基于線(xiàn)激光掃描的葉片三維型面重構(gòu)方法

董潔 王宗平 歐登熒 陳龍慶 謝羅峰 殷國(guó)富

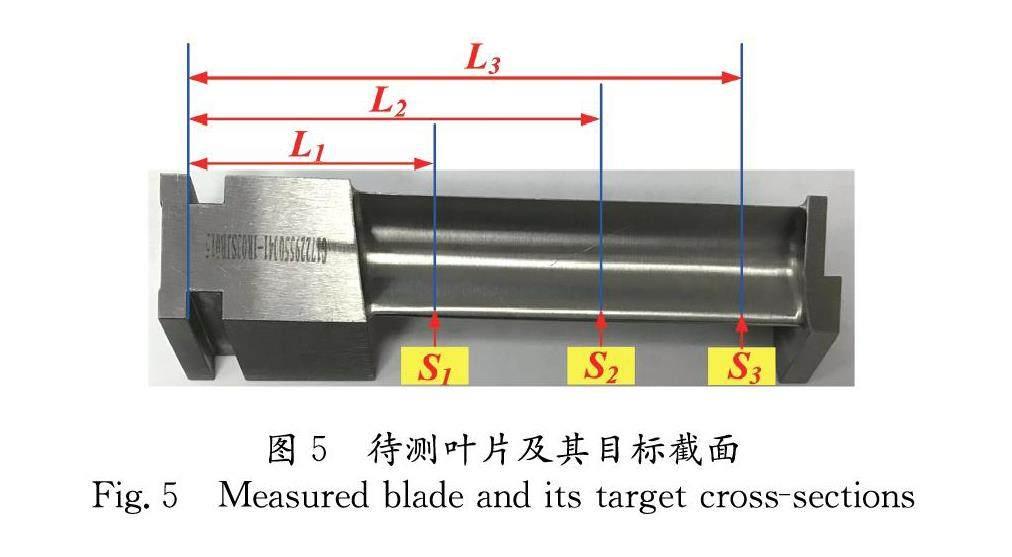

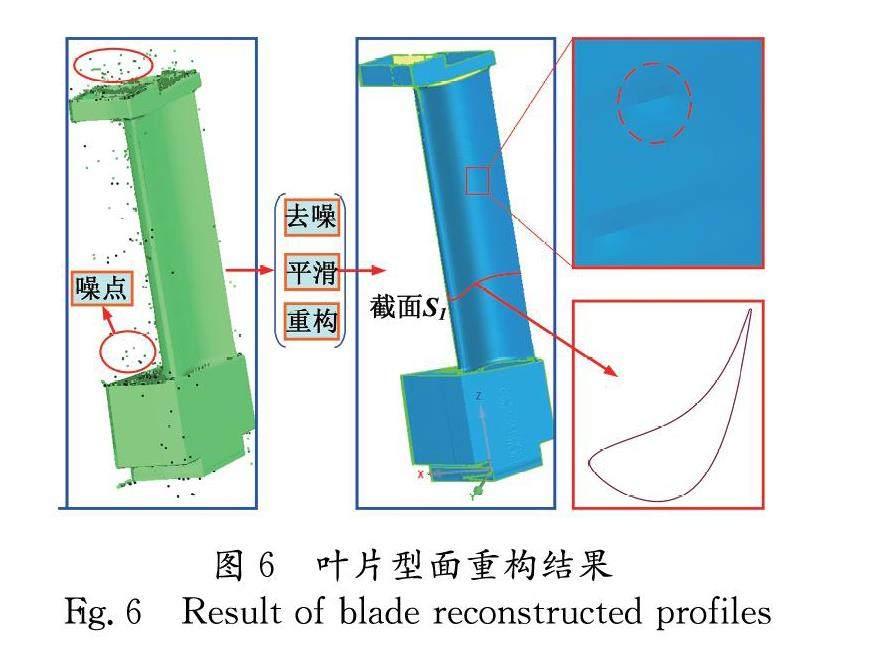

葉片作為航空發(fā)動(dòng)機(jī)的核心部件,對(duì)整機(jī)的安全性和可靠性起著關(guān)鍵性作用.一直以來(lái)葉片型面的尺寸、形狀精度在加工和檢測(cè)過(guò)程中均有著嚴(yán)格要求.為此,本文提出一種基于線(xiàn)激光掃描的葉片三維型面重構(gòu)方法.首先,基于研制的葉片四軸檢測(cè)裝置,結(jié)合線(xiàn)性編碼器與線(xiàn)激光傳感器實(shí)現(xiàn)了葉片型面的快速掃描與數(shù)據(jù)采集.然后,提出基于葉片基準(zhǔn)面幾何特征的多視場(chǎng)掃描數(shù)據(jù)拼接方法,完成了葉片型面的高精度重構(gòu).最后,以典型葉片為實(shí)驗(yàn)對(duì)象進(jìn)行型面重構(gòu)實(shí)驗(yàn),并將重構(gòu)數(shù)據(jù)與三坐標(biāo)測(cè)量結(jié)果進(jìn)行對(duì)比.結(jié)果表明葉片截面輪廓的平均偏差在0.040 mm以?xún)?nèi),標(biāo)準(zhǔn)差小于0.028 mm.驗(yàn)證了提出的葉片型面重構(gòu)方法的精確性與可行性.

線(xiàn)激光; 葉片型面; 三維重構(gòu); 多視場(chǎng)數(shù)據(jù)拼接

Th741A2023.034001

收稿日期: 2022-09-22

基金項(xiàng)目: 四川省科技廳項(xiàng)目(2022YFG0358, 2021YFG0049); 四川省科技計(jì)劃(2022ZDZX0034); 德陽(yáng)市科技計(jì)劃(2021JBJZ001); 中央高校基金業(yè)務(wù)費(fèi)(2021SCU12146)

作者簡(jiǎn)介: 董潔 (1991-), 女, 甘肅慶陽(yáng)人, 博士研究生, 主要研究方向?yàn)楹娇瞻l(fā)動(dòng)機(jī)葉片光學(xué)檢測(cè). E-mail: 250511550@qq.com

通訊作者: 王宗平. E-mail: 1522156141@qq.com

Reconstruction method of blade 3D profile based on line-laser scanning

DONG Jie1,3, WANG Zong-Ping2, OU Deng-Ying2, CHEN Long-Qing4, XIE Luo-Feng2, YIN Guo-Fu2

(1.Chengdu Aeronautic Polytechnic, Chengdu 610100, China; 2. School of Mechanical Engineering, Sichuan University, Chengdu 610065, China; 3. School of Aeronautics and Astronautics, Sichuan University, Chengdu 610065, China; 4. Key Laboratory of Radiation Physics and Technology of the Ministry of Education, Institute of Nuclear Science and Technology, Sichuan University, Chengdu 610065, China)

