Trim Drag Prediction for Blended-Wing-Body UAV Configuration

Deng Haiqiang(鄧海強),Yu Xiongqing(余雄慶),Yin Hailian(尹海蓮),Deng Feng(鄧楓)

1.UAV Research Institute,Nanjing University of Aeronautics and Astronautics,Nanjing 210016,P.R.China;

2.Key Laboratory of Eundamental Science for National Defense Advanced Design Technology of Elight Vehicle,Nanjing University of Aeronautics and Astronautics,Nanjing 210016,P.R.China

Trim Drag Prediction for Blended-Wing-Body UAV Configuration

Deng Haiqiang(鄧海強)1,Yu Xiongqing(余雄慶)2*,Yin Hailian(尹海蓮)1,Deng Feng(鄧楓)2

1.UAV Research Institute,Nanjing University of Aeronautics and Astronautics,Nanjing 210016,P.R.China;

2.Key Laboratory of Eundamental Science for National Defense Advanced Design Technology of Elight Vehicle,Nanjing University of Aeronautics and Astronautics,Nanjing 210016,P.R.China

A rapid method of the trim drag prediction for the blended-wing-body unmanned aerial vehicle(UAV)configuration is proposed.The method consists of four steps.The first step is to parameterizedly model the blended-wing-body UAV configuration;the second is to analyze the aerodynamics of the geometric model;the third is to create aerodynamic surrogate model;and the final step is to predict the trim drag using the surrogate model. Hence,a tool for trim drag prediction is developed by integration of the four steps.The impacts of the allocation of control surfaces,position of gravity center and planform parameters on the trim drag are investigated by using the tool.Results show that using the control surface in outer wing for trim has an advantage of lower trim drag,and the position of gravity center has a primary impact on the trim drag.Moreover,the planform has secondary impacts on the trim drag.

aerodynamic configuration;blended-wing-body;trim drag;unmanned aerial vehicles(UAVs)

0 Introduction

The features of higher aerodynamic efficiency and lower observability[1-5]guarantee the blendedwing-body(BWB)an attractive configuration for unmanned aerial vehicles(UAVs).However,the trim and static margin are critical for the BWB configurations[3]due to the absence of a horizontal tail.

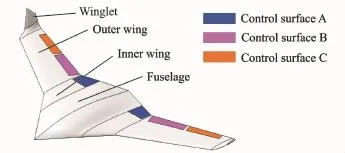

This paper addresses the trim drag issues of a subsonic BWB UAV.The trim drag is the increment in drag from aerodynamic trimming[6].Eor BWB configurations,the trim drag comprises:(1)the profile drag increment due to control surface deflections;(2)the induced drag increment due to the change of lift distribution caused by the control surface deflections.The impacts of allocations of control surfaces,gravity center position and planform parameters on the trim drag are investigated.The baseline configuration of the UAV is shown in Eig.1.The reference area Swis 20 m2,the aspect ratio AR=4.9.The leading edges of inner wing and winglet are parallel,the same to the trailing edges of inner wing and opposite outer wing.The trailing edges of outer wing and winglet are coincident.The rapid method and tool for the trim drag prediction is presented. Eurthermore,the impacts of parameters are discussed.

Eig.1 Baseline configuration of BWB UAV

1 Computational Method

1.1 Geometry parameterization

A VB code is developed[7]to generate the geometry model by defining three sets of parameters.

