鈣質砂中靜力觸探試驗的大變形有限元模擬

裴會敏 王棟 劉清秉

摘 要:靜力觸探試驗(CPT)被廣泛用于確定無黏性土的力學性質,現有研究集中在普通石英砂,由CPT貫入阻力推測鈣質砂強度特性的成果很少。鈣質砂的峰值內摩擦角一般高于石英砂,內摩擦角和剪脹角隨應變的變化也不同于石英砂。采用任意拉格朗日歐拉公式的大變形有限元方法,模擬石英砂和鈣質砂中CPT的完整貫入過程,有效避免了錐尖周圍的網格扭曲。引入修正摩爾庫倫模型描述石英砂和鈣質砂強度發揮與塑性剪應變的關系,由彎曲元和三軸排水試驗確定本構模型參數。數值模擬得到的錐尖貫入阻力與離心機試驗結果吻合,表明建立的數值模型能夠模擬鈣質砂中的CPT試驗。

關鍵詞:靜力觸探試驗;鈣質砂;有限元;大變形分析

1 Introduction

The cone penetration test (CPT) is arguably the most important in-situ test in geotechnical investigation. The measured cone resistance can be used to estimate soil properties and pile tip resistance. The analytical approaches used in studying the cone penetration in sands include bearing theories by limit plasticity or slip-line analysis, cavity expansion theories and strain path method[1-3]. Numerically, Mahmoodzadeh et al., Huang et al. and Ahmadi & Dariani reproduced the CPT using different finite element approaches[4-6]. The model tests in the calibration chamber were conducted as well, to validate the above theoretical and numerical results[7].

Most existing studies on the CPT in sands have focused on ordinary silica sands, and studies on the practical applications of CPT in calcareous sands are very limited. Calcareous sands are composed of calcium carbonate particles originating from sedimentation or chemical precipitation, and commonly appear between 30°N latitude and 30°S latitude. Compared with silica sands, features of calcareous sands include an inner pore, more irregular shapes, cementation and particle breakage. Calcareous sands have higher internal friction angles[8], but particle breakage may cause greater strength reduction. It is still not clear if the cone penetration resistance in calcareous sand follows a similar tendency to that of silica sands.

The aim of this paper was to reproduce the CPT in calcareous sands using a large deformation finite element approach. A modified Mohr-Coulomb constitutive model was adopted, considering the strain-softening and elastic stiffness to be varied by stress level. The CPT in silica sands is replicated as well, for comparison.

2 Methodology

2.1 ALE technique

The Arbitrary Lagrangian Eulerian (ALE) function in commercial finite element package Abaqus was used to simulate the cone penetration. The Arbitrary Lagrangian Eulerian technique combines the Lagrangian and Eulerian steps, allowing the mesh to move independently of the material, leaving the remaining mesh topology unchanged. The equilibrium equations, boundary conditions, external loads and contact conditions are satisfied, as in conventional Lagrangian analyses, followed by relocating the nodes and remapping all variables from the old mesh to the new mesh[9]. Therefore, a high-quality mesh is maintained when large deformations occur. Since the far-field soil elements are not seriously distorted during the entire cone penetration, the ALE technique was applied to soil elements around the cone only.

2.2 Soil models

The CPTs in silica or calcareous sands are performed under nearly drained conditions. The total stress analysis is thus sufficient to reproduce the soil response. The soil around the cone undergoes large deformation, and the traditional Mohr-Coulomb model with fixed internal friction angle φ and dilation angle ψ cannot capture the evolution of the mobilized soil strength. Therefore, the Mohr-Coulomb model was modified here to describe the strain-softening response of medium dense or dense sands under drained conditions. The elastic response was captured by Poisson's ratio and elastic shear modulus G as a function of the stress level and void ratio. Poisson's ratio was selected empirically as 0.3 for both silica and calcareous sands.

2.2.1 Shear modulus of sands

The CPT in two sands,KW sand and UWA sand, is studied through ALE analysis incorporating the modified Mohr-Coulomb model. The KW sand is natural calcareous sand from Perth, Australia. Although the calcareous sands spreading in a number of onshore and offshore areas are vulnerable to particle breakage, it was not found in the centrifuge tests with KW sands[10]. The UWA sand is commercial fine silica sand widely used in the physical model tests at the University of Western Australia. The maximum and minimum void ratios of KW sand are emax=1.42 and emin=0.89, while emax=0.78 and emin=0.49 for UWA sand. The particle size distributions of KW sand and UWA sand are given in Fig.1.

