電石渣礦化CO2-可控制備碳酸鈣的實驗研究

丁文金 劉卓齊 陳秋菊 孫紅娟 彭同江

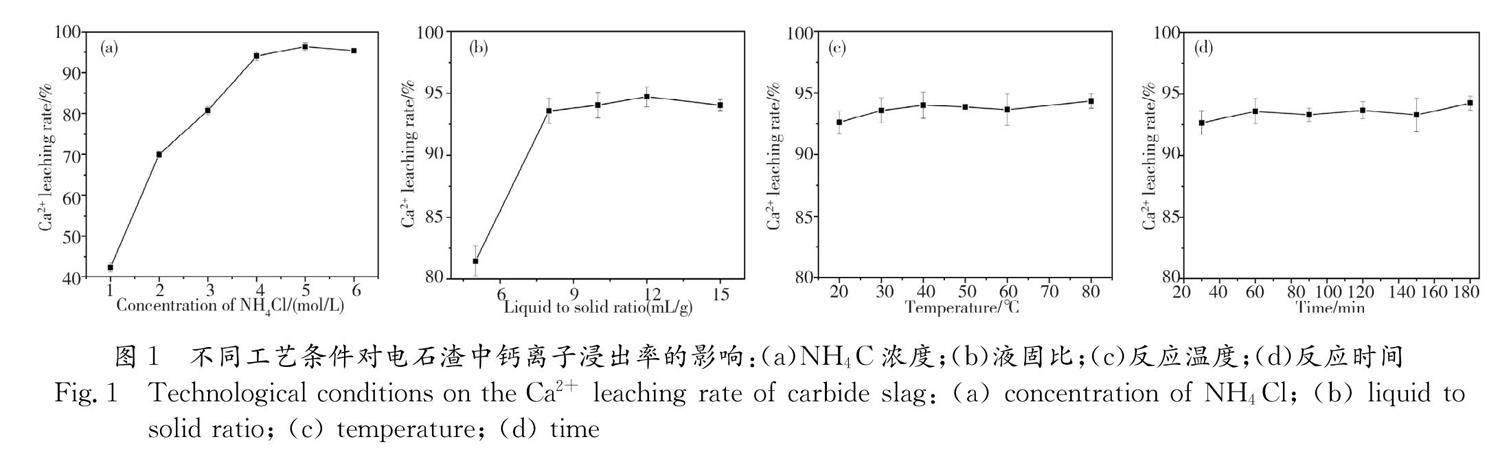

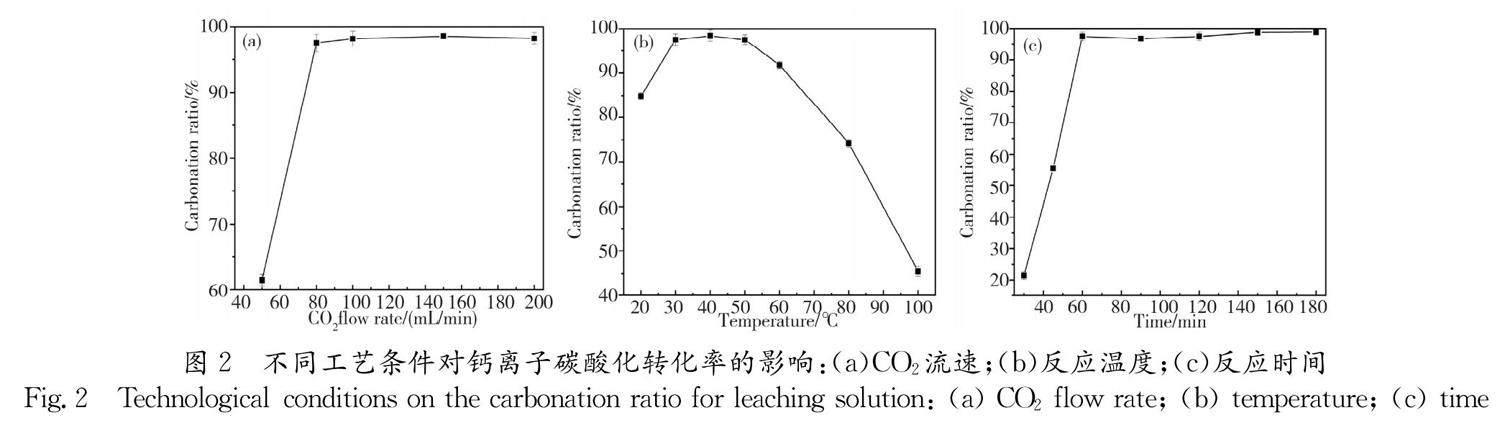

摘 要 ???:本文提供了一種以電石渣為原料,循環利用氯化銨制備高純碳酸鈣的方法;通過實驗系統討論了碳酸鈣制備的工藝條件以及不同工藝條件對所得碳酸鈣晶型與形貌的影響. 結果表明:碳酸鈣制備的優化工藝條件為CO ?2流速 80 mL/min,反應溫度30 ℃,反應時間60 min;所得產物為納米的球形球霰石,產物中CaCO ?3的含量為99.95%,白度為99.3%,產物具體良好的自流動性和自粉化性;整個制備工藝中碳酸化反應濾液可循環利用8次,此時的反應效能大于50%;通過工藝條件的調控成功制備出高純納米碳酸鈣、球霰石型碳酸鈣、文石型碳酸鈣以及方解石型碳酸鈣. 論文提出的研究方案有望應用于電石渣的資源化利用與碳酸鈣的可控制備.

關鍵詞 :電石渣; CO ?2礦化; 晶型; 形貌; 循環利用

中圖分類號 : X781 文獻標識碼 :A DOI : ?10.19907/j.0490-6756.2023.045001

收稿日期: ?2023-04-03

基金項目: ?四川省自然科學基金面上項目(2023NSFSC0348); 四川省科技創新創業苗子工程重點項目(2023JDRC0070)

作者簡介: ??丁文金(1985-), 男, 博士, 江蘇興化人, 主要從事工業固廢資源化利用研究. E-mail: dwjdykclx@163.com

Controllable preparation of CaCO ?3 from carbide slag by CO ?2 sequestration

DING Wen-Jin ?1,2, LIU Zhuo-Qi ?1,2, CHEN Qiu-Ju ?1,2, SUN Hong-Juan ?1,2, PENG Tong-Jiang ?1,2

(1. Key Laboratory of Solid Waste Treatment and Recycling, Ministry of Education, ?Southwest University of Science and Technology, Mianyang 621010, China;

2. Institute of Mineral Materials and Applications, Southwest University of ?Science and Technology, Mianyang 621010, China)

