不同來源淀粉特性對水晶皮質構品質的影響

艾志錄,孫茜茜,潘治利,2,謝新華,索 標,田萍萍(.河南農業大學食品科學技術學院,鄭州450002;2.速凍面米及調制食品河南省工程實驗室,河南省高校重點實驗室培育基地,鄭州450002;3.河南糧食作物協同創新中心,鄭州450002)

?

不同來源淀粉特性對水晶皮質構品質的影響

艾志錄1,3,孫茜茜1,潘治利1,2,謝新華1,索標1,田萍萍1

(1.河南農業大學食品科學技術學院,鄭州450002;2.速凍面米及調制食品河南省工程實驗室,河南省高校重點實驗室培育基地,鄭州450002;3.河南糧食作物協同創新中心,鄭州450002)

摘要:為了研究原料淀粉特性對水晶皮質構品質的影響,該文選用小麥、玉米、馬鈴薯、木薯、綠豆5種淀粉原料,測定并分析淀粉顆粒特性、破損淀粉含量、糊化特性與水晶皮的透明性、質構等品質的關系。結果表明:不同來源的淀粉制作水晶皮品質差異較大,小麥淀粉皮品質最好,其次是馬鈴薯、木薯、玉米淀粉皮,綠豆淀粉皮品質最差。淀粉顆粒特性、破損淀粉含量與水晶皮品質指標密切相關。平均粒徑、膨脹度越大,水晶皮亮度、透明性越好;適宜的破損淀粉含量能夠保證水晶皮較好的綜合質構品質;淀粉的糊化特性與水晶皮品質指標之間存在顯著相關性;淀粉峰值粘度和衰減值與水晶皮透光率呈極顯著正相關。谷值粘度、最終粘度、回生值與水晶皮硬度、彈性、咀嚼性、剪切力呈極顯著正相關,起始糊化溫度與水晶皮品特性相關性不顯著。因此,在水晶皮制作進行原料選擇時,可以測定淀粉粒徑、膨脹度、峰值粘度、衰減值來預測淀粉皮亮度與透光率;測定淀粉破損淀粉含量、谷值粘度、最終粘度、回生值來預測淀粉皮適口性等品質特性。該文旨在為加工水晶產品原料選擇以及品質改善提供基本的理論支撐。

關鍵詞:淀粉;品質控制;農產品;顆粒特性;水晶皮;糊化;質構品質

艾志錄,孫茜茜,潘治利,謝新華,索標,田萍萍.不同來源淀粉特性對水晶皮質構品質的影響[J].農業工程學報,2016,32(01):318-324.doi:10.11975/j.issn.1002-6819.2016.01.044 http://www.tcsae.org

Ai Zhilu, Sun Xixi,Pan Zhili, Xie Xinhua, Suo Biao, Tian Pingping.Effect of different starch source properties on crystal leather textural quality[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2016, 32(01): 318-324.(in Chinese with English abstract)doi:10.11975/j.issn.1002-6819.2016.01.044 http://www.tcsae.org

0 引言

自古以來,在人們的主食結構中,面制品都扮演著非常重要的角色。如今,隨著面制品市場產品的日益豐富,人們對產品的要求,除了要好吃、營養豐富以外還要求要美觀并有較強的可接受性。水晶類淀粉制品如:水晶蝦餃、水晶月餅等,以其剔透的外觀、光滑的表面、細膩而有韌性的口感深受消費者的喜愛,因此提高這類產品的透明度等品質就尤為重要。淀粉類產品的性質及品質的優劣,不僅與加工過程中相關,更與淀粉的品種及其糊化性質密切相關[1-5]。近些年來許多學者對淀粉糊透明性影響因素進行探究,認為淀粉的顆粒大小、膨脹能力、介質環境、常用添加劑、改性淀粉都顯著影響淀粉糊的透明性[6-10]。杜先鋒等[7]研究了淀粉糊的透明度以及氯化鈉、蔗糖、檸檬酸等食品成分和老化作用對透明度的影響。認為分子結構是影響淀粉糊透明度高低的內在因素,對于所添加的食品成分來說氯化鈉降低淀粉糊的透明度,而蔗糖、檸檬酸則提高糊液的透明度。黎曉等[6]認為,與原淀粉相比,木薯淀粉磷酸酯透明度和表觀黏度明顯提高。且隨取代度的增大而增高,不同介質對其透明度和表觀黏度影響不同,其中氯化鈉對其影響較大。然而這些研究都只是對于淀粉糊的研究,而對于真正的淀粉類產品的透明度,以及破損淀粉對于淀粉產品透明度的影響國內外卻鮮有研究。

本文選擇小麥、玉米、馬鈴薯、木薯、綠豆等常用淀粉原料,測定并分析淀粉特性、破損淀粉含量對水晶皮的透明性等品質的影響,旨在為加工水晶產品原料選擇以及品質改善提供基本的理論支撐。

1 材料與方法

1.1試驗材料

小麥淀粉(含水率12.27%,蛋白質質量分數0.40%),范縣黃河實業有限公司;玉米淀粉(含水率12.62%,蛋白質質量分數0.37%)、馬鈴薯淀粉(含水率20.63%,蛋白質質量分數0.18%)、木薯淀粉(含水率11.55%,蛋白質質量分數0.17%)、綠豆淀粉(含水率16.6%,蛋白質質量分數0.27%),無錫市天之源食品有限公司;豬油,沂城金鑼肉制品集團有限公司;試驗所用的無水乙醇、硼酸、碘化鉀、硫代硫酸鈉均為分析純。

