雙逾滲結構碳系填充導電高分子復合材料的研究進展

王 英

[山西省化工研究所(有限公司),山西 太原 030001]

雙逾滲結構碳系填充導電高分子復合材料的研究進展

王 英

[山西省化工研究所(有限公司),山西 太原 030001]

綜述了導電高分子復合材料(CPCs)導電性能的逾滲理論和雙逾滲機理,闡述了以碳材料為導電填料的具有雙逾滲結構的CPCs的研究進展,其填料主要包括炭黑、碳納米管;展望了雙逾滲結構CPCs的研究前景。

炭黑;碳納米管;雙逾滲結構;逾滲閾值;導電性;復合材料

0 前言

探索和發展CPCs制備的新方法,以保證在具有良好導電功能的情況下,降低導電逾滲閾值、獲得良好力學性能、加工性能和電性能且電性能不受成型加工外場影響或影響極小的CPCs理論和應用已成為研究重點和熱點[1]。截止目前,研究者具體開發了諸多方法來降低CPCs的逾滲值,如隔離結構導電[2]、多逾滲(其中最常用的為雙逾滲)[3]、在基體聚合物合成過程中原位加入導電填料[4-5]、多層共擠出[6]、泡孔結構CPCs[7-9]、靜電紡絲技術[10-11]、原位微纖化[12]等。相對于其他方法,雙逾滲現象由于具有以下優勢而表現出獨特的優越性:(1)減弱體系負溫度系數(NTC)現象[13-15];(2)改善導電復合材料的加工性能及力學性能[16-17];(3)降低材料的體積電阻率及炭黑(CB)的逾滲閾值[18-20]。本文以CB和碳納米管(CNTs)為例,對碳系填充雙逾滲結構的CPCs進行了研究。

1 逾滲理論和雙逾滲機理

1.1 逾滲理論

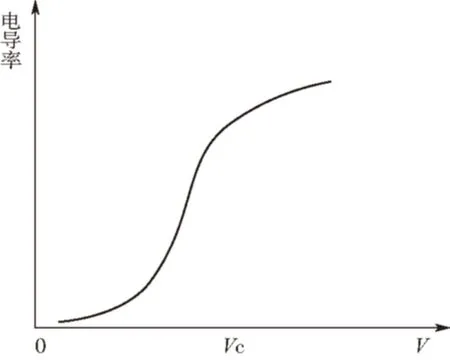

CPCs是將導電填料如CB、CNTs、碳纖維(CF)、石墨或金屬粉末等一種或幾種導電填料分散到一相或多相高分子基體中制得的復合材料。在CPCs中當填料含量超過某一臨界值時,材料的電導率將急劇上升,并發生從絕緣體到導體的轉變,將此現象稱為逾滲現象[21],可用圖1表示。設基體中填料所占的體積分數為V,Vc為逾滲閾值。當0

圖1 CPCs的逾滲現象Fig.1 Percolation phenomenon of CPCs

1.2 雙逾滲機理

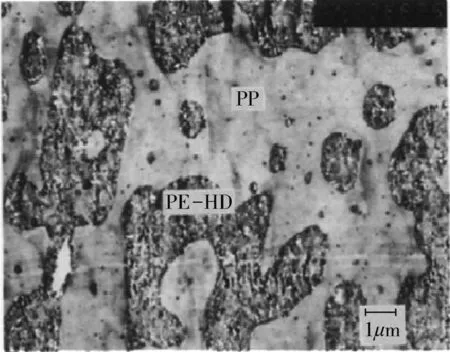

以上是導電填料填充單相聚合物基體的逾滲理論,而導電填料在多相體系中可能出現不均勻分布的現象,這種不均勻分布存在2種可能的情況:一種是導電粒子與某一相親和性較好,界面張力小,幾乎全部分散在其中,如圖2所示在雙逾滲結構聚丙烯(PP)/高密度聚乙烯(PE-HD)/CB復合材料中,CB選擇性分布在PE-HD相中;另一種是導電粒子優先在相界面中分布。Sumita[22]在研究CB填充PE-HD/PP和PP/聚甲基丙烯酸甲酯(PMMA)復合材料的分散情況后首先提出了雙逾滲的概念。其含義為第一層次的逾滲是CB在其富集相或界面內形成微導電網絡,第二層次的逾滲是CB富集相或界面在整個基體內形成宏觀導電網絡。因此雙逾滲現象大大促進了微導電鏈及宏觀導電網絡的形成,使復合材料導電的逾滲閾值大幅度下降。

