High Velocity Impact Experiment on Ti/CFRP/Ti Sandwich Structure

Huan Dajun(還大軍),Ding Bing(丁冰),Li Yong(李勇),Xiao Jun(肖軍)

College of Material Science and Technology,Nanjing University of Aeronautics and Astronautics,Nanjing 210016,P.R.China

High Velocity Impact Experiment on Ti/CFRP/Ti Sandwich Structure

Huan Dajun(還大軍)*,Ding Bing(丁冰),Li Yong(李勇),Xiao Jun(肖軍)

College of Material Science and Technology,Nanjing University of Aeronautics and Astronautics,Nanjing 210016,P.R.China

Aircraft laminated composite components often suffer a variety of high velocity impacts with large quantity of energy,which usually affects aircraft behavior and would incur component damages,even disastrous consequences.Therefore,one investigates the impact resistance of a new type of composite material,Ti/CERP/Ti sandwich structure,and launches impact tests by using an air gun test system.Then one acquires the critical breakthrough rate of the structure and analyzes the damages.The results show that the main failure mode of the front titanium sheet is shear plugging and brittle fracture of adhesive layer with fiber breakage,while the back titanium sheet is severely ripped.The rear damage is worse than the front one.Compared with traditional CERP laminates,the critical breakthrough rate of Ti/CERP/Ti sandwich structure is improved by 69.9%when suffered the impact of a bearing ball with 2 mm radius.

Ti/CERP/Ti sandwich structure;high velocity impact;critical velocity;damage mode

0 Introduction

Aircraft laminate composite structures often encounter various impacts,including low velocity impacts,e.g.missing a part during fabrication or dropping a tool on the structure during maintenance;and high velocity ones,like splashing sand while taking off and landing or bird-striking in flight[1-2].Since composite structures are vulnerable to impacts,it is necessary to minimize impact damages on them.

The impact resistance of metals is much better than that of laminated composites.However,specific strength,specific modulus and fatigue resistance of most metals cannot compete with those of composites.Therefore,aramid fiber reinforced aluminum alloy laminates(ARALL)[3-4]and glass fiber reinforced aluminum alloy laminates(GLARE)[5-6]were developed to take full advantages of the two materials.The properties of fiber metal laminates(EMLs)are strongly related to the types of reinforced fiber and the metal:(1)Carbon fiber′s unidirectional mechanical property is excellent,and its crack growth rate is very low;(2)Titanium alloy has no potential corrosion problem with carbon fiber,and can effectively improve shock resistance of the composite.Therefore,the research on high velocity impact damage for carbon fiber reinforced titanium alloy laminates is academically significant.

Most carbon fiber reinforced titanium alloy laminates are manufactured with polyether ether ketone(PEEK)currently.But the processing of PEEK prepreg is complicated;the price is extraordinarily high;and it lacks stickiness.Compared with thermoplastic materials,thermosetting materials will undoubtedly dominate the market for a long time.Therefore,for practical reason,the impact property of Ti/carbon-fiberreinforced polymer(CERP)/Ti sandwich structure with the adhesive of epoxy resin(Eig.1)was investigated.Eurthermore,to improve the impact resistance of structures,titanium is sticked on the margin of the composite fan blades as usedin GE90 engines,which have run safely for nearly 20 years with only three blades been substituted.

