仿生超疏水表面的發展及其應用研究進展

佟威, 熊黨生

仿生超疏水表面的發展及其應用研究進展

佟威, 熊黨生

(南京理工大學 材料科學與工程學院, 南京 210094)

受自然界荷葉 “出淤泥而不染”的啟發, 超疏水現象引起了研究者廣泛的關注, 并成功制備了人工超疏水表面。本文對典型的仿生超疏水材料進行梳理, 并針對近期研究成果進行了綜述, 對超疏水涂層的諸多制備方法作了優缺點總結和評述, 概述了超疏水涂層在自清潔、防覆冰、耐腐蝕和油水分離領域的應用研究現狀, 尤其對超疏水防覆冰的機理及實現方式作了總結分析, 剖析了現階段超疏水研究過程中面臨的挑戰, 展望了未來的發展趨勢, 希望為超疏水涂層在工程領域的應用研究提供參考。

仿生材料; 超疏水涂層; 自清潔; 防覆冰; 耐腐蝕; 油水分離; 綜述

仿生材料是從生物體獲得啟示, 通過模仿生物某個方面的特異功能, 實現材料的功能化設計, 并可能最終超越自然[1]。受自然界“荷葉效應”的啟發, 超疏水現象引起了研究者的廣泛關注。靜態接觸角大于150°且滾動角小于10°的表面被定義其具有超疏水特性[2]。其表面浸潤性理論依據由Young’s方程[3]發展到Wenzel模型[4]最終變為Cassie-Baxter模型[5], 目前所報道的超疏水模型都基于Cassie-Baxter模型的改進。從Web of Science以超疏水為主題發表的論文數量顯示, 超疏水領域依然是研究熱點, 并且文章數量呈現遞增趨勢, 研究者普遍認為超疏水表面具有自清潔、防覆冰、耐腐蝕和油水分離等方面的潛在應用價值[6-7]。本文依照時間發展順序對仿生動植物的典型研究論文進行梳理, 對近期的研究成果進行綜述, 對多種超疏水涂層的制備方法的優缺點進行評論及總結, 同時對超疏水涂層的應用前景進行概述, 說明現階段研究存在的問題, 并展望今后超疏水領域的研究發展趨勢。

1 仿生超疏水材料的發展

大自然為人類提供了取之不盡的靈感源泉(圖 1), 1997年Barthlott和Neinhuis[8-9]通過觀察分析荷葉表面的微觀形貌, 提出該表面憎水性是由毛狀體、表皮褶皺和蠟狀晶體構成的表面粗糙微結構結合疏水性的表皮蠟狀物而引起的, 粗糙/蠟質的荷葉表面不僅具有拒水性, 而且對顆粒污染物具有低粘附性。通過對荷葉、稻葉表面微觀結構的進一步研究, 微米/納米級復合結構被認為是獲得人工超疏水表面的關鍵[2]。為實現多功能化超疏水表面, 研究者又相繼報道了多種仿生材料, 其典型性研究如: 實現飛檐走壁的壁虎腳部[10], 呈現疏水–親水交替界面的沙漠甲蟲背部[11], 可以輕盈地在水面上行走的水黽腳部[12]。隨著仿生超疏水表面的發展, 研究者進一步報道了抗反射和光學透明的仿生蟬翅膀[13], 仿生蝴蝶翅膀的定向粘附性[14], 具有干式防霧性能的仿生蚊蟲復眼[15], 具有高粘附力超疏水狀態的“花瓣效應”[16], 仿生魚鱗狀超疏水表面在水下的自清潔特性和減阻功能[17], 可實現低摩擦流體運輸的仿生槐葉萍超疏水表面[18-19], 仿生楊樹葉高反射超疏水白色涂層[20], 仿生蛤蜊殼高能無機涂層在水下具有低粘附力的超疏水狀態[21], 仿生超疏水企鵝羽毛的抗凍效果[22]等。

圖1 仿生超疏水材料的發展及其典型的動植物微觀結構

隨著多種仿生植物、動物的超疏水表面仿生材料的涌現, 具有特殊浸潤性及特殊應用前景的仿生材料被相繼報道(表1)。江雷課題組報道的仿生蜘蛛絲[23]、仙人掌脊柱[24]和瓶子草毛狀體[25]均可實現水滴的收集及其定向傳輸過程。仿生鯊魚皮減阻表面所引發的減阻涂層用于醫療、船舶和工業等領域的應用研究[26-27]。通過仿生跳蟲表面的結果證明了膠原蛋白表面可抵抗多種液體的浸潤以及可承受較高壓力的環境, 指出仿生無脊柱動物表面在抗磨損低摩擦領域具有應用前景[28]。通過對燕鷗鳥嘴部呈現的低氣流阻力的研究, 提出一種可能減阻的方法[29]。具有響應性自補充潤滑劑現象的仿生蚯蚓潤滑涂層對于固體環境中用于減磨、抗磨和自清潔涂層的設計與發展具有推動作用[30]。另外, 通過對仿生豬籠草的研究[31-33]掀起了研究者對滑液注入式多孔界面(SLIPS)[34]的關注與研究, 其光滑各向異性的兩親特征啟發了研究者制備滑液面針對疏冰、抗冰的研究。