圖2 雙逾滲結構PP/PE-HD/CB復合材料的微觀結構(10000×)Fig.2 Typical morphology of PP/PE-HD/CB with double percolation structure

2 碳材料雙逾滲結構CPCs的研究現狀

2.1 CB填充型

CB是目前應用最廣、用量最大的導電填料,其體積電阻率為0.1~10 Ω·cm,導電性能穩定持久,可大幅度調整復合材料的導電性能(1~1×108Ω·cm)。通常,CB填充型共混物導電復合材料的逾滲閾值會隨基體連續度的增加而降低[23]。不同CB填充型共混物導電復合材料的逾滲閾值如表1所示。

Wu等[24]將CB加入到ABS/PA6的共混物中,通過調整PA6與ABS的比例,發現當ABS/PA6的共混比例為60/40時,體系具有最大的連續度,此時復合材料對應著最低的逾滲值。此外,研究表明,當CB選擇性分布在具有雙連續結構不相容共混物的相界面處時,材料的逾滲值會進一步降低[22]。

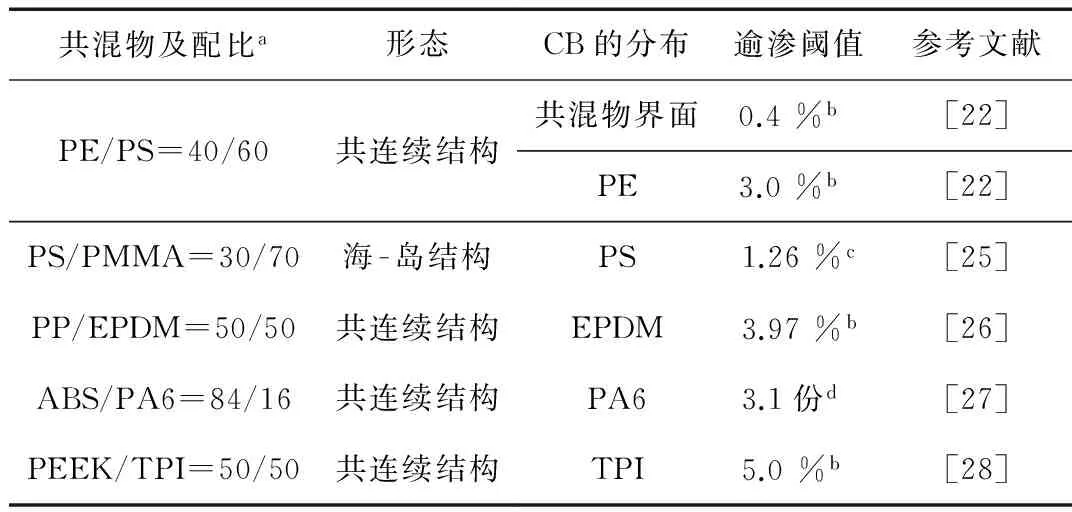

表1 不同CB填充型共混物導電復合材料的逾滲閾值Tab.1 Percolation threshold of conductive composites filled with different carbon black blends

注:EPDM為三元乙丙橡膠,ABS/PA6為丙烯腈 - 丁二烯 - 苯乙烯共聚物/聚酰胺6,PEEK/TPI為聚醚醚酮/熱塑性聚酰亞胺;a為質量比;b為質量分數;c為體積分數;d為質量份。

