大逐漸減小,增大壓力和頻率可有效增大流量調節范圍。

2)采用PWM變量噴霧時,瞬間霧滴粒徑發生周期性的變化;VMD在平均值附近以正弦波上下浮動,增大頻率和占空比,可以減小霧滴粒徑的變化。

3)由于PWM變量噴霧的工作特性會導致噴頭霧化區霧化帶斷裂,并且不同類型噴頭在不同頻率下霧化帶斷裂的最大占空比不同,ST-110-02號噴頭在各頻率下占空比都小于20%,ST120-04號在15 Hz時的最大,為60%。霧化帶斷裂瞬間會產生大霧滴,導致霧滴粒徑瞬間增大。

4)PWM頻率和占空比影響霧滴沉積,增大占空比和頻率能夠提高霧滴沉積均勻性。

[參考文獻]

[1]何雄奎.改變我國植保機械和施藥技術嚴重落后的現狀[J].農業工程學報,2004,20(1):13-15.He Xiongkui.Improving severe draggling actuality of plant protection machinery and its application techniques[J].Transactions of the Chinese Society of Agricultural Engineering (Transaction of CSAE), 2004, 20(1): 13-15.(in Chinese with English abstract)

[2]邱白晶,李佐鵬,吳昊,等.變量噴霧響應性能的試驗研究[J].農業工程學報,2007,23(11):148 -152.Qiu Baijing, Li Zuopeng, Wu Hao, et al.Experimental study on variable-rate spraying equipment response capability [J].Transactions of the Chinese Society of Agricultural Engineering (Transaction of CSAE), 2007, 23(11): 148-152.(in Chinese with English abstract)

[3] Giles D K, Comino J A.Droplet size and spray pattern characteristics of an electronic flow controller for spray nozzles [J].Journal of Agricultural Engineering Research, 1990, 47(4): 249 - 267.

[4]鄧巍,丁為民.基于PWM技術的連續式變量噴霧裝置設計與特性分析[J].農業機械學報,2008,39(6):77-80.Deng Wei, Ding Weimin.Variable-rate continuous spray equipment based on PWM technology and it’s spray characteristics [J].Transactions of the Chinese Society for Agricultural Machinery, 2008, 39(6): 77-80.(in Chinese with English abstract)

[5]王麗霞,張書慧,馬成林,等.基于ARM的變量噴藥控制系統設計[J].農業工程學報,2010,26(4):113-117.Wang Lixia, Zhang Shuhui, Ma Chenglin, et al.Design of variable spraying system based on ARM[J].Transactions of the Chinese Society of Agricultural Engineering Engineering (Transactions of the CSAE), 2010, 26(4): 113-117.(in Chinese with English abstract)

[6] Giles D K.Independent control of liquid flow rate and spray droplet size from hydraulic atomizers[J].Atomization and Sprays, 1997, 7: 161-181.

[7] John P Lang.Evaluation of pulse width modulation sprays for spray quality[C].2013 ASAE paper No.131620682, 2013.

[8] Lebeau F.Modeling the dynamic distribution of spray deposits [J].Biosystems Engineering, 2004, 89(3): 255-265.

[9] Lebeau F, Bahir L EI, Destain M-F, et al.Improvement of spray deposit homogeneity using a PWM spray controller to compensate horizontal boom speed variation.Computers and Electronics in Agriculture, 2004(43): 149-161.

[10] Pierce Robert A, Ayers Paul D.Evaluation of deposition and application accuracy of a pulse width modulation variable rate field sprayer, SAE paper, 2001.

[11]史萬蘋,王熙,王新忠,等.基于PWM控制的變量噴藥技術體系及流量控制試驗研究[J].農機化研究,2007(10):125-127.Shi Wanping, Wang Xi, Wang Xinzhong, et al.Study on variable rate spraying technology based on pulse width modulation and volume control[J].Journal of Agricultural Mechanization Research, 2007(10): 125-127.(in Chinese with English abstract)

[12]陳勇,鄭加強.精確施藥可變量噴霧系統的研究[J].農業工程學報,2005,5(21):69-72.Chen Yong, Zheng Jiaqiang.Control system for precision pesticide application based on variable rate technology[J].Transactions of the Chinese Society of Agricultural Engineering(Transaction of CSAE), 2005, 5(21): 69-72.(in Chinese with English abstract)

[13]王錦江,陳志,楊學軍.基于AT89C51單片機的變量施藥控制系統研究[J].農機化研究,2007(11):147-149.Wang Jinjiang, Chen Zhi, Yang Xuejun.Study on controlling system based on AT89C51 single-chip microcomputer for variable spraying[J].Journal of Agricultural Mechanization Research, 2007(11): 147-149.(in Chinese with English abstract)

[14]鄧巍,何雄奎,丁為民.用大噴頭脈寬調制間歇噴霧提高沉積率的試驗研究[J].農業工程學報,2009,25(1):104-108.Deng Wei, He Xiongkui, Ding Weimin.Experimental study on improving deposition rate using PWM-based intermittent spray from enlarged nozzle[J].Transactions of the Chinese Society of Agricultural Engineering(Transaction of CSAE), 2009, 25(1): 104-108.(in Chinese with English abstract)

[15] Han S, Hendrickson L L, Ni B, et al.Modification and testing of a commercial sprayer with PWM solenoids for precision spraying [J].Applied Engineering in Agriculture, 2001, 17(5): 591-594.