2 超疏水涂層的制備方法

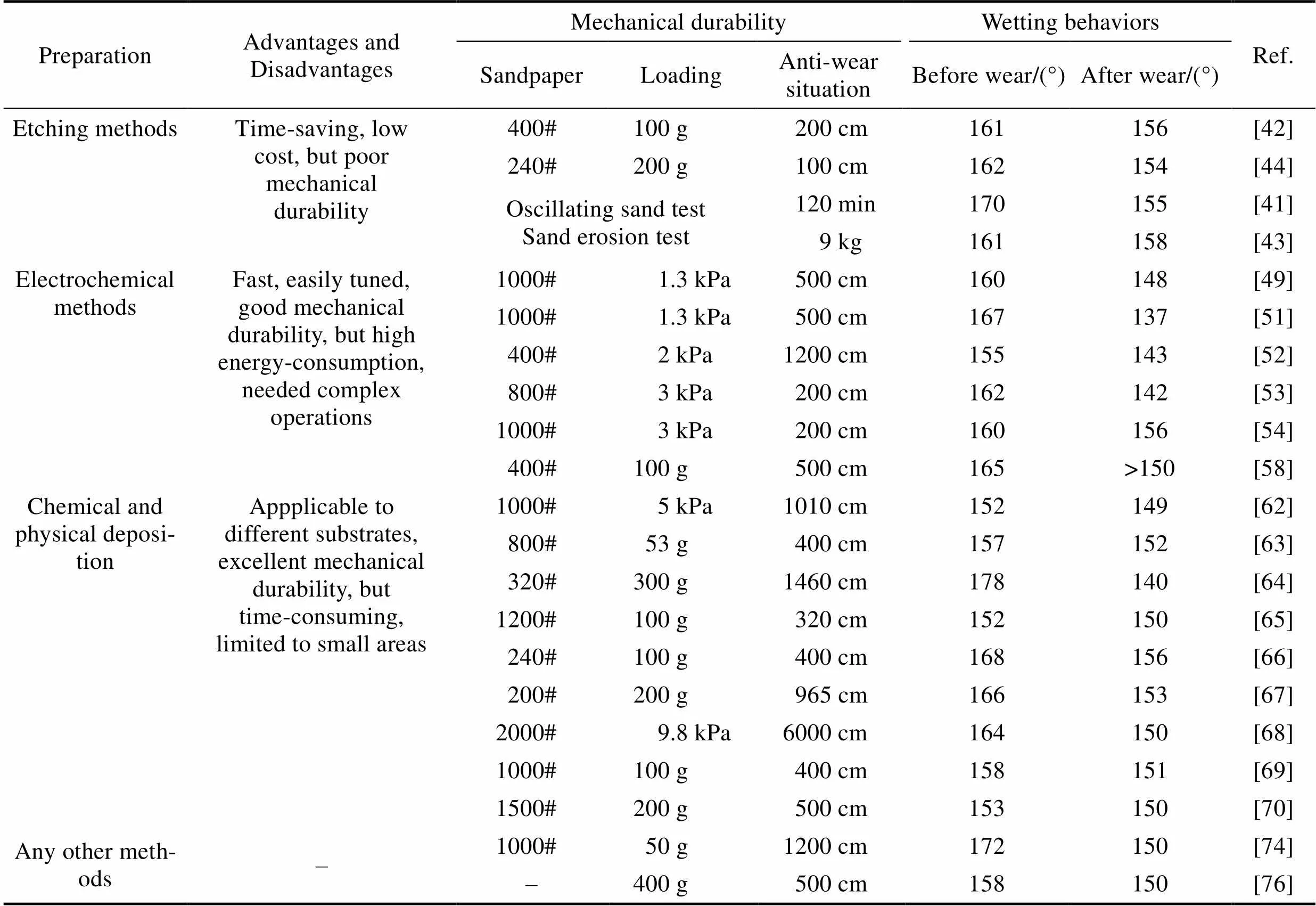

通過模擬自然界植物、動物表面的浸潤性特點,微納結構的構建及其低表面能物質的修飾依舊是現階段制備人工超疏水表面并加以應用的主要方法(表2)。

2.1 刻蝕修飾法

刻蝕修飾法是最簡單的實現人工超疏水表面的方法, 該方法通過化學濕法刻蝕[35-39]、激光刻 蝕[40-44]、機械加工處理[45-46]等方式構建微米/納米級粗糙結構, 然后采用低表面能物質對刻蝕后的粗糙結構表面進行超疏水修飾。目前的研究結果表明, 刻蝕修飾法制得的超疏水表面機械耐久性較差, 表面的微米/納米級粗糙結構很容易遭到破壞, 而且采用該方法制備可控厚度的超疏水涂層難度較大, 導致其未來應用將面對較大挑戰。

表1 仿生材料的功能性應用

表2 采用不同制備方法制得超疏水表面的優缺點

2.2 電化學法

電化學法是在外加恒定電流或恒定電壓的情況下, 通過控制一定的工藝參數制備超疏水涂層的方法。早期研究者采用陽極氧化法[47-48]制備超疏水涂層, 金屬試樣通過陽極氧化過程構建微米/納米級粗糙結構, 然后采用低表能物質對其進行超疏水修飾, 最終在金屬表面制得超疏水膜, 該方法獲得的超疏水涂層通常較薄且機械耐久性較差。隨著研究的不斷深入, 研究者采用電鍍、電化學沉積的方式[49-54]制備多層疊加的超疏水涂層, 該涂層有利于實現超疏水在腐蝕防護領域的工程應用。隨著電化學沉 積法的進一步發展, 研究者采用電化學納米共沉積法[55]制備超疏水涂層, 采用電化學等離子處理結合電化學沉積法[56]提升超疏水涂層的機械耐久性, 以及采用水熱法結合電化學沉積法[57-58]制備超疏水涂層, 該方法將納米粒子均勻地沉積于基體表面, 制得的超疏水涂層均勻致密, 機械耐久性得到一定的提升。

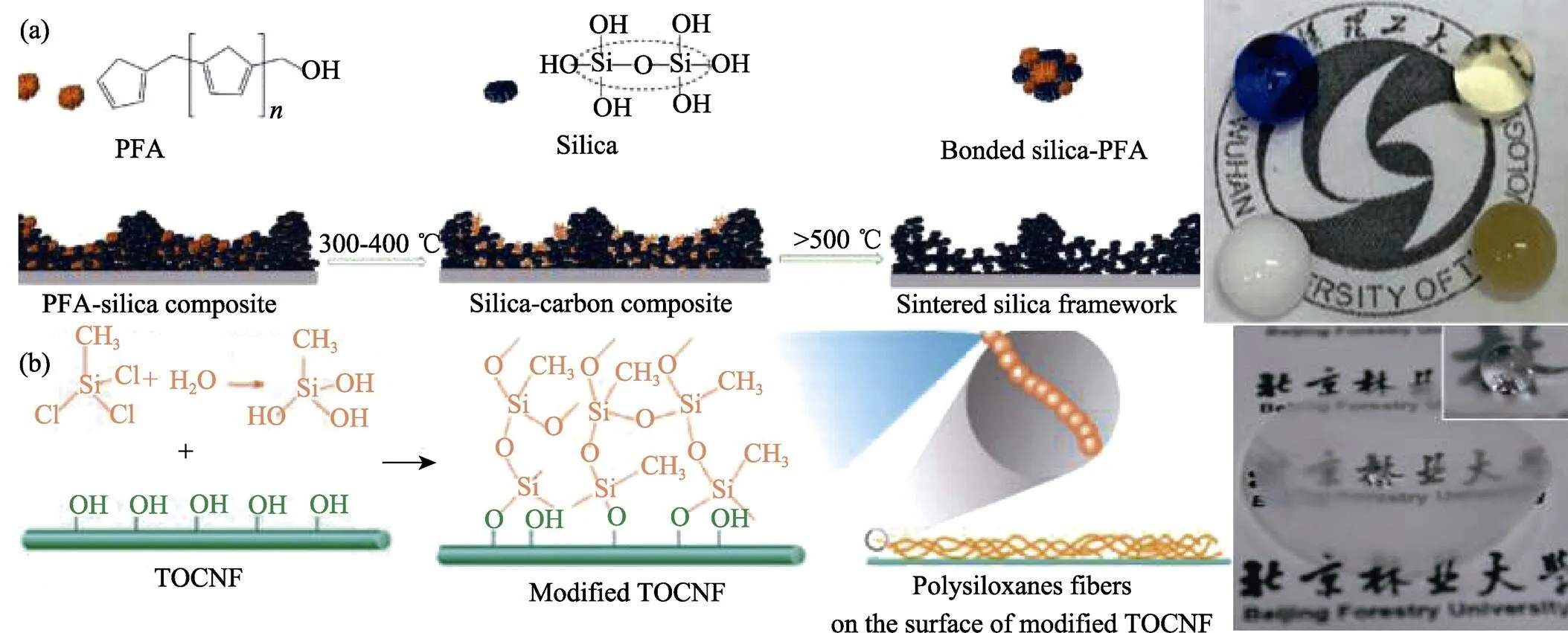

2.3 物理、化學沉積法

為增強超疏水表面的機械耐久性及其多種基體適用性, 研究者發現多層結構的超疏水涂層有利于實現持久的超疏水性。當表層超疏水膜遭到磨損甚至破壞時, 暴露的新表面與表層超疏水膜基本相同, 從而提高了超疏水表面的機械耐久性。早期研究者采用物理氣相沉積法(PVD)、化學氣相沉積法(CVD)[59-61], 為了實現大規模化、工藝簡單、低成本、可操作性強的超疏水涂層, 基于溶膠–凝膠法的浸涂或刷涂的方式[62-65]受到研究者廣泛的關注, 為了進一步提高涂層與基體的結合力, 噴涂固化的方式[66-70]得到更為廣泛的應用。

2.4 其他方法

除上述制備方法外, 蠟燭燒蝕過程中的納米級碳黑附著于基體表面, 從而獲得超疏水表面[71-73]; 采用機械滾動法通過電火花加工和碳納米顆粒包覆的方式在金屬基體上制得耐久性較好的超疏水表面[74]; 采用超疏水改性SiO2結合環氧樹脂的固化成膜作用, 通過自組裝法制得超疏水涂層[75-76], 其中熱壓方式改進自組裝法制得了結合力較好的超疏水涂層[77]; 通過對環氧樹脂進行疏水改性, 經成膜固化后制得耐久性較好的超疏水涂層[78-79]。但目前 的研究方法中, 機械耐久性相對較好的超疏水涂層普遍存在可加工范圍小、工藝復雜和制備成本高等問題。

3 超疏水涂層的潛在應用

隨著超疏水仿生材料的發展及其制備方法的多樣化, 研究者關注超疏水表面的功能化應用研究, 擬將所制備的超疏水涂層應用于日常生活、工業生產、軍事發展等領域。

3.1 自清潔

超疏水自清潔性能是研究較早的應用性能之一, 其超疏水涂層在戶外玻璃、太陽能電池板、紡織品和外墻涂料等領域具有較高的應用研究價值(圖2)。由于水滴在超疏水表面的極不浸潤性, 當水滴與超疏水表面接觸時, 水滴在重力或輕微外力的作用下滾動滑落而離開表面, 因此, 超疏水表面的污染物或某些細菌隨著水滴的滾動離開, 從而達到表面自清潔的目的。現階段研究存在的問題集中在高透明、耐久性的自清潔涂層, 近期也有研究表明[80-83], 增加超疏水納米粒子的含量有助于提高涂層的持久性超疏水, 但涂層的透明度同時下降。因此, 研究者致力于開發高透明/耐久性一體化的超疏水自清潔薄膜涂層。

