RPV模擬鋼中納米富Cu析出相的復雜晶體結構表征

馮 柳,周邦新,彭劍超,王均安

(1 上海大學 材料研究所,上海 200072;2 山東理工大學 分析測試中心,山東 淄博 255049;3上海大學 微結構重點實驗室, 上海 200444)

?

RPV模擬鋼中納米富Cu析出相的復雜晶體結構表征

馮 柳1,2,周邦新1,3,彭劍超1,3,王均安1,3

(1 上海大學 材料研究所,上海 200072;2 山東理工大學 分析測試中心,山東 淄博 255049;3上海大學 微結構重點實驗室, 上海 200444)

RPV模擬鋼樣品經(jīng)過890℃水淬,660℃調(diào)質(zhì)處理,然后在400℃時效13000h后,用高分辨透射電鏡和能譜儀相結合的方法研究了RPV模擬鋼中納米富Cu析出相中的復雜晶體結構。納米富Cu析出相的平均尺寸約為20nm,除了觀察到常見的亞穩(wěn)態(tài)9R結構、3R結構和穩(wěn)態(tài)fcc結構外,還觀察到同一富Cu析出相由3種不同的晶體結構組成,并分別分布在5個不同的區(qū)域中,包括1處9R、2處fcc 和2處3R 結構。9R結構與相鄰的2個fcc結構形成的界面都具有特定的晶體取向,呈半共格關系,是由非孿晶9R結構演化而來。2處3R結構互為孿晶關系,是由孿晶9R結構演化而來。這種狀態(tài)反映了納米富Cu析出相從亞穩(wěn)態(tài)演化到穩(wěn)態(tài)結構的復雜過程。

RPV模擬鋼;熱時效;納米富Cu析出相;9R晶體結構

本工作采用HRTEM和能譜儀(EDS)相結合的方法,研究了660℃調(diào)質(zhì)處理后的RPV模擬鋼在400℃時效13000h后析出富Cu相中的某些復雜晶體結構特征,為認識RPV鋼中納米富Cu相的晶體結構演變及輻照脆化機理提供了實驗依據(jù)。

1 實驗材料與方法

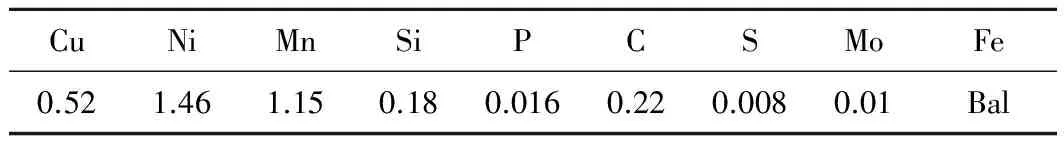

目前,大多數(shù)壓水堆核電站的RPV均采用Mn-Ni-Mo低合金鐵素體鋼(A508-Ⅲ),其中的Cu為煉鋼原料中引入的雜質(zhì)元素,標準中規(guī)定其含量應低于0.08%(質(zhì)量分數(shù),下同),Ni含量在0.4%~1.0 %之間。本實驗所用材料是在A508-Ⅲ鋼成分基礎上提高了Cu和Ni的含量,這種改變了成分的鋼稱為RPV模擬鋼,化學成分如表1所示。

鋼錠質(zhì)量約40kg,由真空感應爐冶煉,將鋼錠經(jīng)熱鍛和熱軋制成6mm厚的鋼板,然后再切成35mm×40mm的小樣品。隨后在890℃加熱0.5h后水淬,在660℃加熱10h進行調(diào)質(zhì)處理,最后在400℃進行了長達13000h的時效處理。本實驗提高了RPV鋼中Cu和Ni的含量,并選用了高于RPV運行溫度(290℃)的400℃時效,這主要是為了能夠方便地觀察到熱時效過程中富Cu相的析出以及長大過程中晶體結構的轉(zhuǎn)變。