1.2主要儀器與設備

Rise-2008型激光粒度分析儀,濟南潤之科技有限公司;T6新世紀紫外可見分光光度計,北京普析通用儀器有限公司;RVA4500粘度分析儀,瑞典波通儀器公司;TDL-5-A低速大容量離心機,上海安亭科學儀器廠;RQH-250型程控人工氣候箱,上海新諾儀器設備有限公司;SD mat ic型破損淀粉測定儀,法國肖邦公司;A-XT2i物性分析儀,英國Stable Micro System;Sortourius電子天平,北京賽多利斯天平有限公司;SHZ-82A水浴恒溫震蕩器,金壇市醫療儀器廠;DHG-9143BS-Ⅲ-電熱恒溫鼓風干燥箱,上海新苗醫療器械制造有限公司;Minolta Color Miniscan CR400色差儀,日本美能達公司。

1.3試驗方法

1.3.1淀粉特性的測定

1)淀粉粒徑測定

采用Rise-2008型激光粒度分析儀測定,測定條件:遮光比1%~2%;分散劑:乙醇;分散劑折光率:1.33%,測定量程:0.02~1 200 μm。

2)淀粉膨脹性質的測定[11]

將不同品種的淀粉分別配制成質量分數為2%的淀粉乳,在不同溫度的水浴中加熱攪拌30 min,在3 000 r/min條件下離心30 min,取上清液在水浴上蒸干,并在105℃烘至恒重,稱重得被溶解淀粉質量A,按公式(1)計算淀粉的溶解度S;由離心管中膨脹淀粉質量P,即離心后離心管中沉淀淀粉質量,按公式(2)計算淀粉的膨脹度B:

式中:W為淀粉質量,g,以干基計。

3)淀粉中破損淀粉含量的測定

使用肖邦SD matic型破損淀粉測定儀進行測定,在反應杯中加入120 mL蒸餾水、3 g硼酸和3 g碘化鉀,將反應杯放入卡槽內時加入1滴硫代硫酸鈉(0.1 mol/L),再稱取1 g淀粉樣品,放到儀器樣品小斗中,點擊開始,測定破損淀粉值,用碘吸收率(%)來表示破損淀粉含量。

4)淀粉糊化特性的測定[12]

采用RVA-Super4粘度分析儀對淀粉糊化特性進行測定,測定時先在RVA專用樣品筒中加入(25±0.1)mL蒸餾水(按14%濕基換算),然后稱取(3.0±0.01)g淀粉(按14%濕基校正),移入已加有蒸餾水的樣品筒中。最初10 s轉子以960 r/min攪拌,待樣品筒中形成均勻懸濁液后,保持160r/min轉速直至試驗結束。采用美國谷物化學家協會(American Association of Cereal Chemists,AACC)標準溫度模式即RVA初始溫度為50℃保持1 min,然后升高至95℃,在95℃保持2.5 min后,再降至50℃并保持2 min。測量結果單位用快速粘度分析儀單位(cp)表示,每個樣品重復3次,結果取平均值。

主要試驗參數:峰值粘度(peak viscosity)、谷值粘度(trough viscosity)、粘度破損值(breakdown)、最終粘度(final viscosity)、回生值(setback)、起始糊化溫度(pasting temperature)。

1.3.2水晶皮的制作

稱取淀粉100g,加水量為淀粉質量的80%,水溫100℃,豬油添加量為淀粉質量的3%,和至成團,用紗布覆蓋,在25℃條件下,靜置熟化20 min。將熟化后的淀粉團制成質量約3 g的小劑子,用模具制成直徑約5 cm,厚約2 mm的淀粉皮,大火蒸制5 min備用。

1.3.3水晶皮品質指標的測定

1)水晶皮透明性的測定

參照李光磊[13]的方法略加改進,將蒸熟的淀粉皮冷卻5 min后,用刀切成寬約5 mm、長約4 cm的長條,放入1 cm的石英比色皿中(每次保證淀粉皮處于比色皿同一側)在620 nm波長條件下測其透光率。每種樣品制成6個長條進行測定,6次結果求平均值。

2)水晶皮亮度的測定

水晶皮亮度采用色彩色差計進行測定。方法如下:采用CIE—L*a*b*色空間表示方法,L代表亮度。將熟制的淀粉皮冷卻3 min后進行亮度的測定。每種樣品測定6次求平均值。

