花管注漿加固松散碎石土層試驗與效果參數預測模型

楊 溢,盧 杰,楊志全,丁 一

?

花管注漿加固松散碎石土層試驗與效果參數預測模型

楊 溢,盧 杰,楊志全※,丁 一

(昆明理工大學公共安全與應急管理學院,昆明 650093)

注漿技術可用來加固松散碎石土層,以提高其防滲與承載能力。該文以滲透注漿工作原理與注漿花管技術為基礎,開展了加固松散碎石土層注漿試驗研究;并依據數值分析方法與Minitab 16軟件,探討了注漿加固松散碎石土層注漿量、擴散半徑、擴散高度及結石體抗壓強度等效果參數預測模型;同時設計試驗進行了驗證。研究結果表明:1)相鄰注漿孔流出的漿液在松散碎石土層中相容,且側邊與底部注漿孔流出的水泥漿液在松散碎石土層滲透擴散時產生了明顯的群效應,從而形成一個整體近似呈圓柱形的注漿結石體;2)由這些模型計算得到的注漿量實測值大于預測值,而擴散半徑、擴散高度及結石體抗壓強度的實測值都小于預測值,但均相差不大,其相對誤差分別在9%、7%、6%與6%左右變動。因此,該文構建模型可作為采用注漿技術加固松散碎石土層的注漿量、擴散半徑、擴散高度及結石體抗壓強度等效果參數的設計基礎。研究成果可為碎石土地質災害的防災減災提供一定的理論參考。

水泥;抗壓強度;模型;松散碎石土層;注漿花管技術;效果參數;預測模型

0 引 言

碎石土是由殘坡積、風化卸荷及沖洪積等形成的第四紀土與石塊的二重介質非均質土石混合體,是一種特殊的地質體[1-2]。在中國,碎石土地層在每個省份均有分布,尤其在西南及西北山區更為廣泛[2],目前較多的自然災害在碎石土地層中誘發,如滑坡、崩塌與泥石流等;尤其在地震與人為活動作用下更易發生,不僅損毀大量的農田,而且造成非常慘痛的事故,嚴重影響著人民群眾的生命財產安全。如2010年8月8日甘肅舟曲誘發的泥石流災害造成了300余間碎石土地基房屋倒塌、1 824人受傷、208人失蹤及1 557人遇難的慘劇[3-5]。

目前,學者在碎石土的物理力學性質、碎石土邊坡穩定性及防治措施等領域開展了較深入的探索,并取得了較多的研究成果。李泯蒂等[2,6-8]研究了碎石土的滲透特性;王生新等[9]與董輝等[10]分別研究了碎石土濕陷性與三軸剪切特性。吳銳等[11]分析了碎石尺寸對碎石土強度的影響;王春得等[12-16]研究了含石量對碎石土工程力學特性的影響。Fourie等[17-21]探索了滲透特性對碎石土邊坡穩定性的影響;鄭開歡等[22]分析了暴雨作用下碎石土邊坡穩定性的變化特征。陳志超等[23-25]探索了碎石土滑坡的工程防治對策。雷進生等[26-28]在利用注漿技術加固碎石土方面取得了一定的研究成果;但它們存在研究對象與碎石土具有一定差異、選取因素不合理或研究不全面等方面的不足。

當前,注漿技術,尤其是花管注漿技術,在國內外眾多的注漿工程實踐中具有較廣泛的應用,已遍及邊坡、地鐵、礦山、建筑、公路、隧道、鐵路及水電等較多工程領域[1,29-31]。然而,在采用花管注漿技術加固巖土體的理論研究方面目前還處于探索階段,導致其理論滯后于工程應用,難以滿足注漿實踐的需要。為此,本文以滲透注漿工作原理與花管注漿技術為基礎開展加固松散碎石土層注漿試驗研究;并依據數值分析方法與Minitab 16軟件探討注漿量、擴散半徑、擴散高度及結石體抗壓強度等效果參數與注漿壓力、水灰比、注漿花管側邊注漿孔間平均孔距、注漿時間與碎石土孔隙率等影響因素間的相互關系,以期為松散碎石土災害的防治減災提供一定的理論支撐。

1 材料與方法

1.1 試驗材料

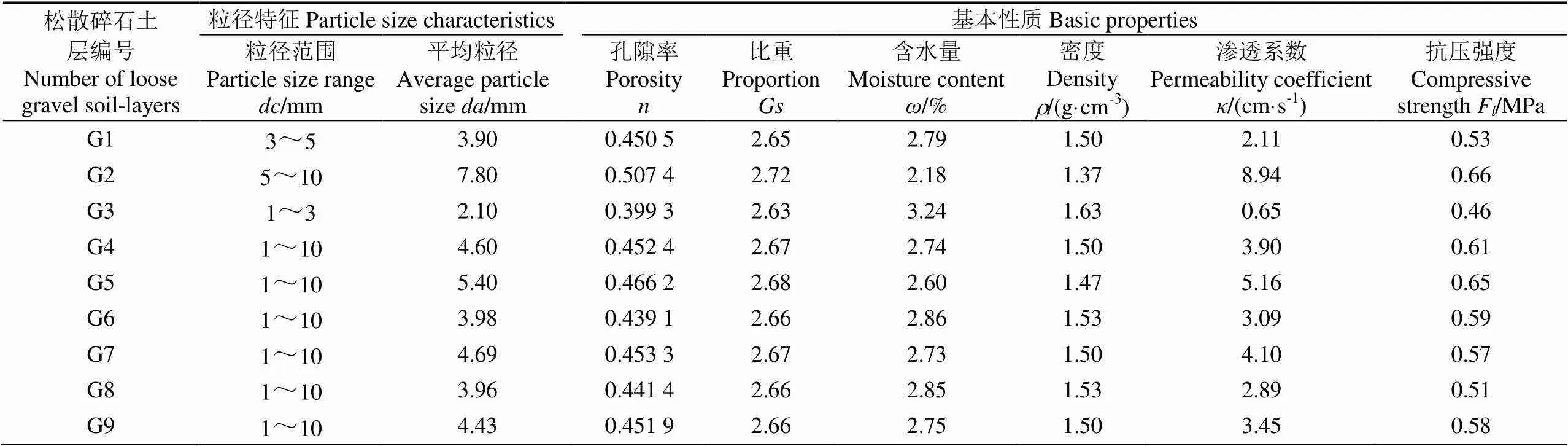

試驗材料來源于云南省昆明市某建筑基地。根據野外實踐調查可知:大多碎石土地層災害發生在孔隙率為0.35~0.50區間,尤其在0.40~0.50的范圍更廣泛。因此,本文設計9種松散碎石土層作為被注材料,其粒徑特征與基本性質見表1。表1中,粒徑范圍、平均粒徑、比重、含水量、密度、滲透系數與抗壓強度等性質指標能直接測試獲得,而孔隙率可依據土力學基礎知識由比重、含水量與密度聯合計算得到。