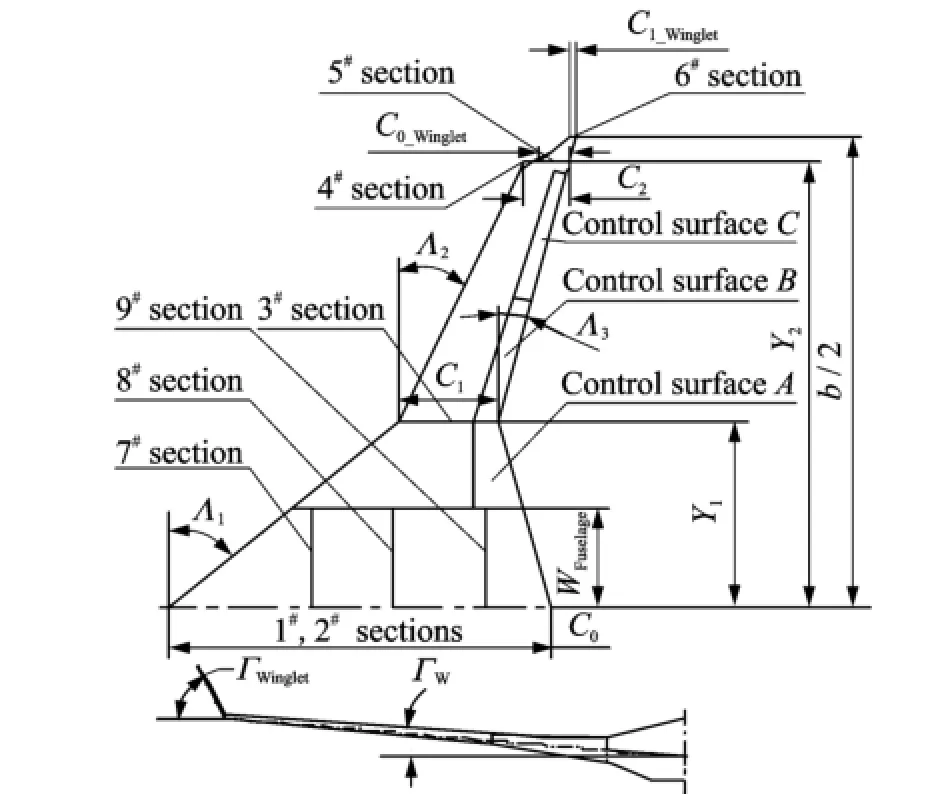

(1)Planform parameters are listed as follows:the ratio of winglet′s lateral projection area to reference area RS,half of fuselage width WEuselage,the sweeping anglesΛ1,Λ2andΛ3of the the leading and trailing edge(Eig.2),the dihedralsΓWandΓWingletof the wing and winglet.

Eig.2 Definition of configuration parameters

(2)Cross section parameters include the airfoils and twist angles of sections 1 to 6,as well as the parameters of sections 7 to 9.The method presented by Ref.[8]is used to parameterize these cross sections.

(3)Deflections of control surfaces areδA,δB,andδCfor control surfaces A,B and C,respectively.

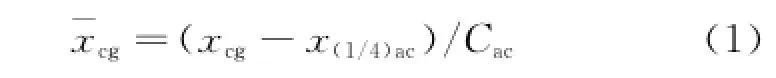

where xcgand x(1/4)acare the x coordinate of gravity center and the quarter point of mean aerodynamic chord,respectively.

1.2 Grid generation and aerodynamic analysis

Two Gridgen scripts are programmed to generate the meshes for the geometries without and with the control surface deflections,respectively. After that,the panel method program Pan Air[9]is ultilized to predict lift coefficient CL,induced drag coefficient CDiand pitching moment coefficient Cm.

1.3 Surrogate model for aerodynamic analysis

Eor each planform of the BWB UAV,the aerodynamic coefficients CL(α,δA,δB,δC),CDi(α,δA,δB,δC)and Cm(α,δA,δB,δC)are computed by the above aerodynamic method.The radial basis function method[10]is utilized to create the aerodynamic surrogate model.It takesα,δA,δB,δCas input parameters and CL,CDi,Cmas output parameters.

1.4 Trim drag computation

The trim drag coefficient CD_trimis given by

whereΔCD_tr_pis the profile drag increment estimated by an engineering method[6],ΔCD_tr_wthe induced drag increment,CDi_cleanthe induced drag coefficient of the clean configuration,and CDi_deflectedthe induced drag coefficient in trimming condition obtained from an trimming optimization.The formulation of the optimization is to minimize the value of CD_trimvia design variablesα,δA,δB,δCwith the constraints of a fixed CL,as well as Cm=0.