3.2 防覆冰

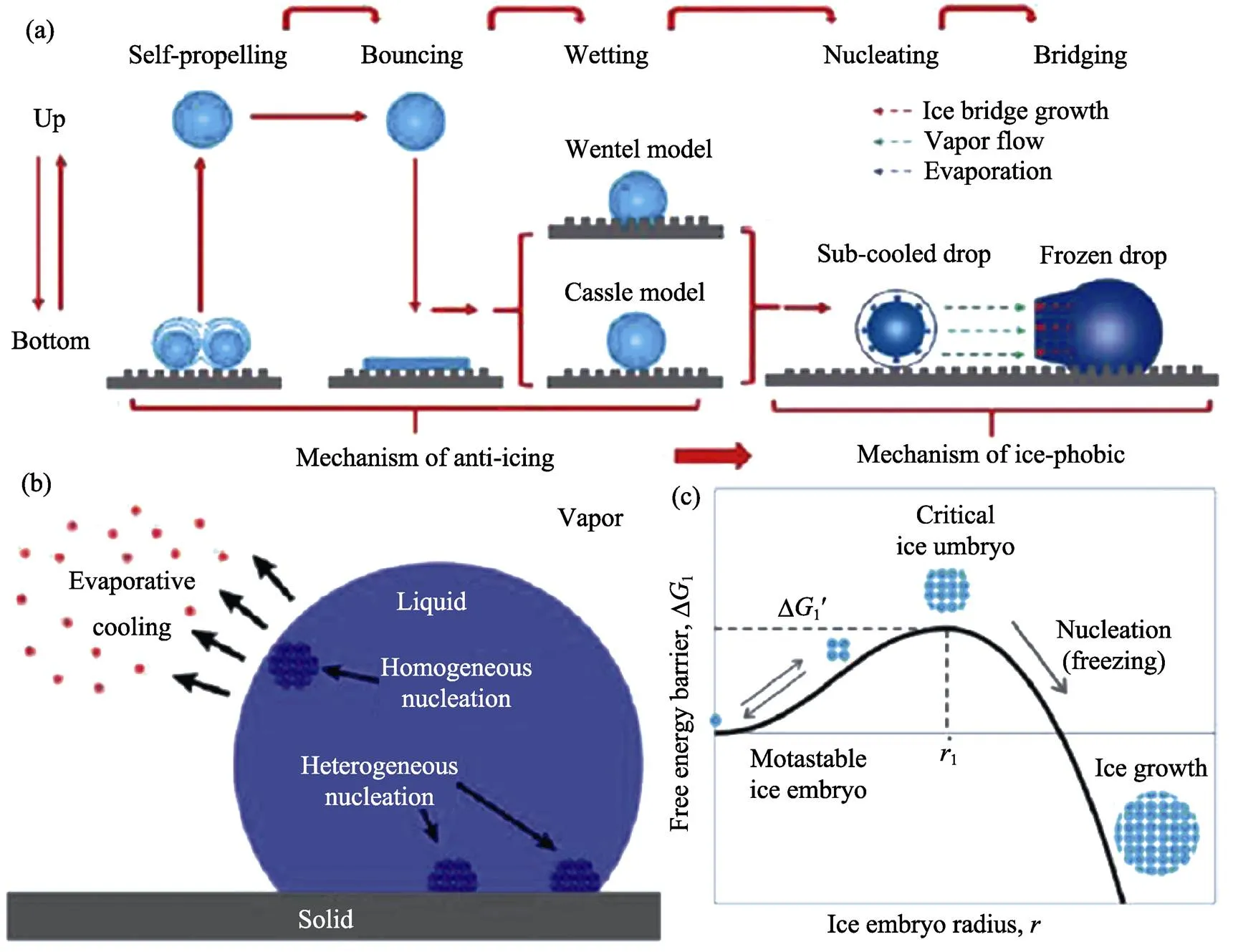

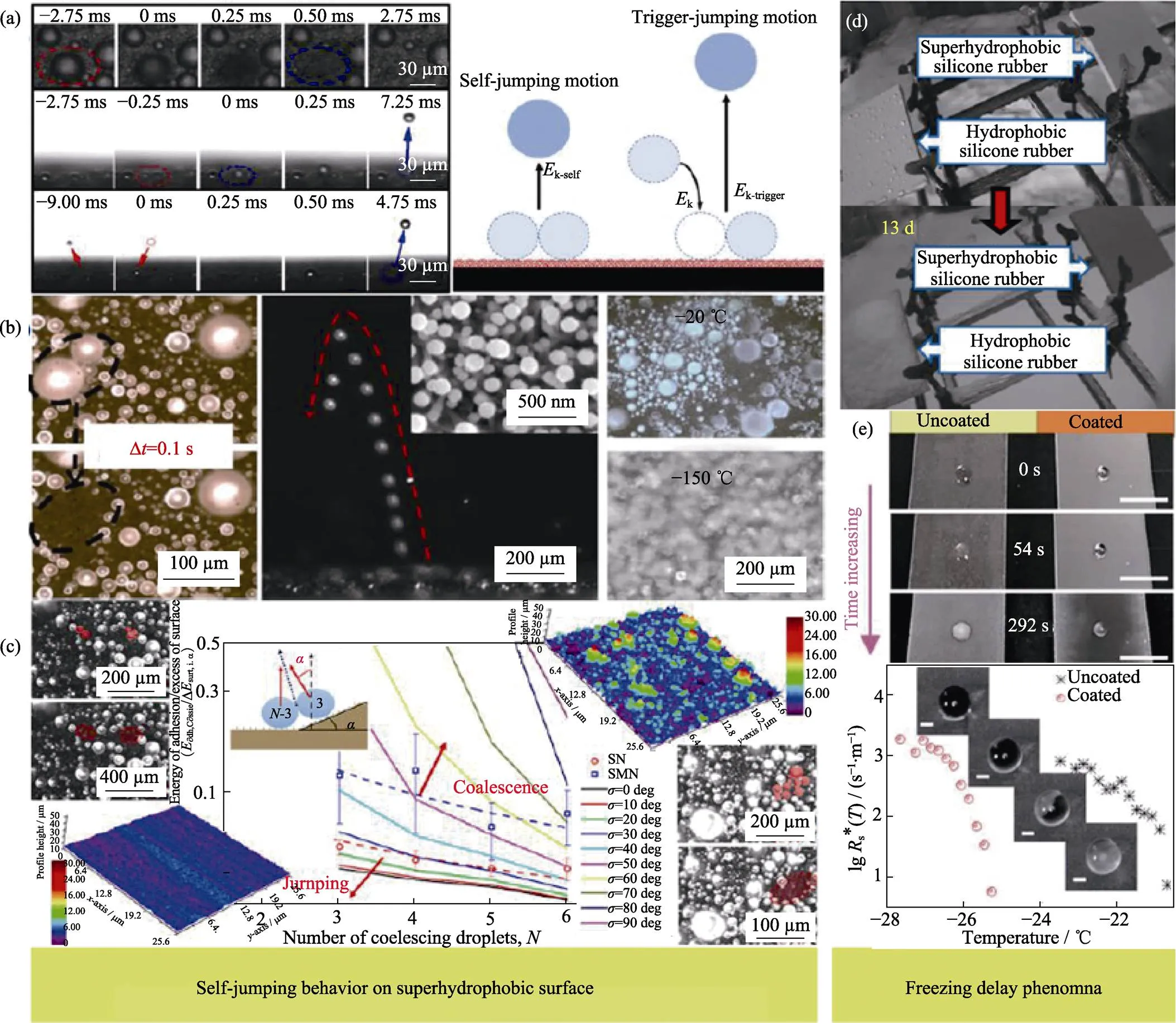

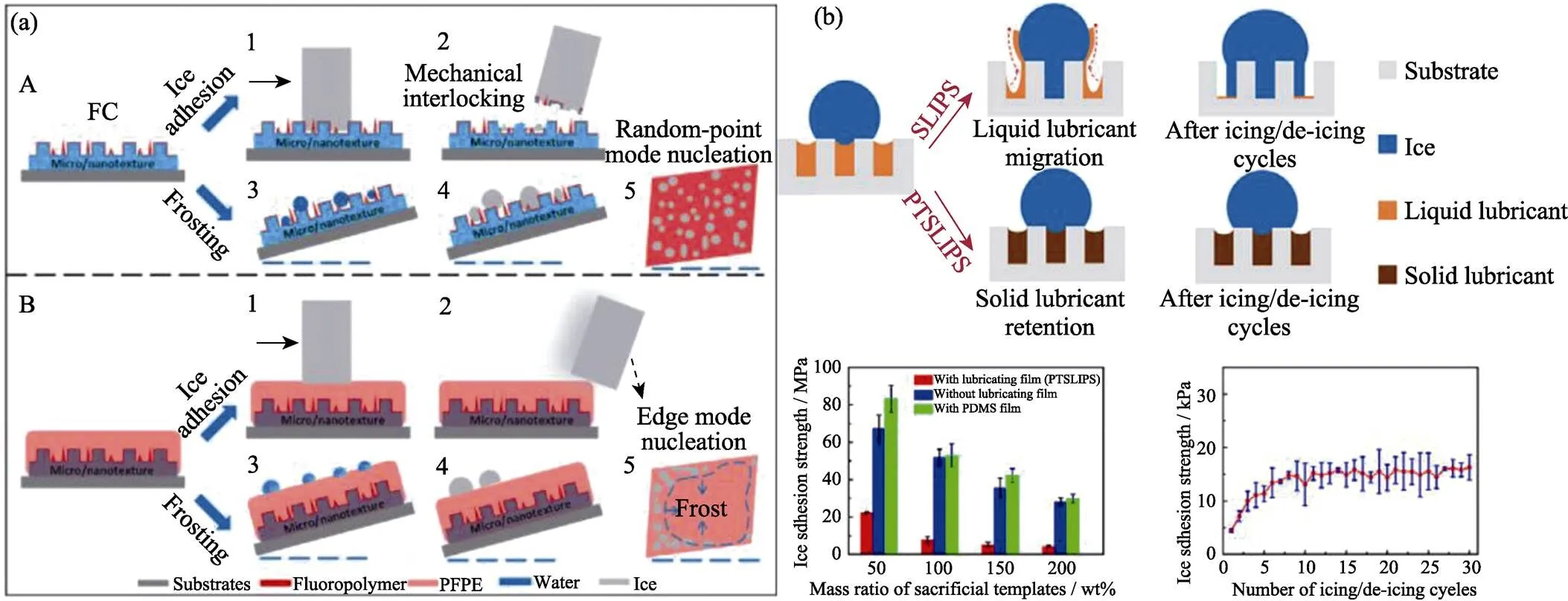

目前的超疏水防覆冰領域主要體現在三個方面: 減少液滴與界面長時間接觸(小液滴在過冷條件下的反彈)、降低凝固點及延遲結冰時間(微小冷凝液滴的自跳動現象)和構建疏冰低結冰粘附力表面(滑液面防冰)。當固–液界面出現結冰現象時, 表面結冰過程可用開爾文方程和克拉伯龍方程分析小液滴的分類形核理論和抑制形核能理論[84]來分析該表面的防覆冰能力(圖3)。

超疏水表面普遍存在小液滴彈跳現象[87-89], 其原因為遭到液滴撞擊時的小液滴動能不易轉變為超疏水表面內能[90-91], 超疏水涂層的表面張力較小(圖4)。因此, 當低溫環境下的超疏水表面出現彈跳現象時, 彈跳的液滴于結冰形核前離開超疏水表面, 從而減緩界面的過冷傳輸過程, 達到防覆冰的目的。Quéré課題組[92]研究表明, 液滴以20~230 cm/s的速度撞擊超疏水表面時, 液滴和界面的接觸時間僅與液滴半徑和界面張力有關, 與撞擊速度無關。

冷凝在微納結構內部的小液滴受限于粗糙結構而導致其形狀改變, 小液滴匯集結合后的液滴自由能過剩, 即表面自由能大于液滴平衡態自由能, 最終液滴在低表能的超疏水表面彈起或滾動離開[93], 宏觀表現為小液滴連續的自跳動現象(圖5)。通過控制微納結構的尺寸變化及其不同的結構粗糙度, 可提高超疏水表面的自跳動防冰效果[94-96]。