窄間隙激光焊研究現狀及發展趨勢

駱傳萬 馮杰才 沈裕航 劉樹磊 姜夢 魏連峰

摘要: 針對鈦合金、鎳基高溫合金、高強鋼、不銹鋼及鋁合金等材料的窄間隙激光焊進行了介紹。在窄間隙激光焊焊接過程中,焊接工藝參數(如激光功率、焊接速度及送絲速度等)會影響焊縫的微觀組織和力學性能,坡口尺寸影響焊縫側壁熔合性;若焊接過程控制不當,常規的窄間隙激光焊仍有可能出現焊縫側壁未熔合、氣孔等問題。激光-電弧復合焊、激光熱絲焊、超窄間隙激光焊、擺動激光焊、真空激光焊和電磁輔助激光焊等新方法應運而生,解決了窄間隙激光焊中存在的焊接缺陷,同時進一步拓寬了窄間隙激光焊的應用領域。在焊接前對熔池流動行為、匙孔穩定性、溫度場等進行模擬和分析,不僅可以揭示激光焊接復雜的物理過程及連接機理,還可用來優化焊接工藝,得到材料的有效連接。

關鍵詞: 窄間隙焊接; 激光焊; 工藝; 組織; 力學性能

中圖分類號: TG 456.7

Research status and development trend of narrow gap laser welding

Luo Chuanwan1, Feng Jiecai1, Shen Yuhang1, Liu Shulei1, Jiang Meng2, Wei Lianfeng3

(1.Shanghai University, Shanghai 200444, China; 2.State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, Harbin 150001, Heilongjiang, China; 3.Science and Technology on Reactor Fuel and Materials Laboratory, Nuclear Power Institute of China, Chengdu 610041, Sichuan, China)

Abstract: Narrow gap laser welding of titanium alloy, nickel base superalloy, high strength steel, stainless steel and aluminum alloy was introduced. In the process of narrow gap laser welding, welding parameters such as laser power, welding speed and wire feeding speed, would affect microstructure and mechanical properties of weld, and groove size would affect side wall fusion of weld. If the welding process was not properly controlled, the conventional narrow gap laser welding might still cause problems such as side wall incomplete fusion of weld wall and porosity. New methods such as laser-arc hybrid welding, laser hot wire welding, ultra-narrow gap laser welding, swing laser welding, vacuum laser welding and electromagnetic assisted laser welding emerged at the right moment, which solved welding defects in narrow gap laser welding, and further broadened application field of narrow gap laser welding. Simulating and analyzing flow behavior of molten pool, keyhole stability and temperature field before welding could not only reveal complex physical processes and connection mechanisms of laser welding, but also be used to optimize welding process and obtain effective material connections.

Key words:? narrow gap welding; laser welding; technology; microstructure; mechanical properties

基金項目: 先進焊接與連接國家重點實驗室開放課題研究基金資助(AWJ-22M02)

0 前言焊接是航空航天、船舶、核電和軌道交通等行業大型構件制造的關鍵技術[1]。鈦合金、鎳基高溫合金、高強鋼和鋁合金等常用材料傳統的焊接方法主要有熔化極電弧焊、埋弧焊和鎢極氬弧焊(TIG)等,但仍存在焊接效率低、熱影響區寬、工件變形嚴重、能耗大和勞動強度大等問題[2-3],急需開發先進的焊接技術。電子束焊接雖然可以實現高速焊,但是需要抽真空,且不易實現大型復雜構件的焊接,極大的限制了該技術的推廣應用。近年來,激光焊因具有焊接速度快、熱輸入小、焊材消耗低和易于自動化等優點,已成為一種重要的高效高質連接技術[4-9]。與傳統電弧焊相比,窄間隙激光焊在焊接變形、焊材消耗[10-11]和焊接效率[12-13]等方面更勝一籌,而且,磁場輔助激光焊、擺動激光焊和雙光束激光焊等新型激光焊方法進一步拓寬窄間隙激光焊的應用領域。

1 不同材料的窄間隙激光焊

航空航天、船舶和軌道交通等行業常用的材料有鈦合金、鎳基高溫合金、高強鋼、不銹鋼和鋁合金等,國內外研究機構對上述材料的激光焊接可行性、焊縫組織及力學性能等方面開展了大量的研究,取得了豐碩的研究成果。