采用電火花線切割方法將時效處理后的樣品沿截面切下厚度約0.5mm的薄片,然后用砂紙將其磨薄至0.1mm,用沖片機沖出直徑為3mm的圓片,再用細砂紙將其磨至約50μm,最后用10%HClO4+90%C2H5OH溶液在-40℃ 進行雙噴電解拋光。采用JEM-2010F HRTEM觀察富Cu相的微觀結構,并用INCA-OXFORD能譜儀對析出相進行成分分析。HRTEM圖像用Digital Micrograph軟件進行輔助分析,研究析出相的晶體結構。

表1 RPV模擬鋼的化學成分(質(zhì)量分數(shù)/%)

2 結果與分析

2.1 富Cu析出相的HRTEM觀察

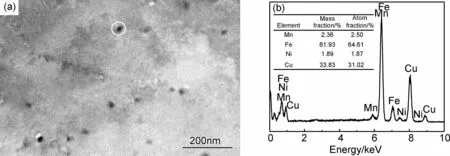

圖1為納米富Cu析出相的分布狀態(tài)及元素分析結果,圖1(a)中可以看出,富Cu相的平均尺寸約為20 nm,形貌主要以橢球形為主。與時效1000h的RPV模擬鋼中析出的納米富Cu析出相相比[20],數(shù)量密度較低。圖1(b)為(a)圖圓圈內(nèi)一個析出相的EDS分析結果,析出相中除含有34%的Cu外,還有大量的Fe及少量的Mn和Ni。因為富Cu相尺寸較小,能譜分析結果中有部分Fe的含量可能源自基體,所以Fe比實際析出相中的含量偏高,導致Cu含量偏低。

圖1 RPV模擬鋼樣品調(diào)質(zhì)處理后在400℃時效13000h得到富Cu析出相的分布狀態(tài)和富Cu相的元素分析(a)TEM圖像;(b)圖(a)中白色圓圈內(nèi)富Cu析出相的EDS分析結果Fig.1 Distribution and element analysis of Cu-rich precipitates in RPV model steel after aging at 400℃ for 13000h (a)TEM micrograph;(b)EDS analysis of a Cu-rich precipitate marked with a white circle in fig.(a)

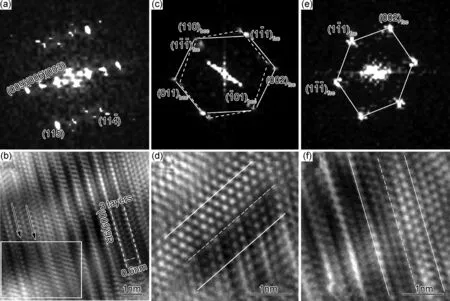

為了研究富Cu相的晶體結構,需要拍攝HRTEM圖像進行分析。在拍攝HRTEM圖像時,將電子束入射方向調(diào)整至與α-Fe基體的〈111〉方向平行。所觀察到的富Cu相中除常見的亞穩(wěn)態(tài)3R結構、9R結構和穩(wěn)態(tài)fcc結構外,還觀察到同一個富Cu相中具有多種晶體結構的復雜現(xiàn)象。圖2為典型的具有復雜晶體結構的富Cu析出相,此富Cu相的大小約27 nm,可以看出該富Cu相的圖片中具有不同方向的莫爾條紋,由于該富Cu相嵌入的基體是一個單晶體,同一個富Cu相中存在不同方向的莫爾條紋,只可能是該富Cu相中存在不同的晶體結構或者是不同的晶體取向。按照莫爾條紋的走向?qū)⑵浞譃?個區(qū)域,以便詳細地分析其晶體結構和晶體取向的差別,如圖2(a)中白線所標示。圖2(b)為富Cu相的能譜分析結果,Cu含量約為60%,仍含有35%左右的Fe和少量的Ni和Mn。

圖2 一個富Cu相的微觀形貌圖及該富Cu相的元素分析 (a)HRTEM圖;(b)EDS分析結果Fig.2 Micrograph and element analysis of Cu-rich precipitate (a)HRTEM micrograph;(b)EDS analysis of Cu-rich precipitate

