基于6-UCU型平臺并聯機床的軌跡時間優化

嚴昊 吳建民

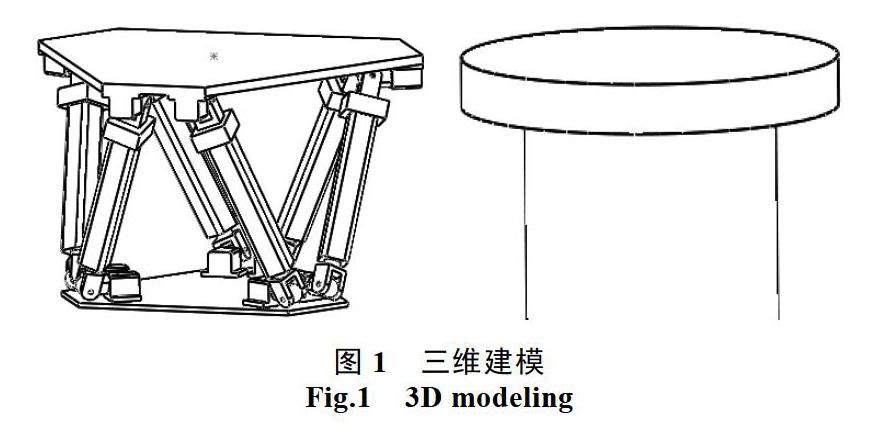

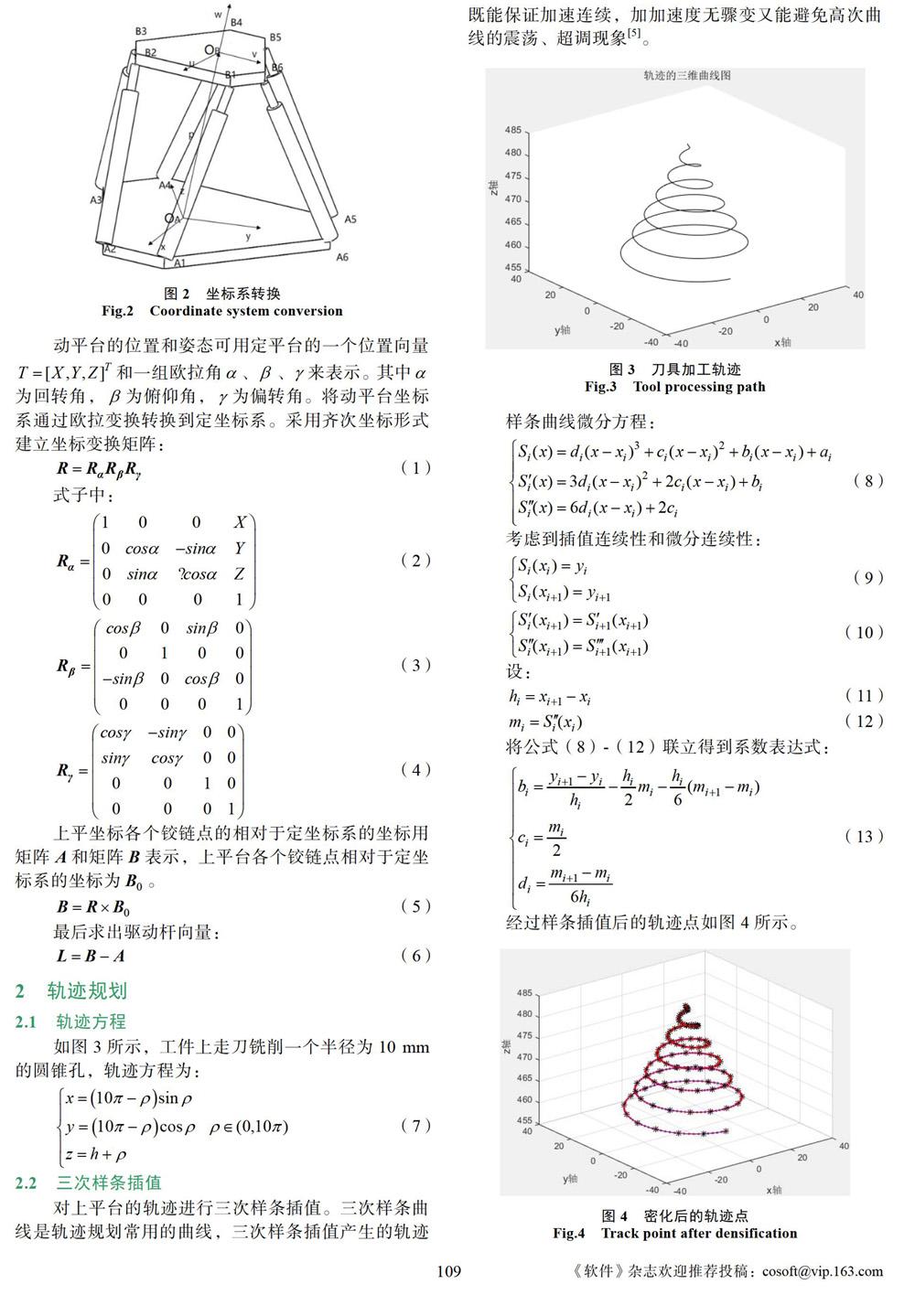

摘 ?要: 本文針對基于6-UCU型Stewart平臺的并聯機床提出了一種軌跡時間優化方法。建立該運動平臺的運動學逆解模型。通過三次多項式插值對上平臺的軌跡點進行插值,通過反解模型求出各個驅動臂對應的位移。建立時間優化的模型,使用遺傳算法結合五次多項式插值對軌跡點之間的速度,加速度進行求解。計算得出優化后的運行時間與未優化前對比優化了14.9%。最后將得到的加速度導入到ADMAS模型中進行仿真驗證,結果表明該軌跡運行平穩,仿真測量的驅動臂位移與計算得出無明顯差別。

關鍵詞: Stewart平臺;遺傳算法;軌跡優化

中圖分類號: TP249 ???文獻標識碼: A ???DOI:10.3969/j.issn.1003-6970.2020.09.030

【Abstract】: This paper proposes a trajectory time optimization method for parallel machine tools based on the 6-UCU Stewart platform. In this paper, the inverse kinematics model of the motion platform was established firstly. The trajectory points of the upper platform are interpolated by cubic polynomial interpolation, and the corresponding displacement of each driving arm is obtained by the inverse solution model. Establish a time-optimized model and use genetic algorithm combined