生物炭還田機關鍵部件設計與仿真分析

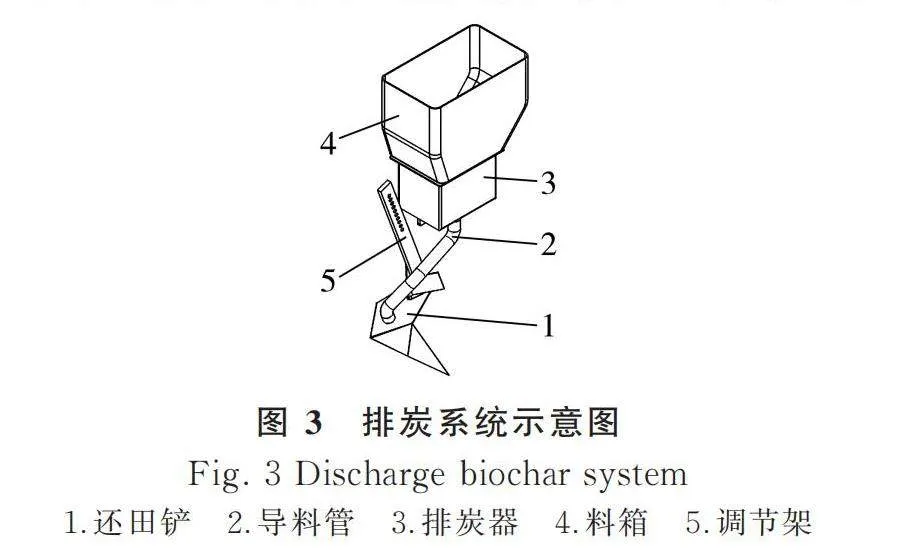

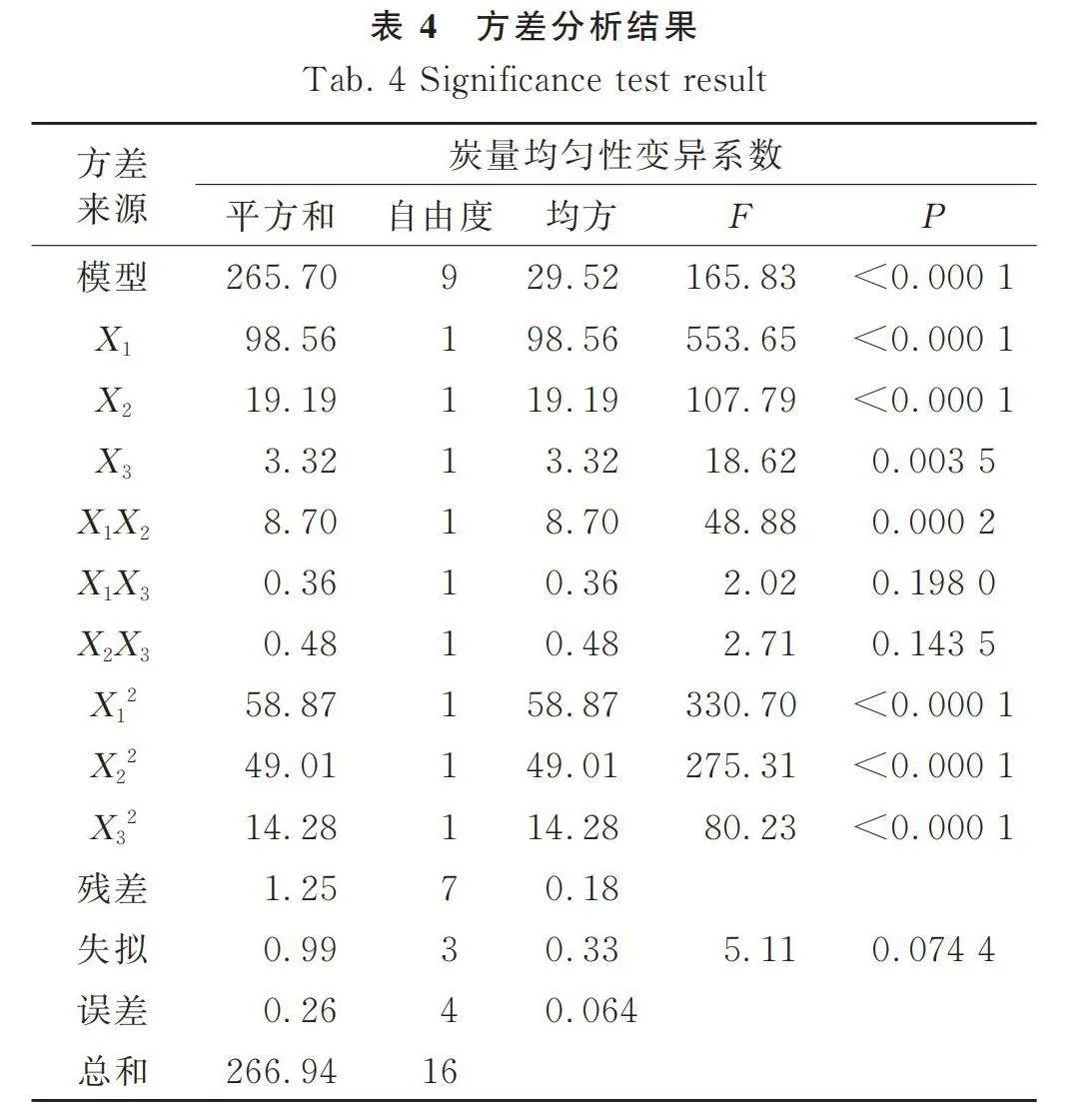

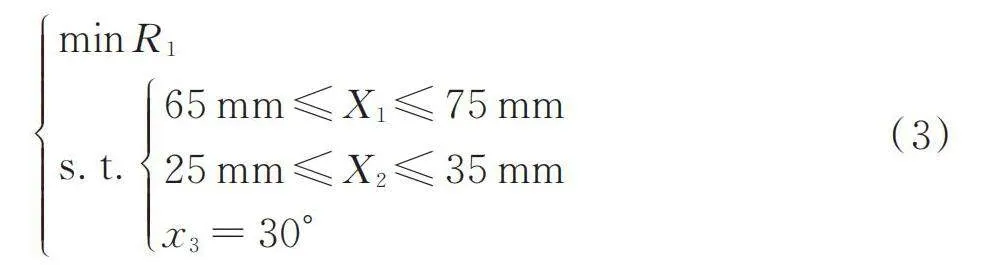

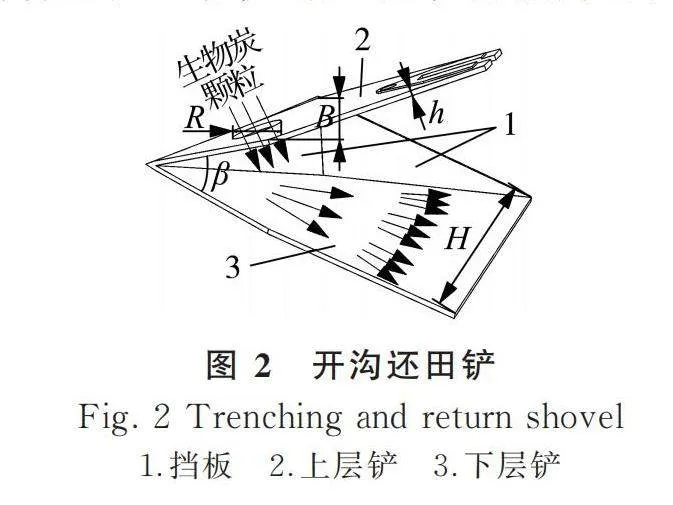

摘要:當前生物炭還田過程煩瑣,費時費力,為實現(xiàn)生物炭還田開溝—排炭—覆土一體化技術,設計適用于生物炭還田機上的排炭系統(tǒng)關鍵部件——開溝還田鏟和排炭器。通過離散元軟件洛基(Rocky)建立關鍵部件的仿真模型,模擬生物炭還田的工作過程。以炭量均勻性變異系數(shù)作為試驗指標,出口距離、導管直徑和擋板夾角為試驗因素,運用Design-Expert軟件設計單因素試驗和三因素三水平響應面試驗,通過分析響應面圖和參數(shù)優(yōu)化模塊得到最優(yōu)工作參數(shù)組合:出口距離65.20 mm、導管直徑25.30 mm和擋板夾角30°。試驗結(jié)果表明,在最優(yōu)工作參數(shù)下,生物炭還田關鍵部件的炭量均勻性變異系數(shù)為28.622%,能一次性完成開溝、排炭還田、覆土工作,可為生物炭還田技術提供參考。

關鍵詞:生物炭還田;洛基程序;離散元仿真;響應面試驗;參數(shù)優(yōu)化

中圖分類號:S23 文獻標識碼:A 文章編號:2095?5553 (2024) 11?0240?05

Design and simulation analysis of key components of biochar return machine

Jiang Shuying1, Chen Zhongyu1, Ma Fang1, Zhang Luji2,Li Mingliang1, Ren Dezhi2

(1. Yancheng Polytechnic College, Yancheng, 224005, China;

2. College of Engineering, Shenyang Agricultural University, Shenyang, 110866, China)

Abstract: At present, the process of biochar return to the field is complicated, laborious and time?consuming. In order to achieve the integration of trenching, biochar distribution, and soil covering for biochar return to the field, the key components for the biochar distribution system on the biochar return machine are designed, such as a trenching shovel and a biochar distributor. A simulation model of the key components is established by using the discrete element software Rocky to