注漿材料選用昆明水泥廠生產的#32.5普通硅酸鹽水泥,該標號水泥在目前的注漿實踐工程中被廣泛使用。

表1 注漿試驗采用的松散碎石土粒徑特征與基本性質

1.2 試驗設備與工作原理

1.2.1 試驗設備

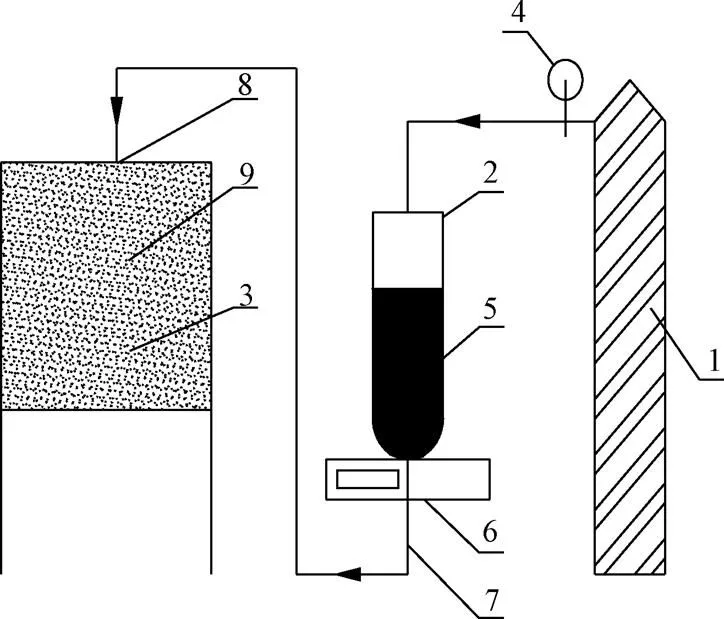

注漿試驗設備自行設計與加工,由試驗箱、供壓裝置與儲漿容器3部分組成[27],見圖1。

1.氮氣減壓器與注漿控制開關 2.試驗箱 3.供壓裝置 4.儲漿容器 5.注漿花管 6.電子稱

在圖1中,試驗箱的三維尺寸為600 mm×600 mm× 600 mm,由有機玻璃板與鋼支架構成,用來放置松散碎石土層;供壓裝置裝有的氮氣可為注漿試驗提供所需的注漿壓力,聯合氮氣減壓器與注漿控制開關可實現對每組試驗所設計的注漿壓力值與注漿時間的精確定量控制;儲漿容器用來盛注漿流體,由電子稱、密閉鋼制圓筒及圓形鐵架組成,電子稱可對試驗過程注入的漿液量較精確地測量與控制;密閉鋼制圓筒設計能承受的最大壓力為2.5 MPa,高與底面直徑分別為40、15 cm;底部與頂部分別開口,開展注漿試驗時,有壓氮氣由頂部開口進入儲漿容器,對注漿漿液提供所需的壓力,在注漿壓力的推動下,漿液由底部開口注入放置在試驗箱的松散礫石土層中。

1.2.2工作原理

本文開展的注漿試驗采用滲透注漿,其工作原理見圖2,注漿具體步驟如下:

1)配置不同性質特征的松散碎石土層,并測量它們各自的性質特征參數。如,比重、含水量、密度、滲透系數及孔隙率等;

2)按設計要求拼裝試驗箱體,鋪設塑料薄膜(防止注漿過程中漏漿),將步驟1)中配置好的松散碎石土層裝入試驗箱體,同時預埋注漿花管;

3)按照設計的水灰比配置注漿流體—水泥漿液;

4)將配置好的水泥漿液灌入儲漿容器中,并安裝注漿導管;

5)開始注漿。打開注漿控制開關,并緩慢開啟氮氣減壓器,不斷調節注漿壓力直到壓力表達到設計的注漿壓力值,觀察并記錄漿液流動情況;

6)停止注漿。當儲漿容器中水泥漿液注完或大幅度增大注漿壓力漿液仍不再進入,則停止注漿;

7)拆模。待漿液凝固后拆模,觀察并記錄容器內部漿液的分布和擴散情況;

8)整理試驗數據,測量、測試與分析在松散碎石土層中形成的注漿結石體擴散效果參數。

1.供壓設備 2.儲漿容器 3.試驗箱 4.氮氣減壓器(裝有壓力表)與注漿控制開關 5.注漿流體(本文采用水泥漿液) 6.電子稱 7.注漿導管 8.注漿花管 9.松散碎石土層