[16]隨順濤,朱瑞祥,王麗麗.基于脈寬調制的變量噴藥技術控制系統[J].農機化研究,2009,31(4):143-145.Sui Shuntao, Zhu Ruixiang, Wanglili.Controlling system based on pulse width modulation for variable spraying[J].Journal of Agricultural Mechanization Research, 2009, 31(4): 143-145.(in Chinese with English abstract)

[17] Bennur P J, Taylor R K.Evaluating the response time of a rate controller used with a sensor-based, variable rate application system[J].Applied Engineering in Agriculture, 2010, 26(6): 1069-1075.

[18]鄒偉,李麗,王秀,等.基于PWM調速的變流量噴藥系統[J].農機化研究,2011,33(2):163-166.Zou Wei, Li Li, Wang Xiu, et al.Variable pesticide spraying system based on PWM speed control[J].Journal of Agricultural Mechanization Research, 2011, 33(2): 163-166.(in Chinese with English abstract)

[19] Gu J, Zhu H, Ding W, et al.Droplet size distributions of adjuvant-amended sprays from an air-assisted five-port PWM nozzle.Atomization and Sprays,2011, 21(3): 263-274.

[20]魏新華,于達志,白敬,等.脈寬調制間歇噴霧變量噴施系統的靜態霧量分布特性[J].農業工程學報,2013,29(5):19-24.Wei Xinhua, Yu Dazhi, Bai Jing, et al.Static spray deposition distribution characteristics of PWM-based intermittently spraying system[J].Transactions of the Chinese Society of Agricultural Engineering(Transaction of CSAE), 2013, 29(5): 19-24.(in Chinese with English abstract)

[21]閆棟,張文愛,王秀,等.基于PWM的農藥變量注入控制系統設計與試驗[J].農機化研究,2011(6):115-118.Yan Dong, Zhang Wenai, Wang Xiu, et al.The design of pesticide variable injection control system based on PWM [J].Journal of Agricultural Mechanization Research, 2011(6): 115-118.(in Chinese with English abstract)

[22] Bora G C, Schrock M D, Oard D L, et al.Reliability tests of pulse width modulation(PWM)valves for flow rate control of anhydrous ammonia[J].Applied Engineering in Agriculture, 2005, 21(6): 955-960.

[23]劉偉,汪小旵,丁為民,等.背負式噴霧器變量噴霧控制系統設計與特性分析[J].農業工程學報,2012,28(9):16-21.Liu Wei, Wang Xiaochan, Ding Weimin, et al.Design and characteristics analysis of variable spraying control system for knapsack sprayer[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of CSAE), 2012, 28(9): 16-21.(in Chinese with English abstract)

[24]吳春篤,杜彥生,張偉,等.脈寬調制型變量噴霧系統霧量沉積分布[J].農業機械學報,2007,38(12):70-73.Wu Chundu, Du Yansheng, Zhang Wei, et al.Study on the deposit distribution of the modulated variable rate spray system [J].Transactionsofthe Chinese Societyfor Agricultural Machinery, 2007, 38(12): 70-73.(in Chinese with English abstract)

[25]翟長遠,王秀,等.PWM變量噴霧噴頭流量模型[J].農業機械學報,2012,43(4):40-44.Zhai Changyuan, Wang Xiu.Nozzle flow model of PWM variable-rate spraying[J].Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(4): 40-44.(in Chinese with English abstract)

[26]鄧巍,丁為民,何雄奎.PWM間歇式變量噴霧的霧化特性[J].農業機械學報,2009,40(1):74-78.Deng Wei, Ding Weimin, He Xiongkui.Spray characteristics of PWM-based intermittent pulse variable spray[J].Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(1): 74-78.(in Chinese with English abstract)

[27]張文君,何雄奎,宋堅利,等.助劑S240對水分散性粒劑及乳油藥液霧化的影響[J].農業工程學報,2014,30(11):61-67.Zhang Wenjun, He Xiongkui, Song Jianli, et al.Effect of adjuvant S240 on atomization of water dispersible granule and emulsion solution[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of CSAE), 2014, 30(11): 61-67.(in Chinese with English abstract)

[28]馬寧.防飄噴頭和標準扇形霧噴頭的噴霧特性研究[D].北京:中國農業大學,2012:35.Ma Ning.Study of spray characteristics of Anti-floating nozzle and standard fan-shaped nozzle[D].Beijing: China agricultural university, 2012: 35.

