Mechanical Amplifier for Giant Magnetostrictive Materials and Piezoelectric Materials

JIANG Xin, ZHU Yuchuan,2*

1.School of Electromechanical Engineering, Nanjing University of Aeronautics and Astronautics,Nanjing 210016, China; 2.The State Key Laboratory of Fluid Power and Mechatronic Systems,Zhejiang University, Hangzhou 310027, China

MechanicalAmplifierforGiantMagnetostrictiveMaterialsandPiezoelectricMaterials

JIANG Xin1, ZHU Yuchuan1,2*

1.SchoolofElectromechanicalEngineering,NanjingUniversityofAeronauticsandAstronautics,Nanjing210016,China; 2.TheStateKeyLaboratoryofFluidPowerandMechatronicSystems,ZhejiangUniversity,Hangzhou310027,China

Giant magnetostrictive materials (GMM) and piezoelectric (PZT) materials have been significantly used in commercial products as well as military applications, with high energy density, long life, and electric drive advantages. Although these materials have high force and large bandwidth capabilities, their use has been limited due to their small stroke. The use of mechanical amplifiers is an effective way to overcome this problem. This article will review recent literatures of three main kinds of design methodologies of mechanical amplifiers for GMM and PZT materials. It is proposed that the flexure-hinged displacement amplifiers, Hydraulic displacement amplifiers and Flexural frame displacement amplifiers are suitable for piezoelectric materials, miro-electro-mechanical systems and Giant Magnetostrictive materials, respectively.

mechanical amplifier, giant magnetostrictive materials, piezoelectric materials

1.Introduction

GMM as well as PZT materials offer a number of alternatives in applications where precise, well-controllable displacements with good force transmission are needed[1-3]. A problem with actuators using these materials is that their use is usually limited for their small stroke. Without a means of displacement amplifier, these actuators can only reach strain levels on the order of micro. To overcome the limitation, various types of the mechanical amplifiers have been investigated. The following chapters will review the three main kinds of design methodologies of mechanical amplifiers used in amplifying micrometric displacement to help to choose the suitable mechanical amplifiers for actuators.