圖3 富Cu相區(qū)域1~3之間的FFT和IFFT圖 (a)區(qū)域“1”的FFT圖;(b)區(qū)域“1”的IFFT圖;(c)區(qū)域“2”的FFT圖;(d)區(qū)域“1”和區(qū)域“2”界面附近IFFT圖;(e)區(qū)域“3”的FFT圖;(f)區(qū)域“1”和區(qū)域“3”界面附近的IFFT圖Fig.3 FFT and IFFT patterns of the Cu-rich precipitate from region 1 to 3 (a)FFT pattern of region “1”; (b)IFFT pattern of region “1”;(c)FFT pattern of region “2”;(d)IFFT pattern near the interface of region “1” and “2”;(e)FFT pattern of region “3”;(f)IFFT pattern near the interface of region “1” and “3”

圖4 富Cu相區(qū)域4,5的FFT和IFF圖 (a)區(qū)域“4”的FFT圖;(b)區(qū)域“5”的FFT圖;(c)區(qū)域“4”的IFFT圖;(d)區(qū)域“5”的IFFT圖;(e)區(qū)域“3”和區(qū)域“4”界面附近的IFFT圖;(f)區(qū)域“4”和區(qū)域“5”界面附近的IFFT圖Fig.4 FFT and IFFT patterns of the Cu-rich precipitate between region 4 and 5 (a)FFT pattern of region “4”; (b)FFT pattern of region “5”;(c)IFFT pattern of region “4”;(d)IFFT pattern of region “5”;(e)IFFT pattern near the interface between region “3” and region “4”;(f)IFFT pattern near the interface between region “4” and region “5”

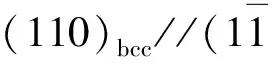

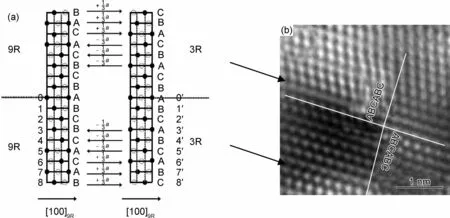

上述對圖2(a)的一系列分析表明,此富Cu相中包括了9R,3R 和fcc等3種不同的晶體結構,分別分布在5個不同的區(qū)域中。在“1”,“2”,“3”區(qū)域中,9R與其相鄰兩側(cè)的fcc結構組成的界面呈半共格關系。Heo等[25]報道了非孿晶9R結構可以直接轉(zhuǎn)變?yōu)閒cc結構,而不需要優(yōu)先轉(zhuǎn)變?yōu)?R結構。9R到fcc結構演變的過渡結構是由9R及其兩側(cè)的fcc結構組成。本工作觀察到富Cu相中的 “1”,“2”,“3” 區(qū)域與此現(xiàn)象類似,可以認為是9R結構向?qū)\晶fcc結構演化的過渡階段。區(qū)域“4”和“5”都為3R結構,且互為孿晶關系,根據(jù)目前的研究結果[26],9R孿晶結構會繼續(xù)演變?yōu)楦€(wěn)定的3R結構,可以認為此結構是由9R孿晶結構經(jīng)過切變后形成。

2.2 討論

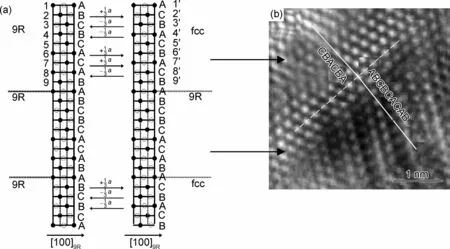

RPV模擬鋼中提高了Cu的含量,同時Ni,Mn元素也會促進富Cu相的析出[27,28],形核時間較短,所以試樣在400℃時效時間13000h后,富Cu相應處于長大或粗化階段,這時富Cu相尺寸不斷增大,數(shù)量密度減小,相間距也變大[29]。富Cu相長大的過程中,其晶體結構會發(fā)生一系列復雜的變化。圖2(a)中所示的富Cu相,為亞穩(wěn)態(tài)的9R結構繼續(xù)向更穩(wěn)定的晶體結構演化時的過渡狀態(tài),區(qū)域“1”,“2”,“3”和區(qū)域“4”,“5”的演變機理都是通過不全位錯沿9R結構的(001)9R基面進行a/3 [100]9R大小的切變[25,30],但切變方向不同。

