基于VDM-SSA-LSTM考慮刀具磨損的數控銑床切削功率預測模型研究

王秋蓮 歐桂雄 徐雪嬌 劉錦榮 馬國紅 鄧紅標

摘要:

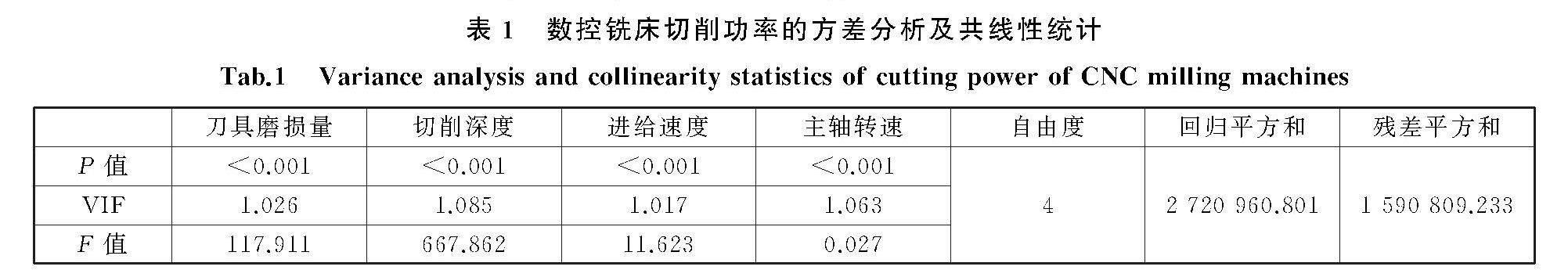

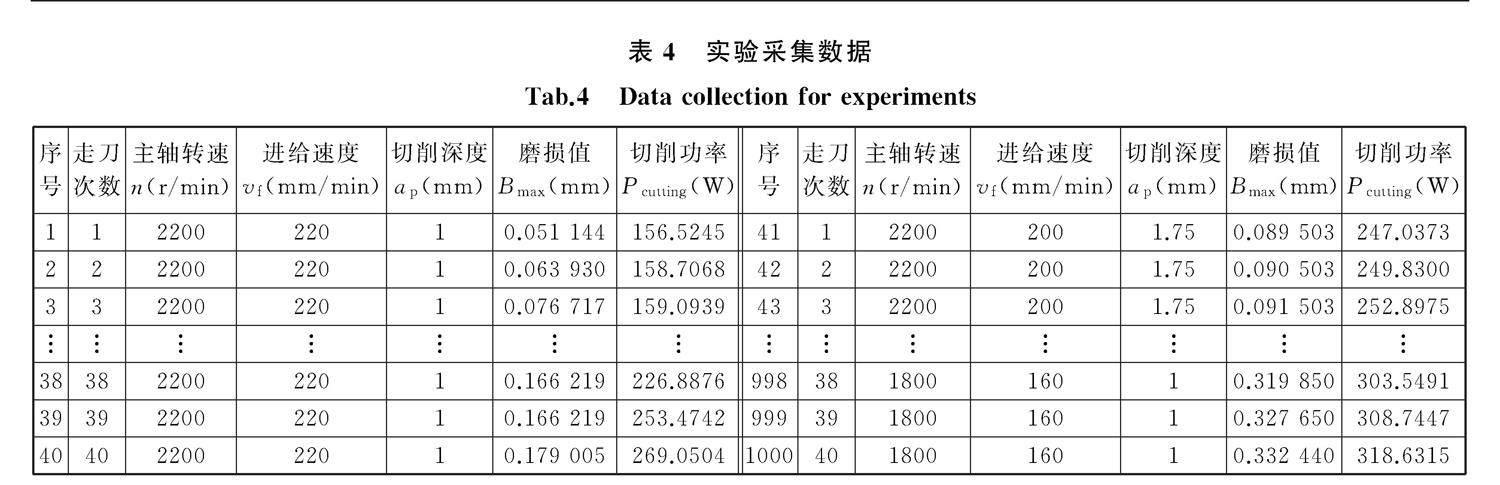

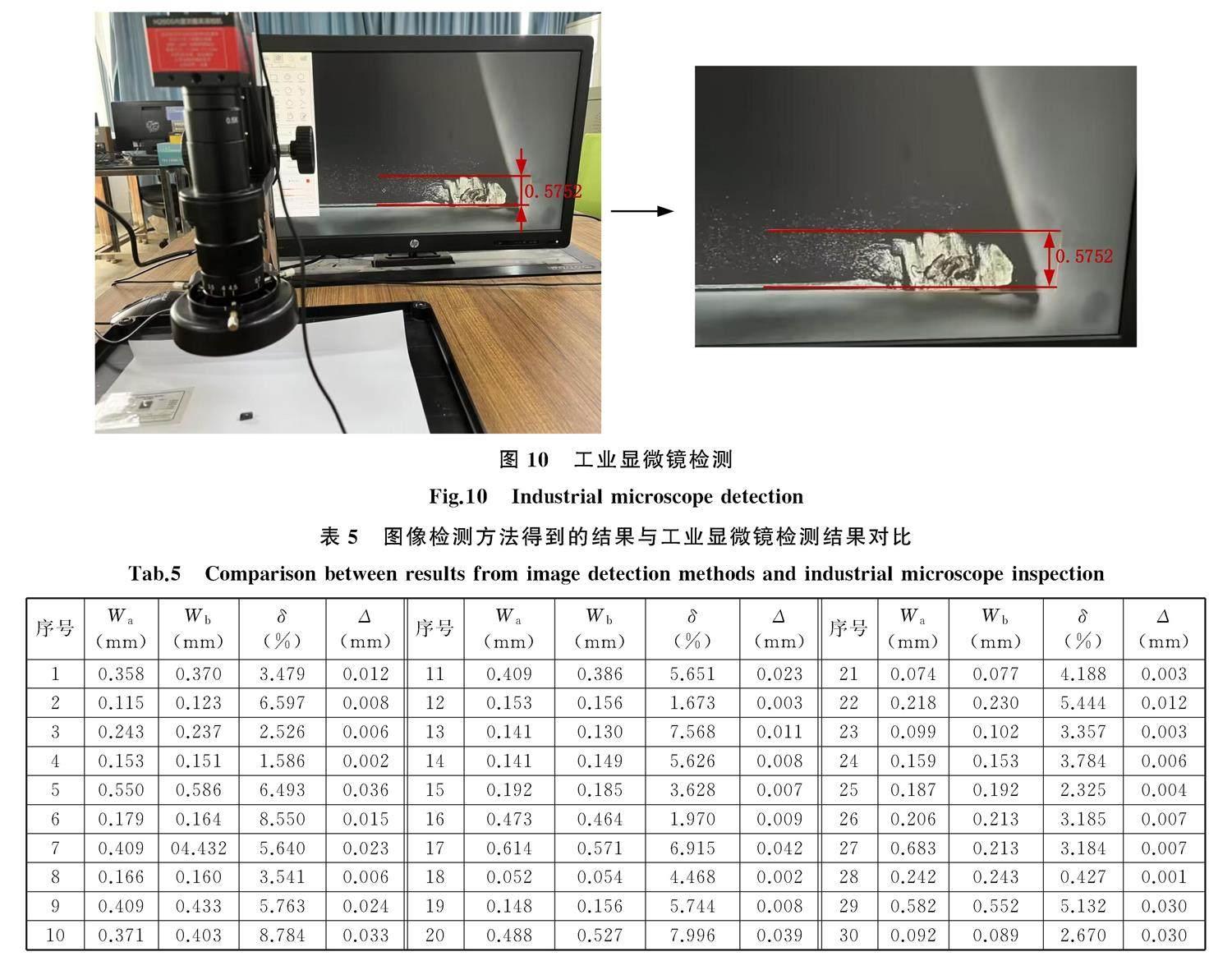

傳統的切削過程功率獲取需要基于復雜的切削功率模型且很少考慮刀具磨損的影響,針對此設計了一種基于變分模態分解(VMD)、麻雀搜索算法(SSA)、長短時記憶(LSTM)神經網絡的考慮刀具磨損的數控銑床切削功率預測模型,該模型無需解構數控銑床運行過程的能耗機理,基于一次性的歷史實驗數據即可實現數控銑床切削過程功率的高精度預測。首先,采用人工智能機器視覺技術對刀具磨損圖片進行分析處理,獲取刀具磨損圖像的數字化特征,從而得到刀具最大磨損量;然后,建立基于VMD-SSA-LSTM考慮刀具磨損的數控銑床切削功率預測模型,利用VMD對數控銑床運行數據進行分解,采用SSA算法對LSTM神經網絡超參數進行尋優,并將分解出的銑床運行數據分量輸入到LSTM神經網絡中,接著將每個分量的預測值相加,得到切削功率預測值;最后以面銑加工為例,將所提出的預測模型與BP神經網絡、LSTM神經網絡和傳統模型進行對比分析,驗證了所提模型的有效性和優越性。

關鍵詞:切削過程功率;刀具磨損;麻雀搜索算法;長短時記憶神經網絡;變分模態分解;計算機視覺技術

中圖分類號:TH17

DOI:10.3969/j.issn.1004132X.2024.06.011

開放科學(資源服務)標識碼(OSID):

Research on CNC Milling Machine Cutting Power Prediction Model

Considering Tool Wear Based on VMD-SSA-LSTM

WANG Qiulian1? OU Guixiong1? XU Xuejiao1? LIU Jinrong1? MA Guohong2? DENG Hongbiao2

1.School of Economics & Management,Nanchang University,Nanchang,330031

2.School of Advanced Manufacturing,Nanchang University,Nanchang,330031

Abstract: Traditional researches of cutting process powers required complex cutting power models and often neglected the influences of tool wear, so a CNC milling machine cutting power prediction model considering tool wear was designed based on VMD, SSA, and LSTM neural network. This model did not require the deconstruction of the energy consumption