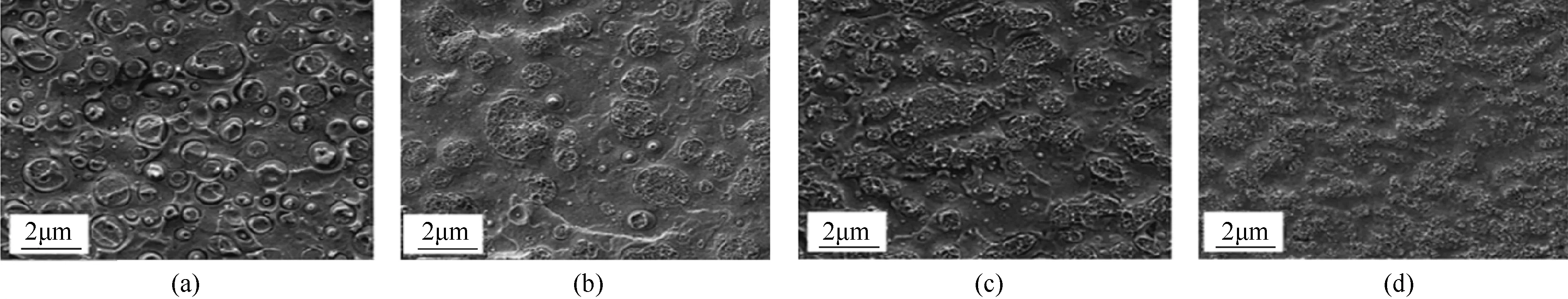

Liu等[25]在制備PS/PMMA/CB導電復合材料時發現,CB含量增加到一定量時會使不相容聚合物的相形貌發生轉變。如圖3所示,當PS/PMMA的共混比例為30/70時,兩相呈現海 - 島結構[圖3(a)],在PS/PMMA/CB導電復合材料中,CB選擇性分布在PS相中,因此,隨著CB含量的增加,體系中PS的黏度增大,當CB的體積含量達到4 %時,體系呈現的是共連續結構,PS/CB復合材料中,逾滲閾值為2.5 %(體積分數)。當PMMA的體積含量達到70 %時,復合材料的逾滲閾值為1.26 %(體積分數)。

CB體積含量/%:(a)0 (b)1 (c)2 (d)4圖3 PS/PMMA(30/70)混合物的冷沉淀斷裂面的SEM照片Fig.3 SEM of cryo-fractured surfaces of PS/PMMA(30/70) blends

目前,雖然CB填充型共混物導電復合材料取得了長足的發展,但是對其導電性以及CB分布的理論研究尚不完善。此外,這類材料的基體一般為呈現雙連續結構的不相容共混物,因而使得復合材料的力學性能有所降低。因此,開展這方面的研究對CB填充型共混物導電材料而言十分必要。

2.2 CNTs填充型

以PLLA/CNTs為母粒的EVA/PLLA/CNTs=40/60/1復合材料放大倍數:(a)100× (c)1000×以EVA/CNTs為母粒的PLLA/EVA/CNTs=60/40/1復合材料放大倍數:(b)100× (d)1000×圖4 CNTs在不同復合材料和不同放大倍率下分布的SEM照片Fig.4 SEM showing location of CNTs in different composites at different magnifications