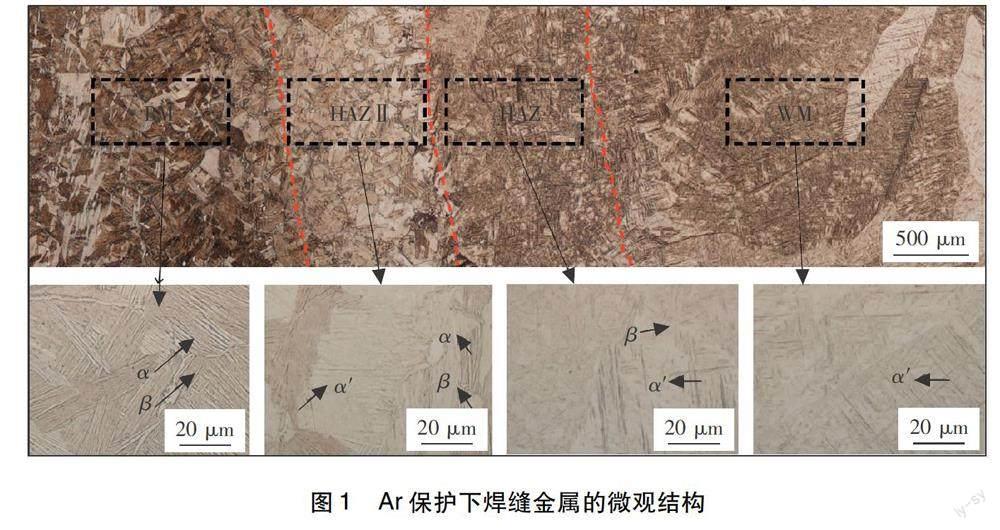

鈦合金因具有較高的比強度、優異的耐腐蝕性和良好的加工成形等特點[14],廣泛應用于航天航空、核潛艇等領域[15-16],但鈦合金的焊縫組織及力學性能對焊接熱輸入非常敏感,大的熱輸入會使組織惡化,降低焊縫的力學性能。Fang等學者[17]通過控制激光功率大小來控制焊接時的熱輸入大小,研究了10 mm厚TC4鈦合金激光焊接頭組織及性能,研究表明:增加焊接熱輸入,焊縫中心等軸區的寬度會增大,其晶粒的平均尺寸也變大,但焊縫熔合區硬度卻降低了。此外,Liu等學者[18]采用試驗和模擬相結合的方法,開展了TC4鈦合金窄間隙激光多道焊接研究,該研究指出,焊縫區柱狀晶體的生長方向與最高溫度梯度的方向一致。同時,焊縫重熔區經歷了多次熱循環,是導致該區域組織晶粒粗大的主要原因。同時,Fang等學者[19]則研究了Ar,He保護氣體對20 mm厚TC4鈦合金窄間隙激光焊組織及性能的影響,發現:Ar作為保護氣體時,形成的熱影響區比He氣的寬,這主要是因為Ar比He的電離能低,形成了更多的等離子體,在焊縫表面以熱傳導的形式對焊縫加熱,導致了其熱影響區較寬;同時,與Ar相比,采用He作為保護氣體,得到的α′馬氏體顯微結構更加細小,焊縫硬度更加均勻,且其硬度值略高,如圖1[19]和圖2[19]所示。Gui等學者[20]指出:激光焊的冷卻速率較快,是鈦合金焊縫熱影響區寬度較窄的主要原因;當焊接速度為1.6 mm/min、激光功率為2~3 kW時,焊縫氣孔率最低。

鎳基高溫合金具有良好的耐高溫腐蝕性、熱穩定性和抗蠕變性等[21-23],廣泛應用于燃氣輪機鍋爐管、燃燒室、超高溫反應堆(VHTR)等器件[24]。Keler等學者[25]采用窄間隙激光多道焊(Laser-multi-pass-narrow-gap-welding, Laser-MPNG)焊接了72.5 mm厚的鎳基高溫合金,如圖3[25]所示,研究發現:與窄間隙TIG(圖6a)相比,Laser-MPNG(圖3b)不僅焊材消耗量減少了2倍,而且焊接速度提高了5倍。Thejasree等學者[26]研究焊接熱輸入對Inconel 625鎳基合金焊縫的影響,發現:隨著激光功率的增大,焊縫熔深也增大,如圖4[26]所示;同時,采用數值模擬的方法,獲得的顯微組織、力學性能和熱循環等模擬結果與實際試驗所獲得的結果非常接近,這表明:數值模擬可以有效的指導焊接試驗,對深入了解焊接的相關物理過程有較大的意義。Sun等學者[27]研究了焊接坡口對12 mm厚Inconel 617鎳基高溫合金激光焊接特性的影響,研究表明:相比于U形坡口,V形坡口容易產生未熔合、氣孔等缺陷;對于U形坡口,熔融金屬的潤濕性更好,有助于獲得形成良好的焊縫;該研究還發現:由于激光焊縫出現碳化物沉淀強化現象,焊縫的硬度、抗拉強度和沖擊韌性都高于母材,與電弧焊[28]相比,采用Laser-MPNG,焊接效率更高,焊材消耗更少。高強鋼一直被廣泛應用于船舶、核電、大型鋼鐵建筑等行業,高效高質焊接技術是相關產品制造過程的關鍵技術。Wu等學者[29]對35 mm厚的CLF-1鋼進行Laser-MPNG,研究表明:經過焊后熱處理(PWHT)后,焊縫側壁完全熔合,沒有發現未熔合、氣孔及裂紋等缺陷,但PWHT會降低晶界強度,容易產生裂紋。此外,Guo等學者[30]采用激光填絲焊焊接8 mm厚的S60高強度鋼,研究表明:傳統的TIG會使焊接接頭產生較高的殘余應力和變形。同時,Guo等學者[31]提出:采用單道自熔焊焊接S960和S700高強鋼時,采用2G焊接位置更有利于解決1G焊接位置出現的未熔合及焊縫下凹等缺陷;同時,該研究還發現:采用超窄間隙激光多道焊不僅能夠得到無裂紋、氣孔及未熔合等缺陷的焊縫,如圖5b[31]所示,相比于單道自熔焊,避免了對于高功率激光器的要求,但多層激光焊接過程中的快速冷卻,使得焊縫的熔合區和熱影響區出現了馬氏體組織,降低了焊接接頭的韌性。隨后,Ning等學者[32]指出:與傳統的TIG相比,采用Laser-MPNG焊接D406超強度鋼,焊縫組織更加均勻,抗拉強度更高。