Spray characteristics on pulse-width modulation variable application based on high frequency electromagnetic valve

Li Longlong1, He Xiongkui1※, Song Jianli1, Zhong Chongshan2

(1.College of Science, China Agricultural University, Beijing 100193, China; 2.College of Information and Electrical Engineering, China Agricultural University, Beijing 100083, China)

Abstract:High frequency solenoid valve has the advantage of fast response, and it can effectively improve the deposition uniformity especially for high-speed operation.In order to study the variable spraying characteristics of high frequency solenoid valve, a pulse width modulation(PWM)variable rate spraying system based on high frequency solenoid valve was developed.The minimum pulse width of the solenoid valve used in the research was 1.3 ms.The PWM variable rate spraying system was made up of power supply, drive, single chip microcomputer, solenoid valve, serial communication module, computer, and so on.Frequency and duty cycle of solenoid valve could be regulated by the PWM control system in real time.This article applied the ST standard fan nozzle and IDK anti-drift nozzle which are commonly used in the agriculture to carry out experiment, which focused on how frequency and duty cycle of solenoid valve influenced flow rate, droplet diameter, atomization process and longitudinal deposition uniformity.In the flow rate test, 12~37 Hz and 20%~100% were chosen as the working frequency and duty cycle and the working pressure was 0.2~0.5 MPa.The water weight was measured by precision balance in 30 s to get flow rate(L/min), and each test was repeated 5 times.It was observed that the flow rate had a linear relation with the duty cycle in the fixed working pressure and the R2 of regression line was greater than 0.9 at 12~37 Hz.Linear interval was 0.8 at 12 Hz and 0.56 at 37 Hz, and it was concluded that the linear interval decreased with the increasing of frequency.For the nozzle of ST120-04 under the working condition of 0.4 MPa and 30 Hz, the flow rate increased by 6 times at duty cycle of 100% compared to 20%, while the flow rate increased by 10 times in the pressure of 0.5 MPa.Therefor it was essential to collect proper frequency and spraying pressure to meet working requirement.In the article, 2 measurement modes of Spraytec particle sizer were chosen in the test of droplet diameter.The continuous measurement mode could measure the droplet diameter continuously for 10 s.Droplets could be measured discontinuously at the measure frequency of 100 Hz which meant that droplets were measured for 100 times in one second by the Spraytec particle sizer.The frequency and duty cycle were 15~35 Hz and 20%~100% and the working pressure was 0.3 MPa.Nozzle was fixed at 50 cm above the Spraytec particle sizer and volume medium diameter(VMD)was used to describe the droplet diameter in the article.The results showed that in the continuous measurement mode, the droplet diameter decreased from 20% to 100% respectively for the nozzle of ST110-02, ST110-03 and ST120-04.Moreover, for ST110-03 and ST120-04, the droplet diameter increased from 20% to 40%, because these 2 nozzles needed more flow rate to form the atomization zone yet the flow rate was too small from 20% to 40%.In the discontinuous measurement mode, the droplet diameter changed periodically and the average VMD of 3 nozzles was consistent with the test result of continuous measurement mode.In order to further research the atomization characteristics of PWM variable spraying system based on the high frequency solenoid valve, high-speed camera was used to observe the atomization zone at different frequency and duty cycle.The frame and shutter of high-speed camera were set in 3 000 FPS and 1/4000 s respectively.It was observed that the atomization zone would break up because of nozzle's instantaneous open-close.The duty cycles at the fracture of atomization zone were 26%~43% and 35%~60% for the ST110-03 and ST120-04 nozzle from 15 to 35 Hz.Deposition test bench based on the traveling boom was developed in the Center of Chemical Application Technology, China Agricultural University.Petri dishes(35 mm)were used to collect droplets.The collectors were set in 5 parallel columns and the interval of adjacent 2 columns was 12 cm.Each column contained 16 Petri dishes and the 3rd column was placed under the traveling direction of nozzle.Tartrazine(3‰)was chosen as the tracer material and spray boom speed was 2 m/s.In the deposition test, 15 and 30 Hz, and 40%, 70% and 100% were chosen as the working frequency and duty cycle.The results showed that frequency and duty cycle would influence deposition uniformity.For the IDK120-04 nozzle at duty cycle of 40%, the CV(coefficient of variation)at 30 Hz decreased by 6.07% compared with 15 Hz.From 40% to 100%, CV decreased by 11.75% and 18.31% respectively for IDK120-02 and IDK120-04 at 15 Hz while decreased by 8.72% and 12.24% respectively at 30 Hz.Also, the deposition uniformity of ST standard nozzle was better than the IDK anti-drift nozzle.These results show that the high frequency solenoid valve can be used in the PWM variable rate spraying system and it has advantage in longitudinal deposition uniformity.

Keywords:spraying; agricultural machinery; nozzles; high frequency electromagnetic valve; variable spray application; atomization; deposition; flow rate

通信作者:※何雄奎(1966-),教授,博士生導師,主要從事植保機械與施藥技術研究。北京中國農業大學理學院,100193。Email:xiongkui@cau.edu.cn

作者簡介:李龍龍(1989-),博士生,主要從事植保機械與施藥技術研究。北京中國農業大學理學院,100193。Email:lizefeng1219@126.com

基金項目:國家自然科學基金資助項目(31470099);公益性行業(農業)科研專項資助項目(201203025,201503130)

收稿日期:2015-09-14

修訂日期:2015-11-18

中圖分類號:S491

文獻標志碼:A

文章編號:1002-6819(2016)-01-0097-07

doi:10.11975/j.issn.1002-6819.2016.01.013