超疏水涂層的表面能較小且靜態接觸角較大, 導致液滴與超疏水表面的接觸面積較小。根據小液滴的分類形核理論和抑制形核能[84], 控制超疏水表面的粗糙度小于且無限接近于臨界晶核的最小半徑值[97], 此時, 超疏水表面具有結冰延遲效果[98-99]。

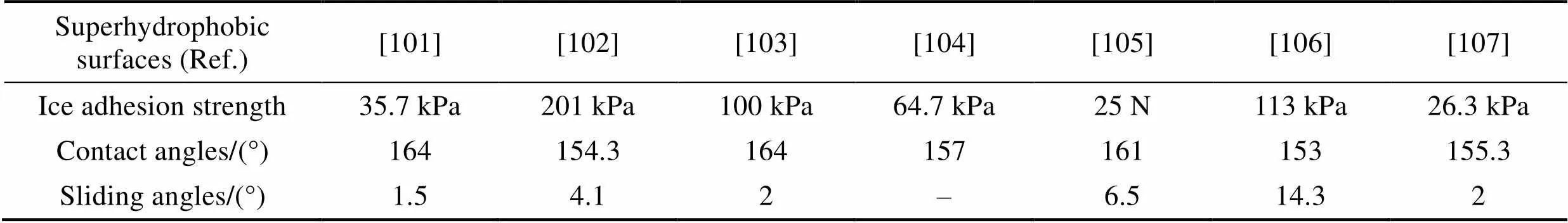

覆冰與物體表面存在范德華力、氫鍵作用和靜電引力(表3)。界面接觸時范德華力普遍存在且與接觸面面積呈現線性關系, 具有親水基團表面的氫鍵作用較強, 靜電引力是三種作用力中最重要的影響結冰粘附力因素, 材料的介電常數越低, 覆冰的靜電引力作用越小[100]。研究表明, 低表面能的超疏水表面可降低覆冰的粘附力[101-107], 但由于超疏水表面形貌和微納結構的差異, 具體的防結冰及降低覆冰粘附力的機理研究還有待完善。

圖2 高透明超疏水涂層[80-81]

圖3 防–疏冰機理和小液滴形核結冰過程[85-86]

圖4 超疏水表面的小液滴彈跳現象[87-89]

受仿生豬籠草研究的啟發[34], 研究者構建多孔結構水潤滑層[108-109]以實現表面疏冰、抗冰的效果(圖6)。其構建過程中應滿足三個要求: 水潤滑層液體與外來浸潤液體不相容; 水潤滑層與基體的吸附力優于外來浸潤液體在其滑液面的化學親和力; 保證水潤滑層液體可以持久地貯存在多孔結構中, 且化學穩定性較好。

圖5 (a~c)冷凝液滴的自跳動行為[94-96]和(d, e)延遲結冰現象[98-99]

