高壓井口天然氣渦流管節流加熱參數優選

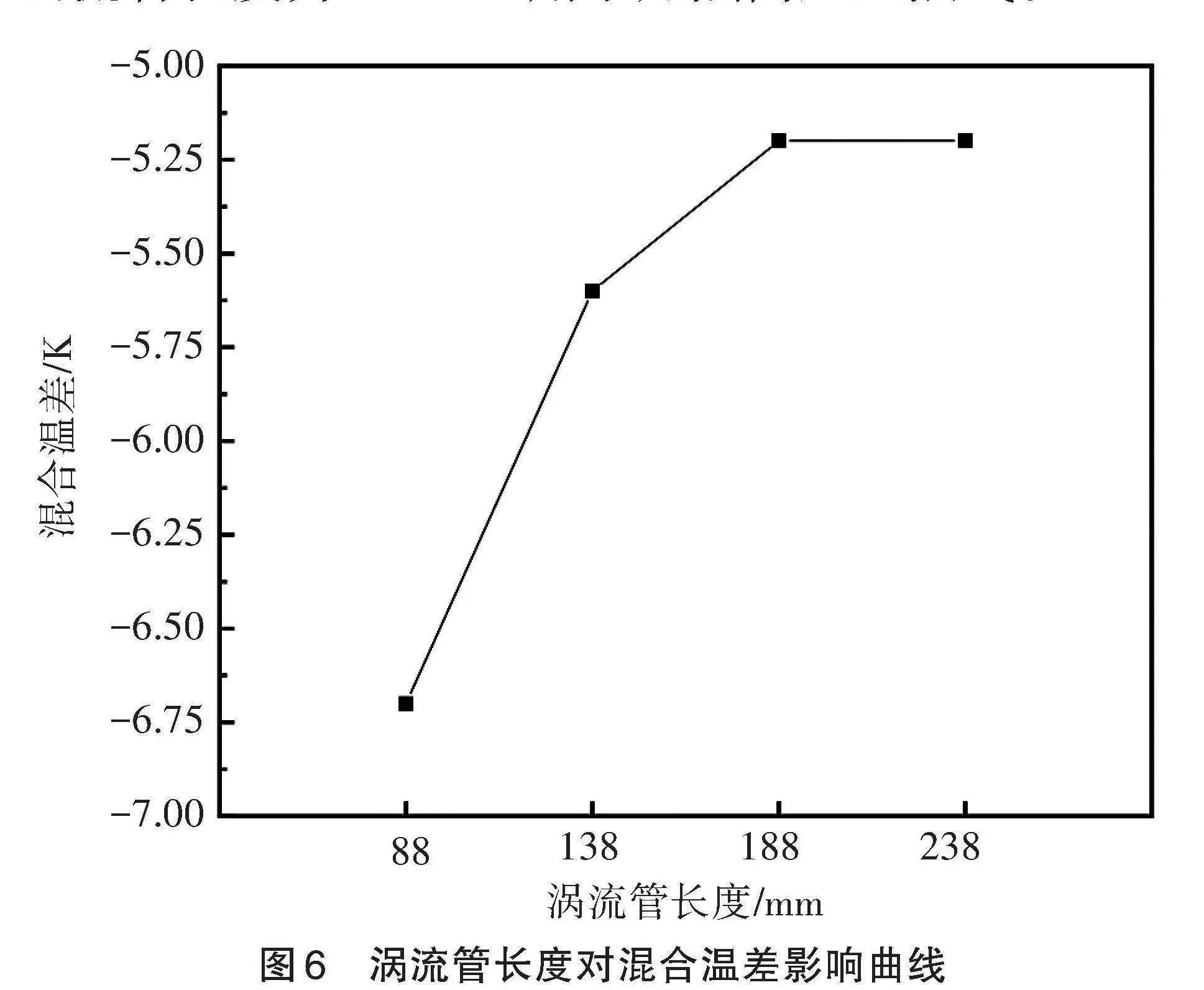

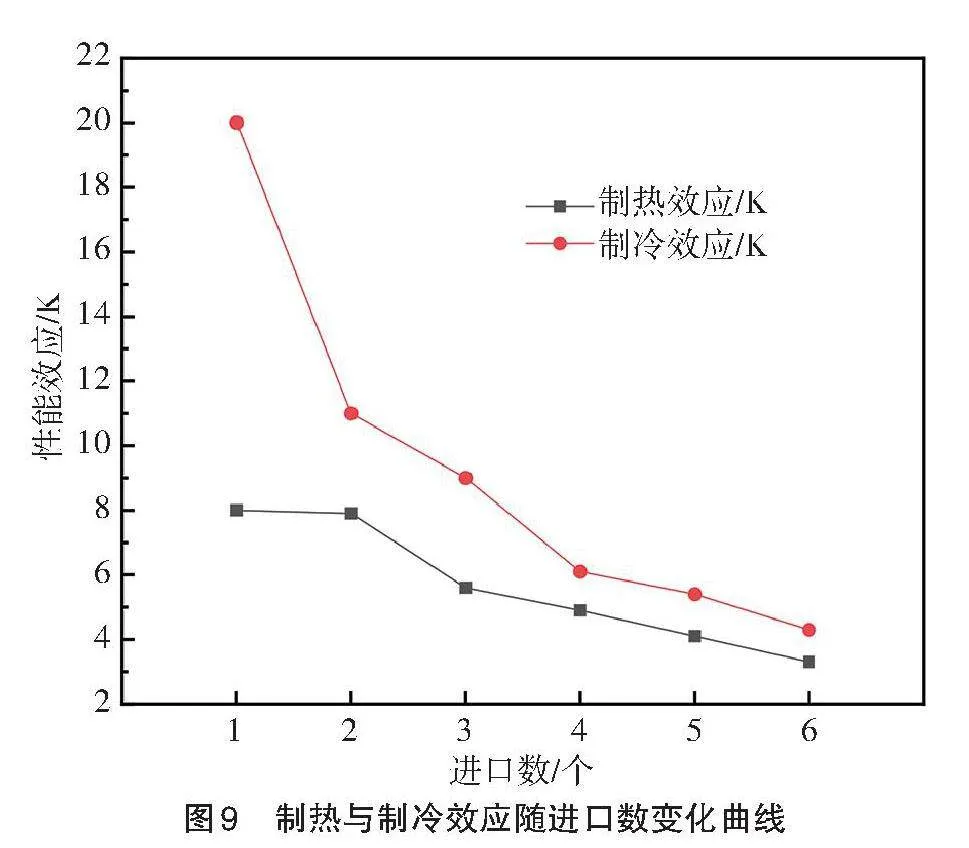

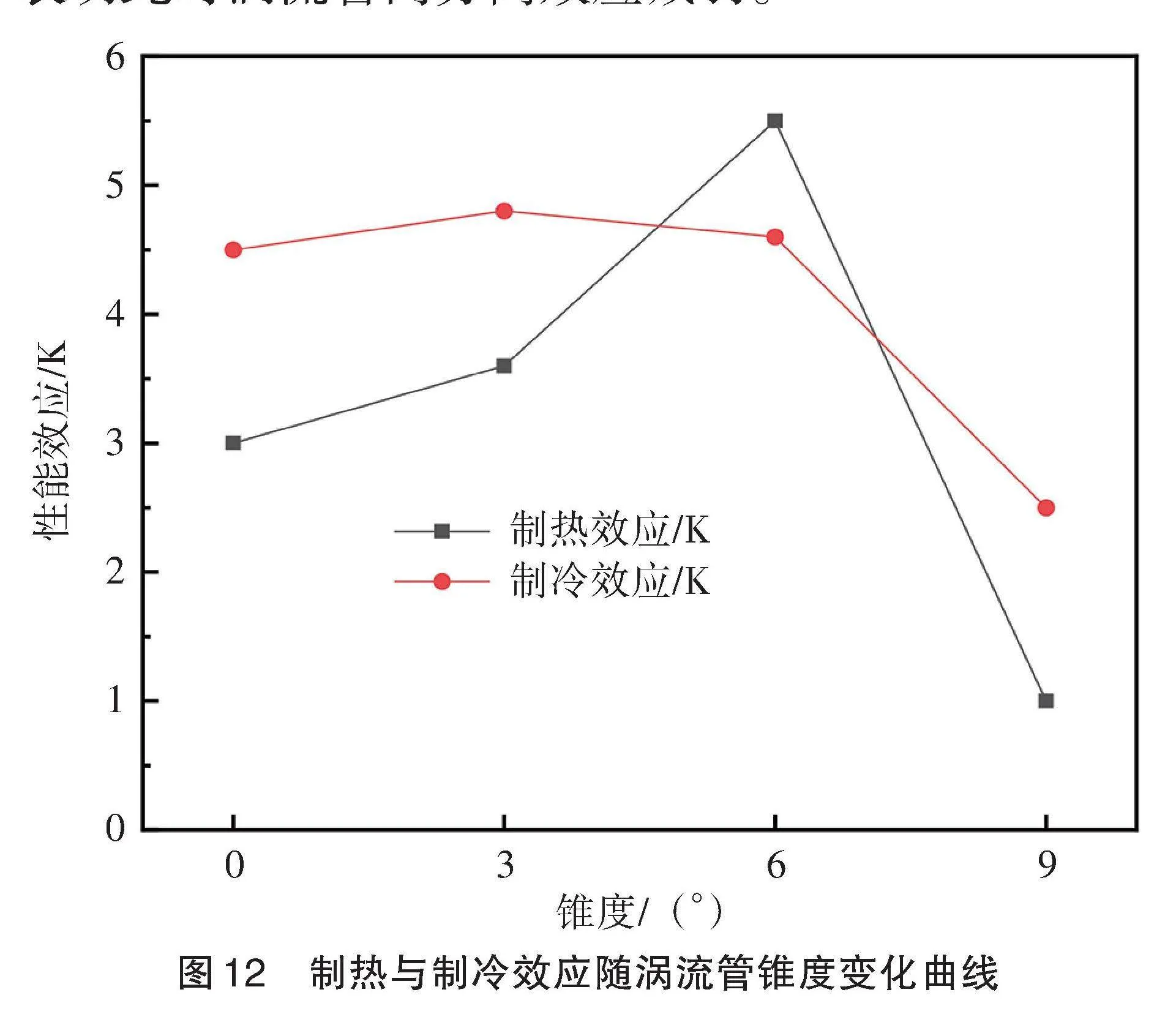

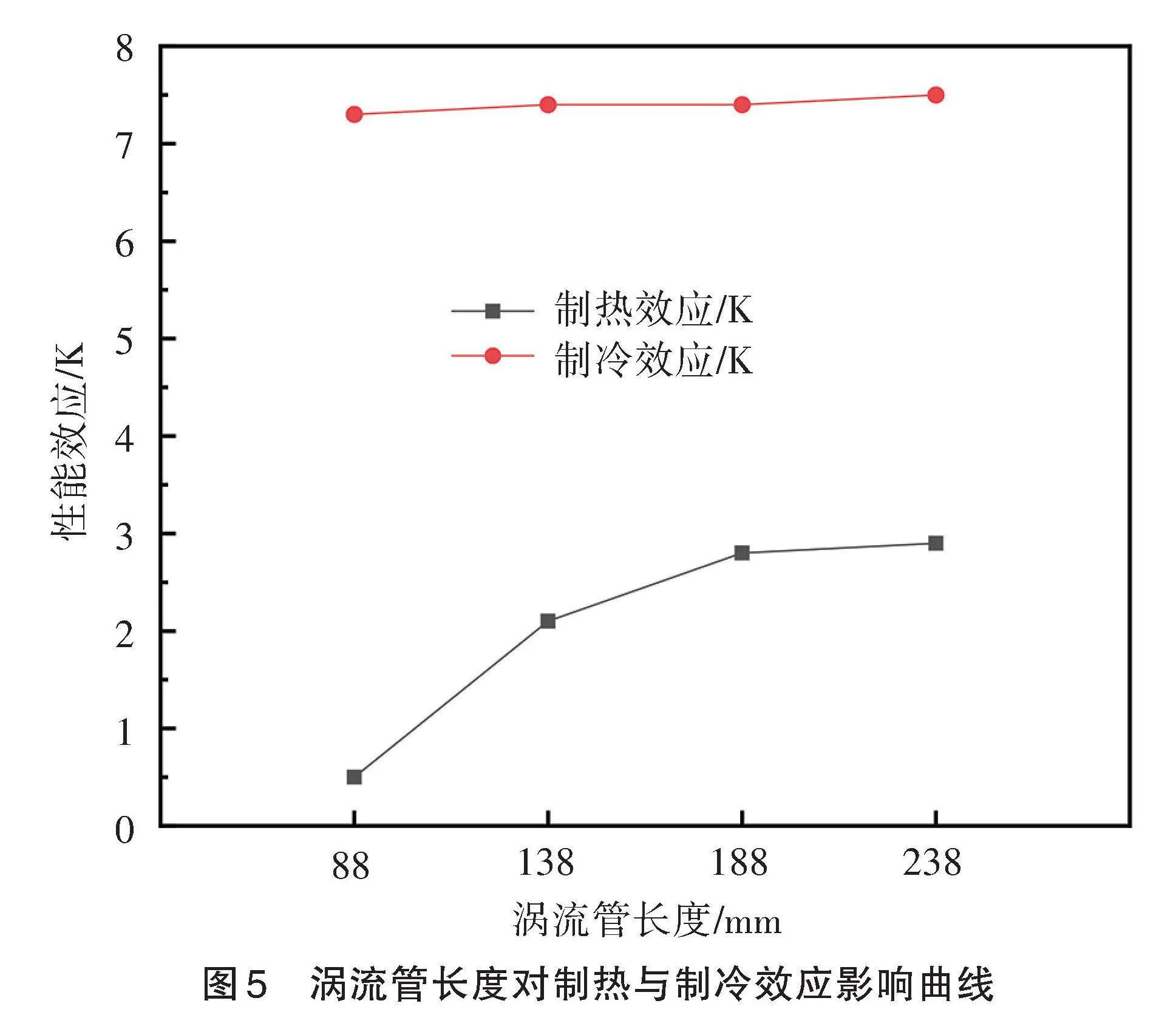

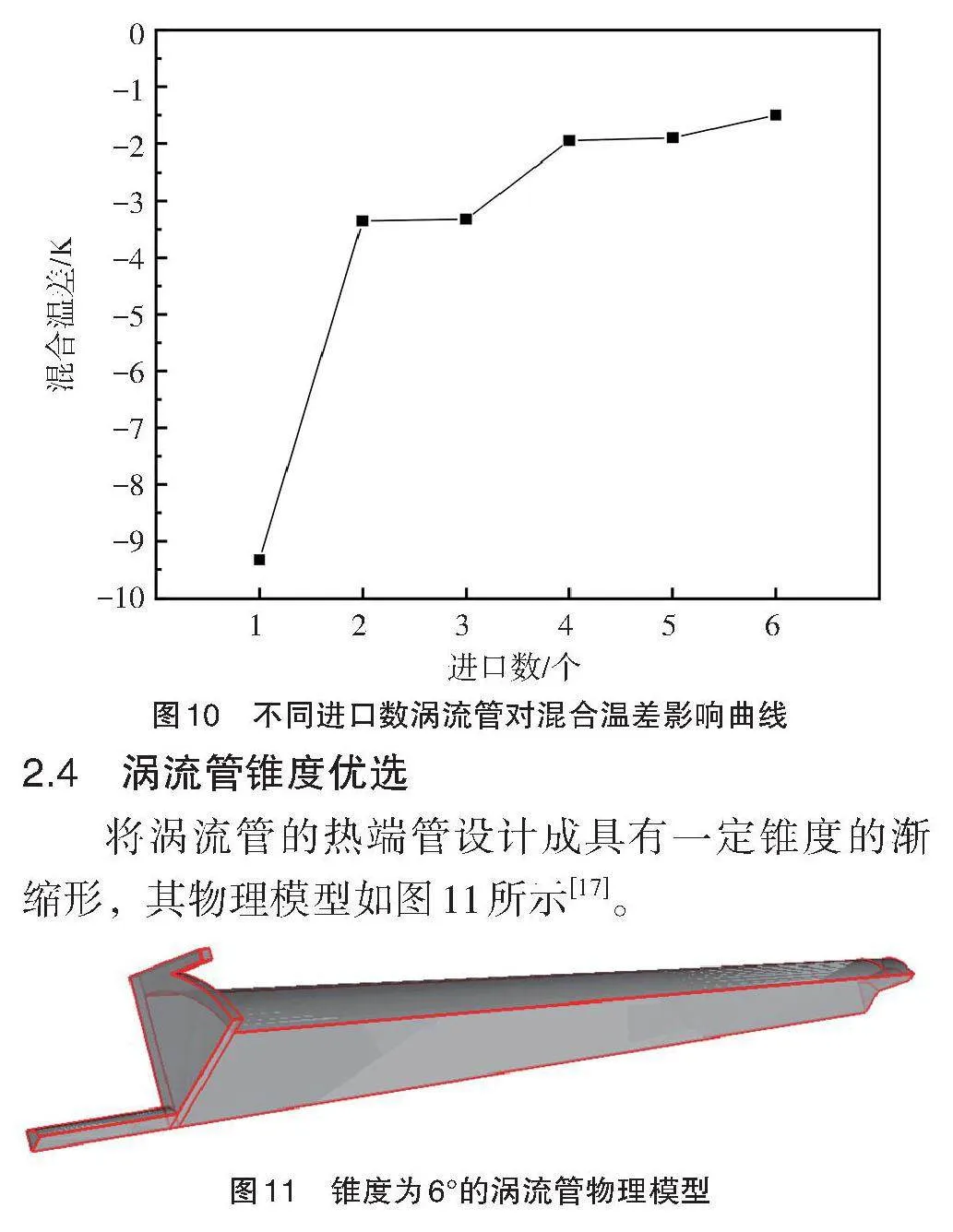

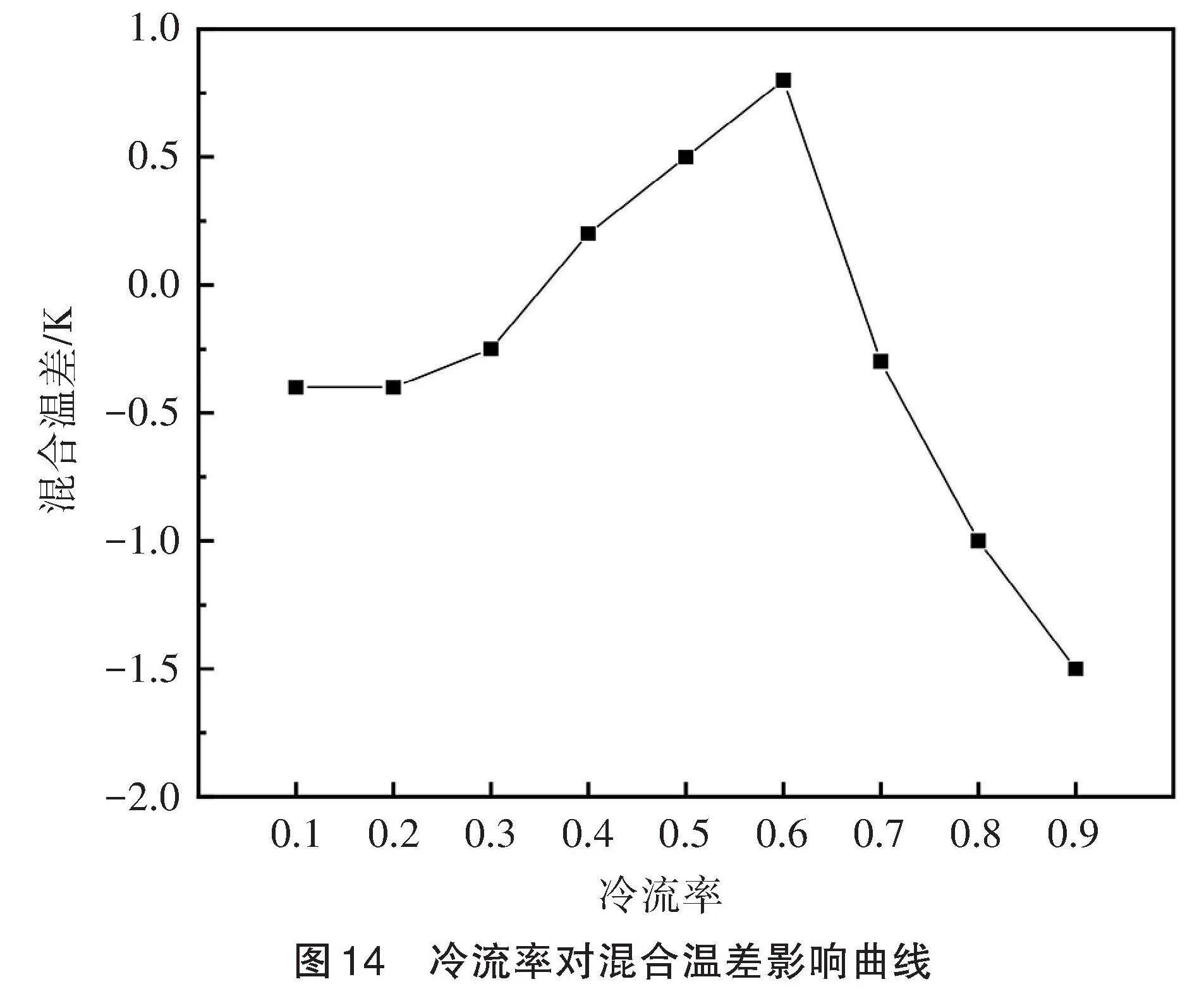

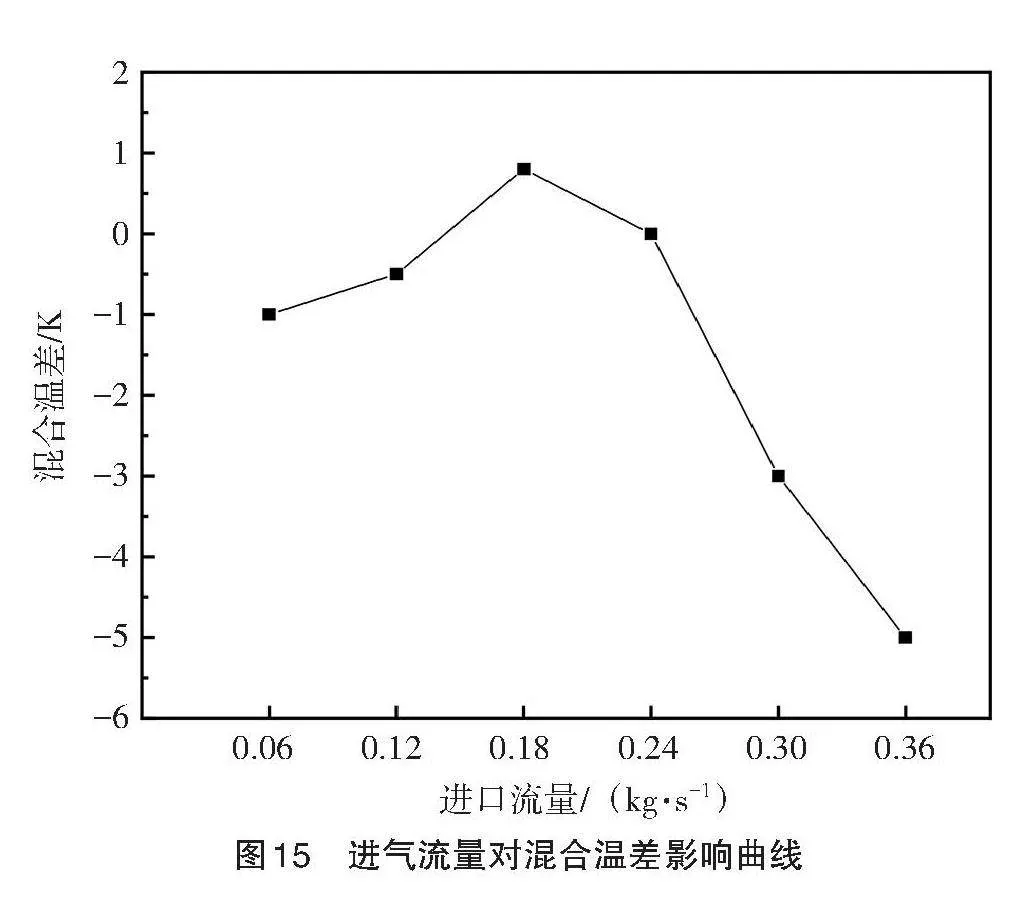