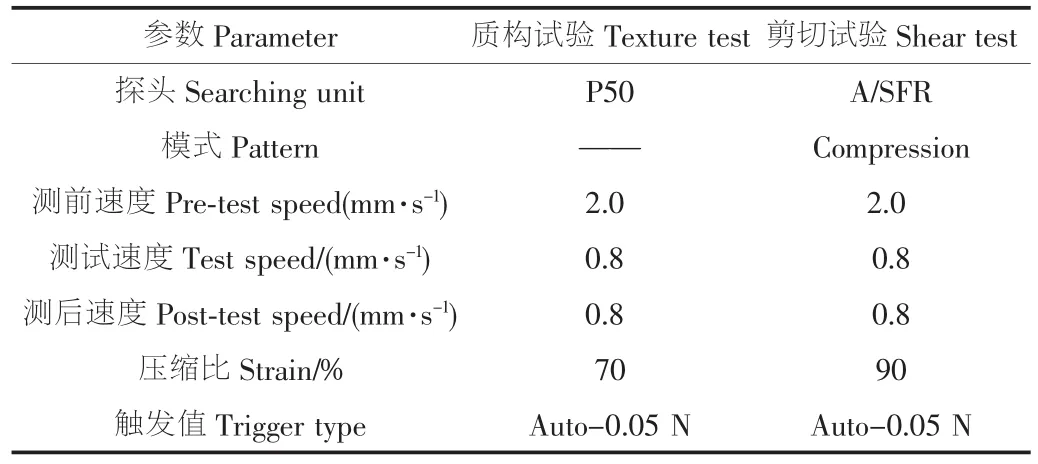

3)水晶皮質構特性的測定

參照樊奇良和葉曉楓[14-15]的方法,將熟制的淀粉皮冷卻5 min后用質構儀測定。每種樣品取樣6次測定并求平均值,物性分析儀的具體參數設定見表1。

表1 物性分析儀參數設定Table 1 Parameter of texture analyzer

1.3.4數據分析

試驗數據采用SPSS13.0進行單因素方差分析和相關性分析,用Origin8.0軟件作圖。

2 結果與分析

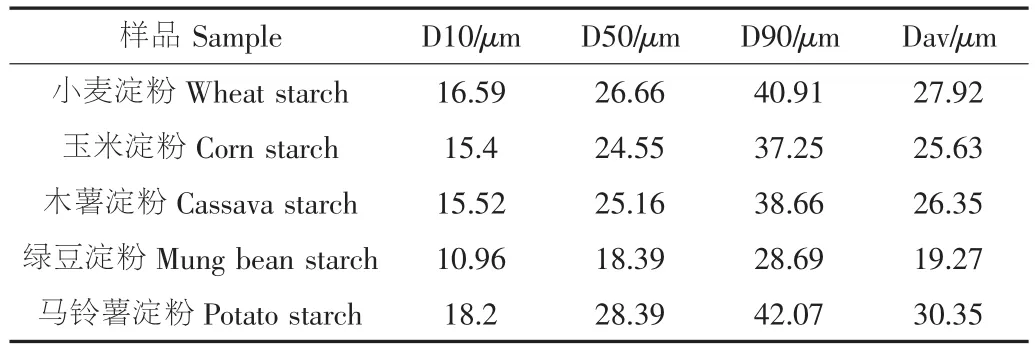

2.1不同來源淀粉的粒徑分布

由圖1和表2可知,不同來源的淀粉顆粒粒徑分布有明顯的差異。粒徑較大的是馬鈴薯淀粉,粒徑范圍為:9~105 μm,平均粒徑為30.35 μm。粒徑最小的是綠豆淀粉,粒徑范圍為:4~74 μm,平均粒徑為19.27 μm。小麥、玉米、木薯淀粉的粒徑較為接近,平均粒徑分別為:27.92、25.63和26.35 μm。周愛梅等[11]認為淀粉顆粒的大小由遺傳決定,與淀粉的生物合成機理有關,并且直接影響淀粉粒的相關性質。有研究表明,淀粉的許多理化性質,如膨脹能力,與水結合能力,糊化以及凝膠化能力等都與淀粉的平均顆粒尺寸有關[16]。

圖1 不同來源淀粉顆粒粒徑分布圖Fig.1 Particle size distribution of starch from various sources

表2 不同來源淀粉顆粒粒徑分布Table 2 Particle size distribution of starch from various sources

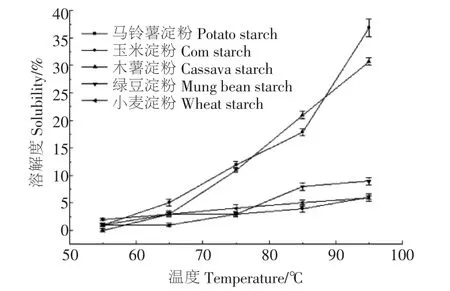

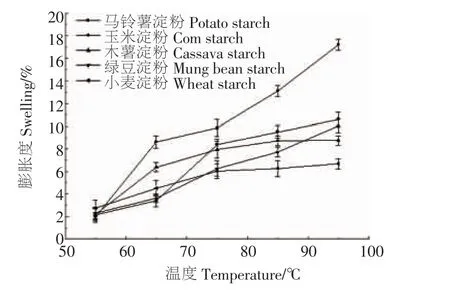

2.2不同來源淀粉的膨脹特性

圖2和圖3是不同來源淀粉溶解度和膨脹度隨溫度變化情況圖。由圖可知淀粉的溶解度和膨脹度都是隨著溫度的升高而增大。除了在85℃時木薯淀粉的溶解度高于馬鈴薯淀粉,其余溫度下馬鈴薯淀粉的溶解度和膨脹度均是最高的。這可能是因為薯類淀粉有較低的糊化溫度,直鏈淀粉較早溶出,淀粉顆粒表現出了較高的膨脹度。玉米、小麥、綠豆淀粉則有著相對較小且較為接近的溶解度和膨脹度,這與袁美蘭等[17]的研究結果一致。