2.Flexure-hinged displacement amplifiers

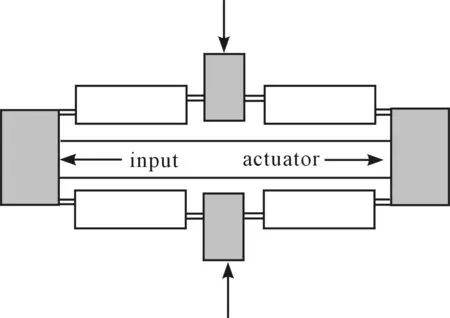

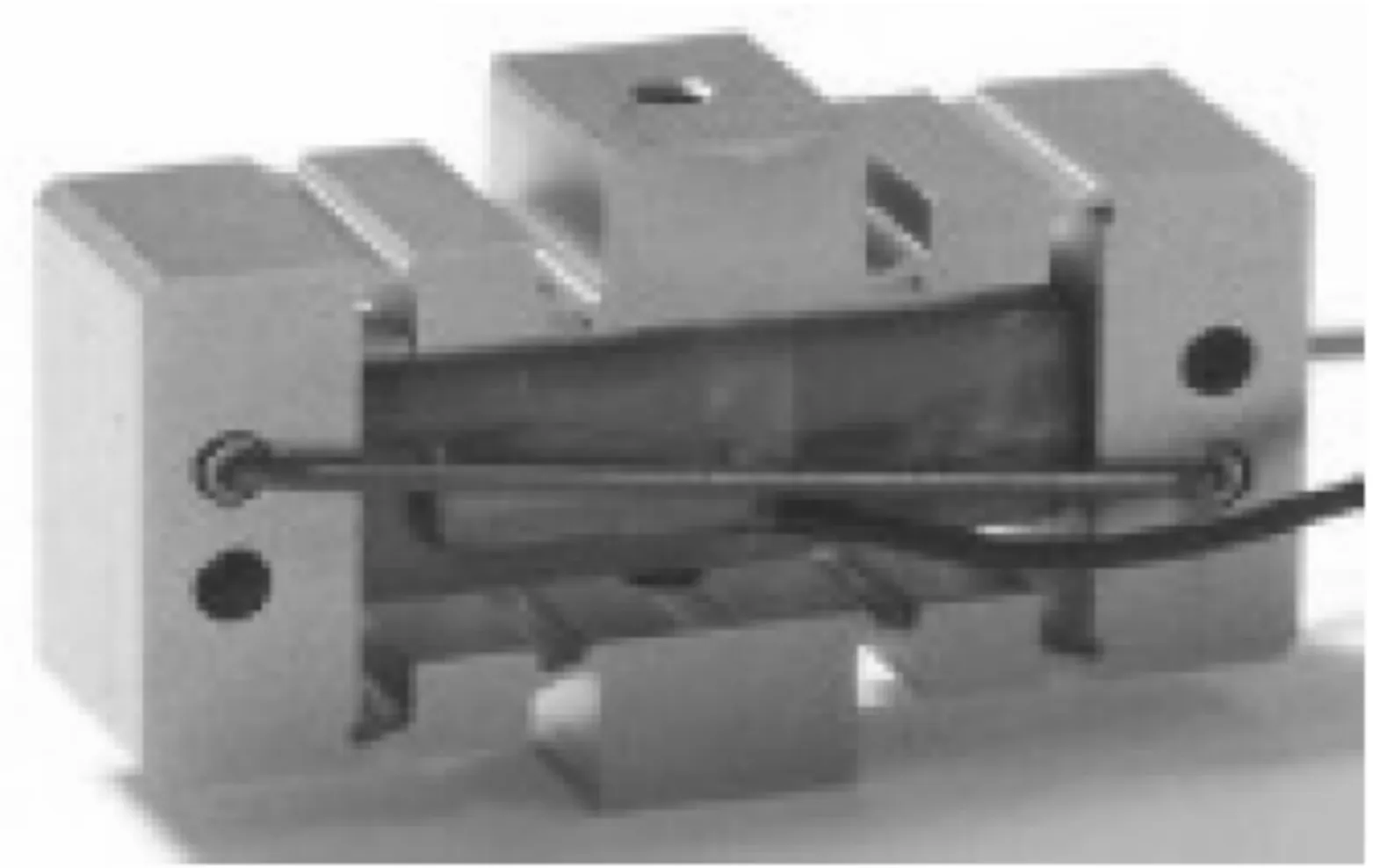

Flexure-hinged displacement amplifiers have been widely used in applications based on PZT materials and GMM, to increase the output displacement of Piezoelectric actuators and Giant magnetostrictive actuators (GMA). This kind of displacement amplifiers contains some characteristics such as compact structure, small volume, no mechanical friction, high resonance frequency and shock resistant interference ability. Numerous types of flexure-hinged displacement amplifiers have been investigated during the past a few decades. Most of them are based on various types of lever mechanisms[4-5], Scott-Russell mechanisms[6-7], etc. Recent years, a bridge-type flexure-hinged displacement amplifier (BTA) has attracted scholars’ attentions. The Fig.1 shows the amplifying mechanism of BTA. The displacement provided by a piezo-stack along the x axis is amplified through a BTA resulting in an amplified displacement along the y axis. Besides, the bridge-type flexure-hinged with right-angle hinges is commercially available on the market (e.g. FPA Series piezoelectric actuators from Dynamic Structures and Materials, LLC[8] Fig.2 even so, the mechanical properties of BTA still not been fully discovered and the analytic modeling of the amplifier is still in the study.

Fig.1 The bridge-type flexure-hinged displacement amplifier

Fig.2 FPA piezoelectric actuator

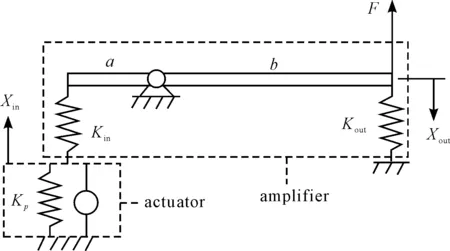

Patrick Mottard and Yves St-Amant investigated the modeling of the BTA[9]. A simple static model as shown in Fig.3 was proposed, whereKin,KoutandKPare the input, output and piezo-stiffnesses, respectively;aandbare the short and long diagonals of the bridge. The flexure hinges were regarded as zero-backlash pivot points. They also derived the approximate analytical expressions of the input and the output stiffness for two hinge configurations: parallel and aligned. The model showed that the aligned hinges were preferred in the BTA and the aligned configuration could increase the free stroke, the blocking force and the efficiency which were confirmed by FE simulation.