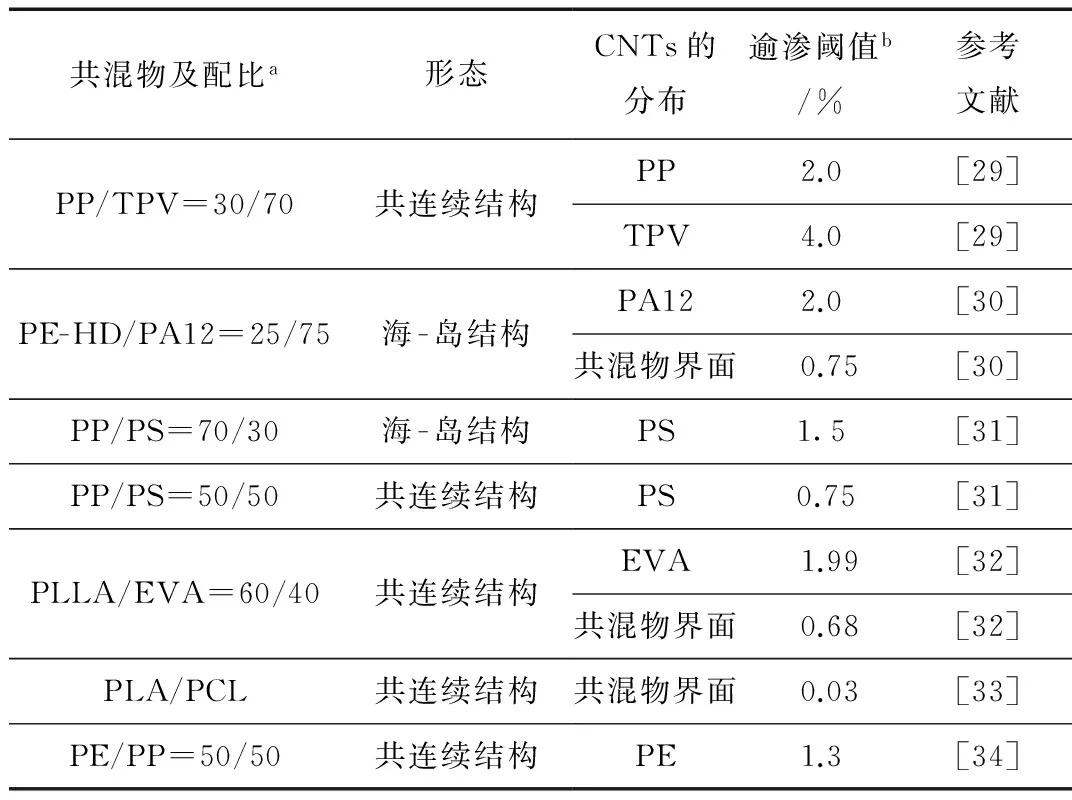

CNTs是完全由碳原子組成的一種直徑處于納米級的一維管狀納米材料。與傳統碳系導電填料相比,CNTs具有更為優異的導電性和強度,將CNTs添加到不相容共混物中將得到導電性更加突出的CPCs。大量研究者將CNTs添加到不相容共混物中,得到了一系列逾滲值不同的CNTs填充型導電復合材料,結果如表2所示。從表中可看出,CNTs填充型共混物導電復合材料的逾滲閾值與共混物相形貌和CNTs的分布狀況密切相關。

表2 不同CNTs填充型共混物導電復合材料的逾滲閾值Tab.2 Percolation threshold of conductive composites filled with different carbon nanotubes blends

注:TPV為熱塑性三元乙丙動態硫化橡膠;PA12為聚酰胺12;PLLA/EVA為聚左旋乳酸/乙烯 - 醋酸乙烯共聚物; PLA/PCL為聚乳酸/聚ε - 己內酯;a為質量比;b為質量分數。

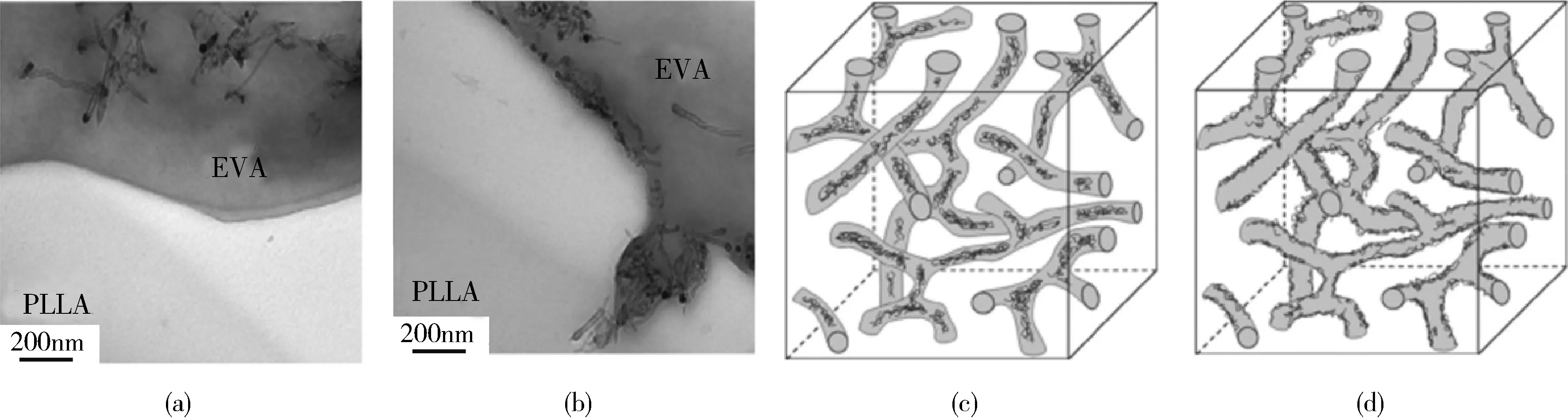

Zonder等[30]發現在通過PE-HD/多壁碳納米管(MWCNTs)母料制備的具有海 - 島結構的PA12/PE-HD/MWCNTs復合材料中,MWCNTs選擇性分布在共混物的相界面處時,復合材料的逾滲閾值為0.75 %(質量分數),低于MWCNTs選擇性分布在PA12中的逾滲值(2 %,質量分數)。Hwang等[31]將CNTs加入到PP/PS共混物中制備了導電復合材料。結果表明,當共混物呈現雙連續結構時,材料的逾滲閾值約為0.75 %(質量分數),低于以海 - 島結構為基礎得到的逾滲值1.5 %(質量分數)。另外,CNTs分布情況的不同也會影響復合材料的逾滲值,當CNTs分布在共混物的相界面處時,復合材料的逾滲值會進一步降低。同樣,Shi等[32]通過改變加工順序制備了具有雙連續結構的PLLA/EVA/CNTs復合材料。結果表明,在以PLLA/CNTs為母料的樣品中,CNTs選擇性分布在共混物相界面處,對應的逾滲值為0.68 %(質量分數);而在EVA/CNTs為母料的樣品中,CNTs則選擇性分布在EVA中,且材料的逾滲值為1.98 %(質量分數)。材料的掃描電子顯微鏡(SEM)和透射電子顯微鏡(TEM)照片如圖4、5所示,其中EVA在SEM測試前通過正庚烷去除,且CNTs在復合材料中的質量分數為1 %;在TEM照片中CNTs在復合材料中的質量分數為2 %。

