Research and Realization of the Control System for Cement Screw Packing Machine Based on MCGS and S7-200PLC

MA Zhuang

Department of Information Engineering, Tangshan College, Tangshan 063000, China

ResearchandRealizationoftheControlSystemforCementScrewPackingMachineBasedonMCGSandS7-200PLC

MA Zhuang*

DepartmentofInformationEngineering,TangshanCollege,Tangshan063000,China

Thispaperisbasedonrotatingcementpackagingmachine.Filling,weighing,andfillingbagcountingstatisticsareinonebody.TheclientcomputeradoptedS7-200PLCascontrollerandhostcomputerwasoperatedinoverallmonitoringofMCGSconfigurationsoftware.Throughsystemdebuggingandtheexperiments,ithasshownthatitisfeasibleanditworksperfectly.Itprovidesareferenceforcementpackingmachinecontrolsystem.

cementscrewpackingmachine,MCGS,S7-200PLC

1.Introduction

Although a half century of development, the cement packaging technology is still in the development through manual, semi-automatic and fully automatic. Now the new type of cement packing machine developed in China had gradually applied in a real production processes. Whether in mechanical structure or in the control the new cement packing machine has a qualitative leap than ever, as mentioned in[1]. Basic automated action such as filling, weighing and bag are controlled by the PLC completely. It realizes not pocket to fill without bags is not to the calibration values are not off the bag, the bag shedding gate closes unexpectedly stop filling cement packaging requirements, as mentioned in[2]. Although new cement packing machine has been greatly improved in terms of performance, but it is still unsatisfied in some respects, and there are rarely manufacturers which can research and develop, which is our weakness as well.

2.The structural performance and working principle of rotating cement packaging

machine

2.1.Thestructuralperformanceofrotatingcementpackagingmachine

This system use Rotary cement packing machine for the controlled object, and is composed of mechanical systems, electronic systems, pneumatic control systems. It primarily consists of driving device, lifting device, storage device, filling irrigation devices, weighing device, pneumatic control devices, power control unit and other installations, as mentioned in

2.2.Workingprincipleofrotatingcementpackagingmachine

Rotating package machine has inserted-pocket position, baiting position and bag unloading position. After you start the packaging machines, pocket will be filled from pocket-position, photoelectric switch signal will be adopted and the weighing module is cleared to zero. Pressure cylinder and pressure bag will be controlled, after running to the bevelling, by three cylinders sliding gate, and the impeller motor will run to start filling; Until to the set value, the impeller motor will stop, slide gate will close and filling will be end; Full bag unloading state is reached, pushing cylinder push bag the bag, to unload machine loading and unloading bags, completing a bag filling. Other filling nozzles are under the similarly procedure.