However, there is a drawback of the BTA since the lateral stiffness is relatively low. In practice, they need a specific device connected to the end of the amplifier to avoid the lateral stiffness. Otherwise, the tips of the PZT will suffer from lateral loads as well, which are the potential hazards to damage the PZT. An efficient way to solve this problem is to enhance the BTA with multiple bridges, which is called a compound bridge-type (CBT) amplifier.

Fig.3 The static model of BAT

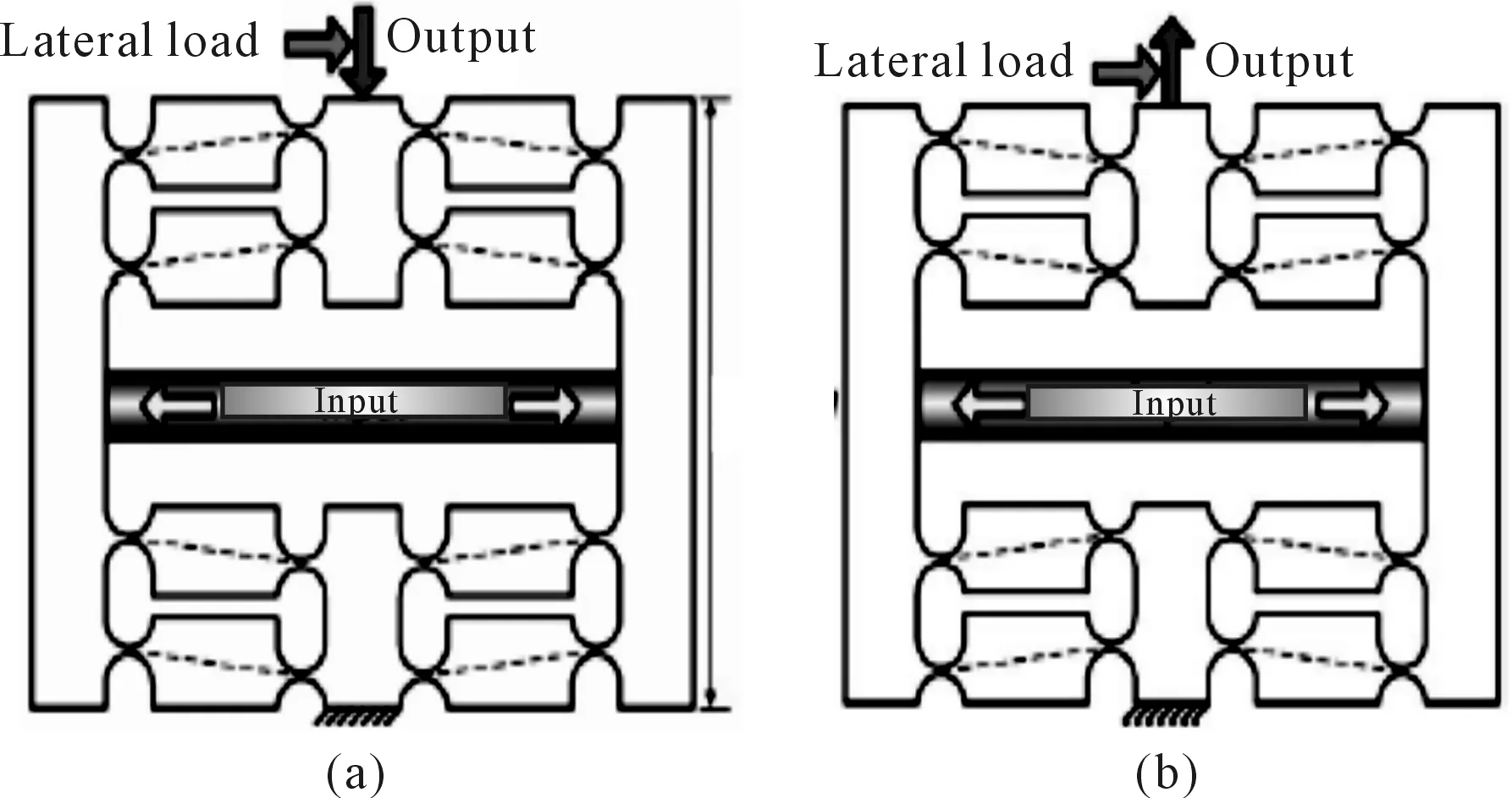

Qingsong Xu and Yangmin Li investigated a type of CBT amplifiers illustrated in Fig.4. They analyzed two same-size CBT amplifiers with backward and forward output directions, as shown in Fig.4 (a) and(b), respectively. Geometric relations analysis, elastic analysis with rotational and translational stiffness and the elastic analysis based on the Euler-Bernoulli beam theory were used to establish the models of CBT amplifiers. The input stiffness and amplification ration of the amplifier were derived by the three models. According to the FEA simulation results, the analysis based on the Euler-Bernoulli beam theory was more accurate. These models were used to optimize the amplifier. The performances of the fabricated amplifier with optimized parameters were confirmed by experimental studies (as shown in Fig.5). The optimized amplifier could achieve an output displacement over 1mm and the amplification ration could be 11.

Fig.4 A CBT displacement amplifier with backward(a) and forward (b) outputs and large lateral stiffness

Fig.5 The detail of the experiment

3.Hydraulic micro-displacement amplifying mechanism (HDAM)