以PLLA/CNTs為母粒的EVA/PLLA/CNTs=40/60/2復合材料:(a)典型分布 (c)相應分布以EVA/CNTs為母粒的PLLA/EVA/CNTs=60/40/2復合材料:(b)典型分布 (d)相應分布圖5 CNTs在不同復合材料中分布的TEM照片和模型圖Fig.5 TEM and model images showing localization of CNTs in different composites

從表1和表2對比可以看出,用CNTs填充的導電復合材料的逾滲值明顯低于用CB填充的導電復合材料。由此可見,導電率的高低除了與填料在基體中的分散狀態有關外,還與填料的形貌密切相關。一維的CNTs比零維CB更有利于導電性能的提高。

3 雙逾滲結構CPCs的研究進展

近年來,雙逾滲導電高分子材料在2個方面獲得了重要進展。一方面是可通過計算機模擬手段控制預測導電填料在聚合物基體中選擇性分布[35-37];另一方面是利用新型填料(石墨烯、鍍鎳碳纖、鍍鎳玻纖等)來制備雙逾滲導電高分子材料[38]。

Yasser等[39]結合聚合物/碳納米管納米復合材料(PCNT)界面的增強功效和逾滲效應,研制出了用于拉伸模量的微觀力學模型,該模型認為界面逾滲通過相同的厚度可提高PCNT的模量,同時CNTs的半徑和長度可能影響納米粒子的逾滲閾值和填料網狀物的濃度。Kelsey等[40]探討了多分散混合物中逾滲閾值預測的分析方法,該方法擴展了排除體積的概念,并將其應用于二維二進制磁盤系統,用于設計復合材料。Zhang等[41]使用分子動力學模型研究了聚合物 - 納米棒相互作用下,納米棒的縱橫比、塊剛度和外部張力對二嵌段共聚物納米復合材料的微觀結構和電學性能的影響。結果表明,各向異性的納米棒在具有輕微單軸取向的連續嵌段中的連續定位可顯著降低逾滲閾值。Sima等[42]通過將石墨烯納米片(GNP)分散在聚對苯二甲酸丁二醇酯 - 對苯二甲酸酯(PBAT)中制備了一系列可生物降解的納米復合材料。結果表明,逾滲不僅起源于片晶之間的網絡形成,而且可能與組合的PBAT/GNP凝膠網絡相關,PBAT/GNP凝膠網絡隨著溫度升高而增強,導致其在提高溫度時更像固體反應。納米復合材料的剪切黏度隨溫度的變化也表明,增加GNP負載降低了黏度的溫度敏感性,導致納米復合材料的相對黏度隨溫度升高而增加。Li等[43]研究了一種具有隔離網絡結構的熱還原石墨烯氧化物/硅藻土復合材料的新制備方法。在硅藻土中混合質量分數為13 %的玻璃粉,并利用硅藻土顆粒包覆氧化石墨烯原位熱還原法制備了導電復合材料,其逾滲閾值體積分數為0.229 %。同時,硅藻土的最高壓縮強度從11.3 MPa增加到了21.1 MPa。 Lu等[44]使用2步法造紙/熱黏合工藝合成了一種高柔性、高導電性的無紡布,稱為PP/PE/碳纖維(CF)并排纖維(ESF)無紡布(CEF-NF),其作為電磁干擾(EMI)屏蔽材料,具有良好的力學強度、優異的柔韌性、超薄性以及顯著的電學性能。通過SEM對純CF非織造織物和CEF-NF進行全面表征,可了解和驗證由于引入ESF而導致的拉伸強度的改善;通過測量CEF-NF的電導率以闡明熱壓效應,并研究其在增強CEF-NF導電性能中的重要性。結果發現,CEF-NF的電導率隨著CF長度的增加和體積密度的增加而增大。從電導率和CF體積密度關系模型中確定了CEF-NF的CF體積密度逾滲閾值。GUO等[45]通過鍍鎳玻璃纖維制成了具有低逾滲值的導電PP復合材料。玻璃纖維較高的縱橫比使之可以輕松地和聚合物連接從而構建聚合物基質中的網絡結構,因此玻璃纖維表面導電鎳涂層成功地形成了一個連續的導電網絡,以相對較低的鎳含量(1.17 %)就可得到導電性良好的復合材料(8.7 S/cm),并且導電復合材料的逾滲閾值低至0.46 %(體積分數)。