with fifth-degree polynomial interpolation to solve the velocity and acceleration between trajectory points. It is calculated that the optimized running time is optimized by 14.9% compared with that before the optimization. Finally, the obtained acceleration was imported into the ADMAS model for simulation verification. The results show that the trajectory runs smoothly, and the measured displacement of the driving arm is not significantly different from the calculation.

【Key words】: Stewart platform; Genetic algorithm; Trajectory optimization

0 ?引言

隨著機器人技術的進步,各種各樣的機器人投入到了生產中取代人力進行繁重、重復的人力勞動。基于這種現狀,一些專家學者著手研究對機器人的運行軌跡進行時間的優化,來進一步提高生產效率。Geering[1]等人利用Pontryagin最小化原理,提出了一種機器人最優時間的軌跡規劃方法。Cong M[2]提出了一種基于模糊遺傳算法,基于速度和加速度的約束條件下,對軌跡運行時間進行優化。施祥玲等[3]以從時間、能耗、沖擊三方面考慮對串聯機械臂,建立五次非均勻有理B樣條模型,采用NSGA-II算法求解實現了有效的多目標優化。王宇[4]使用三次樣條插值對3R串聯機器人進行估計規劃,并提出了一種基于遺傳算法的時間優化方法。

本文以6-UCU型Stewart并聯機構為研究對象,針對其在并聯機床的應用場景,在保證其平穩運行的前提下,對其運行軌跡進行時間上的優化。……