圖2 不同來源淀粉的溶解度Fig.2 Solubility of starch from various sources

圖3 不同來源淀粉的膨脹度Fig.3 Swelling of starch from various sources

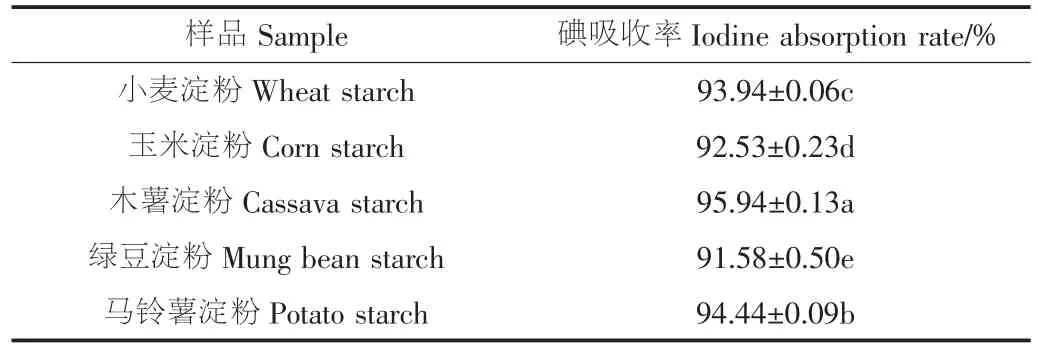

2.3不同來源淀粉的破損淀粉含量

破損淀粉是指在制粉時,由于機械的碾壓作用,有少量的淀粉外層細胞膜被損傷,從而造成淀粉粒的損傷。破損淀粉對面制品的蒸煮品質有一定影響,其含量太高或太低均不能制作出優質的產品[18]。由表3可知,5種淀粉的破損淀粉含量數值差異顯著(P<0.05)。碘的吸收率大小表現為:木薯淀粉>馬鈴薯淀粉>小麥淀粉>玉米淀粉>綠豆淀粉,即5種淀粉的破損淀粉含量大小順序為:木薯淀粉>馬鈴薯淀粉>小麥淀粉>玉米淀粉>綠豆淀粉。有研究表明破損淀粉吸水率比未破損淀粉高2.5倍,因此破損淀粉含量高的淀粉擁有較高的吸水性,這與本文膨脹度的測定結果一致。

表3 不同來源淀粉的破損淀粉含量Table 3 Damaged starch content of starches from various sources

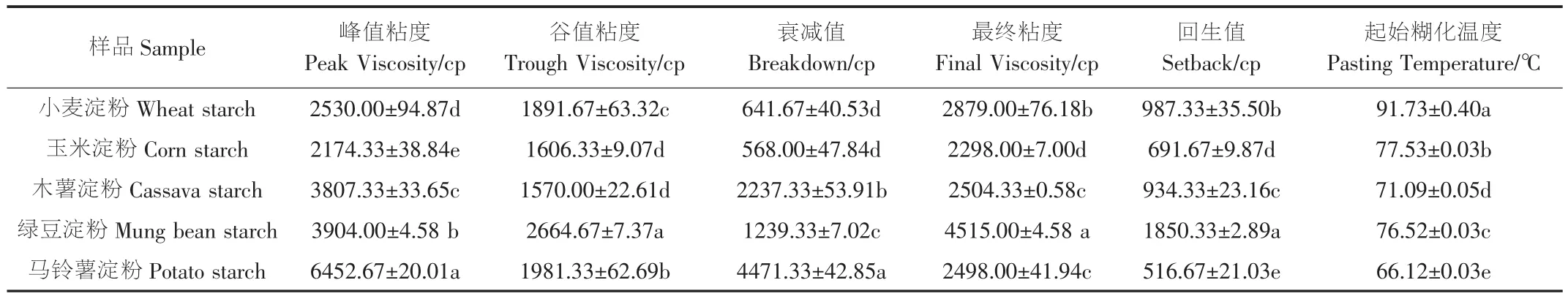

2.4不同來源淀粉的糊化特性

RVA測定的是從淀粉顆粒吸水和溶脹開始,到顆粒結構在剪切力的作用下被破壞,淀粉分子浸出的過程[19]。不同來源淀粉糊化特性值如表4所示,可以看出5種淀粉的糊化特性值差異性顯著(P<0.05)。峰值黏度反映的是淀粉在糊化升溫過程中淀粉顆粒的膨脹程度。由表4可知馬鈴薯淀粉的峰值黏度最大,玉米淀粉的峰值黏度最小。這表明馬鈴薯淀粉顆粒在糊化過程中有較大膨脹程度,玉米淀粉膨脹程度較小。衰減值反映淀粉熱糊的穩定性,由表4可知小麥和玉米淀粉的衰減值較小,這表明淀粉顆粒膨脹過程中強度比較大,不易破裂,熱糊的穩定好,而馬鈴薯淀粉和木薯淀粉的衰減值較大,說明熱糊穩定性差。回生值反映淀粉冷糊的穩定性和老化程度[20]。表4結果表明綠豆淀粉的回生值最高,馬鈴薯淀粉的回生值最低,說明馬鈴薯淀粉穩定性差,易老化。由表4可知起始糊化溫度由高到低的淀粉分別為小麥、玉米、綠豆、木薯、馬鈴薯淀粉,研究表明這可能與淀粉顆粒的粒徑有關,由于小顆粒淀粉之間堆積緊密,造成糊化比較困難,至使淀粉的成糊溫度較高[21]。

表4 不同來源的淀粉糊化特征值Table 4 Gelatinization characteristics of starch from various sources