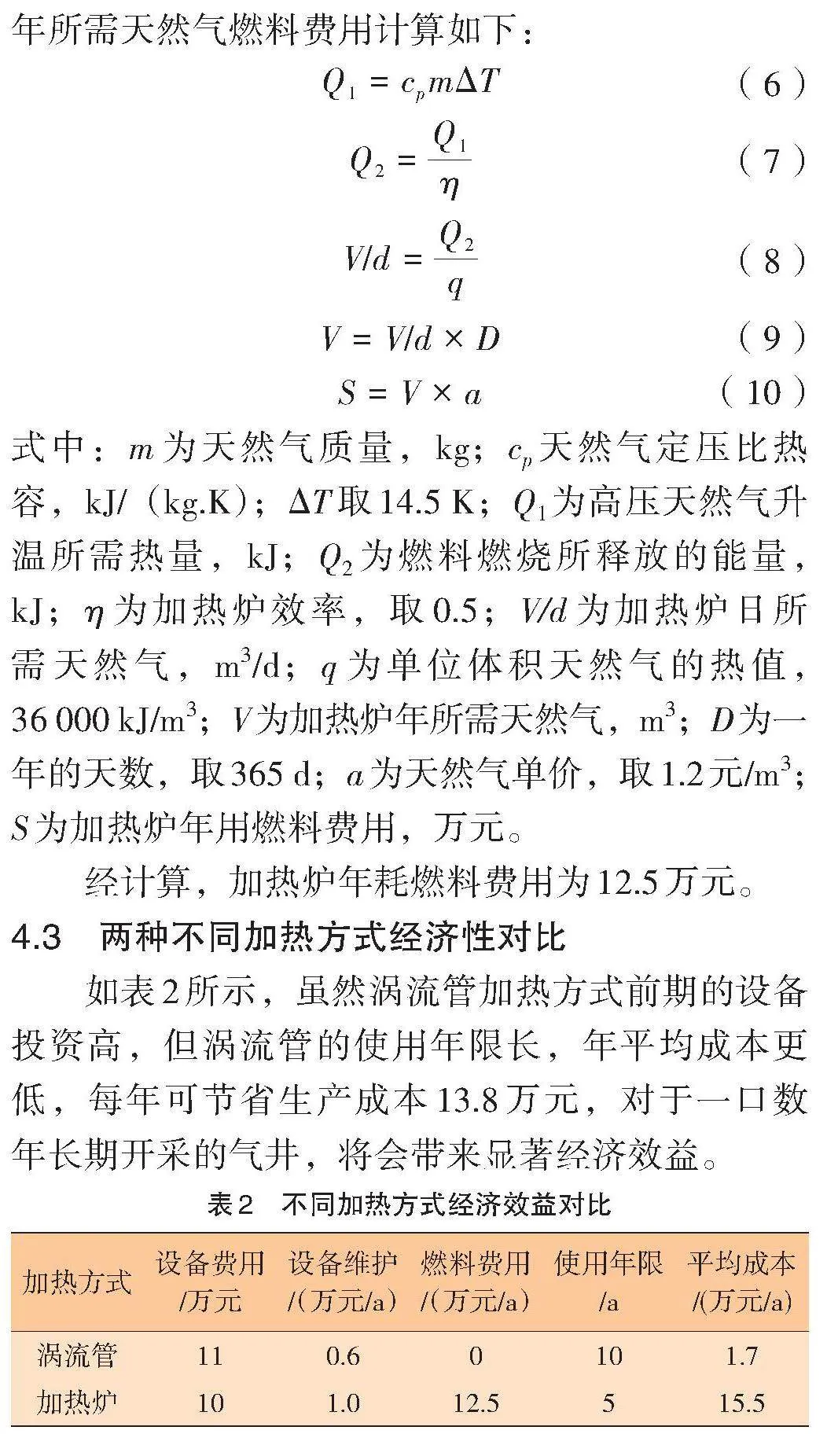

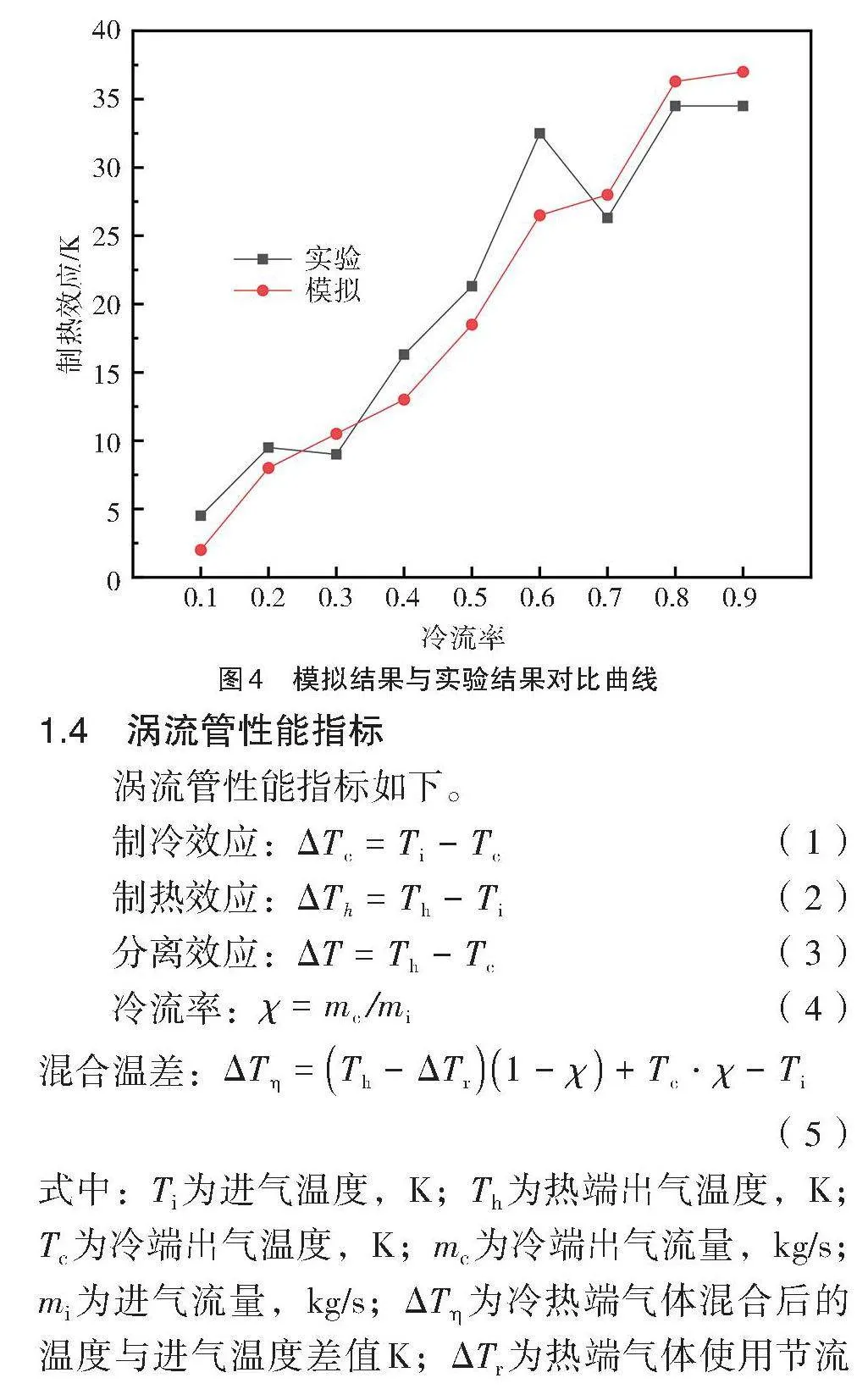

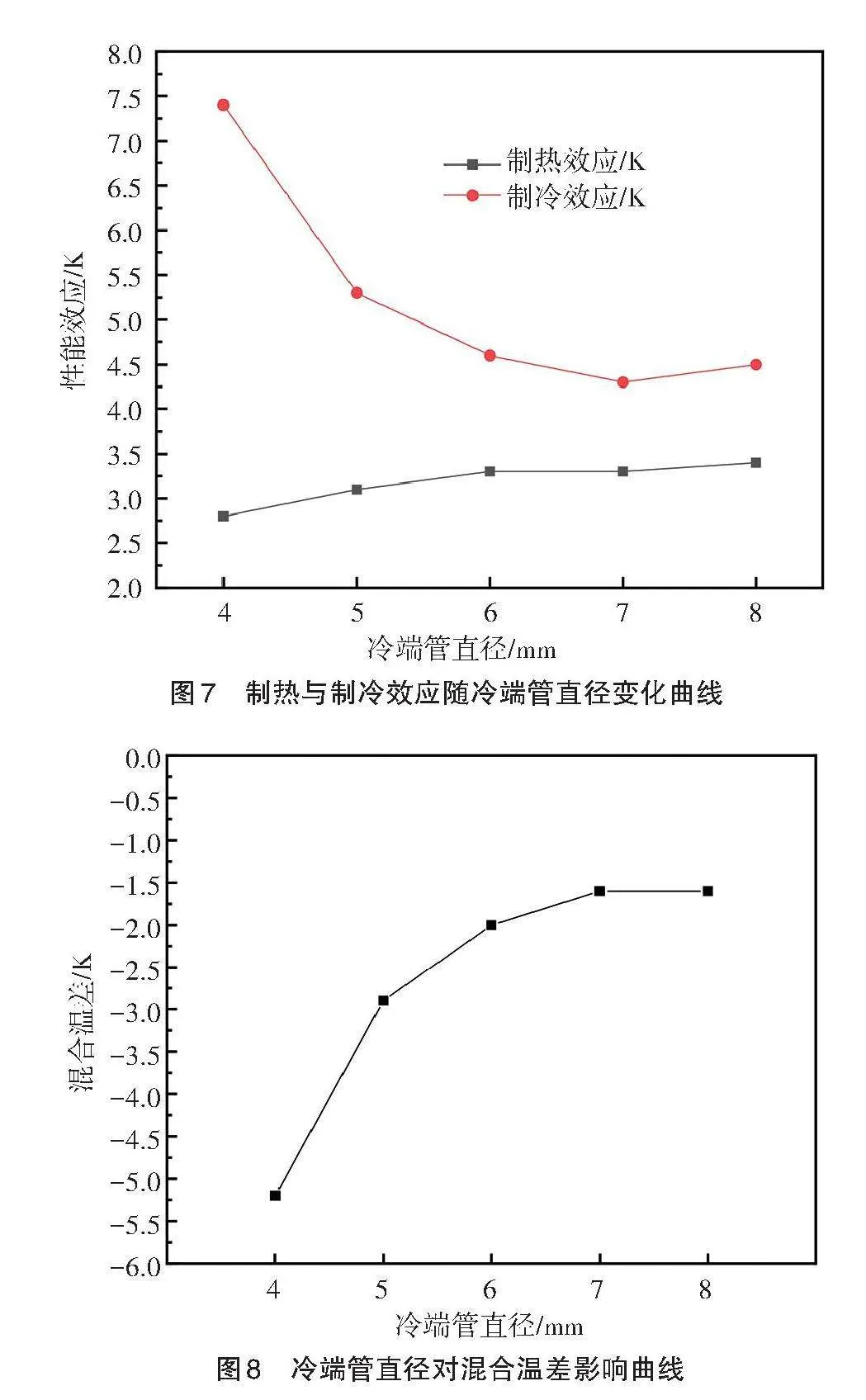

摘" " 要:渦流管具有制熱性能,因此可用渦流管替代加熱爐,用于加熱節流后的井口高壓天然氣。為了優選渦流管的最佳結構參數與操作參數,發揮渦流管加熱高壓井口天然氣的最佳效果,利用Fluent進行了數值模擬研究,建立用于高壓氣井井口加熱的渦流管模型,通過模擬結果與實驗結果對比,驗證了數學模型及模擬結果的正確性。當渦流管長度為188" mm、冷端管直徑為7 mm、進口數為6、錐度為6°、進氣流量為0.18 kg/s、冷流率為0.6時,達到最佳加熱效果。