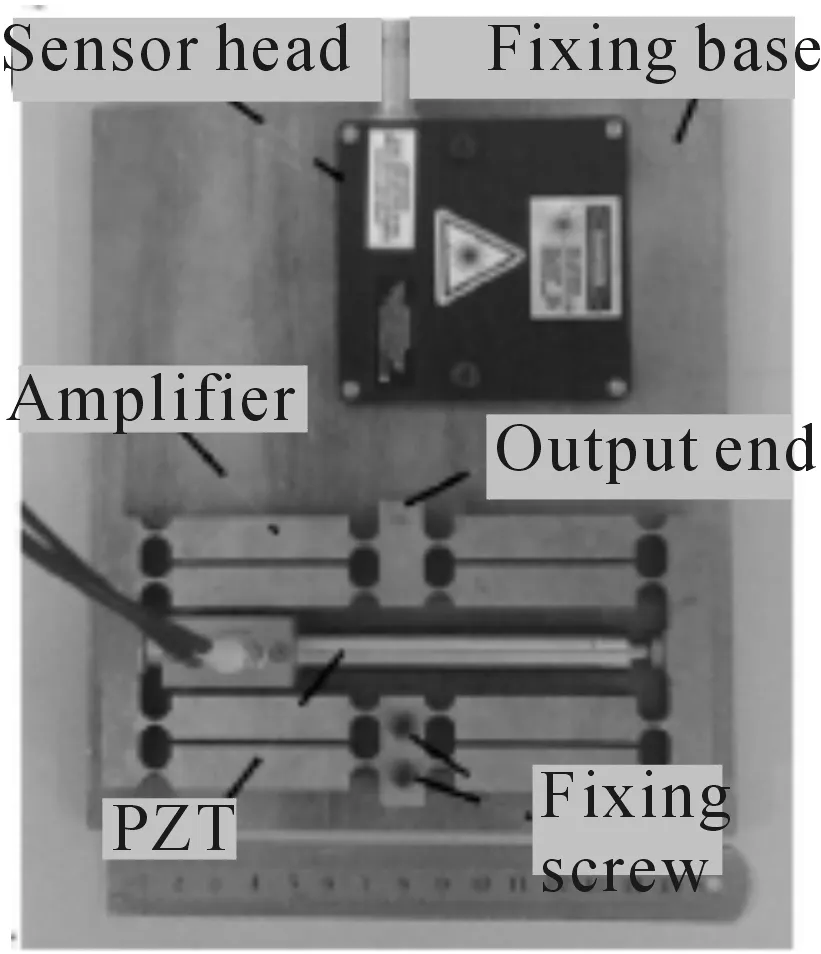

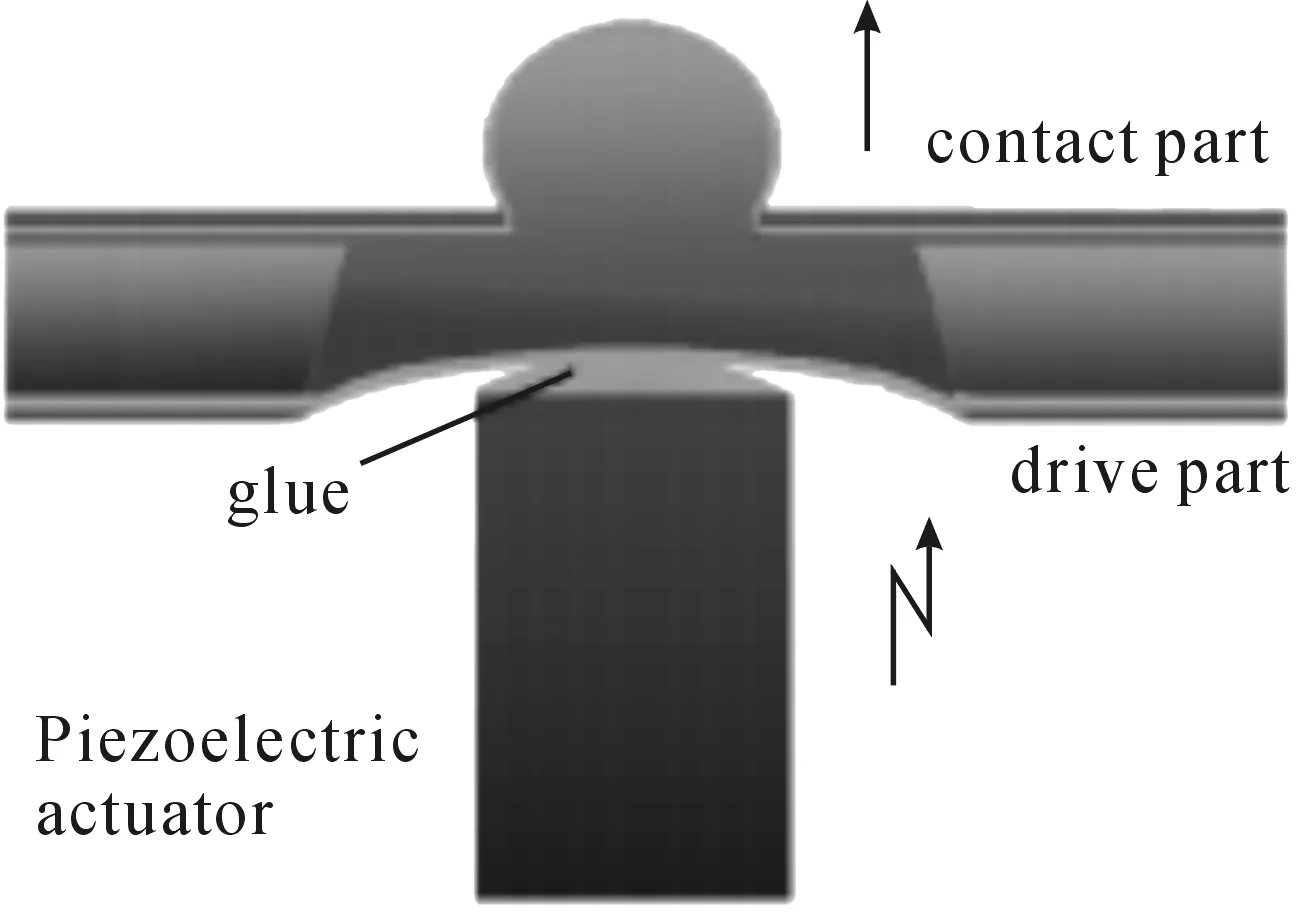

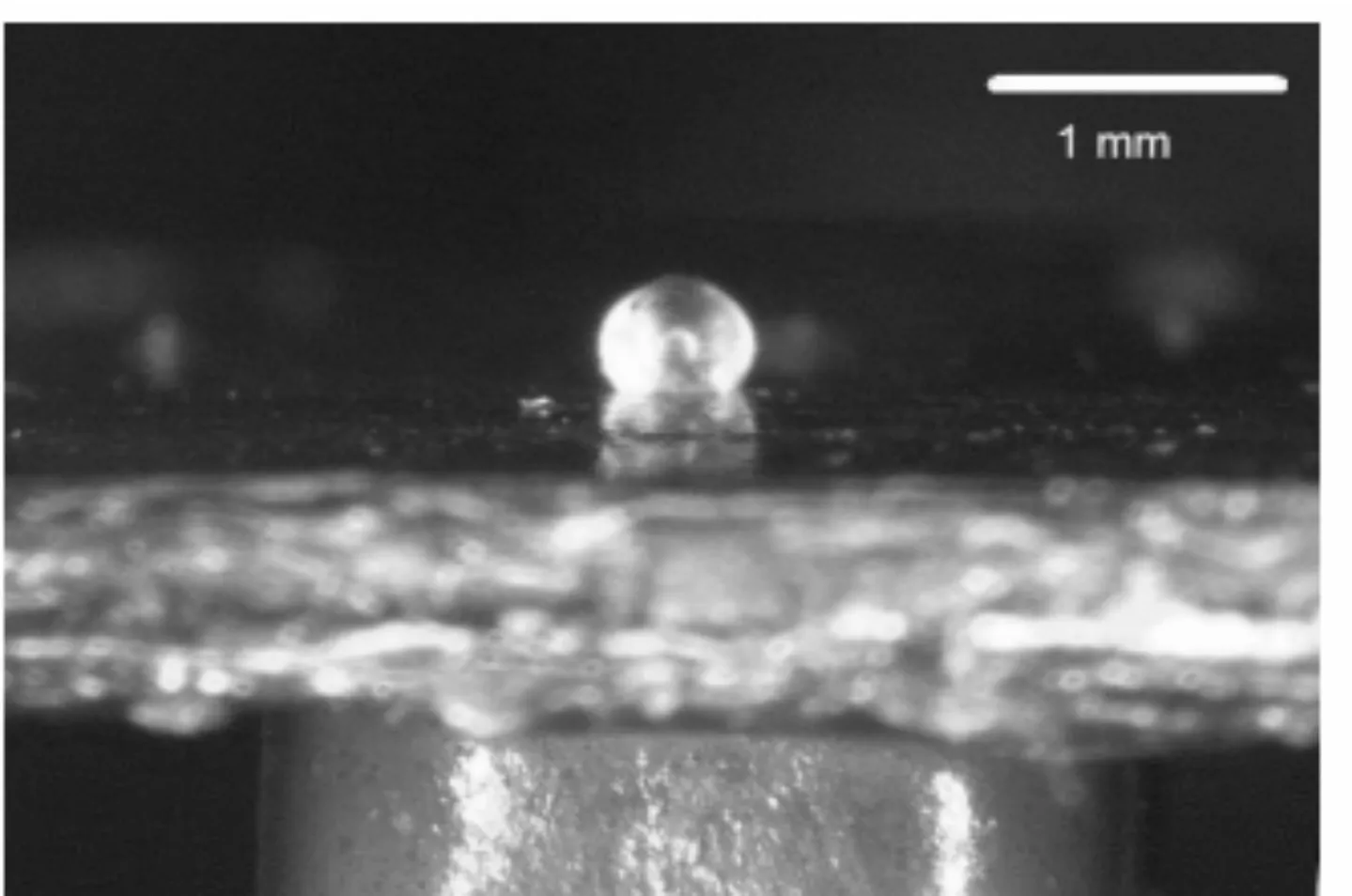

In 2010, Matsumoto and Arouette designed a vibrational Braille code display with a large-displacement MEMS actuator incorporated with HDAM driven by piezo-electric actuator[10], as shown in Fig.6. In this design, two largely deformable polydimethylsiloxane (PDMS) membranes were used to make the closed chamber of the HDAM, as shown in Fig.7. The fabrication of the HDAM was based on photolithography. The experimental results showed that the driven displacement was amplified as great as 18-fold statically and 11-fold at 70 Hz by hydraulic displacement amplification mechanisms. The influences on optimum design and the amplification ratio made by the thickness of the top membrane and PDMS membranes and the opening of the cover layer were discussed through the FEA simulation[11].

Fig.6 Schematic cross-sectional views of our HDAM

Fig.7 Deformation of membrane at the contact part by piezoelectric actuator

In 2009, Suryarghya Chakrabarti investigated a compact bidirectional magneto-hydraulic actuator (MHA) driven with Terfenol-D for active engine mounts[12], as shown in Fig.8. The dynamic model of the Magneto-hydraulic actuator had been established[13-14]. The model contained magnetic diffusion, Terfenol-D constitutive model based on the Jiles-Atherton model and mechanical actuator model based on LuGre friction model. The model is shown to accurately quantify the dynamic behavior of the actuator over the frequency range from DC to 500 Hz. The performance of MHA had been compared to the performance of the commercial mount actuator, which is referred to as CMA, under mechanically-free and mechanically-blocked conditions. The MHA provided more than twice the bandwidth of the CMA in terms of unloaded stroke response and comparable force outputs in the frequency range 120 Hz to 400 Hz. Furthermore, the MHA had lower and flatter high order components than the CMA, which implies a greater response linearity.