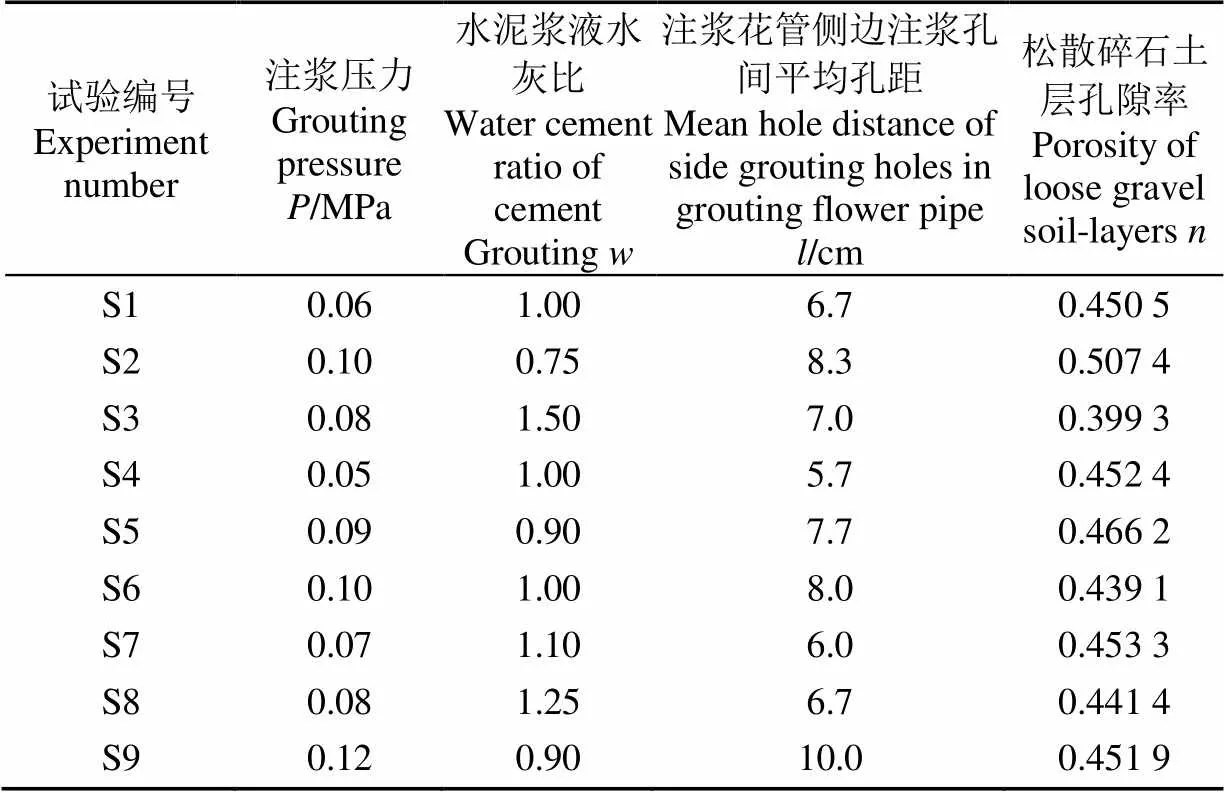

1.3 試驗設計

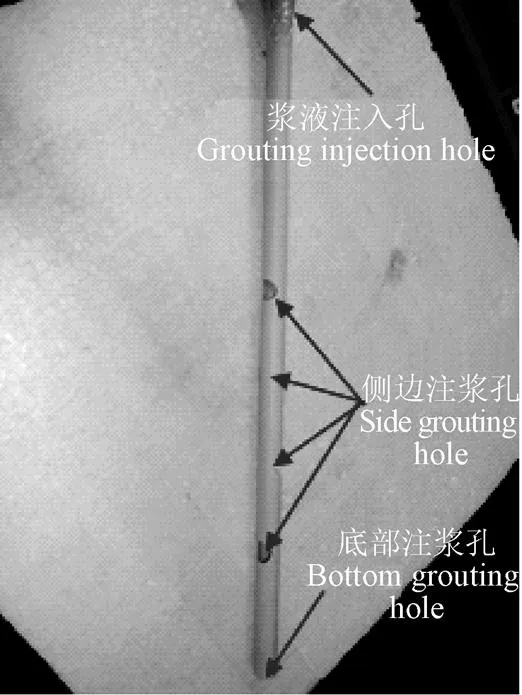

依據實際調查結果及注漿理論,本研究選取注漿壓力、水泥漿液水灰比、注漿花管側邊注漿孔間平均孔距與碎石土層孔隙率等4個因素作為開展注漿試驗的影響因素,由此設計的注漿試驗方案見表2。注漿花管上設計的注漿孔與漿液注入孔分布見圖3。

表2 注漿試驗設計方案

注:編號為S1~S9的試驗設計分別采用表1中編號為G1~G9所代表的松散碎石土層作為被注材料。

Note: Experiments numbered S1-S9 are designed to adopt respectively loose gravel soil-layer represented by number G1-G9 in the table 1 as injected materials.

圖3 注漿花管上的注漿孔與漿液注入孔分布示意圖

2 試驗結果與分析

2.1 試驗結果

依據表2的試驗方案開展注漿試驗,可觀察得到水泥漿液在松散碎石土層中具有如下的擴散規律:

1)水泥漿液從頂部注入孔注入注漿花管后,由側邊注漿孔從上到下依次流出進入松散碎石土層滲透擴散,而底部注漿孔最后流出少量的水泥漿液;