根據氣井井口溫度與壓力參數,確定了渦流管的串并聯組合方式,并將渦流管加熱與加熱爐加熱進行了經濟性對比,結果表明渦流管加熱具有優異的加熱效果,經濟效益顯著。

關鍵詞:渦流管;結構參數;操作參數;高壓氣井;井口加熱;串并聯組合

Optimization of vortex tube parameters for heating throttled high pressure

natural gas at wellhead

YU Kaiyang1, MA Hongwei2

1. China Petroleum Pipeline Engineering Corporation (Shenyang Branch), Shenyang 110031, China

2. Shandong Gangyuan Pipeline Logistics Co., Ltd., Yantai 264000, China

Abstract:The heating performance of the vortex tube enables it to replace the heating furnace to heat the throttled high pressure natural gas at the wellhead. To choose the optimal structural parameters and operating parameters of the vortex tube, and give full play to the heating effect of the vortex tube on high pressure natural gas at the wellhead, this paper uses Fluent to carry out numerical simulation research to constructa vortex tube model for heating high pressure air gas at the wellhead and verifies the mathematical model and simulation results through the comparison with the experimental results.When the length of the vortex tube is 188 mm, the diameter of the cold end tube is 7 mm, the number of inlets is 6, the taper is 6°, the intake flow is 0.18 kg/s, and the cold flow rate is 0.6, the best heating effect is achieved. Based on the wellhead temperature and pressure parameters of the gas well, the series-parallel combination mode of the vortex tube is determined, and the economic comparison between the two heating ways using the vortex tube and heating furnace respectively is carried out. The results show that the vortex tube manifests a good heating effect and has significant economic benefits.