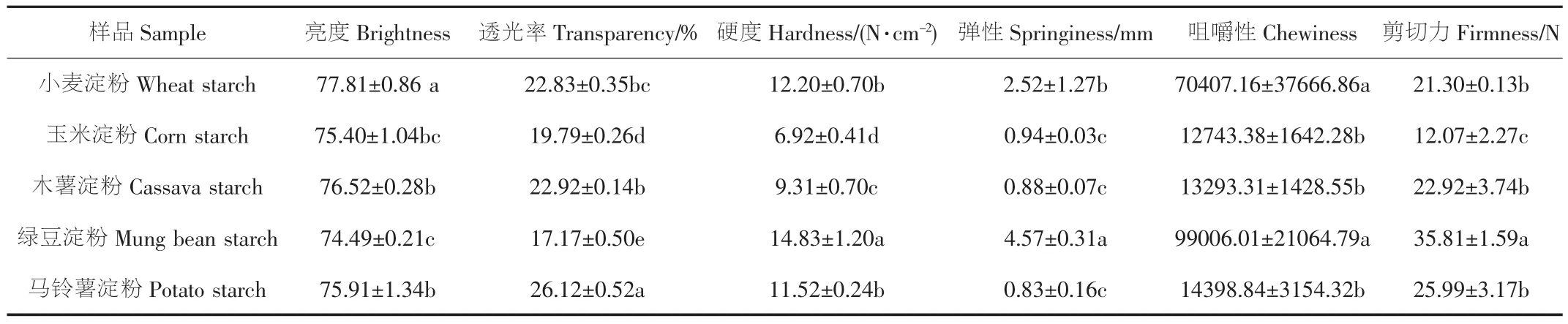

2.5不同來源淀粉皮的質構品質特性

有研究表明,產品的質構特性與其感官品質之間有顯著相關性[22-23],因此用質構儀來測定淀粉皮的質構特性可以避免人為感官帶來的差異,測定結果更為真實可靠。不同來源的淀粉皮品質特性值如表5所示,從表中可以看出,不同來源的淀粉制皮后品質指標差異顯著。亮度和透明度是水晶皮的重要指標,由表5可知在相同的條件下小麥淀粉皮亮度最高,玉米、木薯、馬鈴薯淀粉制皮亮度差異不顯著,綠豆淀粉皮亮度最差,可能是與原料自身略帶顏色有關。對于透光率,馬鈴薯淀粉皮透光率最高,其次是木薯、小麥淀粉皮,且兩者差異不顯著,綠豆淀粉皮透明性最差。從淀粉皮質構特性分析,綠豆淀粉皮略硬,玉米淀粉皮質地較軟爛,而相較于透明度較好的馬鈴薯與木薯淀粉皮,小麥淀粉皮有較好的咀嚼性,較為適中的硬度、彈性和剪切力,即擁有較好的適口性,且在工藝制作上,由于薯類淀粉粘性較大,不太容易制皮,因此綜合分析小麥淀粉更易制作水晶皮,且擁有較為優異的品質特性。

表5 不同來源的淀粉皮質構品質特性值Table 5 Crystal leather textural quality characteristic values from different sources

2.6淀粉特性與水晶皮質構品質特性相關性分析

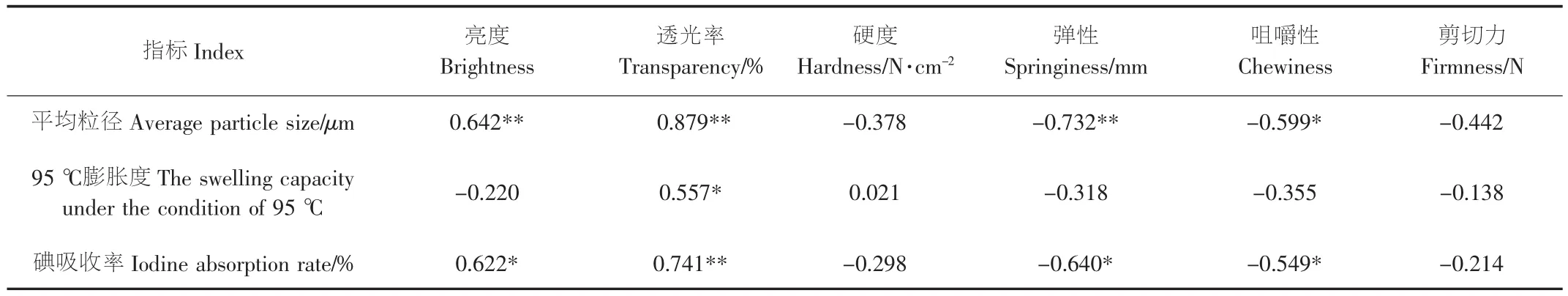

2.6.1淀粉顆粒特性、破損淀粉含量與水晶皮質構品質特性相關性分析

表6為淀粉顆粒特性、破損淀粉含量與水晶皮質構品質特性相關性分析結果,從表中可以看出淀粉平均粒徑與水晶皮亮度、透光率均呈極顯著正相關,這與何晉浙、常虹等[24-25]研究結果一致。淀粉平均粒徑與水晶皮彈性呈極顯著負相關,與咀嚼性呈顯著負相關,說明淀粉粒徑越大,越易膨脹,淀粉持水性越強,淀粉皮彈性、咀嚼性越差,譚洪卓等[26]在蠶豆淀粉與粉絲品質關系研究結果中也有相同的表述。淀粉顆粒在95℃條件下的膨脹度與水晶皮的透光率顯著正相關,與水晶皮其他品質特性沒有顯著相關性。淀粉中破損淀粉含量與水晶皮亮度顯著正相關,與透光率呈極顯著正相關,這是因為破損淀粉的存在使得水晶皮在蒸制過程中吸收相對較多的水分,淀粉顆粒易于膨脹,直/支鏈淀粉能夠充分伸展,產品呈現較高亮度和透明度。但是破損淀粉含量與產品的彈性和咀嚼性均成顯著負相關,這說明破損淀粉含量高時產品的適口性較差,因此綜合考慮水晶皮的質構品質特性,淀粉的破損淀粉含量應控制在一定的范圍內,對于本研究中的5種淀粉,小麥淀粉的破損淀粉含量(約為93.94%)較為適宜。

表6 淀粉顆粒特性、破損淀粉含量與水晶皮質構品質特性相關性分析Table 6 Correlations between starch granules characteristic, damaged starch content and crystal leather textural quality characteristic