The maximum shear modulus G0 of KW sand and UWA sand are determined through the bender element tests. For KW sand, Fig.2 shows the variation of the normalized maximum shear modulus with the normalized mean effective pressure, p′/pa, where pa is the atmospheric pressure. The maximum shear modulus is usually regarded as a function of the void ratio e and p′[11]. The testing data in Fig.2 can be fitted as

Chow et al. reported that the testing results of G0 of UWA sand can be expressed as[12]

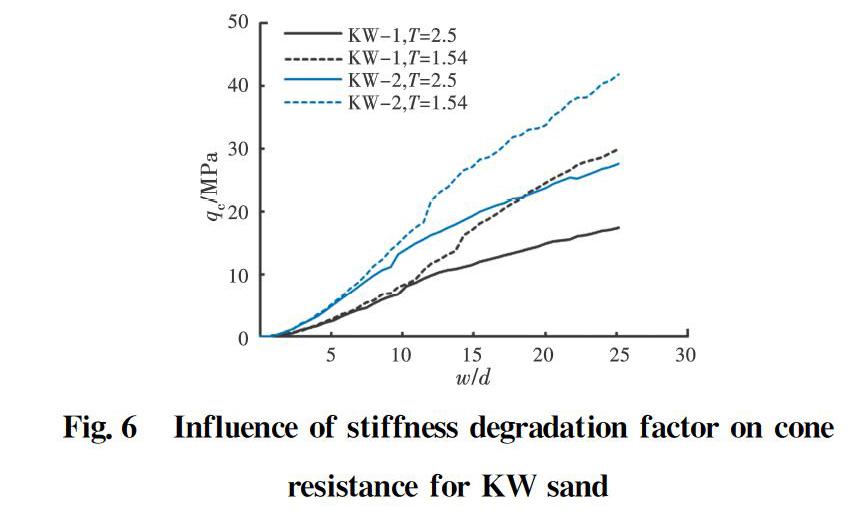

The maximum shear modulus G0 refers to strains at 10-7 ~ 10-6, while the shear modulus G at relatively large strains is smaller. Papadimitriou et al. and Loukidis & Salgado proposed the degradation of the shear modulus as G=G0/T, where T is the degradation factor[13-14]. Here, the value of T is determined by back-analyzing a centrifuge test in Liu & Lehane[10]: the test for dense sand, KW-1 in Table 1, was simulated using the ALE analysis, and the degradation factor was calibrated as T=2.5. Similarly, the degradation factor of the UWA sand was determined as T=1.54 through the test of UWA-1 in Table 1.

Results of the ALE analyses and centrifuge tests for KW sand and UWA sand are compared in Fig.5(a) and (b), respectively. qc is the base resistance and w is the penetration depth in the figure. A good agreement between the numerical and experimental data is achieved, suggesting that the modified Mohr-Coulomb model has the potential to capture the basic behaviors of both the UWA and KW sands. The percentage of particles finer than 1 mm is more than 95% for KW sand (see Fig.1), so the particle breakage of such fine sand sample was not observed in the centrifuge tests. It is not clear if the modified Mohr-Coulomb can be used for calcareous sands with strong particle breakage.

In Fig.5, the cone resistance qc is increased nearly linearly with the penetration depth at the depth larger than 10d. Compared to UWA sand, the qc in KW sand is remarkable lower when penetrating at the same depth although the φcv of KW sand is higher than that of UWA sand. Given a similar relative density, the void ratio of UWA sand is smaller than that of KW sand due to the smaller limit void ratio so that the effective density of the UWA sand is larger. Also, the shear modulus of the UWA sand is larger than that of the KW sand. For the KW sand, the degradation factor T=2.5 is larger than that of the UWA sand. If T=1.54 is employed for the KW sand, the cone resistance would be increased remarkably (see Fig.6). For both the KW and UWA sands, the mobilized friction angle and the dilation angle around the cone are varied with the plastic strain, gradually approaching the critical values (Fig.7 and 8). The contour of the equivalent plastic strain in Fig.7(c) and Fig.8(c) shows that the plastic zone around the penetrometer is similar to those illustrated in Huang et al. The plastic zone is expanded gradually and moves downwards with the cone[5].