圖5 非孿晶9R向fcc/9R/fcc結構演化的簡化示意圖及富Cu相與之相對應的原子排列(a)簡化示意圖;(b)區(qū)域“1”,“2”與(a)相對應的原子排列Fig.5 The schematic diagram showing the transformation of non-twin 9R to fcc/9R/fcc crystal structure (a)the schematic diagram;(b)the corresponding atoms arrangement in region “1” and “2” of the Cu-rich precipitate

圖6 孿晶9R向?qū)\晶3R結構演化的簡化示意圖及富Cu相與之相對應的原子排列(a)簡化示意圖;(b)區(qū)域“4”,“5”與(a)相對應的原子排列Fig.6 The schematic diagram showing the transformation of twin 9R to twin 3R crystal structure (a) the schematic diagram;(b)the corresponding atoms arrangement in region “4”, “5” of the Cu-rich precipitate

圖5和圖6說明了非孿晶9R結構、孿晶9R結構的演化機理相似,但切變方向和切變原子面明顯不同,所得晶體結構也會完全不同。9R結構、3R結構、fcc結構的晶格常數(shù)都不同,所以原子切變后晶格會發(fā)生一定程度的畸變,但會通過方向相反的a/3 [100]9R大小的切變兩兩抵消。需要說明的是,在圖5,6中為了說明不同結構間每層原子的對應關系,將兩對應c軸長度設置為相等。由于此富Cu相由3種不同的晶體結構組成并分布在5個不同的區(qū)域中,所以可推斷此富Cu相最終可能會形成穩(wěn)態(tài)的fcc多孿晶結構,但包括兩種不同的演化序列:非孿晶9R結構直接轉(zhuǎn)變?yōu)閒cc結構;9R孿晶結構優(yōu)先轉(zhuǎn)變?yōu)?R孿晶結構再轉(zhuǎn)變?yōu)閒cc孿晶結構。

3 結論

(1)納米富Cu析出相的平均尺寸約為20nm,除了觀察到常見的亞穩(wěn)態(tài)9R結構、3R結構和穩(wěn)態(tài)fcc結構外,還觀察到同一富Cu相由3種不同的晶體結構組成,并分別分布在5個不同的區(qū)域中,包括1處9R、2處fcc 和2處3R 結構。

(2)9R結構與相鄰的2個fcc結構形成的界面都具有特定的晶體取向,呈半共格關系,是由非孿晶9R結構演化而來。2處3R結構互為孿晶關系,是由孿晶9R結構演化而來。這種狀態(tài)反映了納米富Cu析出相從亞穩(wěn)態(tài)演化到穩(wěn)態(tài)結構的復雜過程。

[1] ZHANG Z W, LIU C T, WANG X L, et al. Effects of proton irradiation on nanocluster precipitation in ferritic steel containing fcc alloying additions[J]. Acta Mater, 2012, 60(6-7):3034-3046.

[2] STYMAN P, HYDE J, WILFORD K, et al. Precipitation in long term thermally aged high copper, high nickel model RPV steel welds[J]. Prog Nucl Energ, 2012, 57(5):86-92.

[3] LAMBRECHT M, MESLIN E, MALERBA L, et al. On the correlation between irradiation-induced microstructural features and the hardening of reactor pressure vessel steels[J]. J Nucl Mater, 2010, 406(1):84-89.

[4] FUJII K, NAKATA H, FUKUYA K, et al. Hardening and microstructural evolution in A533B steels under neutron irradiation and a direct comparison with electron irradiation[J].J Nucl Mater, 2010, 400(1):46-55.

[5] RADIGUET B, PAREIGE P, BARBY A. Irradiation induced clustering in low copper or copper free ferritic model alloys[J]. Nucl Instrum and Methods Phys Res B, 2009, 267:1496-1499.

[6] 呂錚. 核反應堆壓力容器的輻照脆化與延壽評估[J].金屬學報,2011,47(7):777-783.

LU Z. Radiation-induced embrittlement and life evaluation of reactor pressure vessels[J]. Acta Metall Sin, 2011, 47(7): 777-783.