對于不銹鋼焊接,激光焊比傳統電弧焊有更多的優勢,焊接變形更小。Shi等學者[33]采用窄間隙激光填絲焊和窄間隙TIG對20 mm厚奧氏體不銹鋼進行焊接,研究表明:激光填絲焊獲得的焊接變形更小。Ragavendran等學者[34]研究了激光焊、激光-TIG復合焊、激光-MIG復合焊對316L(N)不銹鋼的焊縫組織及力學性能的影響,發現:復合焊焊縫的二次枝晶間距較大,主要是復合焊的冷卻速率比激光焊的小、熱輸入較大所致。由于熱輸入的影響,TIG和MIG焊縫體積也比激光焊的大,頂部和底部的焊縫寬度也更寬;同時,MIG焊縫硬度也高于TIG和激光焊焊縫,其強度、延展性和韌性更好。Yang等學者[35]發現采用超窄間隙激光焊焊接100 mm厚304不銹鋼時,對坡口側壁和底部同時加熱,可以獲得良好的焊縫成形。

近年來,汽車、軌道交通、航天航空等行業越來越關注鋁合金等輕量化材料[36-39]。Zhang等學者[40]采用窄間隙激光多道焊對20 mm厚的7A52高強度鋁合金進行焊接,研究表明:對焊縫進行焊后熱處理,促使焊縫金屬的沉淀相急劇增加,使得焊縫顯微硬度略有增加。Zhang等學者[41]還指出,采用單一的U形或I形坡口,都有利于焊縫側壁的熔合。而且,采用鋁鎂合金焊絲填充焊縫,可提高焊接接頭的抗拉強度、屈服強度和斷后伸長率。Suckow等學者[42]對AA7075鋁合金激光焊接頭進行焊后熱處理,焊縫顯微組織表明:沿晶界處形成富Mg-Al-Cu相和富Mg-Zn相,是AA7075接頭力學性能顯著提高的原因之一。

綜上所述,對于鈦合金、鎳基高溫合金、高強鋼、不銹鋼及鋁合金等材料,窄間隙激光焊方法比傳統電弧焊方法更有優勢。在窄間隙激光焊焊接過程中,焊接工藝參數(如激光功率、焊接速度及送絲速度等)會影響焊縫的微觀組織和力學性能,坡口尺寸影響焊縫側壁熔合性;若焊接過程控制不當,常規的窄間隙激光焊仍有可能出現焊縫側壁未熔合、氣孔等問題。

2 窄間隙激光焊新方法

近年來,研究人員提出了激光-電弧復合焊、激光熱絲焊、超窄間隙激光焊、擺動激光焊、真空激光焊和電磁輔助激光焊等新方法,不僅能夠解決窄間隙激光焊存在的問題,同時進一步拓寬窄間隙激光焊的應用領域。

Li等學者[43]采用激光自熔焊、激光填絲焊和激光-電弧復合焊3種焊接方法組合的形式焊接30 mm厚的Q235鋼板,研究表明:激光復合焊焊縫無明顯的氣孔,表面無焊瘤,如圖6[43]所示,在焊縫頂部,坡口間隙最大的地方,側壁也沒有未熔合的缺陷,但是在焊縫的根部存在未熔合,主要是由于較窄的側壁吸收了更多的激光能量,而導致到達焊接坡口底部的能量減少;激光自熔焊焊縫的熱影響區最小,而后續焊道,依次采用激光填絲焊和激光-電弧復合焊,由于經歷了多次熱循環,熱影響區較寬。Zhang等學者[44]采用窄間隙激光-電弧復合焊對厚40 mm的低碳鋼進行焊接,焊縫無明顯的氣孔、未熔合等等缺陷;焊縫根部針狀鐵素體含量最低,力學性能相對較低,但是其抗拉強度和沖擊吸收能量仍分別比母材高49%和60%。