In this paper, a method was proposed to prepare high-purity CaCO ?3 to sequester CO ?2 by means of the cyclic utilization of ammonium chloride and with carbide slag as the raw material. There was a systematical discussion about the process conditions for carbonation reaction and the effect of different technological conditions on the property of reaction product. The results have shown that the optimum process conditions for the carbonation reaction were as follows: reaction time: 60 min, reaction temperature: 30 ℃, and the flow velocity of CO ?2: 80 mL/min. The optimum carbonated conversion rate was 98.99%. The resulting product was nanoscale spherical vaterite with a CaCO ?3 content of 99.95%, a whiteness of 99.3% and good self-fluidity and self-pulverability. The carbonation reaction filtrate could be recycled 8 times throughout the preparation process, and the reaction efficiency at this time was greater than 50%. High-purity nanoscale CaCO ?3 and fibrous CaCO ?3 could be successfully prepared by the control of process conditions. The study scheme proposed herein is hopeful to be used to the extraction of CO ?2 from carbide slag and the controlled preparation of CaCO ?3.

Carbide slag; CO ?2 sequestration; Crystal phase; Morphology; Cyclic utilization

1 引 言

電石渣是電石法生產乙炔時產生的一種以氫氧化鈣為主要成分的固體廢棄物,每生產1噸乙炔約產生1.2~1.8噸的電石渣. 目前我國電石渣的年產量約為4000萬噸,累積的堆存量超過1億噸 ?[1]. 傳統的電石渣主要采用露天堆放或掩埋處理,不僅占用大量土地資源,而且由于堆積過程缺少防滲處理,電石渣易污染堿化土壤,對空氣、地表水以及地下水產生嚴重侵蝕 ?[2],同時電……