小直徑管材全位置自動對接焊工藝及接頭組織與性能

胡德虎 李博鋒

摘要: 對小直徑低合金管材進行全位置TIG對接焊工藝試驗,分析其工藝特點及焊接接頭組織與力學性能。分析認為:焊接工藝參數需要根據熔池的受力特點分區段進行設置,以獲得合適的熔池大小,達到熔池各作用力之間的合理匹配,從而獲得良好的焊縫成形。焊縫組織為鐵素體和粒狀貝氏,熱影響區各區組織不同,熔合區及粗晶區為粗大的粒狀貝氏體,相變重結晶區組織為貝氏體以及細小均勻的鐵素體。不完全重結晶區為鐵素體、珠光體和貝氏體。焊接接頭各區域硬度相差不大,拉伸、彎曲以及抗內壓性能滿足相關標準要求。

關鍵詞: 低合金鋼;管材;焊接;對接接頭;組織;力學性能;

中圖分類號: TG 444

Abstract: All position TIG butt welding process test of small diameter low alloy tubing ?was carried out. The process characteristics, microstructure and mechanical properties of welded joint were analyzed.According to the analysis, the welding process parameters should be set in different sections according to the stress characteristics of the weld pool, so as to obtain the appropriate size of the weld pool and achieve the reasonable matching between the forces of the pool.The microstructure of the weld is ferrite and granular bainite. The microstructure of heat affected zone is different. The fusion zone and coarse grain zone are coarse granular bainite, and the finegrained region zone is composed of bainite and fine and uniform ferrite.The incomplete recrystallization region is pearlite, ferrite and bainite. The hardness of each area of the welded joint has little difference, and the tensile, bending and internal pressure resistance meet the requirements of relevant standards

Key words: low alloy steel; tubing; welding; butt joint; microstructure; mechanical properties

0 前言

在石油天然氣、鍋爐壓以及力容器等領域的生產建設過程中涉及大量的小直徑管材全位置對接焊接頭,并且其對焊接接頭質量具有較高的要求。然而,對于小直徑管材的全位置焊接,由于管體曲律半徑小,焊縫成形質量控制難度大,采用手工對接焊時,對焊工操作技能要求高。為了保障焊接質量,許多企業開始采用全位置TIG自動焊設備進行小直徑管材的焊接[1-7]。文中采用全位置TIG自動焊工藝對規格為50 mm×5 mm的低合金鋼管材進行焊接試驗,分析其工藝、焊接接頭組織及性能特點,以期為現場作業提供參考。

1 ?試驗材料及方法

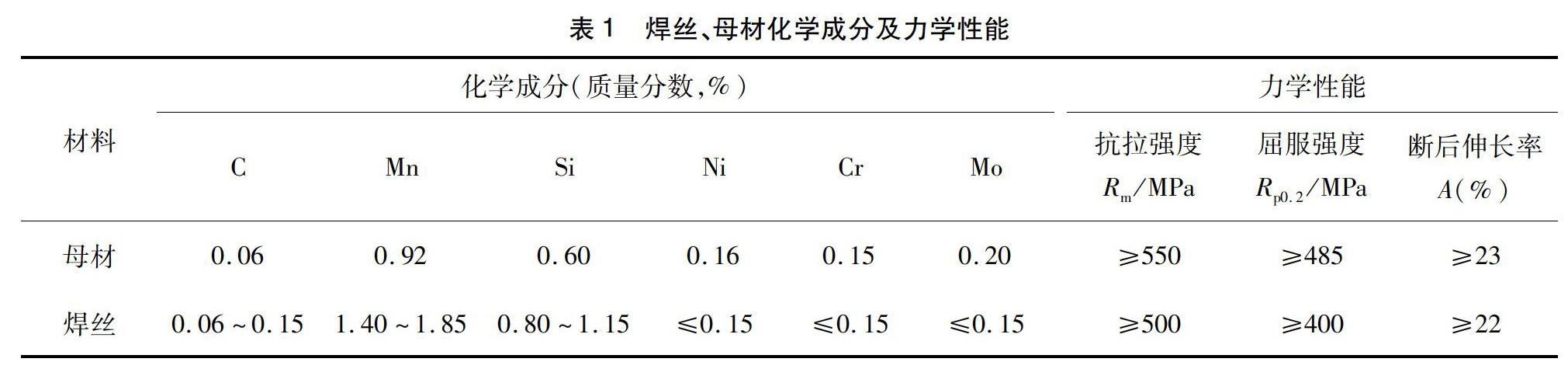

1.1 ?試驗材料

試驗選用的低合金鋼管材規格為50 mm×5 mm,所用焊絲為按照GB/T 8110《氣體保護電弧焊用碳鋼、低合金鋼焊絲》標準生產的型號為ER50-6,規格為1.0 mm焊絲。……