無(wú)刷直流電機(jī)的轉(zhuǎn)子位置檢測(cè)新策略

楊勝浩 李俊良 趙建營(yíng)

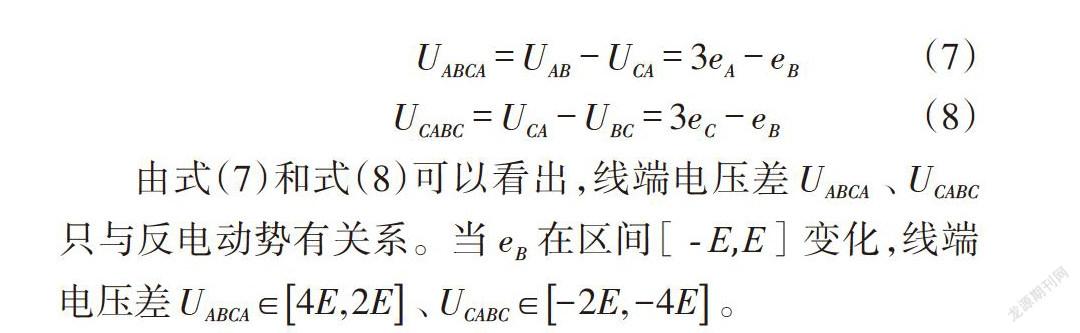

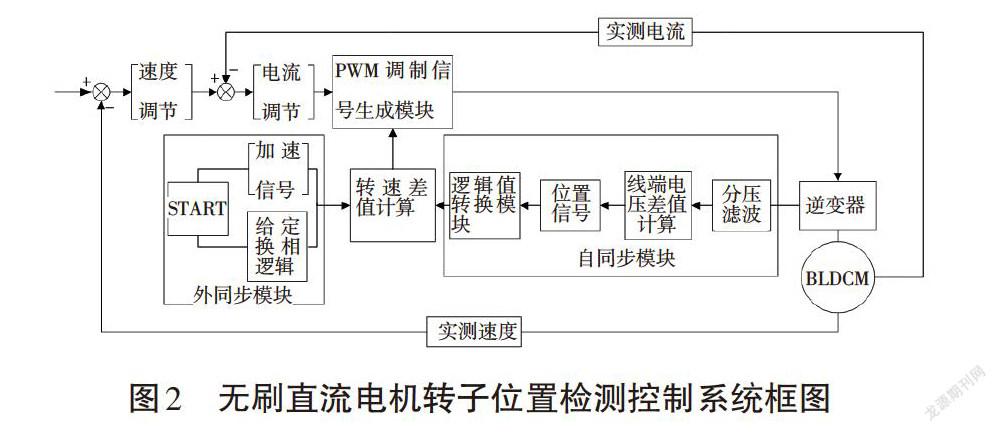

摘 要:在電機(jī)速度控制系統(tǒng)中,轉(zhuǎn)子位置檢測(cè)至關(guān)重要。通過(guò)分析反電動(dòng)勢(shì)法及其改進(jìn)方法可知,當(dāng)電機(jī)在低速運(yùn)行時(shí),反電動(dòng)勢(shì)過(guò)零檢測(cè)法的幅值太小而無(wú)法被檢測(cè)到。對(duì)此,本文提出了一種新的轉(zhuǎn)子位置檢測(cè)方法,并對(duì)該方法進(jìn)行仿真分析。該方法通過(guò)檢測(cè)線端電壓差的過(guò)零點(diǎn),然后延遲90°機(jī)械角得到轉(zhuǎn)子位置信號(hào)。仿真結(jié)果表明,當(dāng)電機(jī)低速運(yùn)行時(shí),新方法均能準(zhǔn)確獲取到轉(zhuǎn)子位置信號(hào),電機(jī)有更寬的運(yùn)行范圍。

關(guān)鍵詞:無(wú)刷直流電機(jī);無(wú)位置傳感器;線端電壓差

中圖分類號(hào):TM33 文獻(xiàn)標(biāo)識(shí)碼:A 文章編號(hào):1003-5168(2019)31-0047-03

Novel Strategy for BLDC Motor Rotor Position Detection

YANG Shenghao LI Junliang ZHAO Jianying

(CAMA(LuoYang) Electronics Co., Ltd.,Luoyang Henan 471003)

Abstract: In the motor speed control system, rotor position detection is very important. By analyzing the back EMF method and its improved method, it can be seen that when the motor is running at low speed, the amplitude of the back EMF zero crossing detection method is too small to be detected. In this paper, a new rotor position detection method was proposed, and the simulation analysis of the modified method was carried out. By detecting the zero crossing point of the line terminal voltage difference, and then delaying 90° mechanical angle, the rotor position signal is obtained. The simulation results show that when the motor runs at low speed, the new method can get the rotor position signal accurately, and the motor has a wider range of operation.

Keywords: Brushless DC motor;position sensorless;line terminal voltage difference

1 研究背景

無(wú)刷直流電機(jī)(Brushless Direct Current Motor,BLDCM)在調(diào)速系統(tǒng)中占有重要地位,其性能直接決定系統(tǒng)性能的好壞。無(wú)刷直流電機(jī)采用電子換相,需要通過(guò)位置傳感器獲取轉(zhuǎn)子位置信號(hào),以控制電子換相裝置完成換相,因此轉(zhuǎn)子位置信號(hào)的獲取至關(guān)重要。目前,我國(guó)工業(yè)控制中使用的無(wú)刷直流電機(jī)大多數(shù)是通過(guò)電子或機(jī)電式位置傳感器直接檢測(cè)電機(jī)的轉(zhuǎn)子位置信號(hào)[1],但在檢測(cè)時(shí),仍存在較多問(wèn)題。一方面,當(dāng)電機(jī)工作于高溫、高壓、潮濕等惡劣環(huán)境時(shí),位置傳感器的性能將會(huì)降低,甚至不能正常工作;另一方面,位置傳感器的安裝和安裝精度,以及位置傳感器與電機(jī)之間的眾多連線,不僅導(dǎo)致電機(jī)的體積、制造成本增加,工藝難度提高,而且直接影響電機(jī)的運(yùn)行性能和運(yùn)行可靠性[2,3]。

國(guó)內(nèi)外提出的無(wú)位置傳感器轉(zhuǎn)子位置的檢測(cè)方法有反電動(dòng)勢(shì)過(guò)零檢測(cè)法、續(xù)流二極管法、電感法和狀態(tài)觀測(cè)器法等[4]。……