Keywords:vortex tube; structural parameter; operating parameter; high pressure gas well; wellhead heating; series-parallel combination

DOI:10.3969/j.issn.1001-2206.2024.05.002

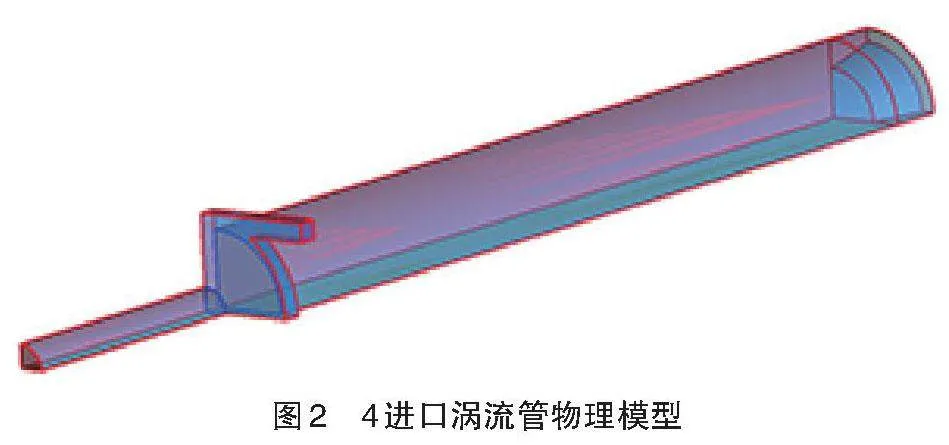

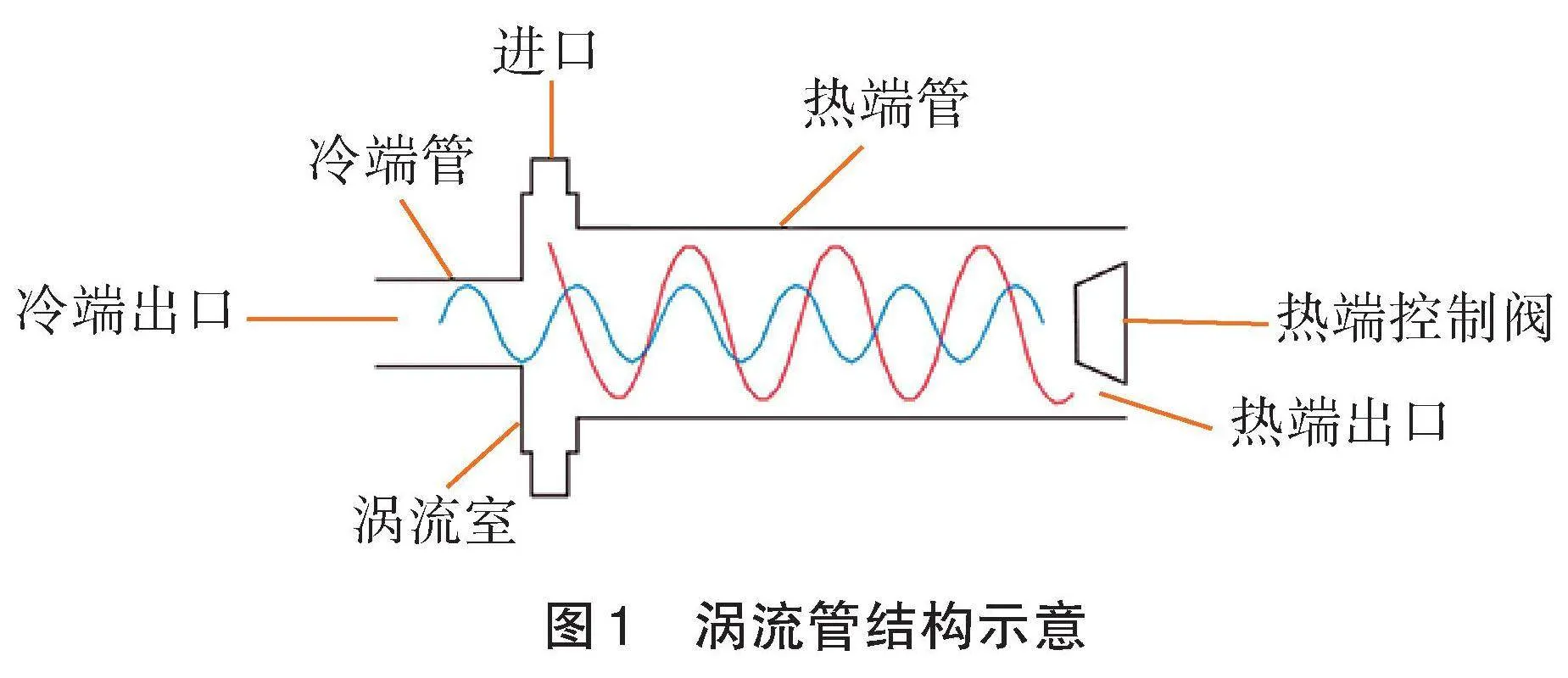

為了滿足集氣工藝的要求,井口高壓天然氣需采用節流閥多級節流降壓,通常采取加熱爐加熱、添加水合物抑制劑、井下節流等方法防止天然氣水合物的形成,這些方法普遍存在投資高、運行技術困難等問題[1-2]。渦流管是一種利用高壓天然氣自身的高壓實現能量轉化升溫從而防止水合物生成的裝置,其主要由切向進口、渦流室、冷端管、熱端管以及熱端控制閥等幾部分組成[3-5],渦流管結構示意如圖1所示。渦流管工作時,高壓天然氣經渦流管進口切向進入到渦流室中,在熱端管中被分離成冷、熱兩股氣流,其中冷氣流位于軸心處,熱氣流位于管壁處,兩股流體分別從冷端出口與熱端出口流出,從而發揮制冷和制熱作用[6-8]。……