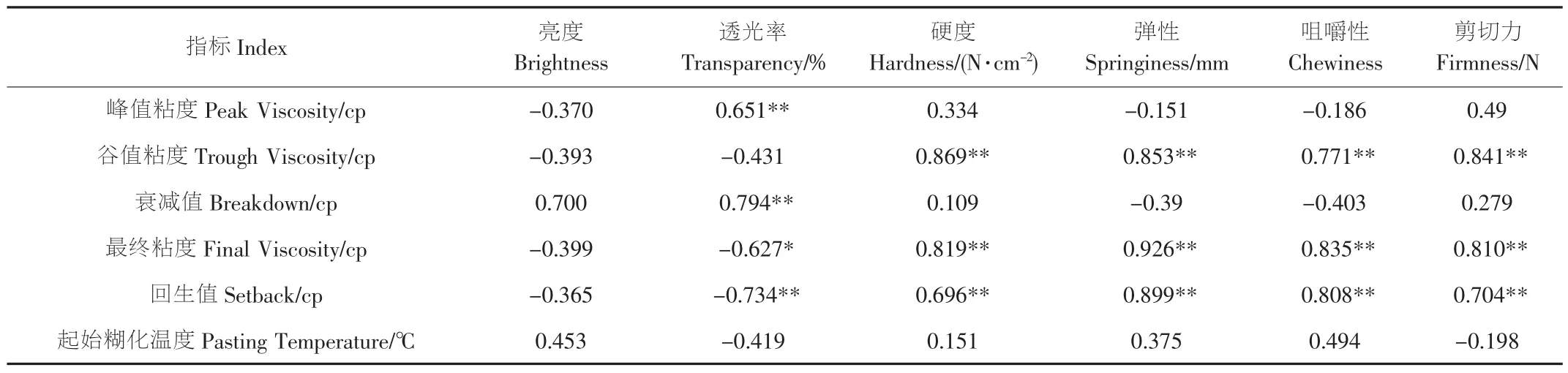

2.6.2淀粉糊化特性與水晶皮質構品質特性相關性分析

表7為淀粉糊化特性與水晶皮質構品質特性相關性分析結果。對于水晶類制品,透明性是相對較為重要的指標,直接影響消費者對于水晶類制品的感官認知,由表7可以看出淀粉峰值粘度和衰減值與水晶皮透光率呈極顯著正相關,說明淀粉的膨脹程度越大,熱糊穩定性越好,淀粉皮透明性越好。回生值與最終粘度與透光率有顯著負相關性,這是由于回生值在一定程度上反映淀粉的老化趨勢,淀粉老化分子重組必然降低水晶皮透明性。因此在水晶類產品制作時,為提高產品的亮度和透明度,原料應有較高的粒度、膨脹度、峰值粘度和衰減值,較低的回生值和最終粘度。

淀粉皮的質構特性反映的是產品的適口性,谷值粘度、最終粘度、回生值與水晶皮硬度、彈性、咀嚼性、剪切力呈極顯著正相關,說明提高這些糊化特征值能夠使水晶皮有較好的彈韌性和咀嚼性。因此谷值粘度、最終粘度、回生值是表征淀粉皮的質構特性的重要指標,按顯著程度的大小排序:最終粘度>回生值>谷值粘度。起始糊化溫度與水晶皮品質特性沒有顯著相關性。因此在水晶皮制作原料選擇及品質改良上,原料的糊化特性可以作為重要考核指標。

表7 淀粉糊化特性與水晶皮質構品質特性相關性分析Table 7 Correlations between starch pasting properties and crystal leather textural quality characteristic

3 結論

1)不同來源的淀粉制做水晶皮質構品質差異較大,小麥淀粉皮品質最好,亮度為77.81,透光率為22.83%,有較好的質構特性,其次是馬鈴薯、木薯、玉米淀粉皮,綠豆淀粉皮品質最差。

2)淀粉顆粒特性、破損淀粉含量與水晶皮品質指標密切相關。平均粒徑、膨脹度越大水晶皮亮度、透明性越好。破損淀粉含量應保持在一定范圍內,水晶皮才能有相對較好的綜合質構品質,本研究中破損淀粉含量用碘吸收率表示為93.94%時,水晶皮品質較好。

3)淀粉的糊化特性與水晶皮質構品質特性之間存在顯著相關性。對于透光率而言,淀粉峰值粘度和衰減值與水晶皮透光率呈極顯著正相關。谷值粘度、最終粘度、回生值與水晶皮硬度、彈性、咀嚼性、剪切力呈極顯著正相關,按顯著程度的大小排序:最終粘度>回生值>谷值粘度。起始糊化溫度與水晶皮質構品特性相關性不顯著。

4)制作蝦餃等水晶類制品的外皮要求有較高的透明性,有光澤同時要有適當的韌性、彈性,有較好的適口性。因此評價淀粉品種對于水晶皮制作適應性時,可以測定淀粉粒徑、膨脹度、峰值粘度、衰減值來預測淀粉皮亮度與透光率;測定淀粉破損淀粉含量、谷值粘度、最終粘度、回生值來預測淀粉皮適口性等品質。

[參考文獻]

[1] Lin J H, Kao W T, Tsai Y C, et al.Effect of granular characteristics on pasting properties of starch blends [J].Carbohydrate Polymers, 2013, 98(2): 1553-1560.

[2]謝新華,艾志錄,王娜,等.不同介質對玉米淀粉糊化黏度特性的影響[J].中國糧油學報,2010,25(3):37-39.Xie Xinhua, Ai Zhilu, Wang Na, et al.Effects of different media on paste property of corn starch[J].Journal of the Chinese Cereals and Oils Association, 2010,25(3): 37-39.(in Chinese with English abstract)

[3]竇紅霞,楊特武,趙思明,等.不同品種秈米化學成分、凝膠和糊化特性及米粉加工品質比較[J].中國糧油學報,2014,29 (3):1-6.Dou Hongxia, Yang Tewu, Zhao Siming, et al.Comparison on main chemical components, gelatinization, pasting properties and processing adaptability for rice noodle of different indica rice varieties [J].Journal of the Chinese Cereals and Oils Association, 2014,29(3): 1-6.(in Chinese with English abstract)

[4] Sandhu K S, Kaur M, Mukesh.Studies on noodle quality of potato and rice starches and their blends in relation to their physicochemical, pasting and gel textural properties[J].LWTFood Science and Technology, 2010,43(8): 1289-1293.