表3 超疏水表面的抗結冰粘附力

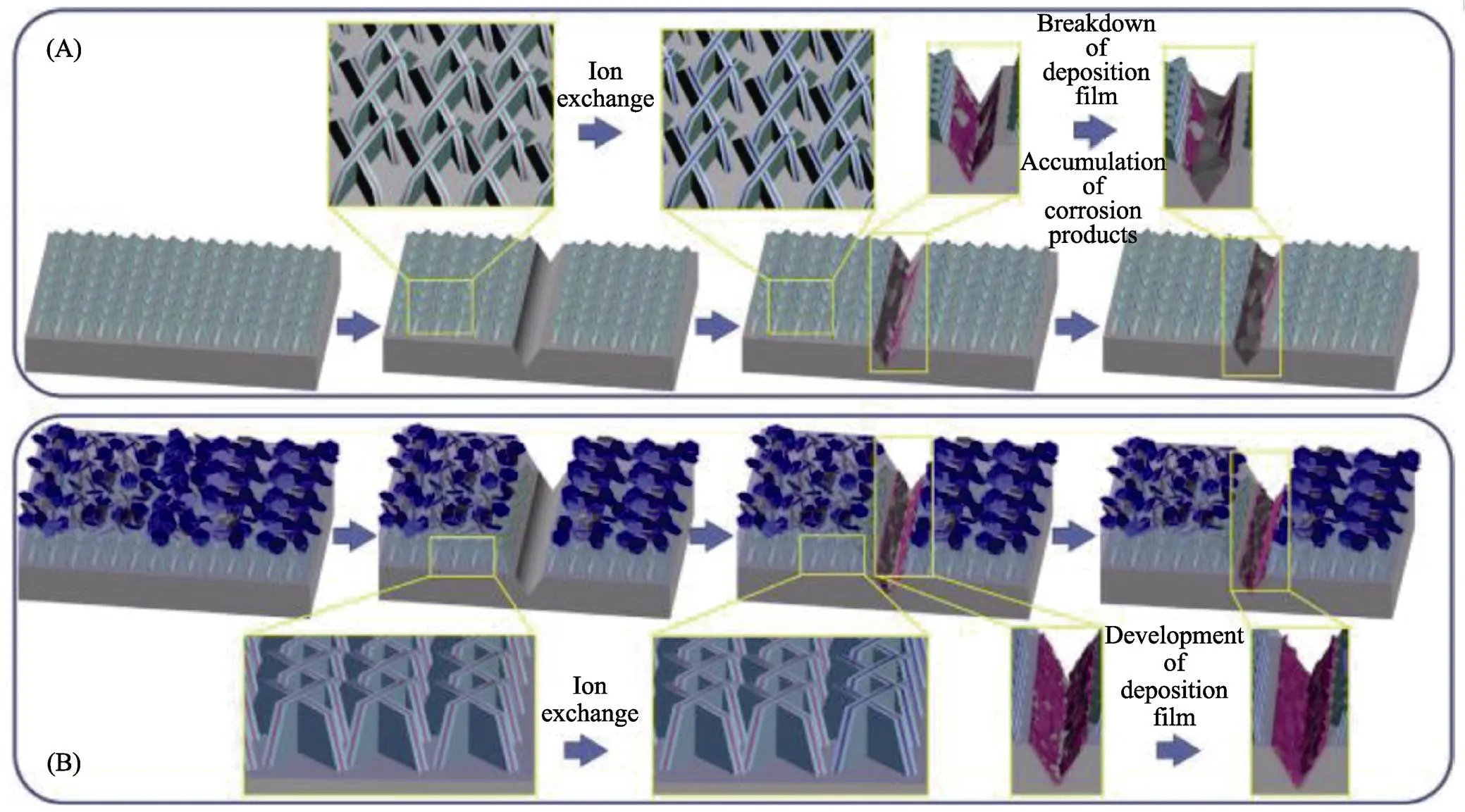

3.3 耐腐蝕

提高金屬的耐蝕防護能力一直是工程應用領域亟待解決的問題, 超疏水涂層由于其超強的憎水性特點, 為解決該問題提供了創新性思路。基于Cassie-Baxter模型[5]的空氣層理論及其微納結構的毛細效應, 使得超疏水表面和腐蝕介質之間存在大量的空氣層, 這些絕緣的空氣層可阻止或抑制離子的遷移, 在金屬基體與腐蝕介質之間形成阻隔屏障。研究表明, 超疏水表面可改善腐蝕電位正向移動, 腐蝕電流密度至少提高兩個數量級, 金屬的抗耐蝕能力得到提高[110]。現階段超疏水耐蝕涂層主要采用電化學沉積及其水熱反應制備多層疊加結構、摻雜緩蝕劑結合氟硅烷修飾的化學轉化膜, 以及采用超疏水納米粒子固化成膜反應等方式(圖7)。長時間暴露于腐蝕介質中引起的憎水性下降是導致超疏水涂層耐蝕性衰減的主要原因, 因此, 具有自修復性能的超疏水耐蝕涂層[111]將成為未來的研究趨勢。

圖6 滑液注入式多孔界面(SLIPS)防冰[108-109]

圖7 超疏水自修復耐蝕涂層[111]

3.4 油水分離

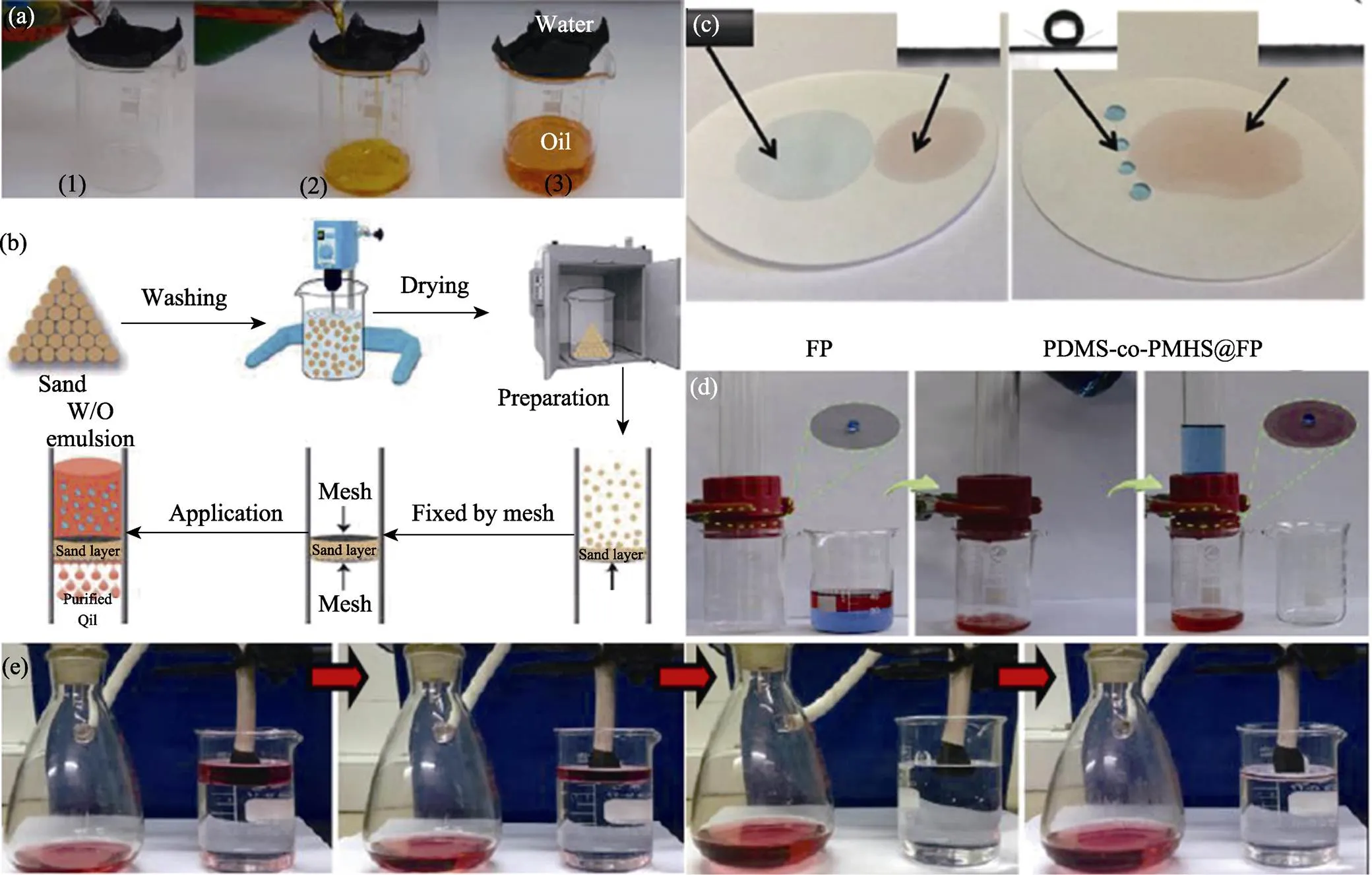

油水分離主要采用超疏水/親油性的分離膜和超親水/疏油性的分離膜, 超疏水表面在油水分離中的應用主要通過重力或外力的驅動作用, 油穿過分離膜且水被攔截在分離膜表面, 從而達到油水分離的目的。江雷課題組[112-113]最早報道了超疏水油水分離膜, 通過重力驅動作用實現高通量的超疏水油水分離, 擬解決工業含油廢水及原油泄露的再收集問題(圖8)。目前超疏水油水分離膜的主要實現形式有金屬網[114]、細沙子[115]、濾紙[116]、纖維織物[117]、海綿[118]等, 一般情況下油密度低于水密度, 油漂浮在水表面, 因此需要在外力驅動下完成油水分離。金屬網為支撐的超疏水油水分離膜具有較好的油通量, 但網孔之間的間隙過大而導致油水分離率嚴重下降; 超疏水改性的濾紙和細沙子很難實現大規模化油水分離; 超疏水改性的海綿和纖維織物具有相對較好的油水分離效果, 但分離膜表面耐污性較差, 多次循環使用后出現油水分離率下降, 長期的耐溶劑性有待提高。