mechanism during the operation of CNC milling machines, and achieved high-precision prediction of cutting process powers based on historical experimental data. Firstly, artificial intelligence machine vision technology was used to analyze and process images of the tool wear, obtaining digital features of the worn tools and determining the maximum wear. Then, the VMD-SSA-LSTM model was established, which considered tool wear in the prediction of CNC milling machine cutting powers. VMD was used to decompose the operational data of CNC milling machines, and then the SSA algorithm optimized the hyperparameters of the LSTM neural network. The decomposed milling machine data components were input into the LSTM neural network, and the predicted values of each component were summed to obtain the cutting power prediction value. Taking face milling as an example, the proposed prediction model was compared and analyzed against BP neural networks, LSTM neural networks, and traditional models, which validated the effectiveness and superiority of the proposed model.

Key words: power of cutting process; tool wear; sparrow search algorithm(SSA); long-short term memory(LSTM) neural network; variational mode decomposition(VMD); computer vision technology

收稿日期:20220801? 修回日期:20240314

基金項目:國家自然科學基金(51765043);江西省自然科學基金(20232BAB204043);江西省高校人文社會科學研究一般項目(JC22120)

0? 引言

為進一步減少能源消耗和環境污染,我國在實施制造強國戰略過程中著重強調了推進綠色制造的重要性。……