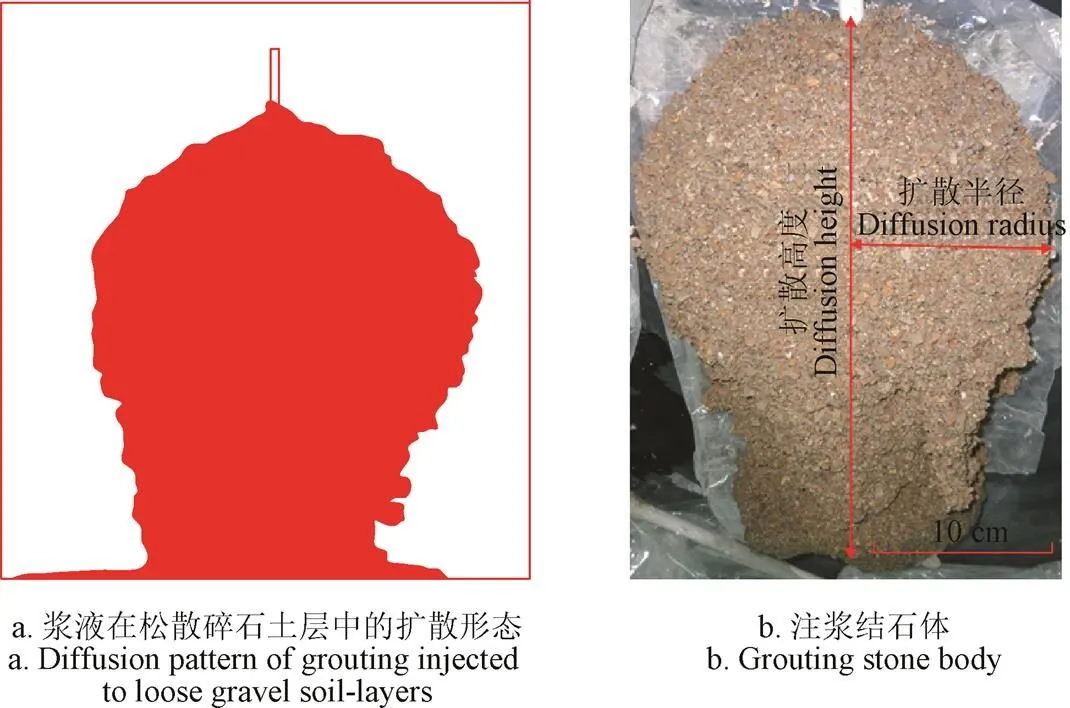

2)相鄰注漿孔流出的漿液在松散碎石土層中相容, 側邊與底部注漿孔流出的水泥漿液在松散碎石土層滲透擴散時產生了明顯的群效應,進而形成一個整體近似呈圓柱形的注漿結石體。

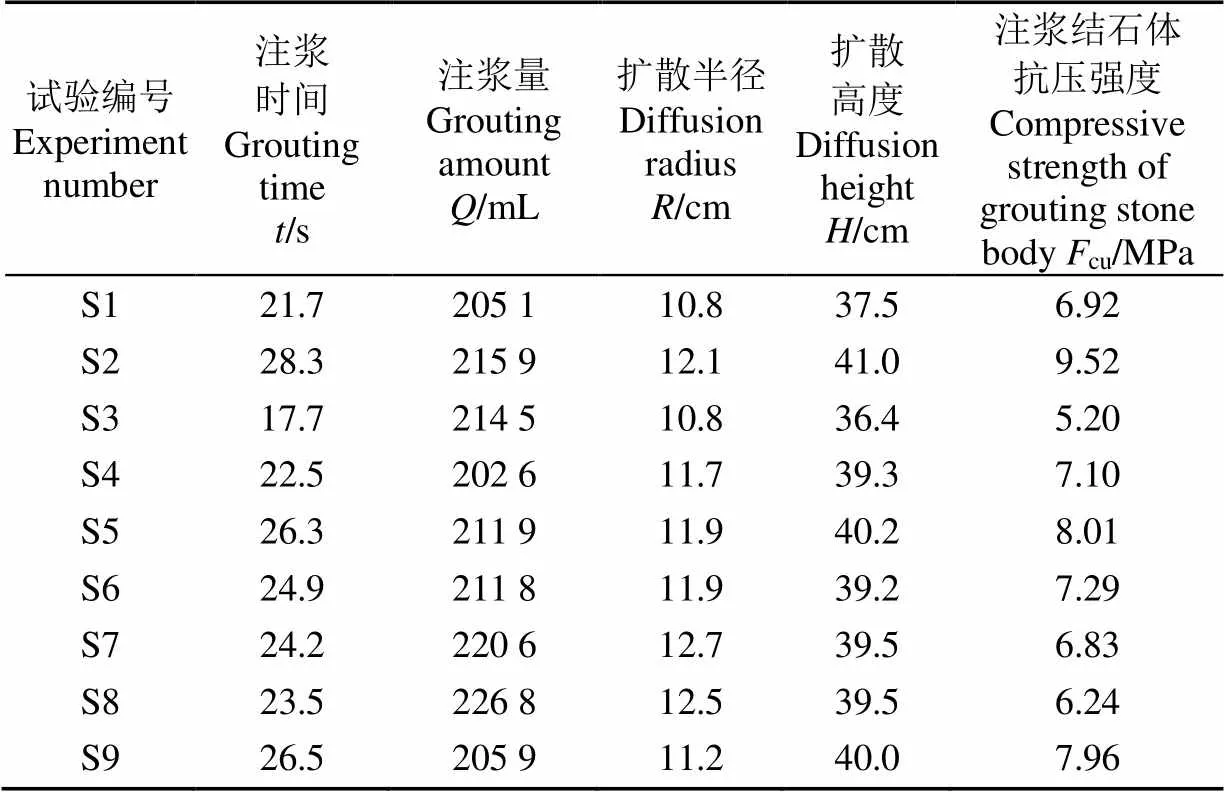

測量獲得的水泥漿液在松散碎石土層中的擴散注漿量、結石體擴散半徑、結石體擴散高度及結石體抗壓強度cu等效果參數結果見表3;其擴散形態與形成的結石體見圖4。

表3 注漿效果參數

Table 3 Parameters of grouting effect

圖4 水泥漿液在松散碎石土層中的擴散形態與形成的結石體

2.2 抗壓強度增長分析

由表3和表1可知,加固松散碎石土層形成的注漿結石體抗壓強度較未加固的松散碎石土層抗壓強度具有明顯地提升,其提升幅度為1 030%~1 342%。這表明采用花管注漿技術加固松散碎石土層具有較好的效果。