3.Hardware selection and plan determination of rotating cement packaging machine

3.1.HardwareselectionandI/Odistributionofrotatingcementpackagingmachine

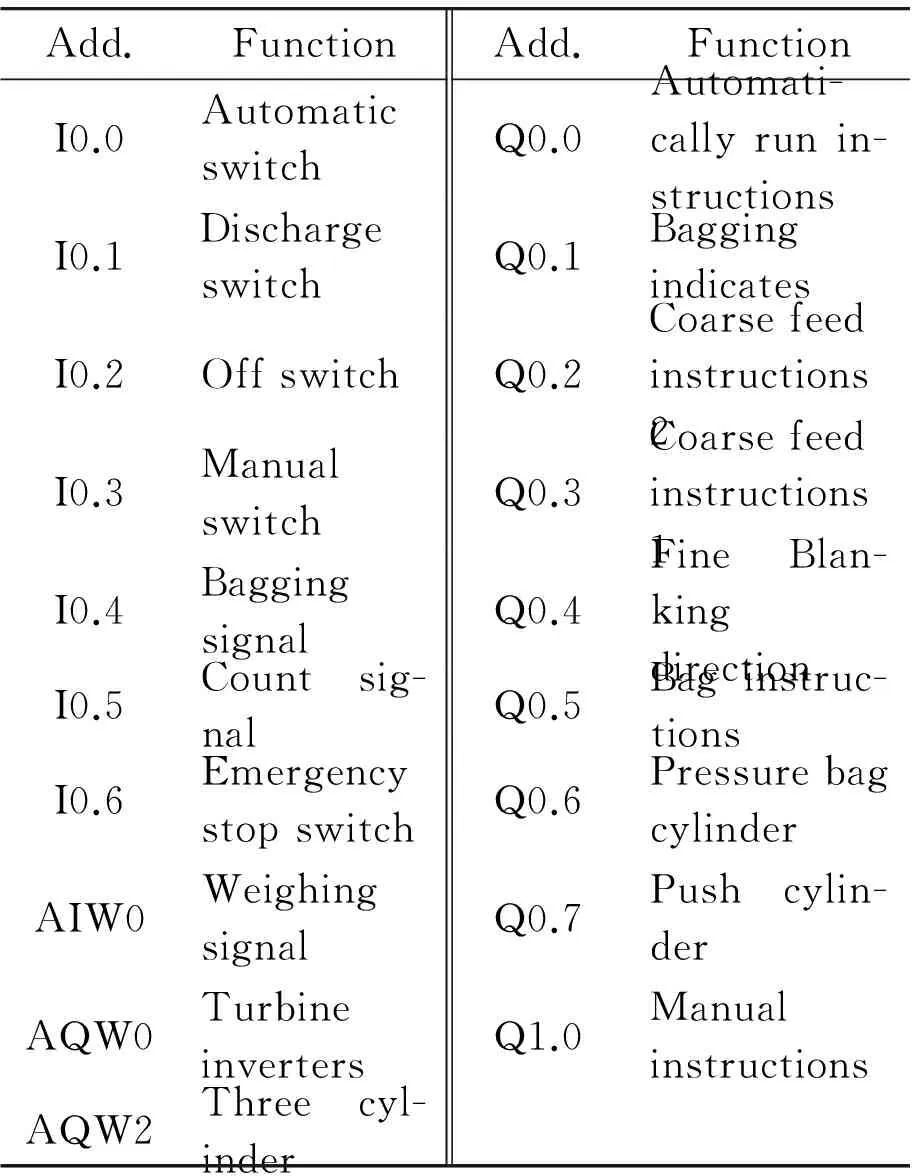

Through the entire process flow analysis of cement packing machine we can see, this cement packing machine control points are: 27 digital inputs, 50 digital outputs, 8 analog inputs and 8 analog outputs. According to this situation, the CPU226CN is selected as the primary module, extension modules are selected by two EM223 modules, two EM232 modules and two EM235 modules. System I/O distribution is shown in Tab.1.

Tab.1 S7-200PLC I/O distribution

3.2.Plandetermination

Limited to the space, this paper mainly introduces the two parts of the system key: weighing and counting.

3.2.1.Plan determination of weighing modules

At present, there are a number of weight control plans, once-filling means the speed of Impeller motor and the opening of shutter are always the same, once filling has a significant control deficiencies, should be eliminated. Re-filling means when the weight closes to the set value, the speed of turbo-machine will decreased to turn down the opening of shutter, to improve the accuracy. Re-filling cement packing machine is the basis for continuous improvement. It implemented in practice without adding hardware and cost basis on once-filling to meet the general control requirements. Three fillings are used to improve the Re-filling. According to different charging motor without brake, bags of cement packing machine yield requirements when heavy demand, machinery, cement fluidity reality many times repeated three times in a test to determine the conversion settings. Its control precision is higher than re-filling and more filling have not increased for the second time supporting equipment, under the General control accuracy, control scheme of three filling is ideal. Closed-loop feedback control scheme of control over the first three are controlling a control scheme with the highest precision, complex production environments and in cement production, generally, all devices work hard to meet the basic and also needs correction device, costs a lot, so have difficult to achieve.

This design uses three filling plan, comprising three feeds, to the packaging machine itself it is the same as re-filling, and it can has a high measurement precision without affecting the packaging machine production. The system is of excellent performance through the practice.

3.2.2.Count module scheme

This article adopts PLC and super computer monitoring system as control scheme of the count, coupled with LED displays, LED to communicate between the computer and connection to the production site for real-time data analysis and query processing. By using correlation photoelectric sensor, the detection range could even be further, the filter effect is more obvious, its dust is better, easier data sampling. Adjust the operating speed of the transmission channel is uniform, therefore, time approximately equal for each bag of cement through the sensor, controlled by PLC program for processing and analysis. Host computer is a data monitoring system, real-time data monitor and PLC in the production of treated data monitoring, and communications, and PLC issued a directive. At the same time, host computer is the database server, and all the data, records, warning information will be stored by this database servers, so that historical queries, the overall number has an accurate statistics.