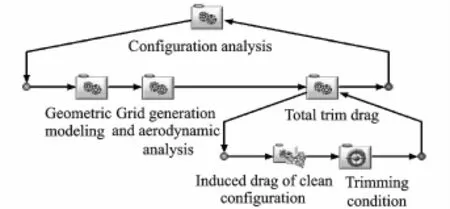

1.5 Tool for trim drag computation

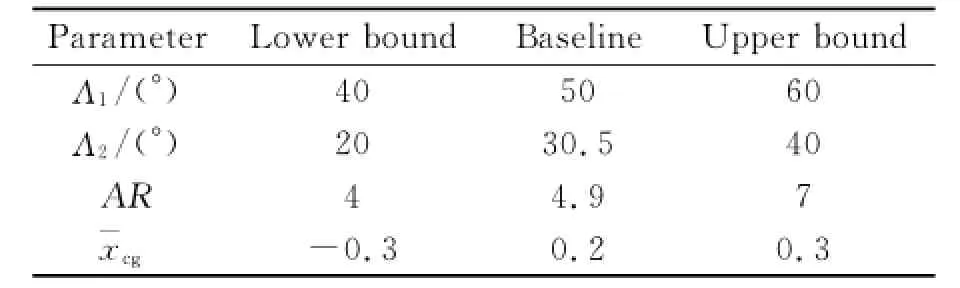

A tool for trim drag computation is developed by integrating the above steps within iSIGHT-ED software,and the workflow is shown in Eig.3. The impact of each parameter listed in Table 1 on trim drag is investigated under the condition that others remain their baseline values by the proposed tool.

Eig.3 Workflow for trim drag computation

Table 1 Baseline values and ranges of parameters

2 Results

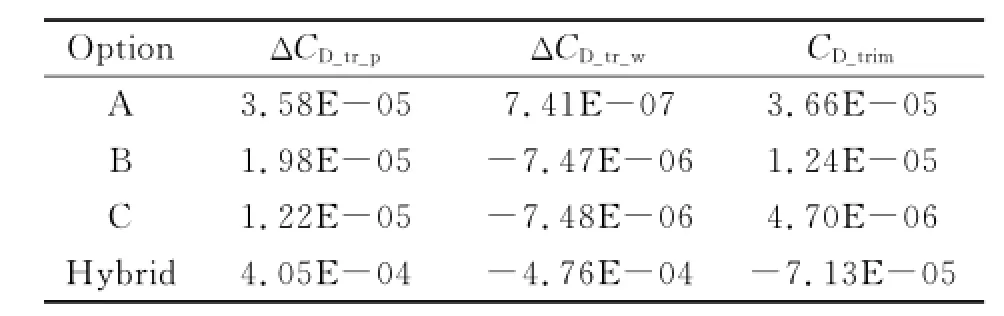

2.1 Impact of control surface allocation

The trim drags for different allocations of control surfaces are listed in Table 2.The options A,B,C signify that only the control surface A,or B,or C is used for trim,respectively.″Hybrid″indicates that all the control surfaces are used simultaneously for trim.The results show that the option C has the lowest trim drag than the options A and B,thus simplifying the control system without remarkable trim drag penalty compared with the option″Hybrid″.

Table 2 Trim drags for different allocations

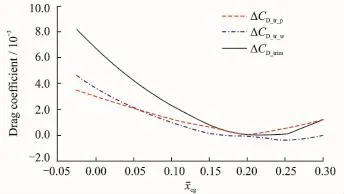

2.2 Impact of gravity center position

The impact ofˉxcgon CD_trimis plotted in Eig.4.The value ofΔCD_tr_pdecreases with the increase ofˉxcguntilˉxcgis greater than 0.2.Subsequently it increases gradually.The reason is that the value of Cmchanges from negative to positive when the parameterˉxcgincreases.Consequently,theδCincreases from negative to positive and is almost zero whenˉxcgis equal to 0.2.