2.3 效果參數與影響因素間的相互關系分析

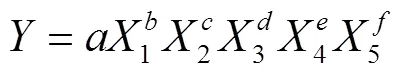

參考文獻[1],注漿加固效果參數與影響因素符合如下的相互變化關系

式中為注漿加固效果參數;1、2、3、4與5為注漿影響因素;、、、、與為擬合參數。

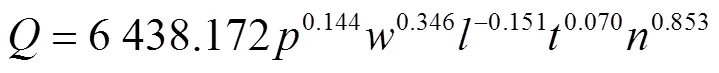

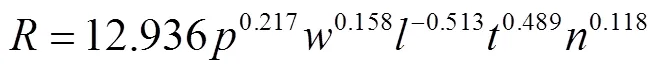

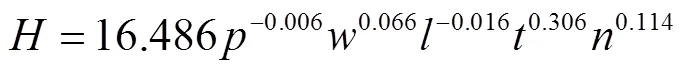

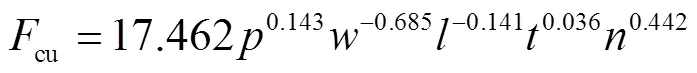

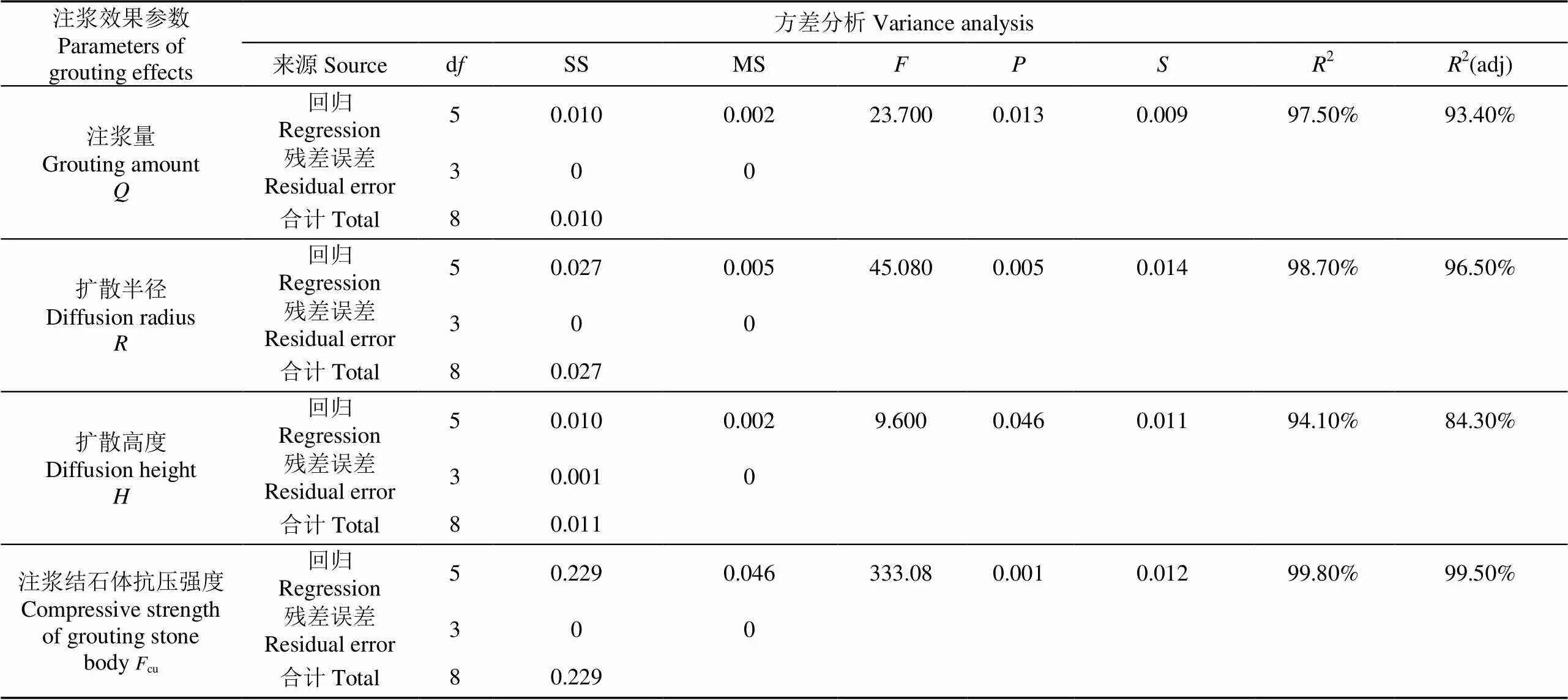

采用Minitab 16軟件分別對注漿量、擴散半徑、擴散高度及結石體抗壓強度cu等效果參數與注漿壓力、水灰比、注漿花管側邊注漿孔間平均孔距、注漿時間及碎石土孔隙率等影響因素間的試驗結果(表3)進行數值分析,可得到它們間分別符合式(3)~(6)的相互變化關系,擬合方差分析結果見表4。

表4 注漿加固松散碎石土層效果參數與影響因素間的擬合方差分析結果

注:為試驗數據與回歸線間的標準偏離距離,mm。

Note:represents standard deviation distance between experimental data and regression line, mm.

由表4可知,各參數擬合相關系數2與調整的2(adj) 均大于84.30%,則表明擬合得到的式(3)~(6)與試驗結果間的回歸分析效果較好;同時,在方差分析結果中,值都小于0.05,表明回歸擬合式(3)~(6)在0.05水平下具有顯著的統計意義。因此,式(3)~(6)可分別作為注漿加固松散碎石土層注漿量、擴散半徑、擴散高度及結石體抗壓強度cu等效果參數預測模型。

3 效果參數預測模型試驗驗證

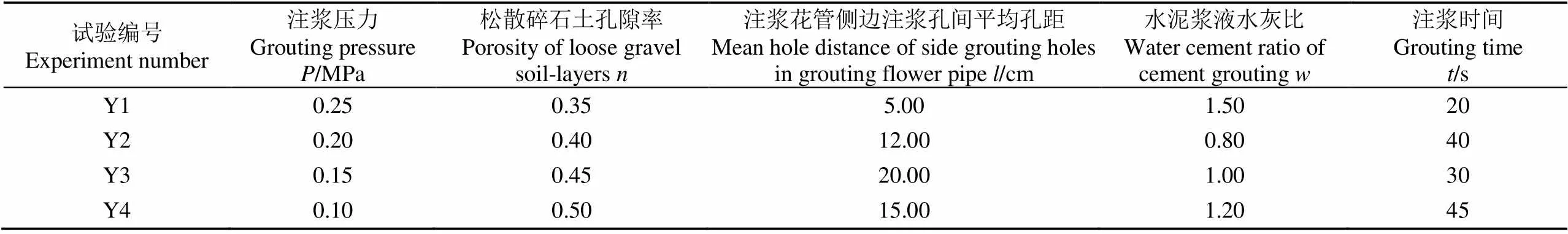

為驗證上文得到的注漿加固松散碎石土層注漿量、擴散半徑、擴散高度及結石體抗壓強度cu等效果參數預測模型(式(3)~(6))在工程實踐中的適用性,筆者設計試驗對其進行驗證。