As the core component of aero-engine, the blade plays a key role in its safety and reliability. The dimension and shape accuracy of the blade profile have always been strictly required in the process of blade machining and measuring. Thus, in this paper we propose a method for reconstructing the three-dimensional profile based on line-laser scanning. First, based on the developed four-axis blade measurement device, the rapid scanning and data acquisition of the blade profile are realized by combining the linear encoder and the line laser sensor. Then, a registration method based on the geometric features of the blade datum plane is further proposed to align the multi-view scanning data of blade profile, and the high precision reconstruction of the blade profile are achieved accordingly. Finally, a typical blade is taken as the experimental object for profile reconstruction experiment, and the profile reconstruction data is compared with the CMM measurement results from the same blade. The results show that the average deviation of cross-sections in blade profile is less than 0.040 mm and the standard deviation is less than 0.028 mm. This demonstrates the accuracy and feasibility of the proposed method.

Line-laser; Blade profile; 3D reconstruction; Multi-view data registration

1 引 言

葉片作為航空發(fā)動(dòng)機(jī)中為數(shù)眾多的核心部件,通常在高溫、高壓、高載荷等惡劣環(huán)境中長(zhǎng)期循環(huán)往復(fù)工作,使得發(fā)動(dòng)機(jī)的綜合性能在很大程度上取決于葉片的設(shè)計(jì)與制造水平[1,2].此外,作為能量轉(zhuǎn)換的核心載體,葉片在制造過(guò)程中還必須滿(mǎn)足較高的尺寸與形狀精度以及嚴(yán)格的表面完整性[3].因此,開(kāi)展葉片……