[5]張豫輝,陸啟玉.淀粉及其結構、性質對面條品質影響的研究進展[J].糧食與油脂,2014,(12):20-23.Zhang Yuhui, Lu Qiyu.Study on the effects of structure and properties of starch on noodle quality[J].Cereals and Oils, 2014, (12): 20-23.(in Chinese with English abstract)

[6]黎曉,童張法,趙奕玲,等.不同介質中木薯淀粉磷酸酯透明度及流變特性的研究[J].食品科技,2008,(10):20-24.Li Xiao, Tong Zhangfa, ZhaoYiling, et al.Study on transparency and rheological properties of cassava starch phosphate in different media[J].Food Science and Technology, 2008,(10): 20-24.(in Chinese with English abstract)

[7]杜先鋒,許時嬰,王璋.淀粉糊的透明度及其影響因素的研究[J].農業工程學報,2002,18(1):129-131.

[8]尹顯鋒,鄔應龍,劉丹.魔芋葡甘露聚糖溶液透明度影響因素的初步研究[J].食品研究與開發,2006,27(2):21-23.Yin Xianfeng, Wu Yinglong, Liu Dan.Pilot study on the influence factors on transparency of konjac glucomannan [J].Food Research and Development, 2006, 27(2): 21-23.(in Chinese with English abstract)

[9] Zhou Hongxian, Wang Chejie, Shi Liu, et al.Effects of salts on physicochemical, microstructural and thermal properties of potato starch[J].Food Chemistry,2014,156:137-143.

[10] Sun Suling, Zhang Ganwei, Ma Chaoyang.Preparation,physicochemical characterization and application of acetylated lotus rhizome starches[J].Carbohydrate Polymers, 2016(135): 10-17.

[11]周愛梅,楊慧,楊磊,等.不同品種南瓜淀粉的理化特性對比研究[J].現代食品科技,2013,29(8):1784-1790.Zhou Aimei, Yang Hui, Yang Lei, et al.Physicochemical properties of pumpkin starches from different cultivar[J].Modern Food Science & Technology, 2013,29(8): 1784 -1790.(in Chinese with English abstract)

[12]廖盧艷,吳衛國.不同淀粉糊化及凝膠特性與粉條品質的關系[J].農業工程學報,2014,30(15):332-338.Liao Luyan, Wu Weiguo.Relationship between gelatinization and gel properties of different starch and their noodles [J].Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(15): 332-338.(in Chinese with English abstract)

[13]李光磊,李剛,曾潔,等.玉米淀粉餃子皮透明度研究[J].食品工業科技,2010,(9):89-94.Li Guanglei, Li Gang, Zeng Jie, et al.Study on the transparency of corn starch Chinese dumpling wrappers [J].Science and Technology of Food Industry, 2010,(9):89-94.(in Chinese with English abstract)

[14]樊奇良,章烜.黑麥粉餃子皮生產工藝及品質的研究[J].糧食科技與經濟,2014,39(6):66-69.

[15]葉曉楓,韓永斌,趙黎平,等.凍融循環下冷凍非發酵面團品質的變化及機理[J].農業工程學報,2013,29(21):271-278.Ye Xiaofeng, Han Yongbin, Zhao Liping, et al.Quality changes and mechanism of frozen non-fermented dough upon consecutive freeze-thaw cycles [J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2013, 29 (21): 271-278.(in Chinese with English abstract)

[16] Puncha-arnon S, Pathipanawat W, Puttanlek C, et al.Effects of relative granule size and gelatinization temperature on paste and gel properties of starch blends [J].Food Research International, 2008,(41): 552-561.

[17]袁美蘭,魯戰會,程永強,等.不同植物來源淀粉之問的理化性質的比較[J].食品科學,2009,30(1):122-127.Yuan Mei1an, Lu Zhanhui, Cheng Yongqian, et al.Comparison study on physico-chemical properties of various starches from different botanical sources[J].Food Science, 2009, 30(1): 122-127.(in Chinese with English abstract)

[18]譚彩霞,封超年,郭文善,等.不同品種小麥粉黏度特性及破損淀粉含量的差異[J].中國糧油學報,2011,26(6):4-7.Tan Caixia, Feng Chaonian, Guo Wenshan, et al.Difference of starch viscosity characteristic and damaged starch content among different wheat cuhivar[J].Journal of the Chinese Cereals and Oils Association, 2011, 26(6): 4-7.(in Chinese with English abstract)

[19] Cozzolino D, Roumeliotis S, Eglinton J.Relationships between starch pasting properties, free fatty acids and amylose content in barley[J].Food Research International, 2013, 51(2): 444-449.

[20]鄭學玲,張玉玉,張杰.青稞淀粉和小麥淀粉的理化性質比較研究[J].中國糧油學報,2010,25(10):52-56.Zheng Xueling, Zhang Yuyu, Zhang Jie.Comparison of physicochemical properties of hull-less barley starch and wheat starch [J].Journal of the Chinese Cereals and Oils Association, 2010, 25(10): 52-56 .(in Chinese with English abstract)

[21] Waterschoot J, Gomand S V, Willebrords J K, et al.Pasting properties of blends of potato, rice and maize starches [J].Food Hydrocolloids, 41(2014): 298-308.

[22]李雪琴,葛靜靜,謝沁,等.餃子皮感官品質和質構品質關系的研究[J].河南工業大學學報(自然科學版),2012,33(4):1-4.Li xueqin,Ge Jingjing,Xie Qin, et al.Relationship between sensory quality and texture quality of dumpling wrappers [J].Journal of Henan University of Technology(Natural Science Edition), 2012, 33(4): 1-4.(in Chinese with English abstract)

[23]呂軍倉,席小艷.質構分析儀在面制品品質評價中的應用[J].糧油加工,2006,(3):73-74.