Eig.1 Schematic figure of Ti/CERP/Ti sandwich structure

Many researches to date have been conducted to study high velocity impact damage of single fiber composite materials or homogeneous metals[7-9],though few of them focus on the damage of EMLs.Nakatani et al.[10]studied the damage behavior of titanium/GERP hybrid laminates subjected to low-velocity impacts.The observation and experimental results of the four-point bending tests indicated that internal damages and residual out-of-plane deformation of the GERP layer were suppressed by the energy absorption via plastic deformation and crack initiation in the titanium layer on the side opposite the impact.Cortés et al.[11]revealed the energy-absorbing mechanisms of fiber metal laminates during impact.Low velocity impact testing had shown that the specific perforation energy of the CE/PEEK-based EMLs was similar to that offered by the CE/PEEK composite.The experimental evidence proved that the inclusion of strong titanium alloy plies could not improve the perforation resistance of EMLs. Extensive and detailed optical microscope study had shown that interfacial and inter laminar delaminations were the principal energy-absorbing mechanisms during low and high velocity impacts.Chen et al.[12-13]explored the high velocity impact damage modes of fiber metal composite target boards.The board presented a local failure mode.The damage modes of the front fiber were a shear fracture,while the back steel presented a petal-crack damage.When the positions of fiber and steel are switched,the damage modes of the back fiber become tension fracture while the front steel experiences shear destruction damage.Experimental tests show that the energy absorption of the latter combination is superior.

We used air gun test system to carry out the impact tests for Ti/CERP/Ti sandwich structure. The ply stacking sequence was[0/90]3s.The critical velocity of passing through the structure was identified.The damage modes of both the pure CERP and the Ti/CERP/Ti sandwich structure were analyzed.And the damage area was analyzed to determine the impact resistance.

1 Experiments

An air gun test system developed by Nanjing University of Aeronautics and Astronautics was utilized to carry out the impact test.The system consisted of a foreign object damage launcher,a speedometer and a retaining protection device. The projectile with a 2 mm-radius bearing ball was used,and the initial speed was between 150 m/s and 400 m/s.

Here,Ti/CERP/Ti sandwich structures were manufactured by bonding titanium alloy sheet(Ti-6Al-4V,0.2 mm thick)to the crossplied CERP laminates,which were cured in advance by a hot press machine using CE/Epoxy prepreg(Hengshen Co.,Ltd.)with epoxy adhesive(J-272,Institute of Petrochemistry Heilongjiang Academy of Sciences).The mechanical properties of the constituents obtained by static tensile tests were listed in Table 1.

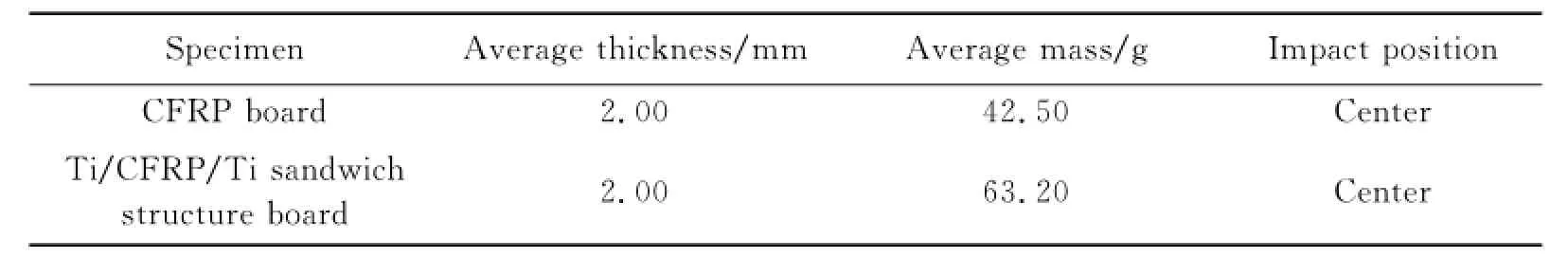

The specimens included two types of target boards,i.e.Ti/CERP/Ti sandwich structure and pure CERP.The Ti/CERP/Ti sandwich structure board consised of two outer layers of titanium sheets sandwiching a CERP layer as the core which was 1.5 mm thick and comprised of twelve plies with a stacking sequence of[0/90]3s.The 2 mm thick CERP panel was made of 16 plies with alay-up sequence of[0/90]4s.The square specimens(120 mm×120 mm)were clamped by a special fixture with an 80 mm-diameter central opening.The average thickness,the average weight,and the location of the neutral line in each laminate are shown in Table 2.