4.Software design

Systems software programming mainly consists of two parts: client computer program design of ladder diagram and MCGS monitoring system design of host computer.

4.1.LowercomputerPLCladderdiagramproceduredesign

This article used rough cutting as an example. The indicator and operation of rough cutting are as shown in Fig.1. Cement packing machine is automatically on a run state, emergency stop switch SK5 is not broken, H92B4 bagging signal comes close, pressure bag cylinder LYD1 runs, after its normal open contact closure, SK2 blanking signal comes, before the weight did not reach 45Kg, rough cutting led is lit, and the motor rated speed run, sliding gate wide open.

Fig.1 Ladder diagram of sliding gate

4.2.MCGSconfigurationofhostcomputermonitoringsystemdesign

Based on the cement production process control requirements and the actual production environment, the monitor of host computer includes the following three parts: the entire technological process monitoring, port monitoring, and under each variety of data processing and printing.

4.2.1.Cement process flow monitoring

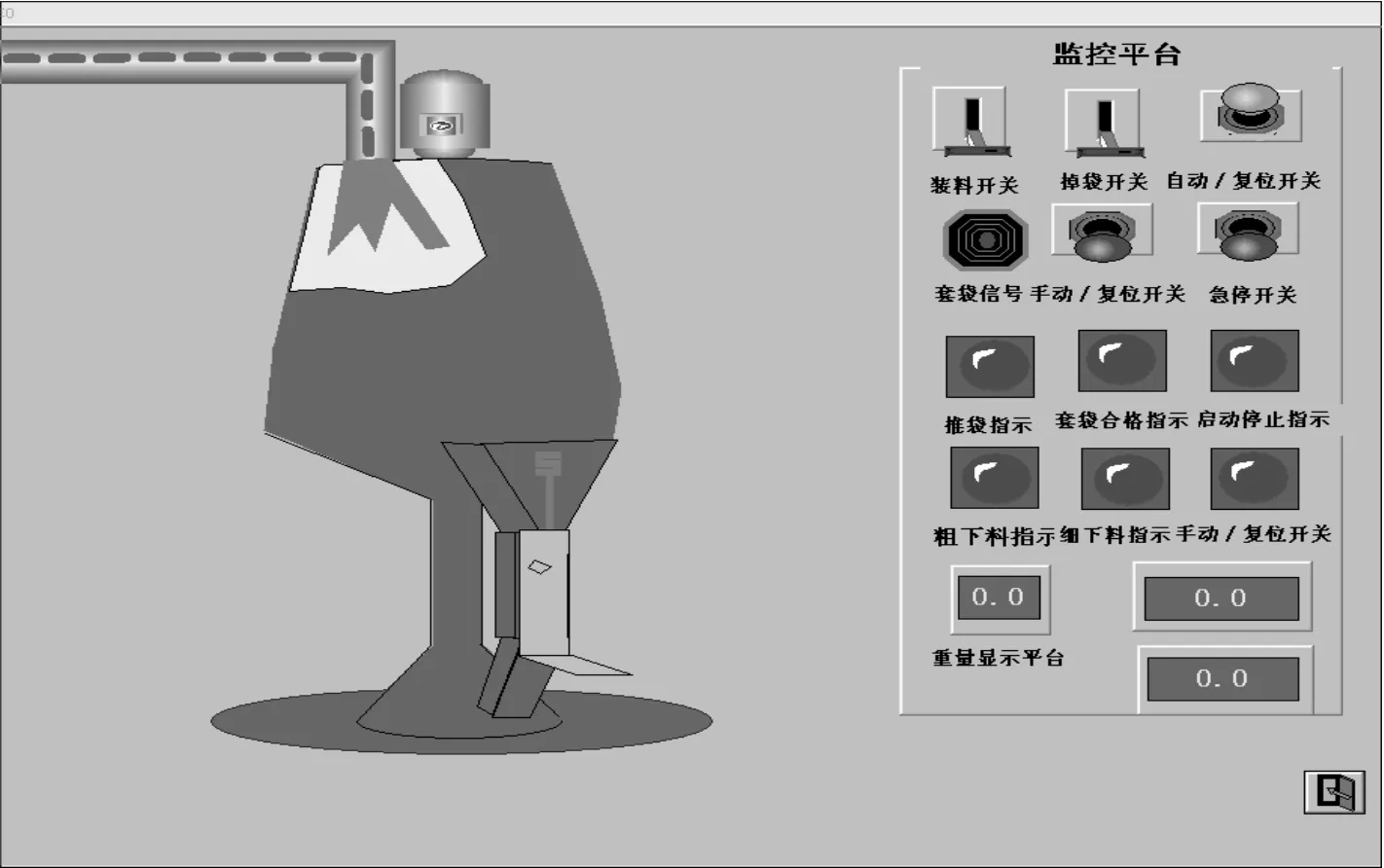

As shown in Fig. 2, it realized the whole process of eight mouths rotary cement implemented packaging and it can be real-time monitoring as Manager and operators.

Fig.2 The chart of process control

4.2.2.Feed monitoring

In the monitor screen, you can use manual and automatic control over the system. It is convenient for system debugging and troubleshooting problems.

As shown in Fig.3, a feed control platform monitoring platform will be set by PLC program to run when MCGS output control signal is obtained, PLC controller reads signal, makes the appropriate control, and then outputs the PLC control signals to the MCGS monitoring platform for reading, and makes the host computer’s monitor, as mentioned in[3].

Fig.3 Monitoring platform

4.2.3.Printing of reports and browsing

In cement produce process, PC monitoring system requires data according to print out reports. Draw a curve based on large amounts of data information, analysis of curve of change and discovery data rule to increase control precision. At the same time, it still needs to be on the packaging of cement MCGS configuration monitoring system set the login window, button, and exit the system, to ensure safe operation.