Fig.8 Mageto-hydraulic actuator (a)and cutout (b)

In 2013, Nakahara and Yamamoto put forward a peristaltic micropump with HDAM that utilized traveling waves on polymer membranes to transport liquids[15] as shown in Fig.7. No valves were required by this micropump and, more importantly, the traveling waves could be generated by a single cantilever-type piezoelectric actuator. The HDAM encapsulated incompressible fluid with two flexible polymer membranes made of PDMS. A micro channel was attached to the top side of the HDAM. A piezoelectric actuator was used to oscillate the flexible membrane at the bottom of the HDAM, while the top-side membranes drove the liquid in the channel. The experimental results showed it could obtain a maximum flow rate of 1.5 mlmin-1at 180 mW.

Fig.9 Photo of the fabricated micropump

4.Flexural frame displacement amplifiers

Flexural frame amplifier (FFA) can generate the amplification in the perpendicular direction. Note that their deformation is a contraction, meaning actuators with these kinds of displacement amplification are pulling actuators.

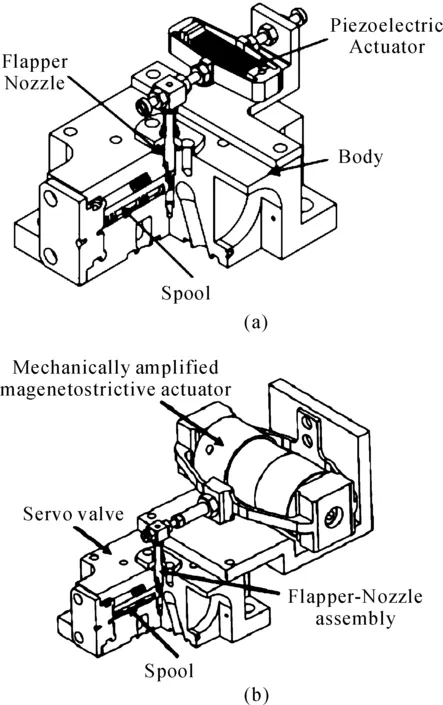

Karunanidhi and Singaperumal developed a two-stage servo valve with a piezoelectric actuator and FFA[16], as shown in Fig.10(a) and Fig.11. The servo valve integrated with an amplified piezoelectric actuator could obtain the resonance frequency of 284 Hz, which is much higher than the conventional valve. The time response of the valve was 0.8 ms, and the max flow of the valve was 10.5 l/min at the input voltage of 35 V. The design of a magnetostrictive actuator with FFA actuator for application in flapper-nozzle servo valve was also developed by them, as shown in Fig.10(b). The servo valve with mechanically amplified magnetostrictive actuator was compared to the servo valve with biasd magnetostrctive actuator. The servo valve with mechanically amplified magnetostrictive actuator could obtain the no load flow of 8 l/min and time response of 0.68 ms at 0.27 A, while the one with biased magnetostrictive actuator could obtain the no load flow of 7 l/min. The time required to reach the steady-state flow out-put by the flow meter for a step input signal for valve with magnetostrictive actuator with mechanical amplifier and magnetically biased were 7.8 ms and 9 ms, respectively[17]. The performance of the servo valve with FFA magnetostrictive actuator was better than the one with biased magnetostrictive actuator. We could not compare the servo valve with an amplified piezoelectric actuator to the one with mechanically amplified magnetostrictive actuator because the design amplification ration and the experimental conditions were different.

Fig.10 Schematic diagrams of servo valve with mechanical amplified piezoelectric actuator (a)and servo valve with mechanical amplified magnetostrictive actuator (b)

Fig.11 Experiment servo valve with piezoelectric actuator

5.Discussion

The three kinds of mechanical amplifiers have been widely used for smart materials. Each has unique advantages. The flexural hinges amplifiers have a well-developed theory and are mostly used in PTZ applications. We paid much attention on the bridge-type flexural-hinged amplification because this flexural-hinged amplifier can obtain stable large amplification ration and compact size. However, this kind of mechanical amplifier is easily to have high stress concentration in the flexural hinges, resulting in fatigue effects, and it can not offer the prestress on the GMM. Therefore, it’s only appropriate for the PTZ applications. The HDAM can generate very high forces and displacement but the leakage is an issue. It’s hard to manufacture the closed chamber. Therefore it’s quite suitable for miro-electro-mechanical system. The flexural frame displacement amplification can offer the amplification stably and offer the prestress for the GMM. But the amplification is not as big as the other kind of mechanical amplifiers. Compared with two kinds of above amplifiers, it suits the GMM more. However, the mechanical properties of the FFA amplifier still have not been fully discovered, and the analytical modeling of the amplifier can hardly be found in the literature.