Table 1 Mechanical properties of constituents

Table 2 Properties of impact specimens

2 Experimental Results

2.1 Critical penetration velocity

Successive approximation is used to obtain the critical penetration velocities of the CERP target and the Ti/CERP/Ti sandwich structure.It is easy to identify whether the plates are punched or not by examining the damage of the plates.And the critical penetration velocity is defined by the incident velocity when the projectile drops on the baseboard of the fixture.The experimental data and damage status of the boards are shown in Table 3.

Table 3 Experimental data and damage status of penetration

As shown in Table 3,CERP plates are penetrated three times,and fail five times.Apparently,when a projectile with a 4 mm-diameter bearing ball impacts a CERP plate,the critical penetration velocity is 203 m/s.However,when a projectile with a 4 mm-diameter bearing ball impacts the Ti/CERP/Ti plate,the critical penetration velocity is 341 m/s,increaing by 69.9% thanks to titanium alloy skin.

2.2 Analysis of damage modes

Many researchers have investigated the high velocity impact damage of pure CERP laminates[14-17].One compares the damage patterns between CERP and Ti/CERP/Ti sandwich structures.Back bulge,fibrous fracture,matrix cracking and delamination are the main damage modes of composite materials.Eigs.2—4 show the damage morphology of CERP laminates im-pacted by projectiles with different impact energy.

Eig.2 Damage morphology of plate impacted by 4.5 J energy

Eig.3 Damage morphology of plate impacted by 5.3 J energy

Eig.4 Damage morphology of plate impacted by 6.1 J energy

It is seen that pure CERP plate impacted with 4.5 J energy is not punched through.When the impact energy increases to 5.3 J,the CERP plate has a critical damage.And a projectile with impact energy of 6.1 J is powerful enough to punch through the CERP plate completely.Apparently,although damage areas of the front side of the three kinds of target boards are small,the back ones are seriously damaged.The morphology results show that the target boards on the front present shear plugging failure and compression failure in different levels.The fiber of the back mainly presents a tensile failure,and the crack propagates along fiber direction.Eurthermore,the back of the target boards is de-bonding and the damage evolution tends to be perpendicular to fiber direction.

Ti/CERP/Ti sandwich plates impacted by high velocity projectiles display different failure modes,and the damage morphologies of the Ti/ CERP/Ti sandwich structure plates are shown in Eigs.5—7.

Eig.5 Damage morphology of plate impacted by 12.7 J energy

Eig.6 Damage morphology of plate impacted by 15.1 J energy

Ti/CERP/Ti sandwich structure plate impacted by the energy of 12.7 J is not punched through.When the impact energy rises to 15.1 J,the target has critical failure.And a projectilewith 17.2 J impact energy is powerful enough to punch the Ti/CERP/Ti sandwich structure.

Eig.7 Damage morphology of plate impacted by energy of 17.2 J

As shown in Eigs.6—7,the area near the impact contact point presents shear plugging and plastic deformation.This is because the front plate is directly impacted by the projectile,and the deformation of the front plate is restricted by the core composites.Therefore,the front sheets are inclined to exhibit shear plugging,and the damage region is limited within the impact zone. Thus,the response of the front titanium sheets is a local failure response.

Different from the small damage area of the front sheets,the rear titanium plates are damaged seriously.The main failure mode of the rear titanium plates is ripping failure.This is because the existence of the front plate and the core composites lowers the projectile speed,and the fiber attached to the surface of the projectile enlarges the contact area.When the impact energy is high,the shear plugging will appear.Therefore,the response of the rear titanium sheets is a local failure response.

Moreover,the rear plate impacts with energy of 12.7 J presents a tear failure of C shape,and the sheet is not destroyed.When the impact energy increases to 17.2 J,the rear sheet on the contact point is totally damaged.The bullet hole and the rattled adhesive can be examined breezily. The projectile residual speeds of the three cases after crossing the front plate and core composites are obviously different.