Kaplan等學者[45]采用窄間隙激光填熱絲焊對7 mm厚的鋼板進行焊接,研究表明:采用填充熱絲,不僅可以減少激光功率的消耗,還能促進熔融金屬的潤濕性,提高填充效率及質量。然而,若加熱焊絲的電壓過高,容易形成電弧或造成熔滴脫落。Wei等學者[46]也發現:通過電流等方式對焊絲進行預熱,可減少激光功率,提高了焊接間隙公差,并獲得了更大的熔深。此外,Liu等學者[47]也指出:與傳統激光填冷絲焊相比,激光填熱絲焊可減少熱輸入,有利于抑制未熔合、氣孔和裂紋等缺陷的形成。

Li等學者[48]的研究表明:采用窄間隙擺動激光焊焊接鋁合金,在較低的激光熱輸入下,合適的激光束擺動參數,可以獲得良好的焊縫成形;而采用常規窄間隙激光焊時,需要增加離焦量,以獲得大激光光斑,將導致熱輸入增加,可能會惡化焊縫組織;當激光束擺動振幅為2.0 mm、頻率為150 Hz時,得到較寬、較淺的焊縫形態,而且更有利于避免側壁未熔合現象。同時,Wu等學者[49]、Fetzer等學者[50]、Hagenlocher等學者[51]及Wang等學者[52]的研究表明:與常規激光焊相比,擺動激光焊可以有效調節激光能量的分布,抑制氣孔缺陷;激光束攪拌熔池,可以細化焊縫晶粒,提高焊接接頭的強韌性。

采用激光一次性焊透厚板材料,雖然易于實現,但是焊接飛濺較大,焊縫容易形成氣孔和裂紋等缺陷[53]。Guo等學者[54]采用超窄間隙激光多道焊對6 mm厚S960高強度鋼板進行焊接,研究表明:超窄間隙激光焊能節省更多的焊材;當激光功率為2 kW、焊接速度為0.6m/min、送絲速率為3.3m/min時,成功獲得了無明顯氣孔和未熔合的焊縫,將優化的參數略作調整后焊接8 mm厚S960和13 mm厚S700鋼,拉伸斷裂位置均位于母材。Elmesalamy等學者[55]采用超窄間隙激光焊焊接20 mm厚的不銹鋼,研究了激光功率、焊接速度和送絲速率等工藝參數對焊縫的熔合性和表面氧化的影響規律,發現:提高激光功率和焊接速度可以提高焊縫熔合性;當焊接速度增加而激光功率降低時,焊縫表面層金屬光澤,無氧化現象,原因是熱量輸入減少,焊縫表面溫度降低,有效抑制了氧化反應。

對于激光焊,激光功率與焊縫熔深一般呈正比關系,但是功率越大,越容易產生飛濺、氣孔及變形等問題[56]。同時,在大氣壓力下,大功率激光焊接的光致等離子體密度較大,會吸收部分激光束能量,影響了材料對激光束能量的吸收,且焊縫表面容易氧化,很難獲得成形良好的焊縫。Gao等學者[57]和Jiang等學者[58]的研究表明:與傳統激光焊相比,在亞大氣壓環境或真空條件下,可以極大的提高激光束的穿透能力,焊縫熔深更大。Luo等學者[59]及Li等學者[60]指出:在亞大氣壓條件下,焊縫的氣孔、裂紋等缺陷受到了明顯的抑制,焊縫質量有所提高。Wang等學者[56]采用低真空激光焊接新技術連接130 mm厚5A06鋁合金,研究表明:焊縫無明顯氣孔和未熔合缺陷;焊縫的抗拉強度達到母材的95%以上。

對于鋁合金的焊接,常規激光焊獲得的焊縫成形較差,焊縫表面通常會有凹陷,背面余高較大。Qi等學者[61]在激光焊中,引入輔助電磁場,以產生一個向上的穩定的電磁力,可以有效降低熔池塌陷現象,焊縫成形良好。Xu等學者[62]也采用電磁場輔助激光焊焊接10 mm厚A5083鋁合金,研究表明:當磁感應強度為80 mT、頻率為400 Hz時,可以有效抑制焊縫根部焊瘤的形成;外加振蕩的電磁場對熔池具有一定的攪拌作用,可以細化晶粒,有效降低焊縫的開裂敏感性。此外,一些學者采用雙束激光焊[63]、雙脈沖激光焊[64]等方法,也可以有效降低鋁合金焊縫裂紋問題。

