響應面中心組合設計法對棉針織物濕蒸染色工藝的優化

俞成丙 陶開鑫 侯頎驁 吳聰杰

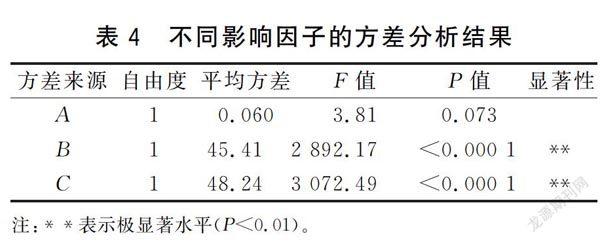

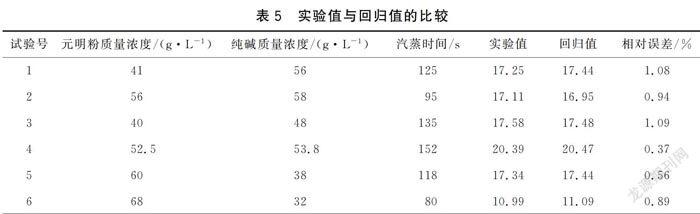

摘 要:采用中心組合設計試驗方案,用響應面分析法考察了雷馬素金黃RGB在棉針織物濕蒸染色時,元明粉和純堿質量濃度、汽蒸時間對染色織物K/S值的影響,建立了二次多項式回歸方程的預測模型。通過模型的回歸分析、3個影響因子方差分析,響應面圖和等高線圖的直觀分析,以及所設計染色工藝的實驗驗證,證明響應面模型能夠準確地預測棉針織物濕蒸染色中各工藝條件對K/S值的影響,最佳染色工藝條件為:元明粉質量濃度52.5 g/L、純堿質量濃度53.8 g/L、飽和蒸汽下汽蒸152 s。

關鍵詞:響應面分析;中心組合設計;濕蒸染色;活性染料;優化

中圖分類號:TS194.4

文獻標志碼:A

文章編號:1009-265X(2019)04-0073-05

Optimization of Wet-Steam Dyeing Technology of Cotton Knitted Fabricby Response Surface Methodology and Central Composite Design

YU Chengbing, TAO Kaixin, HOU Qi’ao, WU Congjie

(School of Materials Science and Engineering, Shanghai University, Shanghai 200444, China)

Abstract:Central composite design and response surface methodology were applied to investigate the influence of the mass concentration of sodium sulfate and soda ash, and steaming time on the K/S value of fabric dyed by wet-steam dyeing process with Ramzol golden yellow RGB. The prediction model of quadratic polynomial regression equation was established. The regression analysis of the model, the variance analysis of three influencing factors and the visual analysis of response surface map and the contour map as well as the experimental verification of the designed dyeing process proved that the response surface model could accurately predict the influence of the process conditions on the K/S value in the wet-steam dyeing process of knitted cotton fabric, and the optimal dyeing conditions were concluded as follows: the mass concentration of sodium sulfate 52.5 g/L, the mass concentration of soda ash 53.8 g/L and steam time 152 s under saturated water steam.

Key words:response surface methodology; central composite design; wet-steam dyeing; reactive dye; optimization

濕蒸染色是一種短流程工藝,將促染劑、堿劑、染料和染色助劑配制在混合液中,紡織物經過浸軋后,直接用飽和蒸汽或過飽和蒸汽進行汽蒸,實現快速固色,一般通過浸軋-汽蒸-水洗工藝,實現紡織物的連續染色,可大大縮短工藝流程,適用于活性染料上染棉針織物[1-2]。響應面分析法是建立在科學合理試驗設計的基礎上,先通過試驗中得到一系列數據,然后采用多元二次回歸方程,來擬合多個變量與一個或幾個響應值之間的函數關系,通過回歸方法進行分析,來尋求最優響應值的工藝參數,它是解決多變量問題時,常用的一種極其重要的統計方法,得到的結果比單因素和正交試驗分析更為有效和全面,已在染色研究中有很多應用[3-6]。本文采用活性染料對棉針織物進行濕蒸工藝染色,通過對染色工藝條件和響應值K/S值的回歸分析,建立染色模型,并對染色工藝條件進行了優化。……