3.1 驗證試驗設計

采用的試驗設備與工作原理分別見圖1~2。本部分擬設計4組驗證試驗,其分別選用粒徑范圍為1~3、3~5、5~8與8~10 mm的松散碎石土層,對應的平均粒徑分別為1.96、4.03、6.62與8.74 mm;比重、含水量、密度、孔隙率、滲透系數與抗壓強度等指標的獲取方法同上文。設計的驗證試驗方案如表5所示。

表5 注漿驗證試驗設計方案

3.2 結果與分析

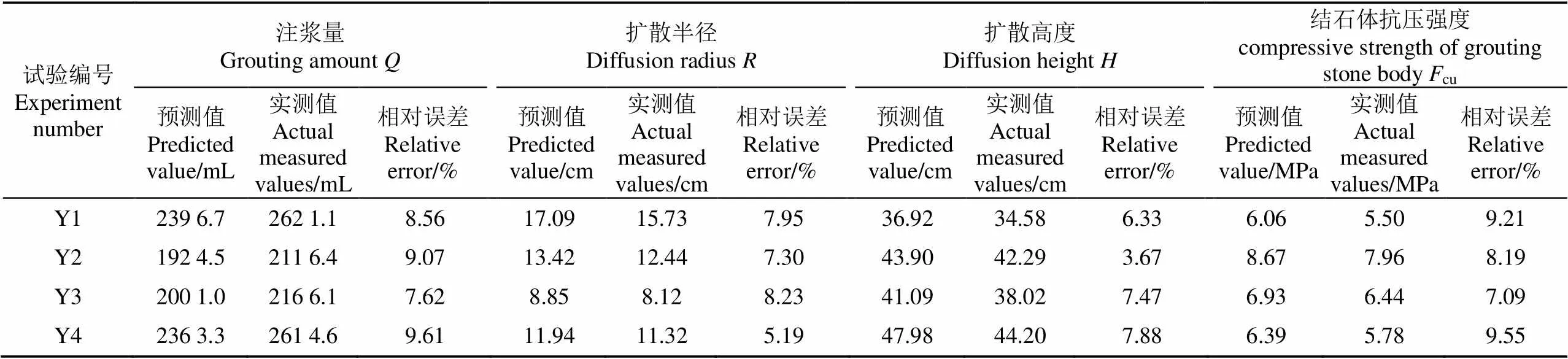

采用注漿加固松散碎石土層注漿量、擴散半徑、擴散高度及結石體抗壓強度cu等效果參數預測模型(式(3)~(6))得到的注漿量、擴散半徑、擴散高度及結石體抗壓強度的預測值與實測值及二者間的相對誤差分析結果見表6。

由表6可看出,采用注漿加固松散碎石土層注漿量、擴散半徑、擴散高度及結石體抗壓強度cu等效果參數預測模型(式(3)~(6))計算得到的注漿量預測值小于實測值,而擴散半徑、擴散高度及結石體抗壓強度的實測值均小于預測值,但均相差不大,其相對誤差分別在9%、7%、6%與6%左右變動,均小于10%。這表明,本文構建的注漿量、擴散半徑、擴散高度及結石體抗壓強度cu等效果參數預測模型(式(3)~(6))能用來分別預測采用注漿加固松散碎石土層的注漿量、擴散半徑、擴散高度及結石體抗壓強度等效果參數指標。

表6 松散碎石土層注漿加固效果參數預測值與實測值及差異分析

4 結 論

以滲透注漿工作原理與注漿花管技術為基礎,開展了加固松散碎石土層注漿試驗研究,依據數值分析方法與Minitab 16軟件,構建了注漿加固松散碎石土層注漿量、擴散半徑、擴散高度及結石體抗壓強度等效果參數預測模型,并對其進行了驗證,得到以下結論:

1)水泥漿液通過花管注漿在松散碎石土層中的擴散規律:相鄰注漿孔流出的漿液在松散碎石土層中相容,且側邊與底部注漿孔流出的漿液在松散碎石土層滲透擴散時產生了明顯的群效應,從而形成一個整體近似呈圓柱形的注漿結石體;

2)由模型計算得到的注漿量實測值大于預測值,而擴散半徑、擴散高度及結石體抗壓強度的實測值都小于預測值,但均相差不大,其相對誤差分別在9%、7%、6%與6%左右變動,模型較準確。

本文的研究成果不僅能為松散碎石土層的注漿加固工程實踐提供技術支撐,而且還可為碎石土地質災害的防災減災提供理論參考。

[1] 巖土注漿理論與工程實例》協作組. 巖土注漿理論與工程實例[M]. 北京:科學出版社,2001.

[2] 李泯蒂. 三峽庫區滑坡碎石土滲透特性研究[D]. 宜昌:三峽大學,2014.

Li Mindi. Gravel Soil Infiltration Characteristics Research of the Three Gorges Area Landslides[D]. Yichang: China Three Gorges University, 2014. (in Chinese with English abstract)

[3] 邱敏,陳行,田明杰,等. 斜入射地震作用下坡面形態對碎石土邊坡穩定性影響研究[J]. 震災防御技術,2015,10(2):324-334.

Qiu Min, Chen Hang, Tian Mingjie, et al. Effect of slope shape on gravel-soil slope stability in obliquely incident seismic wave[J]. Technology for Earthquake Disaster Prevention, 2015, 10(2): 324-334. (in Chinese with English abstract)

[4] 李曉蓮. 降雨和地震影響下碎石土邊坡的穩定性分析[D].蘭州:蘭州大學,2013.