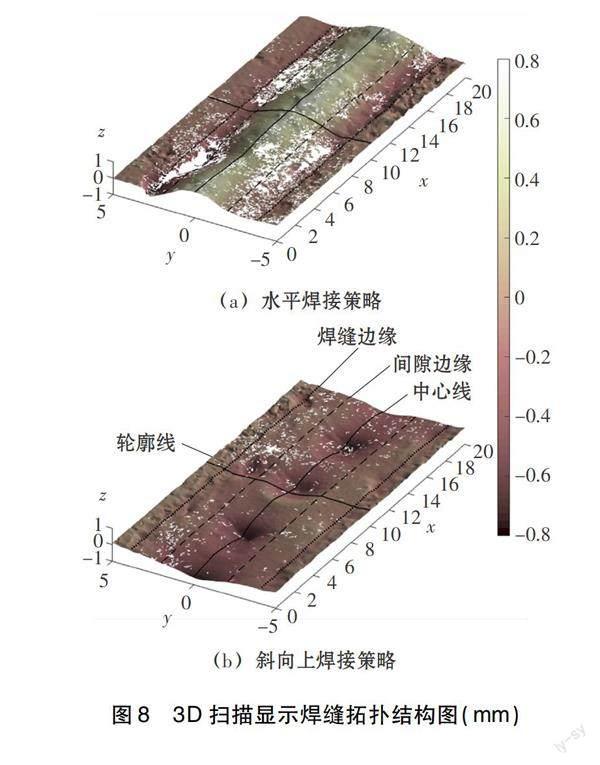

Nsstrm等學者[65]采用斜向上窄間隙激光多道焊焊接15 mm厚鋼板(圖7b[65]),與傳統水平窄間隙激光多道焊(圖7a[65])相比,水平焊接的焊縫表面成形均勻,但在焊縫邊緣有一些凹陷,在焊接縫中心有一些焊接凸起(圖8a[65]);而斜向上窄間隙激光多道焊焊縫的中間出現周期性的凹陷(圖8b[65])。2種方式得到的焊縫孔隙率均小于0.3%,但是采用斜向上窄間隙多層焊新方法的工藝魯棒性更好。

綜上所述,新型的激光焊方法一定程度上可以規避常規窄間隙焊中存在的側壁未熔合、氣孔等問題,極大的拓寬了窄間隙激光焊的應用領域。

3 窄間隙激光焊發展趨勢

近年來,窄間隙激光焊向著多能量場復合的方向發展。窄間隙激光填熱絲焊、電磁輔助激光焊和超窄間隙激光焊等新方法在一定程度上解決了窄間隙激光焊側壁未熔合、氣孔等缺陷,同時也拓寬了激光焊的應用領域。因此,隨著多能量場激光復合焊技術的不斷發展,窄間隙激光焊將有望在厚板焊接領域發揮更重要的作用。同時,相關研究也指出:在激光焊焊接過程中,激光光束作用在焊件表面上的溫度變化、焊件的應力應變變化、熔池的流動行為和匙孔的穩定性,很大程度上決定了焊縫的質量。因此,采用數值模擬對激光焊焊接過程中的溫度場、應力應變場和熔池流動進行分析,一定程度上能夠預測實際焊縫的成形情況,為實際激光焊焊接工藝參數的選擇提供理論指導和參考,更好的發揮出窄間隙激光焊的優勢。

4 結束語

激光焊因具有焊接速度快、熱輸入小和易于自動化等優點,受到了眾多研究機構的關注,取得了較多的研究成果,為該技術的推廣應用提供了理論基礎和技術支撐。側壁未熔合、氣孔和根部裂紋是窄間隙激光焊常見的焊接缺陷,若在焊接前對激光焊焊接過程進行數值模擬,通過對整個過程的熔池流動行為、匙孔穩定性行為、溫度場等進行分析,進而來優化工藝,也可揭示激光焊接復雜的物理過程及其連接機理,實現鈦合金、鎳基高溫合金、高強鋼、不銹鋼和鋁合金等材料的有效連接。同時,隨著電磁場輔助激光焊、擺動激光焊和真空激光焊等多能量場復合窄間隙激光焊的不斷發展,窄間隙激光焊將有望在厚板焊接領域發揮更重要的作用。

參考文獻

[1] You D Y, Gao X D, Katayama S. Review of laser welding monitoring [J]. Science and Technology of Welding and Joining, 2014, 19(3): 181-201.

[2] Wang Jianfeng, Sun Qingjie, Feng Jicai, et al. Characteristics of welding and arc pressure in TIG narrow gap welding using novel magnetic arc oscillation[J]. The International Journal of Advanced Manufacturing Technology, 2017, 90(1-4): 413-420.

[3] Chen Jicheng, Wei Yanhong, Zhan Xiaohong, et al. Weld profile microstructure and mechanical property of laser-welded butt joints of 5A06 Al alloy with static magnetic field support[J]. The International Journal of Advanced Manufacturing Technology, 2017, 92(5-8): 1677- 1686.