4 結語

雙逾滲理論提出導電填料分布在不相容聚合物中的一相或兩相界面處,極大地降低了導電復合材料的逾滲值,并減弱了體系NTC現象,改善了導電復合材料的加工性能及力學性能;在雙逾滲結構CPCs中,導電填料富集相的導電網絡和此富集相在另一種聚合物基體中的連續程度是整個體系導電網絡形成的關鍵所在,目前關于雙逾滲結構導電復合材料研究較多的是以CB、MWCNTs為填料,關于CF的研究較少;此外具有雙逾滲結構的CPCs基體一般為雙連續結構的不相容共混物,材料的力學性能有所降低;因此,開展這方面的研究對碳系填充型共混物導電材料而言十分必要。

[1] Dai K, Xu X B, Li Z M. Electrically Conductive Carbon Black (CB) Filled in Situ Microfibrillar Poly(ethylene terephthalate)(PET)/Polyethylene(PE) Composite with a Selective CB Distribution[J].Polymer, 2007, 48(3): 849-859.

[2] Ou R Q,Gupta S,Parker C A,et al.Fabrication and Electrical Conductivity of Poly(methylm ethacrylate)(PMMA)/Carbon Black(CB) Composites:Comparison Between an Ordered Carbon Black Nanowire-like Segregated Structure and a Randomly Dispersed Carbon Black Nanostructure[J].J Phys Chem B,2006,110:22365-22373.

[3] Sumita M,Sakata K,Hayakaw Y,et al.Double Percolation Effect on the Electrical Conductivity of Conductive Particles Filled Polymer Blends[J].Coll Polym Sci,1992,270(2):134-139.

[4] Hu J W, Li M W, Zhang M Q,et al.Preparation of Binary Conductive Polymer Composites with Very Low Percolation Threshold by Latex Blending[J].Macromol Rapid Comm,2003,24(15): 889-893.

[5] Zhang B,Fu R W,Zhang M Q,et al.Preparation and Cha-racterization of Gas-sensitive Composites from Multi-walled Carbon Nanotubes/Polystyrene[J]. Sensor Actuat B:Chem,2005,109(2): 323-328.

[6] Xu S X,Wen M,Li J,et al.Structure and Properties of Electrically Conducting Composites Consisting of Alternating Layers of Pure Polypropylene and Polypropylene with a Carbon Black Filler[J].Polymer,2008,49(22):4861-4870.

[7] Thompson M R,Motlagh G H,Oxby K J,et al.Multiple Percolation in a Carbon-filled Polymer Composites via Foaming[J].J Appl Polym Sci, 2010, 115(2): 646-654.

[8] Rizvi R, Kim J, Naguib H.Synthesis and Characterization of Novel Low Density Polyethylene-multiwall Carbon Nanotube Porous Composites[J].Smart Mater Struct, 2009, 18(10):104002.

[9] Xu X B,Li Z M,Shi L,et al.Ultralight Conductive Carbon-nanotube-polymer Composite[J]. Small,2007, 3(3): 408-411.

[10] Hunley M T,Potschke P,Long T E.Melt Dispersion and Electrospinning of Non-functionalized Multiwalled Carbon Nanotubes in Thermoplastic Polyurethane[J].Ma-cromol Rapid Comm,2009, 30(24): 2102-2106.

[11] Kim H S,Jin H J,Myung S J,et al.Carbon Nanotube-absorbed Electrospun Nanofibrous Membranes of Nylon 6[J].Macromol Rapid Comm, 2006, 27(2):146-151.

[12] Kiss G.In Situ Composites:Blends of Isotropic Polymers and Thermotropic Liquid Crystalline Polymers[J].Polym Eng Sci, 2010,27(6): 410-423.