圖8 超疏水/超親油性油水分離[114-118]

4 總結與展望

本文通過對經典仿生動植物研究的梳理, 總結人工超疏水表面的制備方法, 報道超疏水應用研究現狀。現階段超疏水涂層趨向于多功能一體化發展, 除經常報道的應用性能外, 受光、電、磁等外部刺激而引起的智能響應涂層更受研究者關注。目前已有研究報道磁性超疏水涂層在磁場驅動下定向油水分離, 磁性隱身超疏水涂層擬應用于提高戰斗機的機動性和突防能力, 同時超疏水阻燃紙的研究改變了人們的傳統思維, 諸如此類超疏水研究成果將對未來的人類生活、工業發展和國防科技等領域帶來巨大改變。

隨著該領域研究不斷深入, 存在的挑戰、爭議和盲區也日趨明顯。目前報道的大多數機械耐久性超疏水涂層仍停留在實驗室階段, 超疏水涂層的抗老化性和化學穩定性有待進一步提高, 其制備方法普遍存在工藝復雜、成本高、無法大規模化生產等缺點。

1) 自修復超疏水涂層為提高其耐久性提供了新的方向, 通過受損自發或外界刺激引起的響應作用, 誘導愈合劑修復受損的超疏水表面并恢復表面原有浸潤特性。采用柔性、軟質、彈性等材料作為功能性疏水添加劑, 減緩超疏水表面的摩擦、磨損, 增強涂層的機械耐久性。

2) 超疏水防覆冰涂層的動力學研究仍需完善。微納結構、低表面能、小液滴結冰形核理論、結冰界面的能量轉化和表面覆冰粘附力的關系需進一步分析, 并給出動力學轉化過程。

[1] 江雷, 馮琳. 仿生智能納米界面材料. 北京: 化學工業出版社, 2007: 1–48.

[2] LIN F, LI S, LI Y,. Super-hydrophobic surfaces: from natural to artificial., 2002, 14(24): 1857–1860.

[3] YOUNG T. An essay on the cohesion of fliuds.., 1805, 95: 65–87.

[4] WENZEL R N. Resistance of solid surfaces to wetting by water., 1936, 28(8): 988–994.

[5] CASSIE A, BAXTER S. Wettability of porous surfaces., 1944, 40: 546–551.

[6] SI Y, DONG Z, JIANG L. Bioinspired designs of superhydrophobic and superhydrophilic materials., 2018, 4(9): 1102–1112.

[7] SUN Y, GUO Z.Recent advances of bioinspired functional materials with special wettability: from nature and beyond nature., 2019, 4: 52–76.

[8] BARTHLOTT W, NEINHUIS C. Purity of the sacred lotus, or escape from contamination in biological surfaces., 1997, 202(1): 1–8.

[9] NEINHUIS C, BARTHLOTT W. Characterization and distri-bution of water-repellent, self-cleaning plant surfaces., 1997, 79(6): 667–677.

[10] AUTUMN K, LIANG Y A, HSIEH S T,. Adhesive force of a single gecko foot-hair., 2000, 405(6787): 681–685.

[11] PARKER A R, LAWRENCE C R. Water capture by a desert beetle., 2001, 414(6859): 33–34.

[12] GAO X, JIANG L. Biophysics: water-repellent legs of water striders., 2004, 432(7013): 36.

[13] LEE W, JIN M K, YOO W C,. Nanostructuring of a poly-meric substrate with well-defined nanometer-scale topography and tailored surface wettability., 2004, 20(18): 7665–7669.

[14] ZHENG Y, GAO X, JIANG L. Directional adhesion of superhydrophobic butterfly wings., 2007, 3(2): 178–182.

[15] GAO X, YAN X, YAO X,. The dry-style antifogging pro-perties of mosquito compound eyes and artificial analogues prepared by soft lithography., 2007, 19(17): 2213–2217.

[16] FENG L, ZHANG Y, XI J,. Petal effect: a superhydrophobic state with high adhesive force., 2008, 24(8): 4114–4119.

[17] LIU M, WANG S, WEI Z,. Bioinspired design of a superoleophobic and low adhesive water/solid interface., 2009, 21(6): 665–669.

[18] KOCH K, BHUSHAN B, BARTHLOTT W. Multifunctional surface structures of plants: an inspiration for biomimetics., 2009, 54(2): 137–178.

[19] BARTHLOTT W, SCHIMMEL T, WIERSCH S,. The salvinia paradox: superhydrophobic surfaces with hydrophilic pins for air retention under., 2010, 22(21): 2325–2328.

[20] YE C, LI M, HU J,. Highly reflective superhydrophobic white coating inspired by poplar leaf hairs toward an effective “cool roof”., 2011, 4(9): 3364–3367.

[21] LIU X, ZHOU J, XUE Z,. Clam’s shell inspired high-energy inorganic coatings with underwater low adhesive superoleo-pho-bicity., 2012, 24(25): 3401–3405.

[22] WANG S, YANG Z, GUO G,. Icephobicity of penguins spheniscus humboldti and an artificial replica of penguin feather with air-infused hierarchical rough structures., 2016, 120(29): 15923–15929.

[23] ZHENG Y, BAI H, HUANG Z,. Directional water collection on wetted spider silk., 2010, 463(7281): 640–643.

[24] JU J, BAI H, ZHENG Y,. A multi-structural and multi- functional integrated fog collection system in cactus., 2012, 3(1): 1247.

[25] CHEN H, RAN T, GAN Y,. Ultrafast water harvesting and transport in hierarchical microchannels., 2018, 17(10): 935–942.

[26] DEAN B, BHUSHAN B. Shark-skin surfaces for fluid-drag reduction in turbulent flow: a review., 2010, 368(1929): 4775–4806.

[27] BIXLER G D, BHUSHAN B. Fluid drag reduction with shark- skin riblet inspired microstructured surfaces., 2013, 23(26): 4507–4528.

[28] HELBIG R, NICKERL J, NEINHUIS C,. Smart skin patterns protect springtails., 2011, 6(9): e25105.

[29] MARTIN S, BHUSHAN B. Discovery of riblets in a bird beak (Rynchops) for low fluid drag. Phil., 2016, 374(2073): 20160134.

[30] ZHAO H, SUN Q, DENG X,. Earthworm-inspired rough polymer coatings with self-replenishing lubrication for adaptive friction-reduction and antifouling surfaces., 2018, 30(29): 1802141.

[31] GORB E V, GORB S N. Physicochernical properties of functional surfaces in pitchers of the carnivorous plant nepenthes alata blanco (Nepenthaceae)., 2006, 8(6):841–848.

[32] BOHN H F, FEDERLE W. Insect aquaplaning: nepenthes pitcher plants capture prey with the peristome, a fully wettable waterlubricated anisotropic surface., 2004, 101(39): 14138–14143.

[33] GORB E, KASTNER V, PERESSADKO A,. Structure and properties of the glandular surface in the digestive zone of the pit-cher in the carnivorous plant nepenthes ventrata and its role in insect trapping and retention., 2004, 207(17): 2947–2963.

[34] WONG T S, KANG S H, TANG S K,. Bioinspired self- repairing slippery surfaces with pressure-stable omnipho-bicity., 2011, 477(7365): 443–447.

[35] DOU W, WU J, GU T,. Preparation of super-hydrophobic micro-needle CuO surface as a barrier against marine atmospheric corrosion., 2018, 131: 156–163.

[36] TONG W, XIONG D, WANG N,. Green and timesaving fabrication of a superhydrophobic surface and its application to anti-icing, self-cleaning and oil-water separation., 2018, 352: 609–618.