4 Conclusions

The cone penetration in silica and calcareous sands was investigated using the Arbitrary Lagrangian Eulerian method. A modified Mohr-Coulomb model was employed to describe the strength evolutions of silica and calcareous sands, with the soil properties determined through bender element and drained triaxial tests. The variation of the cone resistance with penetration depth was obtained for different stress levels. A relatively good agreement between the numerical and experimental cone resistance profiles was achieved, suggesting that the modified Mohr-Coulomb model is suitable for calcareous sands without strong particle breakage.

Acknowledgements

The authors would like to acknowledge the financial support from the National Natural Science Foundation of China (Grant No. 41772294, U1806230).References:

[1] JANBU N, SENNESET K. Effective stress interpretation of in situ static penetration tests [C]//Proceedings of the 1st European Symposium on Penetration Testing. 1974, 2: 181-93.

[2] SALGADO R, MITCHELL J K, JAMIOLKOWSKI M. Cavity expansion and penetration resistance in sand [J]. Journal of Geotechnical and Geoenvironmental Engineering, 1997, 123(4): 344-354.

[3] BALIGH M M. Strain path method [J]. Journal of Geotechnical Engineering, 1985, 111(9): 1108-1136.

[4] MAHMOODZADEH H, RANDOLPH M, WANG D. Numerical simulation of piezocone dissipation test in clays [J]. Geotechnique, 2014, 64(8): 657-666.

[5] HUANG W, SHENG D, SLOAN S W, et al. Finite element analysis of cone penetration in cohesionless soil [J]. Computers and Geotechnics, 2004, 31(7): 517-528.

[6] AHMADI M M, GOLESTANI DARIANI A A. Cone penetration test in sand:A numerical-analytical approach [J]. Computers and Geotechnics, 2017, 90: 176-189.

[7] HOULSBY G T, HITCHMAN R. Calibration chamber tests of a cone penetrometer in sand [J]. Geotechnique, 1988, 38(1): 39-44.

[8] COOP M R. The mechanics of uncemented carbonate sands [J]. Geotechnique, 1990, 40(4): 607-626.

[9] WANG D, BIENEN B, NAZEM M, et al. Large deformation finite element analyses in geotechnical engineering [J]. Computers and Geotechnics, 2015, 65: 104-114.

[10] LIU Q B, LEHANE B M. A centrifuge investigation of the relationship between the vertical response of footings on sand and CPT end resistance [J/OL]. Géotechnique, 2020: 1-11. http://doi.org/10.1680/jgeot.19.P.253.

[11] HARDIN B O, BLACK W L. Sand stiffness under various triaxial stresses [J]. Journal of the Soil Mechanics and Foundations Division, 1966, 92(2): 27-42.

[12] CHOW S H, ROY A, HERDUIN M, et al. Characterisation of UWA superfine silica sand [R]. 2019.

[13] PAPADIMITRIOU A G, BOUCKOVALAS G D, DAFALIAS Y F. Plasticity model for sand under small and large cyclic strains [J]. Journal of Geotechnical and Geoenvironmental Engineering, 2001, 127(11): 973-983.

[14] LOUKIDIS D, SALGADO R. Modeling sand response using two-surface plasticity [J]. Computers and Geotechnics, 2009, 36(1/2): 166-186.

[15] POTTS D M, KOVACEVIC N, VAUGHAN P R. Delayed collapse of cut slopes in stiff clay [J]. Geotechnique, 1997, 47(5): 953-982.

[16] HU P, WANG D, STANIER S, et al. Assessing the punch-through hazard of aspudcan on sand overlying clay [J]. Geotechnique, 2015, 65(11): 883-896.

[17] TRONCONE A. Numerical analysis of a landslide in soils with strain-softening behaviour [J]. Geotechnique, 2005, 55(8): 585-596.

(編輯 章潤紅)