[13] Lee G J, Suh K D, Im S S. Effect of Incorporating Ethy-lene-ethylacrylate Copolymer on the Positive Temperature Coefficient Characteristics of Carbon Black Filled HDPE Systems[J].Polymer Engineering & Science, 2000, 40(1): 247-255.

[14] Tang H,Piao J,Chen X, et al.The Positive Temperature Coefficient Phenomenon of Vinyl Polymer/CB Compo-sites[J].Journal of Applied Polymer Science, 1993, 48(10): 1795-1800.

[15] Feng J, Chan C. Carbon Black-filled Immiscible Blends of Poly(vinylidene fluoride) and High Density Polyethylene:The Relationship Between Morphology and Positive and Negative Temperature Coefficient Effects.[J].Polymer Engineering & Science, 1999, 39(7):1207-1215.

[16] Zhang M Q, Yu G, Zeng H M, et al. Two-step Percolation in Polymer Blends Filled with Carbon Black[J]. Macromolecules,1998,31(19): 6724-6726.

[17] Chen J,Shi Y,Yang J,et al.A Simple Strategy to Achieve Very Low Percolation Threshold via the Selective Distribution of Carbon Nanotubes at the Interface of Polymer Blends[J].J Mater Chem,2012,22(42):22398-22404.

[18] Feng J,Chan C,Li J A.Method to Control the Dispersion of Carbon Black in Immiscible Polymer Blend[J].Polymer Engineering and Science,2003,43(5):1058-1063.

[19] A vlyanov J K,Schwartz K,Gerteisen S R, et al.Self-organized Networks of Intrinsically Conductive Additives in Two-phase Plastics[J].Nursing Standard, 1999, 102(1):1274-1274.

[20] F Gubbels,R Jerome,P Teyssie,et al.Selective Localization of Carbon-Black in Immiscible Polymer Blends a Useful Tool to Design Electrical Conductive Composites[J].Macromolecules,1994,27(7):1972-1974.

[21] 張榮煒,劉鳳岐.炭黑/聚合物復合材料的研究進展[J].高分子材料科學與工程,2005,21(3):45-49. Zhang Rongwei,Liu Fengqi.The Research Progress of Carbon Black/Polymer Composites[J].Polymer Materials Science&Engineering,2005,21(3):45-49.

[22] Gubbels F,Jerome R,Teyssie P.Selective Localization of Carbon Black in Immiscible Polymer Blends:A Useful Tool to Design Electrical Conductive Composites[J]. Macromolecules, 1994,27(7):1972-1974.

[23] Tchoudakov R,Breuer O,Narkis M,et al.Conductive Polymer Blends with Low Carbon Black Loading:High Impact Polystyrene/Thermoplastic Elastomer(styrene-isoprene-styrene)[J].Polymer Engineering & Science, 1997,37(12):1928-1935.

[24] Wu G,Li B,Jiang J.Carbon Black Self-networking Induced Co-continuity of Immiscible Polymer Blends[J]Polymer, 2010,51(9):2077-2083.

[25] Pan Y,Liu X,Hao X,et al.Enhancing the Electrical Conductivity of Carbon Black-filled Immiscible Polymer Blends by Tuning the Morphology[J]. European Polymer Journal, 2016, 78: 106-115.

[26] Ma L F, Bao R Y, Huang S L,et al.Electrical Properties and Morphology of Carbon Black Filled PP/EPDM Blends:Effect of Selective Distribution of Fillers Induced by Dynamic Vulcanization[J].Journal of Materials Science,2013, 48(14):4942-4951.

[27] Wu G Z, Li B P, Jiang J D.Carbon Black Self-networking Induced Co-continuity of Immiscible Polymer Blends[J].Polymer,2010,51(9):2077.

[28] Gao C,Zhang S, Lin Y,et al.High-performance Conductive Materials Based on the Selective Location of Carbon Black in Poly(ether ether ketone)/Polyimide Matrix[J].Composites Part B:Engineering,2015,79:124-131.

[29] Zhu Y,Zhang X,Song Z,et al.The Effect of Selective Location of Carbon Nanotubes on Electrical Properties of Thermoplastic Vulcanizates[J].Journal of Applied Polymer Science,2013,127(5):3885-3890.

[30] Zonder L,Ophir A,Kenig S,et al.The Effect of Carbon Nanotubes on the Rheology and Electrical Resistivity of Polyamide 12/High Density Polyethylene Blends[J].Poly-mer, 2011,52(22):5085-5091.