[4] Zhang Mingjun, Chen Shun, Zhang Yingzhe, et al. Mechanisms for improvement of weld appearance in autogenous fiber laser welding of thick stainless steels[J]. Metals, 2018, 8(8): 625.

[5] Ya Wei, Pathiraj B, Yu Xinghua. From statistical analysis to process optimization during cladding using a Nd:YAG laser[J]. China Welding, 2022, 31(4): 7-22.

[6] Mei Lifang, Yan Dongbing, Chen Genyu, et al. Comparative study on CO2 laser overlap welding and resistance spot welding for automotive body in white[J]. Materials and Design, 2015, 78: 107-117.

[7] Wang Lei, Xu Xuezong Wang Kehong, et al. Effect of shielding gas and defocusing on porosity during laser beam welding of 7A52 alloy[J]. China Welding, 2020, 29(3): 20-25.

[8] Sofia D, Barletta D,Poletto M. Laser sintering process of ceramic powders: the effect of particle size on the mechanical properties of sintered layers[J]. Additive Manufacturing, 2018, 23: 215-224.

[9] Hou Jijun, Dong Junhui, Bai Xueyu, et al. Weld shape and microstructure of TC4 laser welding with activating flux of Na2SiF6[J]. China Welding, 2020, 29(4): 19-24.

[10] Guo Wei , DongShiyun, Guo Wei, et al. Microstructure and mechanical characteristics of a laser welded joint in SA508 nuclear pressure vessel steel[J]. Materials Science and Engineering: A, 2015, 625: 65-80.

[11] Yu Y C, Yang S L, Yin Y, et al. Multi-pass laser welding of thick plate with filler wire by using a narrow gap joint configuration[J]. Journal of Mechanical Science and Technology, 2013, 27(7): 2125-2131.

[12] Li Junzhao, Wen Kai, Sun Qingjie, et al. The comparison of multi-layer narrow-gap laser and arc welding of S32101 duplex stainless steel[J]. China Welding, 2022, 31(4): 37-47.

[13] Elmesalamy A, Francis J A, Li L. A comparison of residual stresses in multi pass narrow gap laser welds and gas-tungsten arc welds in AISI 316L stainless steel[J]. International Journal of Pressure Vessels and Piping, 2014, 113: 49-59.

[14] 杜勇, 李峰, 夏希瑋, 等. TC4鈦合金窄間隙激光填絞股焊絲焊接接頭組織及性能[J]. 焊接, 2022(12): 1-5.

[15] 馮靖, 呂雪巖, 周曉鋒, 等. 熱連軋高強鈦合金厚壁管道的TIG工藝及組織和性能[J]. 焊接, 2022(1): 8-13.

[16] 肖珺, 雷一鼎, 陳樹君, 等. 基于多點柔性支撐的鈦合金激光焊接變形控制[J]. 焊接學報, 2022, 43(8): 8-12.

[17] Fang Naiwen, Guo Erjun, Huang Ruisheng, et al. Effect of welding heat input on microstructure and properties of TC4 titanium alloy ultra-narrow gap welded joint by laser welding with filler wire[J]. Materials Research Express, 2021, 8(1): 016511.

[18] Liu Jinzhao, Zhan Xiaohong, Gao Zhuanni, et al. Microstructure and stress distribution of TC4 titanium alloy joint using laser-multi-pass-narrow-gap welding[J]. The International Journal of Advanced Manufacturing Technology, 2020, 108(11-12): 3725-3735.

[19] Fang Naiwen, Guo Erjun, Xu Kai, et al. Effect of shielding gas on microstructures and mechanical properties of TC4 titanium alloy ultra-narrow gap welded joint by laser welding with filler wire[J]. Advances in Materials Science and Engineering, 2021, 2021: 9582421.

[20] Gui Zhenzhen, Min Guoqing, Liu Dejian, et al. Double-sided laser welding of dissimilar titanium alloys with linear variable thickness[J]. The International Journal of Advanced Manufacturing Technology, 2015, 79(9-12): 1597-1606.

[21] Zhang Yu, Jing Hongyang, Xu Lianyong, et al. Microstructure and mechanical performance of welded joint between a novel heat-esistant steel and Inconel 617 weld metal[J]. Materials Characterization, 2018, 139: 279-292.

[22] 種潤, 郭紹慶, 張文揚, 等. GH4169合金激光增材制造過程熱-力發展數值模擬[J]. 焊接, 2021(3): 13-21.

[23] 滕彬, 武鵬博, 李曉光, 等. GH3128合金激光焊接頭組織與性能[J]. 焊接學報, 2022, 43(7): 82-87.

[24] 王玨, 董建新, 張麥倉, 等. 700 ℃以上超超臨界電站鍋爐過熱器管材用典型鎳基合金的平衡析出相規律[J]. 北京科技大學學報, 2012, 34(7): 799-807.