[37] WAN Y, CHEN M, LIU W,. The research on preparation of superhydrophobic surfaces of pure copper by hydrothermal method and its corrosion resistance., 2018,270: 310–318.

[38] KIM J, MIRZAEI A, KIM H W,. Realization of super-hydrophobic aluminum surfaces with novel micro-terrace nano- leaf hierarchical structure., 2018, 451: 207–217.

[39] NANDA D, SAHOO A, KUMAR A,. Facile approach to develop durable and reusable superhydrophobic/superoleophilic coatings for steel mesh surfaces., 2019, 535: 50–57.

[40] LIU Y, LI X, JIN J,. Anti-icing property of bio-inspired micro- structure superhydrophobic surfaces and heat transfer model., 2017, 400: 498–505.

[41] BOINOVICH L B, MODIN E B, SAYFUTDINOVA A R,. Combination of functional nanoengineering and nanosecond laser texturing for design of superhydrophobic aluminum alloy with exceptional mechanical and chemical properties., 2017, 11(10): 10113–10123.

[42] MA Q, TONG Z, WANG W,. Fabricating robust and repai-rable superhydrophobic surface on carbon steel by nanosecond laser texturing for corrosion protection., 2018, 455: 748–757.

[43] LIN Y, HAN J, CAI M,. Durable and robust transparent superhydrophobic glass surfaces fabricated by a femtosecond laser with exceptional water repellency and thermostability., 2018, 6(19): 9049–9056.

[44] SONG J, WANG D, HU L,. Superhydrophobic surface fabricated by nanosecond laser and perhydropolysilazane., 2018, 455: 771–779.

[45] ZHU J, HU X. A novel route for fabrication of the corrosion- resistant superhydrophobic surface by turning operation., 2017, 313: 294–298.

[46] ZHU J. A novel fabrication of superhydrophobic surfaces on aluminum substrate., 2018, 447: 363–367.

[47] MOKHTARI S, KARIMZADEH F, ABBASI M H,. Deve-lopment of super-hydrophobic surface on Al 6061 by anodizing and the evaluation of its corrosion behavior., 2017, 324: 99–105.

[48] LI S, XIANG X, MA B,. Facile preparation of diverse alumina surface structures by anodization and superhydrophobic surfaces with tunable water droplet adhesion., 2019, 779: 219–228.

[49] LIU Q, CHEN D, KANG Z.One-step electrodeposition process to fabricate corrosion-resistant superhydrophobic surface on magne-sium alloy., 2015,7(3): 1859–1867.

[50] TESLER A B, KIM P, KOLLE S,. Extremely durable biofouling-resistant metallic surfaces based on electrodeposited nanoporous tungstite films on steel., 2015, 6(1): 8649.

[51] ZHANG B, ZHAO X, LI Y,. Fabrication of durable anticorrosion superhydrophobic surfaces on aluminum substratesa facile one-step electrodeposition approach., 2016, 6(42): 35455–35465.

[52] TAM J, JIAO Z, LAU J C F,. Wear stability of super-hydrophobic nano Ni-PTFE electrodeposits., 2017, 374–375: 1–4.

[53] JAIN R, PITCHUMANI R. Facile fabrication of durable copper- based superhydrophobic surfaceselectrodeposition., 2018, 34(10): 3159–3169.

[54] JAIN R, PITCHUMANI R. Fabrication and characterization of zinc-based superhydrophobic coatings., 2018, 337: 223–231.

[55] YE Y, LIU Z, LIU W,. Superhydrophobic oligoaniline- containing electroactive silica coating as pre-process coating for corrosion protection of carbon steel., 2018, 348: 940–951.

[56] ZOU Y, WANG Y, XU S,. Superhydrophobic double-layer coating for efficient heat dissipation and corrosion protection., 2019, 362: 638–649.

[57] ZANG D, ZHU R, ZHANG W,. Corrosion-resistant superhydrophobic coatings on Mg alloy surfaces inspired by lotus seedpod., 2017, 27(8): 1605446.

[58] QING Y, HU C, YANG C,.Rough structure of electro-deposition as a template for an ultrarobust self-cleaning surface., 2017,9(19): 16571–16580.

[59] B?KE F, GINER I, KELLER A,.Plasma-enhanced chemical vapor deposition (PE-CVD) yields better hydrolytical stability of biocompatible SiOthin films on implant alumina ceramics compared to rapid thermal evaporation physical vapor deposition (PVD)., 2016, 8(28): 17805–17816.

[60] VILARó I, YAGüE J L, BORRóS S. Superhydrophobic copper surfaces with anticorrosion properties fabricated by solventless CVD methods., 2017, 9(1): 1057–1065.

[61] ZHANG F, SHI Z, CHEN L,. Porous superhydrophobic and superoleophilic surfaces prepared by template assisted chemical vapor deposition., 2017, 315: 385–390.

[62] WU Y, JIA S, WANG S,. A facile and novel emulsion for efficient and convenient fabrication of durable superhydrophobic materials., 2017, 328: 186–196.

[63] REN G, SONG Y, LI X,. A simple way to an ultra-robust superhydrophobic fabric with mechanical stability, UV durability, and UV shielding property., 2018, 522: 57–62.

[64] ZHONG M, ZHANG Y, LI X,. Facile fabrication of durable superhydrophobic silica/epoxy resin coatings with compatible transparency and stability., 2018, 347: 191–198.

[65] YU N, XIAO X, YE Z,. Facile preparation of durable super--hydrophobic coating with self-cleaning property., 2018, 347: 199–208.

[66] LU Y, SATHASIVAM S, SONG J,. Robust self-cleaning surfaces that function when exposed to either air or oil., 2015, 347(6226): 1132–1135.

[67] WANG N, LU Y, XIONG D,. Designing durable and flexible superhydrophobic coating and its application in oil purification., 2016, 4(11): 4107–4116.

[68] LI Y, LI B, ZHAO X,.Totally waterborne, nonfluorinated, mechanically robust, and self-healing superhydrophobic coatings for actual anti-icing., 2018,10(45): 39391–39399.

[69] CHEN Z, LI G, WANG L,. A strategy for constructing superhydrophobic multilayer coatings with self-cleaning proper-ties and mechanical durability based on the anchoring effect of organopolysilazane., 2018, 141: 37–47.

[70] TU K, WANG X, KONG L,. Facile preparation of mechani-cally durable, self-healing and multifunctional superhy-drophobic surfaces on solid wood., 2018, 140: 30–36.

[71] DENG X, MAMMEN L, BUTT H,. Candle soot as a tem-plate for a transparent robust superamphiphobic coating., 2012, 335(6064): 67–69.

[72] XIAO L, ZENG W, LIAO G,. Thermally and chemically stable candle soot superhydrophobic surface with excellent self- cleaning properties in air and oil., 2018, 1(3): 1204–1211.

[73] TONG W, XIONG D, TIAN T,.Superhydrophobic surface on aeronautical materialsthe deposition of nanoparticles and a PDMS seal., 2019,125(3): 177.

[74] DONG S, WANG Z, WANG Y,.Roll-to-roll manufacturing of robust superhydrophobic coating on metallic engineering mater-ials., 2018,10(2): 2174–2184.

[75] WU Y, ZHAO M, GUO Z. Multifunctional superamphiphobic SiO2coating for crude oil transportation., 2018, 334: 1584–1593.

[76] PENG W, GOU X, QIN H,. Creation of a multifunctional superhydrophobic coating for composite insulators., 2018, 352: 774–781.

[77] SU X, LI H, LAI X,. Vacuum-assisted layer-by-layer super-hydrophobic carbon nanotube films with electrothermal and photothermal effects for deicing and controllable manipulation., 2018, 6(35): 16910–16919.

[78] PENG C, CHEN Z, TIWARI M K. All-organic superhydrophobic coatings with mechanochemical robustness and liquid impalement resistance., 2018, 17(4): 355–360.

[79] KIM Y S, SHANG M, KANG S,. Strong hydrophobic coating by conducting a new hierarchical architecture., 2018, 112(8): 4628–4634.

[80] ZHAO S, ZHAO J, WEN M,. Sequentially reinforced add-itive coating for transparent and durable superhydrophobic glass., 2018, 34(38): 11316–11324.