[24]何晉浙,張安強,丁玉庭.10種淀粉的理化特性研究[J].中國糧油學報,2011,26(4):37-41.He Jinzhe, Zhang Anqiang, Ding Yuting.Physicochemical properties of 10 plant starch pastes [J].Journal of the Chinese Cereals and Oils Association, 2011,26(4):37-41.(in Chinese with English abstract)

[25]常虹,周家華,蘭彥平,等.不同淀粉糊物理特性的比較[J].食品研究與開發,2010,31(10):55-58.Chang Hong, Zhou Jiahua, Lan Yanping, et al.Comparative study on physical properties of different starch paste [J].Food Research and Development, 2010, 31(10): 55-58.(in Chinese with English abstract)

[26]譚洪卓,田曉紅,劉明,等.20種蠶豆淀粉物理特性、糊化回生特性與粉絲品質的關系[J].食品與生物技術學報,2010,29(2):230-236.Tan Hongzhuo, Tian Xiaohong, Liu Ming, et al.Relationship between physical, gelatinized, retrograded properties of starches and their starch noodles qualities from twenty broad bean varieties in China[J].Journal of Food Science and Biotechnology, 2010, 29(2):230-236.(in Chinese with English abstract)

Effect of different starch source properties on crystal leather textural quality

Ai Zhilu1,3, Sun Xixi1, Pan Zhili1,2, Xie Xinhua1, Suo Biao1, Tian Pingping1

(1.College of Food Science and Technology, Henan Agricultural University, Zhengzhou 450002, China; 2.Henan Engineering Laboratory and Key Laboratory Base of Quick-frozen Flour-rice and Prepared Food, Zhengzhou 450002, China; 3.Collaborative Innovation Center of Henan Grain Crop, Zhengzhou 450002, China)

Abstract:High transparency and delicate taste are the most important quality indices of the crystal starch products.In order to clarify the effect of starch characteristics on the crystal products' textural quality, 5 kinds of starch originated from wheat, corn, potato, cassava and mung bean were selected as research material to determine the starch granule property, damaged starch content, gelatinization property, as well as their correlation with crystal skin transparency and texture quality.The brightness, transparency and texture properties were chosen as indices for evaluating the quality of crystal starch product, which could not only reflect the product palatability, but also avoid the difference of artificial factors.The indices were determined by the colorimeter, the ultraviolet-visible spectrophotometer and the texture analyzer, respectively.The experiment was carried out in Henan Agricultural University from March to June in 2015.The results showed that different starch skin showed significant difference in the quality.By evaluating the starch skin brightness, transparency and texture qualities, the wheat starch skin showed the best quality, followed by potato, cassava and corn.The worst quality was found in mung bean starch product.The brightness of wheat starch skin was 77.81, which was the highest brightness in research.The wheat starch skin had the light transmittance of 22.83%, and it also had better chewiness, more moderate hardness, springiness and firmness under the same condition.Therefore, wheat starch skin demonstrated the best palatability to make crystal skin, because it had more excellent quality characteristics.The average particle size of starch was significantly and positively correlated with crystal skin brightness and light transmittance, which should be attributed to the reason that starch molecules with larger size were easier to swell and be fully extended.The average particle size of starch was significantly and negatively correlated with crystal skin springiness and chewiness.The results suggested that excess starch inflation would lead to a water-based starch, which was adverse to the springiness and chewiness of the starch skin.The expansion of the starch granules at 95℃was significantly(P<0.05)related to the light transmittance of crystal skin, but not significantly related to other quality characteristics.The damaged starch content of the starch had significantly positive correlations(P<0.05)with crystal skin brightness and light transmittance.Whereas, the damaged starch content had negative correlations with springiness and chewiness.Therefore, the best overall crystal skin texture quality would be obtained only when the damaged starch content was moderate.In this study, the crystal skin quality was good when iodine absorption rate was 93.94%.Moreover, the crystal starch product quality also showed a close relationship with starch gelatinization, which was evident by the results that starch peak viscosity and breakdown had significantly(P<0.01)positive correlation with the light transmittance of crystal starch products.The results suggested that the starch with greater swelling was easier to form better thermal paste stability, and as a result the transparency of the starch skin was higher.Setback and final viscosity had negative correlation with the light transmittance.Setback reflected the aging trend of starch.Starch aging would lead to the reorganization of molecules, which reduced crystal skin transparency.The positive correlation was also observed between the trough viscosity, final viscosity, setback and the crystal starch product hardness, springiness, chewiness, firmness.However, there was no significant correlation between the gelatinization temperature and the crystal starch products quality.To sum up, the present results suggest that when one kind of raw material is selected for crystal starch products, the viscosity is capable of being used as an important evaluation index.Meanwhile, the particle size, swelling, peak viscosity and breakdown can be well used for predicting the crystal starch product's brightness and light transmittance.The damaged starch content, trough viscosity, final viscosity and setback are the crucial factors that affect the palatability of the crystal starch products.The present result has a great application potential in crystal starch product processing industry, and especially offers a basic theoretical support for raw material selection and quality improvement.

Keywords:starch; quality control; agricultural products; particle characteristics; crystal leather; pasting; textural quality

作者簡介:艾志錄,男,教授,博士,研究方向:農產品精深加工。鄭州河南農業大學食品科學技術學院,450002。Email:Zhila@163.com

基金項目:新型速凍米面食品高效冷凍節能加工技術研究(30600514)

收稿日期:2015-08-06

修訂日期:2015-11-18

中圖分類號:TS236.5

文獻標志碼:A

文章編號:1002-6819(2016)-01-0318-07

doi:10.11975/j.issn.1002-6819.2016.01.044