[25] Keler B, Brenner B,Dittrich D, et al. Laser-multi-pass-narrow-gap-welding of nickel superalloy—alloy 617OCC[J]. Journal of Laser Application, 2019, 31(2): 022412.

[26] Thejasree P, Manikandan N, Binoj J S. Numerical simulation and experimental investigation on laser beam welding of Inconel 625[J]. Materials Today: Proceedings, 2021, 39: 268-273.

[27] Sun Junhao, Ren Wenjie, Nie Pulin, et al. Study on the weldability, microstructure and mechanical properties of thick Inconel 617 plate using narrow gap laser welding method[J]. Materials and Design, 2019, 175: 107823.

[28] Fink C,Zinke M. Welding of nickel-based alloy 617 using modified dip arc processes[J]. Welding in the World, 2013, 57(3): 323-333.

[29] Wu Shikai, Zhang Jianchao, Yang Jiaoxi, et al. Investigation on microstructure and properties of narrow-gap laser welding on reduced activation ferritic/martensitic steel CLF-1 with a thickness of 35 mm[J]. Journal of Nuclear Materials, 2018, 503: 66-74.

[30] Guo Wei, Li Lin, Dong Shiyun, et al. Comparison of microstructure and mechanical properties of ultra-narrow gap laser and gas-metal-arc welded S960 high strength steel[J]. Optics and Lasers in Engineering, 2017, 91: 1-15.

[31] Guo Wei, Li Lin, Crowther D, et al. Laser welding of high strength steels (S960 and S700) with medium thickness[J]. Journal of Laser Applications, 2016, 28(2): 002425.

[32] Ning Jie, Zhang LinJie, Yang Jiannan, et al. Characteristics of multi-pass narrow-gap laser welding of D406A ultra-high strength steel[J]. Journal of Materials Processing Technology, 2019, 270: 168-181.

[33] Shi Hao, Zhang Ke, Xu Zhengyi, et al. Applying statistical models optimize the process of multi-pass narrow-gap laser welding with filler wire[J]. The International Journal of Advanced Manufacturing Technology, 2014, 75(1-4): 279-291.

[34] Ragavendran M, Vasudevan M. Laser and hybrid laser welding of type 316L(N) austenitic stainless steel plates[J]. Materials and Manufacturing Processes, 2020, 35(8): 922-934.

[35] Yang Wuxiong, Xin Jijun, Fang Chao, et al. Microstructure and mechanical properties of ultra-narrow gap laser weld joint of 100 mm-thick SUS304 steel plates[J]. Journal of Materials Processing Technology, 2019, 265: 130-137.

[36] Tan Caiwang, Yang Jia, Zhao Xiaoye, et al. Influence of Ni coating on interfacial reactions and mechanical properties in laser welding-brazing of Mg/Ti butt joint[J]. Journal of Alloys and Compounds, 2018, 764: 186-201.

[37] Zhou L, Li G H, Zhang R X, et al. Microstructure evolution and mechanical properties of friction stir spot welded dissimilar aluminum-copper joint[J]. Journal of Alloys and Compounds, 2019, 775: 372-382.

[38] Geng Huihui, Xia Zehua, Zhang Xu, et al. Microstructures and mechanical properties of the welded AA5182/HC340LA joint by magnetic pulse welding[J]. Materials Charactization, 2018, 138: 229-237.

[39] 范霽康, 倪程, 徐鴻林, 等. 3003鋁合金激光焊接組織和力學性能[J]. 焊接, 2021(3): 22-25.

[40] Zhang Zhihui, Dong Shiyun, Wang Yujiang, et al. Microstructure characteristics of thick aluminum alloy plate joints welded by fiber laser[J]. Materials and Design, 2015, 84: 173-177.

[41] Zhang Z H, Dong S Y, Wang Y J, et al. Study on microstructures and mechanical properties of super narrow gap joints of thick and high strength aluminum alloy plates welded by fiber laser[J]. The International Journal of Advanced Manufacturing Technology, 2016, 82(1-4): 99-109.

[42] Suckow T, Vlkers S, cal E B, et al. Effect of shortened post weld heat treatment on the laser welded AA7075 alloy[J]. Metals, 2022, 12(3): 393.

[43] Li Ruoyang, Wang Tianjiao, Wang Chunming, et al. A study of narrow gap laser welding for thick plates using the multi-layer and multi-pass method[J]. Optics and Laser Technology, 2014, 64: 172-183.

[44] Zhang Chen, Li Geng, Gao Ming, et al. Microstructure and mechanical properties of narrow gap laser-arc hybrid welded 40 mm thick mild steel[J]. Materials, 2017, 10(2): 106.

[45] Kaplan A F H, Kim K H, Bang H S, et al. Narrow gap laser welding by multilayer hot wire addition[J]. Journal of Laser Application, 2016, 28 (2): 022410.