[81] CHEN S, SONG Y, XU F. Highly transparent and hazy cellulose nanopaper simultaneously with a self-cleaning superhydrophobic surface., 2018, 6(4): 5173–5181.

[82] TEISALA H, GEYER F, HAAPANEN J,. Ultrafast processing of hierarchical nanotexture for a transparent superamphiphobic coating with extremely low roll-off angle and high impalement pressure., 2018, 30(14): 1706529.

[83] WU Y, ZENG J, SI Y,. Large-area preparation of robust and transparent superomniphobic polymer films., 2018, 12(10): 10338–10346.

[84] VARANASI K K, MING H, BHATE N,. Spatial control in the heterogeneous nucleation of water., 2009, 95(9): 144101.

[85] LI Q, GUO Z. Fundamentals of icing and common strategies for designing biomimetic anti-icing surfaces., 2018, 6(28): 13549–13581.

[86] JAMIL M I, ALI A, HAQ F,. Icephobic strategies and materials with superwettability: design principles and mechanism., 2018, 34(50): 15425–15444.

[87] LI N, WU L, YU C,. Ballistic jumping drops on superhydrophobic surfaceselectrostatic manipulation., 2018, 30(8): 1703838.

[88] SHEN Y, TAO J, WANG G,. Bioinspired fabrication of hierarchical-structured superhydrophobic surfaces to understand droplet bouncing dynamics for enhancing water repellency., 2018, 122(13): 7312–7320.

[89] SHEN Y, LIU S, ZHU C,. Facile fabrication of hierarchical structured superhydrophobic surface and its ultra dynamic water repellency., 2017, 313: 47–55.

[90] MISHCHENKO L, HATTON B, BAHADUR V,.Design of ice-free nanostructured surfaces based on repulsion of impacting water droplets., 2010, 4(12): 7699–7707.

[91] FAROKHIRAD S, LEE T. Computational study of microparticle effect on self-propelled jumping of droplets from superhydrophobic substrates., 2017, 95: 220–234.

[92] RICHARD D, CLANET C, QUéRé D. Surface phenomena: contact time of a bouncing drop., 2002, 417(6891): 811.

[93] SCHUTZIUS T M, JUNG S, MAITRA T,. Spontaneous droplet trampolining on rigid superhydrophobic surfaces., 2015, 527(7576): 82–85.

[94] WANG S, ZHANG W, YU X,. Sprayable superhydrophobic nano-chains coating with continuous self-jumping of dew and melting frost., 2017, 7(1): 40300.

[95] ZHANG W, WANG S, XIAO Z,. Frosting behavior of superhydrophobic nanoarrays under ultralow temperature., 2017, 33(36): 8891–8898.

[96] ZHANG P, MAEDA Y, Lü F,. Enhanced coalescence- induced droplet-jumping on nanostructured superhydrophobic surfaces in the absence of microstructures., 2017, 9(40): 35391–35403.

[97] JUNG S, DORRESTIJN M, RAPS D,. Are superhy-drophobic surfaces best for icephobicity., 2011, 27(6): 3059–3066.

[98] EMELYANENKO A M, BOINOVICH L B, BEZDOMNIKOV A A,. Reinforced superhydrophobic coating on silicone rubber for longstanding anti-icing performance in severe conditions., 2017, 9(28): 24210–24219.

[99] WU X, CHEN Z. A mechanically robust transparent coating for antiicing and self-cleaning applications., 2018, 6: 16043–16052.

[100] RYZHKIN I A, PETRENKO V F. Proton ordering in ice at an ice-metal interface., 2005, 101(2): 317–321.

[101] JIN M, SHEN Y, LUO X,. A combination structure of microblock and nanohair fabricated by chemical etching for excellent water repellency and icephobicity., 2018, 455: 883–890.

[102] XI N, LIU Y, ZHANG X,. Steady anti-icing coatings on weathering steel fabricated by HVOF spraying., 2018, 444: 757–762.

[103] WANG N, TANG L, TONG W,. Fabrication of robust and scalable superhydrophobic surfaces and investigation of their anti-icing properties., 2018, 156: 320–328.

[104] WU X, ZHAO X, HO J W C,. Design and durability study of environmental-friendly room-temperature processable icephobic coatings., 2019, 355: 901–909.

[105] SONG J, LI Y, XU W,. Inexpensive and non-fluorinated su-perhydrophobic concrete coating for anti-icing and anti-corrosion., 2019, 541: 86–92.

[106] ZHENG S, BELLIDO-AGUILAR D A, WU X,. Durable waterborne hydrophobic bio-epoxy coating with improved anti-icing and self-cleaning performance., 2019, 7(1): 641–649.

[107] SHEN Y, WU Y, TAO J,. Spraying fabrication of durable and transparent coatings for anti-icing application: dynamic water repellency, icing delay, and ice adhesion., 2019, 11(3): 3590–3598.

[108] WEI C, JIN B, ZHANG Q,. Anti-icing performance of super- wetting surfaces from icing-resistance to ice-phobic aspects: robust hydrophobic or slippery surfaces., 2018, 765: 721–730.

[109] WANG F, DING W, HE J,. Phase transition enabled durable anti-icing surfaces and its DIY design., 2019, 360: 243–249.

[110] VAZIRINASAB E, JAFARI R, MOMEN G. Application of superhydrophobic coatings as a corrosion barrier: a review., 2018, 341: 40–56.

[111] DING C, TAI Y, WANG D,. Superhydrophobic composite coating with active corrosion resistance for AZ31B magnesium alloy protection., 2019, 357: 518–532.

[112] WEN Q, DI J, JIANG L,. Zeolite-coated mesh film for efficient oil-water separation., 2013, 4(2): 591–595.

[113] ZHANG W, SHI Z, ZHANG F,. Superhydrophobic and su-peroleophilic PVDF membranes for effective separation of water- in-oil emulsions with high flux., 2013, 25(14): 2071– 2076.

[114] ZULFIQAR U, HUSSAIN S Z, SUBHANI T,. Mechanically robust superhydrophobic coating from sawdust particles and carbon soot for oil/water separation., 2018, 539: 391–398.

[115] LI J, XU C, GUO C,. Underoil superhydrophilic desert sand layer for efficient gravity-directed water-in-oil emulsions separation with high flux., 2018, 6(1): 223–230.

[116] LI X, CAO M, SHAN H,. Facile and scalable fabrication of superhydrophobic and superoleophilic PDMS-co-PMHS coating on porous substrates for highly effective oil/water separation., 2019, 358: 1103–1113.

[117] ZHAO X, LI Y, LI B,. Environmentally benign and durable superhydrophobic coatings based on SiO2nanoparticles and silanes., 2019, 542: 8–14.

[118] ZHANG L, LI H, LAI X,. Thiolated graphene-based superhydrophobic sponges for oil-water separation., 2017, 316: 736–743.

Bioinspired Superhydrophobic Materials: Progress and Functional Application

TONG Wei, XIONG Dang-Sheng

(School of Materials Science & Engineering, Nanjing University of Science and Technology, Nanjing 210094, China)

Inspired by the lotus leaves in nature against contaminants in the muddy environment, superhydrophobic phenomena has attracted tremendous attentions among the research communities, and triggered the researchers to fabricate an artificial superhydrophobic surface for real-time applications. In this paper, the development of bioinspired materials is combed in accordance with time evolution. Besides, the advantages/disadvantages of numerous preparations in superhydrophobic coating are discussed through the recent researches. In addition, the recent advances of superhydrophobic applications are summarized, such as self-cleaning behavior, anti-icing properties, anti-corrosion performance and oil/water separation. Particularly, this review introduces the mechanism and implementation of anti-icing properties by superhydrophobic coating. As for superhydrophobic coating, current challenges are pointed out and its future development for applications is prospected. Overall, this review provides a reference for research and development of superhydrophobic coatings.

bioinspired materials; superhydrophobic coating; self-cleaning; anti-icing; anti-corrosion; oil/water separation; review

TB34

A

1000-324X(2019)11-1133-12

10.15541/jim20180591

2018-12-17;

2019-03-25

國家自然科學基金(51575278); 先進復合材料重點實驗室基金(614290402091702)National Natural Science Foundation of China (51575278); Advanced Composite Materials Key Laboratory Fund (614290402091702)

佟威(1990–), 男, 博士研究生. E-mail: tomson90@126.com

熊黨生, 教授. E-mail: xiongds@163.com