Eig.4 Impact of gravity center position on trim drag

TheΔCD_tr_wdescends with the increase ofˉxcgwhenˉxcgis less than 0.25,thereafter it increases slightly.It is because the nose-down moment and δCdecrease with the increasingwhenis less than 0.2,and the spanwise lift distribution is more″ellipical″.However,the spanwise lift distribution begins to depart from the elliptical shape whenis greater than 0.25.

The CD_trimdrops rapidly when theis less than 0.2.After CD_trimreaches its minimum at=0.2,CD_trimincreases gradually along the positive direction ofwith values more than 0.2. 2.3 Impacts of planform parameters

2.3.1 Impact of inner wing leading edge sweep

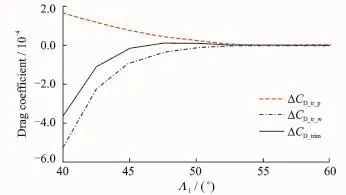

The impact ofΛ1on CD_trimis depicted in Eig.5.

Eig.5 Impact of sweepΛ1on trim drag

Along with the increase ofΛ1,theΔCD_tr_pdecreases since the outer wing area and moment arm of the control surface C increase,thus reducing theδCfor trim.TheΔCD_tr_wis negative and it increases with the increase ofΛ1,which means the spanwise lift distribution is improved.But the beneficial effect decreases with the increase ofΛ1. The minimum and maximum of CD_trimoccur at Λ1=40°andΛ1=47.5°,respectively.WhenΛ1is larger than 47.5°,the trim drag decreases gradually.

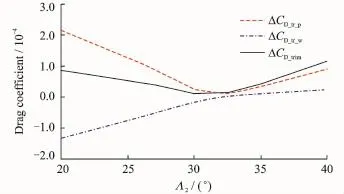

2.3.2 Impact of outer wing leading edge sweep

The impact ofΛ2on CD_trimis shown in Eig.6. When the pitching moment arm of control surface C increases,the Cmdecreases.Therefore,the ΔCD_tr_pdecreases with the increase ofΛ2untilΛ2is more than 32.5°,and then it increases gradually.Consequently,theδCfor trim decreases and approaches zero whenΛ2=32.5°.TheΔCD_tr_wis negative whenΛ2is less than 32.5°,while it turns to positive whenΛ2is more than 32.5°.This indicates that the spanwise lift distribution is improved,but the beneficial effect diminishes withthe increase ofΛ2.The CD_trimdecreases untilΛ2is larger than 32.5°.

Eig.6 Impact of sweepΛ2on trim drag

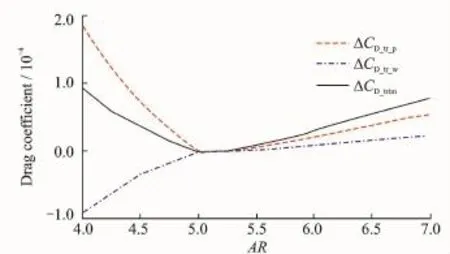

2.3.3 Impact of aspect ratio

The impact of aspect ratio AR on CD_trimis illustrated in Eig.7.TheΔCD_tr_pdecreases until AR exceeds 5.25.After that it increases gradually.It is due to the fact that the span and pitching moment arm of control surfaces C increase.Moreover,the Cmdecreases from positive to negative.Consequently,theδCfor trim decreases and approaches zero at AR=5.25.TheΔCD_tr_wincreases gradually when the AR increases.It changes from negative to positive when AR is larger than 5.25.The whole effect is that the CD_trimdecreases until AR is more than 5.25,and it reaches the minimum at AR=5.25.

Eig.7 Impact of aspect ratio on trim drag

3 Conclusions

The quantitative investigations of the trim drag for the BWB UAV have the following conclusions:

(1)Regarding to the allocations of control surfaces for trim,although the option″Hybrid″has the minium trim drag,the option C can simplify the control system without remarkable trimdrag penalty.