2.3 Analysis of damage area

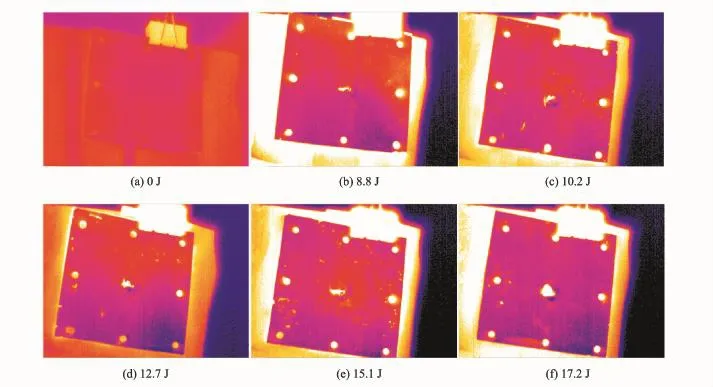

The damage area of the target plates impacted by projectiles was detected by terminology,a nondestructive testing-infrared testing.Eig.8 shows the damage infrared area of Ti/CERP/Ti sandwiched target boards suffers by different impact energy.The highlight parts in the pictures represent the damaged areas.

Eig.8 Infrared detection results of plates impacted with different energy

The Matlab platform was utilized to process the images:The image size was determined by pixels with the external contours as boundaries. The images were captured by a sequence of operations of image grabbing—image smoothing—image enforcing—edge detecting—image segmenting—binary denoising.Eig.9 presents the damage area of Ti/CERP/Ti sandwiched target boards suffer by different impact energies.We can find that the damage areas increase with the increase of impact energy.And the rising slope is abrupt at an initial stage,and then slows down gradually.

Eig.9 Damage area of Ti/CERP/Ti sandwich structure impacted with different energy

3 Conclusions

One launches a high velocity impact test on the Ti/CERP/Ti sandwich target boards and pure CERP plates,and draws the following conclusions:

(1)The critical penetration velocity of the 2 mmthick Ti/CERP/Ti sandwich structure target boards impacted by ball bearings with 2 mm radius is 341 m/s,while that of the 2 mm thick pure CERP target boards is 203 m/s.The critical breakthrough speed of Ti/CERP/Ti sandwich structure is increased by nearly 70%thanks to the thin titanium alloy sheets.

(2)The damage mode of the front titanium sheets of the Ti/CERP/Ti sandwich structure is shear plugging and plastic deformation,and that of the reverse sheets is a ripping failure,while the back damage of the pure CERP target boards is serious:the fiber on the back face sheet is uplifted,and the stratification along the fiber direction is slighter.

(3)The results show that the damage area of target boards increases with the growth of impact energy.The damage area stops enlarging when the target board is punched through.And the damage area is close to a fixed value.

Acknowledgement

This work was funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions.

[1] Jorge L,Ramón Z,Carlos N U.Experimental and numerical analysis of normal and oblique ballistic impacts on thin carbon/epoxy woven laminates[J]. Composites Part A:Applied Science and Manufacturing,2008,39(2):374-387.

[2] Zhang Aying,Zhang Dongxing,Li Dihong,et al. Impact damage of carbon fiber reinforced epoxy laminates[J].Aerospace Materials and Technology,2010(5):1-3.

[3] Zhang Guangcheng,He Qingkong,Yang Yufang. Study on the mechanical properties of ARALL/aluminium alloy laminates[J].Eiber Composites,2001,19(4):19-21.

[4] Marissen R.Eatigue crack growth in ARALL:A hybrid aluminium-aramid composite material,crack growth mechanisms and quantitative predictions of the crack growthrate[D].Delft:Delft University of Technology,1988.

[5] Wang Shiming,Wu Zhongqing,Zhang Zhengjun,et al.Research of glare laminates performance comprehensive evaluation applied to large aircraft[J]. Stanford Materials,2010,17(9):88-95.

[6] Vogelesang L B.Eiber metal laminates—The development of a new family of hybrid materials[C]// Proceedings ICAE Sr-yarposium.Lucern:[s.n.],2003.