[7] NIFFENEGGER M, LEBER H. Monitoring the embrittlement of reactor pressure vessel steels by using the Seebeck coefficient[J]. J Nucl Mater, 2009,389(1): 62-67.

[8] BERGNER F, LAMBRECHT M, ULBRICHT A, et al. Comparative small-angle neutron scattering study of neutron-irradiated Fe, Fe-based alloys and a pressure vessel steel[J]. J Nucl Mater, 2010, 399(2-3):129-136.

[9] TIMOFEEV B. Assessment of the first generation RPV state after designed lifetime[J]. Int J of Pres Ves Pip, 2004, 81:703-712.

[10] LEE K, KIMB M, LEEB B, et al. Analysis of the master curve approach on the fracture toughness properties of SA508 Gr.4N Ni-Mo-Cr low alloy steels for reactor pressure vessels[J]. Mater Sci Eng A, 2010, 527: 3329-3334.

[11] CAMMELLI S, DEGUELDRE C, CERVELLINO A, et al. Cluster formation, evolution and size distribution in Fe-Cu alloy:Analysis by XAFS XRD and TEM[J]. Nucl Instrum and Methods Phys Res B, 2010, 268:632-637.

[12] SCHOBER M, EIDENBERGER E, STARON P, et al. Critical consideration of precipitate analysis of Fe-1at% Cu using atom probe and small-angle neutron scattering[J]. Microsc Microanal, 2011, 17(1):26-33.

[13] KAMADA Y, TAKAHASHI S, KIKUCHI H, et al. Effect of pre-deformation on the precipitation process and magnetic properties of Fe-Cu model alloys[J]. J Mater Sci, 2009, 44: 949-953.

[14] KOLLI R, SEIDMAN D. The temporal evolution of the decomposition of a concentrated multicomponent Fe-Cu-based steel[J]. Acta Mater, 2008, 56: 2073-2088.

[15] 張植權, 周邦新, 蔡琳玲, 等. 利用APT研究RPV模擬鋼中相界面原子偏聚特征[J]. 材料工程, 2014, (9): 89-93.

ZHANG Zhi-quan, ZHOU Bang-xin, CAI Lin-ling, et al. Characterization of atom segregation at phase interfaces in RPV model steel by APT[J]. Journal of Materials Engineering , 2014, (9): 89-93.

[16] HABIBI H. Atomic structure of the Cu precipitates in two stages hardening in maraging steel[J]. Mater Lett, 2005, 59: 1824-1827.

[17] LEE T, KIM Z Y, KIM S. Crystallographic model for bcc-to-9R martensitic transformation of Cu precipitates in ferritic steel[J]. Philos Mag A, 2007, 87(2):209-224.

[18] HABIBI-BAJURIANI H, JENKINS M. High-resolution electron microscopy analysis of the structure of copper precipitates in a martensitic stainless steel of type PH 15-5[J]. Philos Mag Lett, 1996, 73(4): 155-162.

[19] BLACKSTOCK J, ACKLA G. Phase transitions of copper precipitates in Fe-Cu alloys[J]. Philos Mag A, 2001, 81:2127-2148.

[20] 蔡琳玲,徐剛,馮柳,等. 核反應堆壓力容器模擬鋼中納米富Cu相的變形特征[J].上海大學學報:自然科學版,2012, 18(3):311-316.

CAI L L, XU G, FENG L, et al. Deformation characterization of nano-scale Cu precipitates in RPV model steel[J]. J Shanghai Univ:Nat Sci, 2012, 18(3): 311-316.

[21] OTHEN P, JENKINS M, SMITH G, et al. Transmission electron microscope investigations of the structure of copper precipitates in thermally aged Fe-Cu and Fe-Cu-Ni[J]. Philos Mag Lett, 1991, 64: 383-391.

[22] DUPARC H, DOOLE R, JENKINS M, et al. A high-resolution electron microscopy study of copper precipitation in Fe-1.5 wt% Cu under electron irradiation[J]. Philos Mag Lett, 1995, 71:325-333.