Li Xiaolian. Analysis of Gravel Slope Stability Under Rainfall and Earthquake[D]. Lanzhou: Lanzhou University, 2013. (in Chinese with English abstract)

[5] 南如卓瑪. 甘肅舟曲泥石流五周年:浴火重生重振家園[EB/OL].(2015-08-08)[2018-03-02].http://www.Chinanews.com/sh/2015/08-08/7455355.shtml

[6] 王雙,李小春,王少泉,等. 碎石土級配特征對滲透系數的影響研究[J]. 巖石力學與工程學報,2015:34(增刊2):4394-4402.

Wang Shuang, Li Xiaochun, Wang Shaoquan, et al. Study on gravel-soil gradation characteristics influence on the permeability coefficient[J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(Supp.2): 4394-4402. (in Chinese with English abstract)

[7] Wang Z, Feyen J, Nielsen D R, et al. Two-phase flow infiltration equations accounting for air entrapment effects[J]. Water Resources Research, 1997, 33(12): 2759-2767.

[8] Hammecker C, Antonino A C D, Maeght J L, et al. Experimental and numerical study of water flow in soil under irrigation in northern Senegal: evidence of air entrapment[J]. European Journal of Soil Science, 2003, 54(3): 491-503.

[9] 王生新,陸勇翔,尹亞雄,等. 碎石土濕陷性試驗研究[J].巖土力學,2010,31(8):2373-2377.

Wang Shengxin, Lu Yongxiang, Yin Yaxiong, et al. Experimental study of collapsibility of gravel soil[J]. Rock and Soil Mechanics, 2010, 31(8): 2373-2377. (in Chinese with English abstract)

[10] 董輝,陳璽文,傅鶴林,等. 堆積碎石土剪切特性的三軸試驗[J]. 長安大學學報:自然科學版,2015,35(2):59-66.

Dong Hui, Chen Xiwen, Fu Helin,et al. Triaxial test of shear properties of eluvial gravel soil[J]. Journal of Changan University: Natural Science Edition, 2015,35(2):59-66. (in Chinese with English abstract)

[11] 吳銳,鄧清祿,付敏,等. 碎石尺寸對碎石土強度影響的大型直剪試驗研究[J]. 長江科學院院報,2016,33(8):80-85.

Wu Rui, Deng Qinglu, Fu Min,et al. Large direct shear test on the influence of stone size on the strength of gravel soil[J]. Journal of Yangtze River Scientific Research Institute, 2016, 33(8): 80-85. (in Chinese with English abstract)

[12] 王春得,沈秋武,吳銳,等. 含石量對碎石土工程特性的影響試驗研究[J]. 鐵道建筑,2016,56(2):97-101.

Wang Chunde, Shen Qiuwu, Wu Rui, et al. Experimental study on effect of stone content on engineering performance of crushed stone soil[J]. Railway Engineering, 2016, 56(2): 97-101. (in Chinese with English abstract)

[13] Lindquist E S, Goodman R E. Strength and deformation properties of a physical model[C]/ / Proceedings of the 1st North American Rock Mechanics Conference. Rotterdam: Balkema A A, 1994: 843-850.

[14] Medley E E, Lindquist E S. The engineering significance of the scale-independence of some franciscan melanges in California, USA[C]// Proceedings of the 35th US rock Mechanics Symposium. Rotterdam: Balkema A A, 1995: 907-914.

[15] Simoni A, Houlsby G T. The direct shear strength and dilatancy of sand-gravel mixtures[J]. Geotechnical and Geological Engineering, 2006, 24(3): 523-549.

[16] Ghasemi A, Rothenbur G L, Matysel. Influence of particle shape on engineering properties of assemblies of two-dimensional polygon-shaped particles[J]. Geotechnique, 2002, 52(3): 209-217.

[17] Fourie A B, Rowe D, Blight G E. The effect of infiltration on the stability of the slopes of a dry ash dump[J]. Geotechnique, 1999, 49(1): 15-23.

[18] Gavin K, Xue J F. A simple method to analyze infiltration into unsaturated soil slopes[J]. Computers & Geotechnics, 2008, 35(2): 223-231.

[19] Egeli I, Pulat H F. Mechanism and modeling of shallow soil slope stability during high intensity and short duration rainfall[J]. Scientia Iranica, 2011, 18(6): 1179-1193.

[20] Gasmo J M, Rahardjo H, Leong E C. Infiltration effects on stability of a residual soil slope[J]. Computers & Geotechnics, 2000, 26(2): 145-165.

[21] Yang C, Sheng D C, Carter J P. Effect of hydraulic hysteresis on seepage analysis for unsaturated soils[J]. Computers & Geotechnics, 2012, 41(5): 36-46.

[22] 鄭開歡,羅周全,羅成彥,等. 持續暴雨作用下排土場層狀碎石土邊坡穩定性[J]. 工程科學學報,2016,38(9):1204-1211.

Zheng Kaihuan, Luo Zhouquan, Luo Chengyan, et al. Layered gravel soil slope stability of a waste dump considering long-term hard rain[J]. Chinese Journal of Engineering, 2016, 38(9): 1204-1211. (in Chinese with English abstract)

[23] 陳志超,羅旋,柳侃,等. 碎石土滑坡滲流系統特征及防治措施研究[J]. 巖土力學,2016,37(3):813-819.

Chen Zhichao, Luo Xuan, Liu Kan, et al. Seepage characteristics and mitigation measures of a gravel soil landslide[J]. Rock and Soil Mechanics, 2016, 37(3): 813-819. (in Chinese with English abstract)

[24] 孔紀名,蔡強,張引,等.單排微型樁加固碎石土滑坡物理模型試驗[J]. 山地學報,2013,31(4):399-405.

Kong Jiming, Cai Qiang, Zhang Yin, et al. Physical model test of debris landslide reinforcement with single row micro-pile[J]. Journal of Mountain Science, 2013, 31(4): 399-405. (in Chinese with English abstract)

[25] 姚曉陽,楊小永,曾錢幫. 碎石土滑坡工程地質特性及防治方案研究[J]. 工程地質學報,2012,20(3):369-376.