[7] Nunes L M,Paciornik S,d′Almeida J R M.Evaluation of the damaged area of glass-fiber-reinforced epoxy-matrix composite materials submitted to ballistic impacts[J].Composites Science and Technology,2004,64(7/8):945-954.

[8] da Silva J E L,Paciornik S,d′Almeida J R M.Evaluation of the effect of the ballistic damaged area on the redusial impact strength and tensile stiffness of glass-fabric composite materials[J].Composites Structures,2004,4(1):123-127.

[9] Ean Jinjuan,Zhao Xu,Chen Xiaoquan.Compression damage characteristics of composite laminates after low velocity impact[J].Eailure Analysis and Prevention,2006,1(2):33-35.

[10]Nakatani H,Tatsuro K,Osaka K,et al.Damage characterization of titanium/GERP hybrid laminates subjected to low-velocity impact[J].Composites Part A:Applied Science and Manufacturing,2011,42(7): 772-781.

[11]Cortés P,Cantwell W J.The impact properties of high temperature fiber metal laminates[J].Journal of Composite Materials,2007,41(5):613-632.

[12]Chen Changhai,Zhu Xi,Hou Hailiang,et al.An experimental research on low-velocity projectiles perforating fiber and metal combined thin targets[J]. Acta Armamentarii,2012,33(12):1473-1479.

[13]Chen Changhai,Zhu Xi,Hou Hailiang,et al.Influence of structure configuration on perforation-resistance of a warship topside composite armor system[J].Journal of Vibartion and Shock,2013,32(14): 58-63.

[14]Lee S W R,Sun C T.Dynamic penetration of graphite/epoxy laminates impacted by a blunt-ended projectile[J].Composites Science and Technology,1993,49(4):369-380.

[15]Ellert E P,Cimpoeru S J,Woodward R L.A study of the effect of target thickness on the ballisticperforation of glass-fibre-reinforced plastic composites[J]. International Journal of Impact Engineering,2000,24(5):445-456.

[16]Jin Ziming,Sui Jinling,Zhang Hanying,et al.Study of ballistic performance and research process of fiber reinforced composite bulletproof plate[J].Glass Eiber Reinforced Plastic,2001,(1):1-6.

[17]Chen Xiaoquan,Kou Changhe,Li Zhengneng.Study on damage of composite honeycomb core sandwich panels under low velocity impact[J].Acta Materiae Compositae Sinica,1998,15(3):124-128.

(Executive editor:Zhang Tong)

O324 Document code:A Article ID:1005-1120(2015)01-0121-07

*Corresponding author:Huan Dajun,Lecturer,E-mail:huandj@nuaa.edu.cn.

How to cite this article:Huan Dajun,Ding Bing,Li Yong,et al.High velocity impact experiment on Ti/CERP/Ti sandwich structure[J].Trans.Nanjing U.Aero.Astro.,2015,32(1):121-127.

http://dx.doi.org/10.16356/j.1005-1120.2015.01.121

(Received 7 November 2014;revised 5 January 2015;accepted 12 January 2015)

Transactions of Nanjing University of Aeronautics and Astronautics2015年1期

Transactions of Nanjing University of Aeronautics and Astronautics2015年1期

- Transactions of Nanjing University of Aeronautics and Astronautics的其它文章

- Trim Drag Prediction for Blended-Wing-Body UAV Configuration

- Beamforming of Whole Airspace Phased Array TT&C System Based on Linear Subarrays

- CRB for 2-D DOA Estimation in MIMO Radar with UCA

- Improved Shuffled Frog Leaping Algorithm Optimizing Integral Separated PID Control for Unmanned Hypersonic Vehicle

- Tradeoff Analysis of Factors Affecting Longitudinal Carrier Landing Performance for Small UAV Based on Backstepping Controller

- Flight Dynamic Analysis of Hypersonic Vehicle Considering Liquid-Solid Coupling