[23] MOZEN R, JENKINS M, SUTTON A. The bcc-to-9R martensitic transformation of Cu precipitates and the relaxation process of elastic strains in an Fe-Cu alloy[J]. Philos Mag A, 2000, 80(3): 711-723.

[24] 徐剛,楚大峰,蔡琳玲,等. RPV模擬鋼中納米富Cu相的析出和結構演化研究[J]. 金屬學報,2011,47(7): 905-911.

XU G, CHU D F, CAI L L, et al. Investigation on the precipitation and structure evolution of Cu-rich nanophase in RPV model steel[J]. Acta Metall Sin, 2011,47(7): 905-911.

[25] HEO Y, KIM B Y, KIM J, et al. Phase transformation of Cu precipitates from bcc to fcc in Fe-3Si-2Cu alloy[J]. Acta Mater, 2013,61: 519-528.

[26] OTHEN P,JENKINS M, SMITH G. High resolution electron microscopy studies of the structure of Cu-precipitates in α-Fe[J]. Philos Mag A, 1994, 70:1-24.

[27] FUJII K, OHKUBO T, FUKUY K. Effects of solute elements on irradiation hardening and microstructural evolution in low alloy steels[J]. J Nucl Mater, 2011, 417: 949-952.

[28] MILLER M, WIRTH B, ODETTE G. Precipitation in neutron-irradiated Fe/Cu and Fe/Cu/Mn model alloys: a comparison of APT and SANS data[J]. Mater Sci Eng A, 2003, 353:133-139.

[29] 安治國,任慧平,劉宗昌,等. 1.18Cu高純鋼等溫時效時富銅相的析出行為[J]. 特殊鋼,2006, 27(2): 20-22.

AN Z G, REN H P, LIU Z C, et al. Precipitation behavior of rich copper phase in 1.18Cu high purity steel during isothermal aging[J]. Special Steel, 2006, 27(2): 20-22.

[30] 王偉. 反應堆壓力容器模擬鋼中富Cu相的析出及晶體結構演化研究[D].上海:上海大學,2011.

WANG W. Precipitation and structural evolution of copper-rich nano phases in reactor pressure vessel model steels [D]. Shanghai: Shanghai University, 2011.

Characterization of a Complex Crystal Structure Within Cu-rich Precipitates in RPV Model Steel

FENG Liu1,2,ZHOU Bang-xin1,3,PENG Jian-chao1,3,WANG Jun-an1,3

(1 Institute of Materials,Shanghai University,Shanghai 200072,China; 2 Analysis and Testing Center,Shandong University of Technology, Zibo 255049,Shandong,China;3 Laboratory for Microstructures, Shanghai University,Shanghai 200444,China)

The specimens of the reactor pressure vessel (RPV) model steels were tempered at 660℃ after water quenching from 890℃, aging treatment was then conducted at 400℃ for 13000h. The Cu-rich precipitates were characterized by high resolution transmission electron microscopy (HRTEM) and energy dispersive spectroscopy (EDS) in order to study the transition process from metastable to stable structure. The average size of the nano Cu-rich precipitates is about 20nm, besides the metastable 9R,3R and the stable fcc crystal structures, it is observed that three different crystal structures distributed in five different regions existing in the same nano Cu-rich precipitate, including one 9R, two of fcc and two of 3R crystal structures. The boundaries formed by 9R structure with its two adjacent fcc structures have specific crystal orientations, their interfaces are semi-coherent. They are evolved from non-twin 9R structure. The two 3R structures are twins, and evolved from twin 9R structure. The above phenomena reflect the complex processes from metastable to stable structure.

reactor pressure vessel model steel;thermal aging;nano Cu-rich precipitate;9R crystal structure

10.11868/j.issn.1001-4381.2015.07.014

TG113.25

A

1001-4381(2015)07-0080-07

國家重點基礎研究發(fā)展規(guī)劃(973計劃2011CB610503);國家自然科學基金重點項目(50931003);上海市重點學科建設項目(S30107)。

2013-10-09;

2014-11-20

周邦新(1935—),男,中國工程院院士,博士,從事核材料和核燃料元件的研究,聯(lián)系地址:上海大學材料研究所(200072),E-mail: zhoubx@shu.edu.cn