Fig.4 Chart of real-time data and history data

5.Conclusions

Through the research and analysis about eight mouth Rotary type cement packaging machine of control technology process, the client machine PLC program design and host machine monitoring system design are completed, implementation has real-time of, and dynamic of cement packaging monitoring effect, has report print, and curve analysis, and permission set, additional of function, full can meet has cement packaging of actual need, makes entire control system implementation has from control to monitoring of integration. After System testing, practice shows that system automation are much improved, the precision of weighing and counting statistics have been improved, and the entire control system is simple and flexible, therefore the expected production requirements could be reached.

[1] XU Puguo.The control of Bag weighing and Practise Cement-packing Plant[J].Cement,2008(4):60-61.

[2] ZHOU Changhui,FU Yunqiang,ZHU Manping.Improvement on BGY Small Cement Packing Machine[J].Coal Ash China,2006(1):29-30.

[3] ZHOU Wenyuan.The new way of Remote Monitoring System Discussed shallowly about Cement-packing Plant[J].Cement,2003(6):46.

基于MCGS與S7-200PLC水泥包裝機(jī)控制系統(tǒng)

馬 壯*

唐山學(xué)院 信息工程系,河北 唐山 063000

以回轉(zhuǎn)式水泥包裝機(jī)為研究對(duì)象,設(shè)計(jì)了水泥包裝機(jī)控制系統(tǒng)。該系統(tǒng)集灌裝、稱重、掉袋、計(jì)數(shù)統(tǒng)計(jì)于一體,下位機(jī)采用S7-200PLC作為控制器,上位機(jī)選用MCGS組態(tài)軟件進(jìn)行全程監(jiān)控。系統(tǒng)調(diào)測(cè)結(jié)果證明本設(shè)計(jì)的總體控制方案是可行的,為實(shí)現(xiàn)一體化的水泥包裝機(jī)控制系統(tǒng)提供了參考。

水泥包裝機(jī);MCGS;S7-200PLC

TP391

2012-11-28

*MA Zhuang.E-mail: tmzhuange-mail@sina.com

10.3969/j.issn.1001-3881.2013.06.017

- 機(jī)床與液壓的其它文章

- Modeling and Simulation about Sinusoidal Non-circular Gear Pitch Curve of the High Order and Denatured Feature

- The Study of Stability Control Based on the Yawing Moment of Electric Vehicle

- Structure Optimization Design of Time-Grating with Variable Coupling Coefficient Based on ANSOFT Electromagnetic Analysis

- Prediction Chatter Stability and Bifurcation in Milling Machine

- Design of Structure Optimization for Engine Exhaust Manifold

- Design and Research on the Length of Piston’s Buffer Oil Mat Area of a New Type of Hydraulic Rock Drill