[46] Wei Haiying, Zhang Yi, Tan Lipeng, et al. Energy efficiency evaluation of hot-wire laser welding based on process characteristic and power consumption[J]. Journal of Cleaner Production, 2015, 87: 255-262.

[47] Liu Wei, Liu Shuang, Ma Junjie, et al. Real-time monitoring of the laser hot-wire welding process[J]. Optics and Laser Technology, 2014, 57: 66-76.

[48] Li Junzhao. Liu Yibo, Zhen Zuyang, et al. Analysis and improvement of laser wire filling welding process stability with beam wobble[J]. Optics and Laser Technology, 2021, 134: 106594.

[49] Wu Q, Xiao R S, Zou J L, et al. Weld formation mechanism during fiber laser welding of aluminum alloys with focus rotation and vertical oscillation[J]. Journal of Manufacturing Processes, 2018, 36: 149-154.

[50] Fetzer F, Martin S, Weber R, et al. Reduction of pores by means of laser beam oscillation during remote welding of Al-Mg-Si[J]. Optics and Lasers in Engineering, 2018, 108: 68-77.

[51] Hagenlocher C, Sommer M, Fetzer F, et al. Optimization of the solidification conditions by means of beam oscillation during laser beam welding of aluminum[J]. Materials and Design, 2018, 160: 1178-1185.

[52] Wang Lei, Gao Ming, Zhang Chen, et al. Effect of beam oscillating pattern on weld characterization of laser welding of AA6061-T6 aluminum alloy[J]. Materials and Design, 2016, 108: 707-717.

[53] Guo Wei, Liu Qiang, Francis J A, et al. Comparison of laser welds in thick section S700 high strength steel manufactured in flat (1G) and horizontal (2G) positions[J]. CIRP Annals-Manufacturing Technology, 2015, 64(1): 197-200.

[54] Guo Wei, Crowther D, Francis J A, et al. Process-parameter interactions in ultra-narrow gap laser welding of high strength steels[J]. The International Journal of Advanced Manufacturing Technology, 2016, 84(9-12): 2547-2566.

[55] Elmesalamy A S, Li L, Francis J A, et al. Understanding the process parameter interactions in multiple-pass ultra-narrow-gap laser welding of thick-section stainless steels[J]. The International Journal of Advanced Manufacturing Technology, 2013, 68(1-4): 1-17.

[56] Wang Jiming, Peng Genchen, Li Liqun, et al. 30 kW-level laser welding characteristics of 5A06 aluminum alloy thick plate under sub-atmospheric pressure[J]. Optics and Laser Technology, 2019, 119: 105668.

[57] Gao Ming,Kawahito Y, Kajii S. Observation and understanding in laser welding of pure titanium at sub-atmospheric pressure[J]. Optics Express, 2017, 25(12): 13539.

[58] Jiang Meng, Tao Wang, Wang Shuliang, et al. Effect of ambient pressure on interaction between laser radiation and plasma plume in fiber laser welding[J]. Vacuum, 2017, 138: 70-79.

[59] Luo Yan, Tang Xinhua, Lu Fenggui, et al. Effect of sub-atmospheric pressure on plasma plume in fiber laser welding[J]. Journal of Materials Processing Technology, 2015, 215: 219-224.

[60] Li Liqun, Peng Genchen, Wang Jiming, et al. Numerical and experimental study on keyhole and melt flow dynamics during laser welding of aluminum alloys under sub-atmospheric pressure[J]. International Journal of Heat and Mass Transfer, 2019, 133: 812-826.

[61] Qi Yi, Chen Genyu. Root defects in full penetration laser welding of thick plates using steady electromagnetic force[J]. Journal of Materials Processing Technology, 2018, 260: 97-103.

[62] Xu Lidong, Tang Xinhua, Zhang Ruolin, et al. Weld bead characteristics for full-penetration laser welding of aluminum alloy under electromagnetic field support[J]. Journal of Materials Processing Technology, 2021, 288: 116896.

[63] Coniglio N, Patry M. Measuring laser weldability of aluminum alloys using controlled restraint weldability test[J]. Science and Technology of Welding and Joining, 2013, 18(7): 573-580.

[64] von Witzendorff P, Hermsdorf J, Kaierle S, et al. Double pulse laser welding of 6082 aluminum alloys[J]. Science and Technology of Welding and Joining, 2015, 20(1): 42-47.

[65] Nsstrm J, Brueckner F, Kaplan A F H. A near-vertical approach to laser narrow gap multi-layer welding[J]. Optics and Laser Technology, 2020, 121: 105798.

收稿日期: 2022-12-12

駱傳萬簡介: 碩士研究生;主要從事激光焊接機理的研究;2634187248@qq.com。

馮杰才簡介: 通信作者,博士,副教授;主要從事激光焊、激光清洗、激光熔覆、激光切割等激光加工技術的研究;已發表論文30余篇;fengjiecai@shu.edu.cn。