Yao Xiaoyang, Yang Xiaoyong, Zeng Qianbang. Engineering geology characteristics and prevention measure of landslide in soil and rock debris slopes[J]. Journal of Engineering Geology, 2012, 20(3): 369-376. (in Chinese with English abstract)

[26] 雷進生. 碎石土地基注漿加固力學行為研究[D]. 武漢:中國地質大學,2013.

Lei Jinsheng. Research on Mechanical Behavior of Grout in Gravelly Soil Foundations[D]. Wuhan: China University of Geosciences, 2013. (in Chinese with English abstract)

[27] 楊志全. 水泥漿液在小粒徑砂石體中注漿理論及模擬實驗研究[D]. 昆明:昆明理工大學,2008.

Yang Zhiquan. Research on Grouting Theory and Simulation Experiments of Small-size Gravel Injected by Cement Grouting[D]. Kunming: Kunming University of Science and Technology, 2008. (in Chinese with English abstract)

[28] Yang Zhiquan, Qian Shanguang, Hou Kepeng, et al. Technological parameters of reinforced coarse-grained soil by grouting technology[J]. Electronic Journal of Geotechnical Engineering, 2015, 20(27): 13347-13356.

[29] 黃博. 鋼花管注漿型擋墻加固邊坡研究[D]. 成都:西南交通大學,2010.

Huang Bo. Research of Steel Pipe Type of Retaining Wall Reinforced Slope[D]. Chengdu: Southwest Jiaotong University, 2010. (in Chinese with English abstract)

[30] 楊康. 花管注漿補強加固軟基施工技術[J]. 中國管理信息化,2017,20(12):105-106.

Yang Kang. Construction technology for reinforcing soft foundation with flower pipe grouting[J]. China Management Informationization, 2017, 20(12): 105-106. (in Chinese with English abstract)

[31] 王繼坤,張方方. 花管注漿在基坑邊坡加固工程中的應用[J]. 資源環境與工程,2011,25(1):65-70.

Wang Jikun, Zhang Fangfang. Application of flower pipe grouting in foundation pit slope reinforcement[J]. Resources Environment Engineering, 2011, 25(1): 65-70. (in Chinese with English abstract)

Experiments and effect parameters prediction model of reinforcement loose gravel soil-layers by flower pipe grouting

Yang Yi, Lu Jie, Yang Zhiquan※, Ding Yi

(,650093,)

Grouting technology with very strong practicality and wide application can be used to reinforce loose gravel soil layers and improve its anti-seepage and carrying capacity. In China, loose gravel soil layers are distributed in every province, especially in the southwest and northwest mountainous areas. At present, due to their typical dual medium heterogeneity, lots of natural disasters are easily induced in loose gravel soil layers under the actions of rainfall, earthquake and human activities, such as debris flows, dammed lakes, collapses and landslides, which not only destroy a large amount of farmland, but also cause very painful accidents, and then seriously affect safety of people's lives and property. Firstly, based on penetration grouting operational principle and grouting flower pipe technologies in this research, some grouting experiments of reinforcing loose gravel soil layers had been carried out by analyzing and selecting four important influencing factors (grouting pressure, water cement ratio of cement grouting, mean hole distance of side grouting holes in grouting flower pipe and porosity of loose gravel soil layers). After that, according to numerical analysis method and Minitab 16 software, interrelations among grouting reinforcement effect parameters (such as grouting amount, diffusion radius, diffusion height, compressive strength of grouting stone body, et al) of loose gravel soil layers and influencing factors were researched, and then corresponding prediction models of these effect parameters which contains grouting pressure, water cement ratio of cement grouting, mean hole distance of side grouting holes in grouting flower pipe and porosity of loose gravel soil layers also were discussed. What is more, these prediction models were validated by means of designing indoor grouting experiments. Research results show that: 1) cement grouting injected into grouting flower pipe from top injection hole flows into in turn loose gravel soil layers from top to bottom through side grouting holes, while a small amount of it finally flows out from bottom grouting hole; A whole grouting stone body with approximately cylindrical shape is formed as cement grouting from adjacent grouting holes is compatible in loose gravel soil layer. 2) Predicted values of grouting amount calculated by grouting amount prediction models are less than actual measured values from grouting verification experiments, while predicted values of diffusion radius, diffusion height and compressive strength of grouting stone body are all more than corresponding actual measured values. And then these predicted values of grouting reinforcement effect parameters calculated by prediction models have within 10% relative error with the actual measurement values by grouting verification experiments, but these differences values are admitted. Thus, these prediction models of grouting reinforcement effect parameters constructed in this paper may take grouting amount, diffusion radius, diffusion height and compressive strength of stone body of reinforced loose gravel soil-layers by grouting technologies as design basis. Therefore, these research achievements obtained in this research may not only provide theoretical reference for disaster prevention, reduction and mitigation of debris flow, dammed lake, landslide and collapse induced in the loose gravel soil layers, but also can provide technical support for actual grouting engineering of controlled loose gravel soil layers by grouting technology.

cements; compressive strength; models; loose gravel soil-layers; flower pipe grouting technologies; effect parameters; prediction model

楊 溢,盧 杰,楊志全,丁 一. 花管注漿加固松散碎石土層試驗與效果參數預測模型[J]. 農業工程學報,2018,34(24):151-157. doi:10.11975/j.issn.1002-6819.2018.24.018 http://www.tcsae.org

Yang Yi, Lu Jie, Yang Zhiquan, Ding Yi. Experiments and effect parameters prediction model of reinforcement loose gravel soil-layers by flower pipe grouting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(24): 151-157. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.24.018 http://www.tcsae.org

2018-04-15

2018-10-22

國家自然科學基金聯合基金重點項目(U1502232);國家自然科學基金項目(41402272);云南省基礎研究計劃(2015FB122)

楊 溢,教授,博士,主要從事災害起動機理與水土保持方面研究。Email:2919847230@qq.com

楊志全,教授,博士,主要從事災害起動機理與水土保持方面研究。Email:yzq1983816@163.com

10.11975/j.issn.1002-6819.2018.24.018

TU 443

A

1002-6819(2018)-24-0151-07