simulate the process of biochar return to field. The variability coefficient of biochar distribution is taken as the experimental index, the exit distance, the diameter of the conduit and the angle of the deflector blade as experimental factors, the Design-Expert software is utilized to design a single?factor experiment and a three?factor, three?level response surface experiment, the optimal working parameter combination is obtained through the analysis of response surface plots and parameter optimization modules, the outlet distance is 65.20 mm, the conduit diameter is 25.30 mm, and the baffle angle is 30°. The experimental results indicate that the variability coefficient of biochar distribution of the key components designed in this paper is 28.622% under the optimal working parameters, and the trenching, biochar distribution and soil covering process can be completed in one pass, which can provide a reference for the technology of biochar return to field.

Keywords: biochar return to field; Rocky program; discrete element simulation; response surface test; parameters optimization

0 引言

生物炭還田是秸稈綜合利用的重要途徑,是當今研究領域熱點之一[1?3]。目前生物炭還田方法是將生物炭撒播于土壤表層后用旋耕機將炭與土混合[4],這種還田方式極其依賴人力,并且炭土之間無法均勻混合,還田效果較差。所以設計一種專用于生物炭還田的農(nóng)業(yè)機械,可提高生物炭還田效率和效果,為生物炭還田產(chǎn)業(yè)化設備提供參考。

當前關于生物炭以何種方式還田,如何提高還田效果鮮有研究。在農(nóng)業(yè)工程領域與生物炭還田技術相似的有深松施肥技術和免耕播種技術。劉立晶等[5]設計了一種玉米深松全程施肥鏟,并通過EDEM模擬了施肥鏟的工作過程,該過程與生物炭還田過程相似,不同的是物料特性以及由此產(chǎn)生的工作機理上的不同,但其設計和仿真的方式和流程可為生物炭還田提供參考。……