[31] Hwang T Y,Yoo Y,Lee J W.Electrical Conductivity,Phase Behavior,and Rheology of Polypropylene/Polystyrene Blends with Multi-walled Carbon Nanotube[J].Rheologica Acta, 2012,51(7):623-636.

[32] Shi Y Y,Yang J H,Huang T,et al.Selective Localization of Carbon Nanotubes at the Interface of Poly(L-lactide)/Ethylene-co-vinyl Acetate Resulting in Lowered Electrical Resistivity[J].Composites Part B:Engineering,2013,55(9):463-469.

[33] Gubbels F,Jerome R,Vanlathem E,et al.Kinetic and Thermodynamic Control of the Selective Localization of Carbon Black at the Interface of Immiscible Polymer Blends[J].Chemistry of Materials,1998,10(5):1227-1235.

[34] Gao X,Zhang S M.Preparation of High Performance Conductive Polymer Fibres from Double Percolated Structure[J].Journal of Materials Chemistry,2011,21(17):6401-6408.

[35] I Alig,P P?tschke,D Lellinger,et al.Villmow,Establishment, Morphology and Properties of Carbon Nanotube Networks in Polymer melts[J]. Polymer,2012, 53(1): 4-28.

[36] V K Daga,E R Anderson,S P Gido,et al.Hydrogen Bond Assisted Assembly of Well-ordered Polyhedral Oligome-ric Silsesquioxane-block Copolymer Composites[J].Ma-cromolecules,2011,44(17):6793-6799.

[37] Pan Y,Li L,Chan S H,et al.Reinforcing Effects of Kevlar Fiber on the Mechanical Properties of Wood-flour/High-density-polyethylene Composites[J]. Compos Part A:Appl Sci,2010,41(9):1272-1278.

[38] Li M K, Gao C X, Zhang X,et al.Electrical Conductivity of Calcined Graphene Oxide/Diatomite Composites with a Segregated Structure[J].Materials Letters,2015, 141(15):125-127.

[39] Yasser Zare,Kyong Yop Rhee.Accounting the Reinforcing Efficiency and Percolating Role of Interphase Regions in Tensile Modulus of Polymer/CNT Nanocompo-sites[J].European Polymer Journal,2017,87:389-397.

[40] Kelsey Meeks,Michelle L,Micah Green,et al.Extending the Excluded Volume for Percolation Threshold Estimates in Polydisperse Systems:The Binary Disk System[J].Appiled Mathematical Modelling,2017,46:116-125.

[41] Zhang S C,Feng Y C,Ning N Y,et al.Effects of Dispersion and Orientation of Nanorods on Electrical Networksoft Block Copolymer Nanocomposites[J].Computational Materials Science,2017,129:107-114.

[42] Sima Kashi,Rahul Gupta,Nhol Kao,et al.Viscoelastic Properties and Physical Gelation of Poly(butyleneadipate-co-terephthalate)/Grapheme Nanoplatelet Nanocompo-sites at Elevated Temperatures[J].Polymer,2016,101:347-357.

[43] Li M K,Gao C X,Zhang X,et al.Electrical Conductivity of Calcined Graphene Oxide/Diatomite Composites with a Segregated Structure[J].Materials Letters,2015,141:125-127.

[44] Lu L S,Xing D,Xie Y X,et al.Electrical Conductivity Investigation of a Nonwoven Fabric Composed of Carbon Fibers and Polypropylene/Polyethylene Core/Sheath Bicomponent Fibers[J].Materials and Design,2016,112:383-391.

[45] Guo C,Duan H J,Dong C Y,et al.Preparation of the Po-lypropylene/Nickel Coated Glass Fibers Conductive Composites with a Low Percolation Threshold[J].Materials Letters,2015,143(16):124-127.

Research Progresses in Conductive Carbon-based PolymericComposites with Dual-percolation Threshold

WANG Ying

[Shanxi Provincial Institute of Chemical Industry (Co, Ltd), Taiyuan 030001, China]

This paper introduced the mechanisms of percolation and dual-percolation thresholds for conductive carbon-based polymeric composites and reviewed the research progresses in the conductive polymeric composites with a dual-percolation threshold, in which carbon materials mainly including carbon black and carbon nanotubes were used as conductive fillers. The development trend of conductive polymeric composites with dual-percolation threshold was prospected.

carbon black;carbon nanotube; dual-percolation feature; percolation threshold; electrical conductivity; composite

2017-02-23

TQ327.8

B

1001-9278(2017)08-0018-06

10.19491/j.issn.1001-9278.2017.08.003

聯系人,ztzyz615@163.com