[1] Damjanovic D, Newnham R E.Electrostrictive and piezoelectric materials for actuator applications[J].Journal of Intelligent Material Systems and Structures,1992(3):190-208.

[2] Berlincourt D, Curran D R, Jaffe H . Piezoelectric and Piezomagnetic Materials and Their Function in Transducers[J].in Physical Acoustics, Vol. 1, W. P Mason, ed., New York: Academic, (Part A) 1964(1):169-270.

[3] Claeyssen F, Lhermet N, Le Letty R, et al.Actuators, transducers and motors based on giant magnetostrictive materials[J].Journal of Alloys and Compounds,1997,258:61-73.

[4] Choi S B, HanS S, Lee Y S. Fine motion control of a moving stage using a piezoactuator associated with a displacement amplifier[J].Smart Mater Struct,2005,14(1):222-230.

[5] Choi S B, HanS S, Lee Y S. Fine motion control of a moving stage using a piezoactuator associated with a displacement amplifier[J].Smart Mater Struct,2005,14(1):222-230.

[6] Tian Y, Shirinzadeh B, Zhang D, et al. Development and dynamic modelling of a flexure-based Scott-Russell mechanism for nano-manipulation[J]. Mechanical Systems and Signal Processing, 2009, 23(3): 957-978.

[7] Tian Y, Shirinzadeh B, Zhang D, et al. Development and dynamic modelling of a flexure-based Scott-Russell mechanism for nano-manipulation[J]. Mech.Syst. Signal Proc,2009,23(3):957-978.

[8] www.dynamicstructures.com/piezo_fpa.html 2010.

[9] Mottard P, St-Amant Y. Analysis of flexural hinge orientation for amplified piezo-driven actuators[J]. Smart Materials and Structures, 2009,18(3): 035005.

[10] Matsumoto Y, Arouette X.Vibrational Braille code display with MEMS-based hydraulic displacement amplification mechanism, IEEE,2010,978-1-4244-5764-9/10/.

[11] Arouette X, Matsumoto Y.Dynamic characteristics of a hydraulic amplification mechanism for large displacement actuators systems[J].Sensors,2010(10):2946-2956.

[12] Chakrabarti S, Dapino M J.Hydraulically amplified Terfenol-D actuator for adaptive powertrain mounts[J]. Transactions of the ASME,2011(10):10-15.

[13] Chakrabarti S, Dapino M J.Coupled axisymmetric finite element model of a magneto-hydraulic actuator for active engine mounts[J]. Industrial and Commercial Applications of Smart Structures Technologies 2011, Proc. of SPIE Vol. 7979 79790C.

[14] Chakrabarti S, Dapino M J. Modeling of a displacement amplified magnetostrictive actuator for active mounts[C]//Proceedings of the ASME 2009 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, SMASIS09-1411.

[15] Nakahara K, Yamamoto M, Okayama Y, et al. A peristaltic micropump using traveling waves on a polymer membrane[J]. Journal of Micromechanics and Microengineering, 2013, 23(8): 085024.

[16] Karunanidhi S, Singaperumal M.Mathemaical modlling and experimental characterization of a high dynamic servo valve integrated with piezoelectric actuator[J].Proceedings of the Institution of Mechanical Engineers, Part 1: Journal of Systems and Control Engineering,2010:224-419

[17] Karunanidhi S, Singaperumal M. Design, analysis and simulation of magnetostrictive actuator and its application to high dynamic servo valve[J]. Sensors and Actuators A: Physical, 2010, 157(2): 185-197.

2013-09-05

National Natural Science Foundation of China(51175243), Aeronautical Science Foundation of China(20110752006), Visiting Scholar Foundation of Key Lab in University of China(GZKF-201116), NUAA Fundamental Research Funds(NS2013046)

*ZHU Yuchuan, Associate Professor.E-mail: Xinjgz@126.com

10.3969/j.issn.1001-3881.2013.24.006