(2)The position of gravity center has a primary impact on the trim drag,which rapidly decreases with the backward movement of gravity center.Whenˉxcgis 0.2,the trim drag is minimal.

(3)The planform parameters have secondary impacts on the trim drag.Careful selections of the planform parameters can further reduce the trim drag by 1 to 4 counts.

Acknowledgements

This work was supported by the National Defense Basic Scientific Research Program of China(No.A2520110006)and the Eundamental Research Eunds for the Central Universities(Nos.NJ20130001,NJ2012014).

[1] Liebeck R H.Design of the blended wing body subsonic transport[J].Journal of Airctaft,2004,41(1): 10-25.

[2] Qin N,Vavalle A,Le Moigne A.Spanwise lift distribution for blended wing body aircraft[J].Journal of Aircraft,2005,42(2):356-365.

[3] Lyu Z,Martins J R.Aerodynamic shape optimization of a blended-wing-body aircraft[R].AIAA 2013-0283,2013.

[4] Lee D S,Gonzalez L E,Auld D J,et al.Aerodynamic/RCS shape optimisation of unmanned aerial vehicles using hierarchical asynchronous parallel evolutionary algorithms[R].AIAA 2006-3331,2006.

[5] Kuntawala N,Hicken J,Zingg D.Preliminary aerodynamic shape optimization of a blended-wing-body aircraft configuration[R]AIAA-2011-642,2011.

[6] Roskam J.Airplane design,Part 6[M].Ottawa,Kansas:Roskam Aviation and Engineering Corporation,1985:311-312.

[7] You Lianxing,Yu Xiongqing,Ouyang xing.Parametric geometry modeling for conceptual design of high supersonic unmanned aerial vehicles[J].Journal of Nanjing University of Aeronautics&Astronautics,2014,46(3):425-432.(in Chinese)

[8] Zhang Zhenming,Liu Yi,Ding Yunliang.Parametric geometry modeling and shape optimization method for hypersonic flight vehicles[J].Journal of Nanjing University of Aeronautics&Astrnautics,2012,44(2): 172-177.(in Chinese)

[9] Carmichael R L,Erickson L L.PAN AIR—A higher order panel method for predicting subsonic or supersonic linear potential flows about arbitrary configurations[R].AIAA-1981-1255,1981.

[10]Jin R,Chen W,Simpson T W.Comparative studies of metamodeling techniques under multiple modeling criteria[J].Journal of Structural and Multidisciplinary Optimization,2001,23(1):1-13.

(Executive editor:Zhang Tong)

V212.11 Document code:A Article ID:1005-1120(2015)01-0133-04

*Corresponding author:Yu Xiongqing,Professor,E-mail:yxq@nuaa.edu.cn.

How to cite this article:Deng Haiqiang,Yu Xiongqing,Yin Hailian,et al.Trim drag prediction for blended-wing-body UAV configuration[J].Trans.Nanjing U.Aero.Astro.,2015,32(1):133-136.

http://dx.doi.org/10.16356/j.1005-1120.2015.01.133

(Received 12 December 2013;revised 7 January 2015;accepted 12 January 2015)

Transactions of Nanjing University of Aeronautics and Astronautics2015年1期

Transactions of Nanjing University of Aeronautics and Astronautics2015年1期

- Transactions of Nanjing University of Aeronautics and Astronautics的其它文章

- Beamforming of Whole Airspace Phased Array TT&C System Based on Linear Subarrays

- High Velocity Impact Experiment on Ti/CFRP/Ti Sandwich Structure

- CRB for 2-D DOA Estimation in MIMO Radar with UCA

- Improved Shuffled Frog Leaping Algorithm Optimizing Integral Separated PID Control for Unmanned Hypersonic Vehicle

- Tradeoff Analysis of Factors Affecting Longitudinal Carrier Landing Performance for Small UAV Based on Backstepping Controller

- Flight Dynamic Analysis of Hypersonic Vehicle Considering Liquid-Solid Coupling