A novel method based on entransy theory for setting energy targets of heat exchanger network☆

Li Xia,Yuanli Feng,Xiaoyan Sun,Shuguang Xiang*

Institute of Process System Engineering,Qingdao University of Science and Technology,Qingdao 266042,China

1.Introduction

Energy is the driving force for economic growth and sustainable development of a country.Simultaneously,a series of environmental and health problems have been caused by energy production and consumption.Currently China has become the first energy producer and the second largest energy consumer in the world.With the rapid economic development and improved standards of living,energy demand in China is continually rising and resource constraints are becoming more seriously[1].

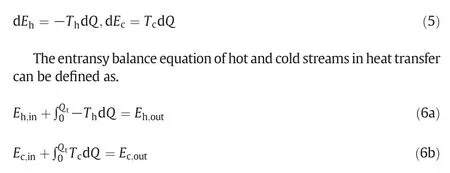

Heat exchanger networks are widely used in oil refining,chemical,metallurgy,pharmaceutical and other large industrial enterprises.Its significance can be attributed to its role in reducing energy consumption and increasing energy utilization ratio[2].Nowadays,three kinds of heat exchangernetwork synthesis methods have been established:the pinch design method(PDM),the mathematical programming approach,and the artificial intelligence approach.PDM is the most mature and successful method in the heat exchange network design.Besides,PDM is applied to analyze the distribution ofenergy flow along the temperature gradient in the heat transfer process.The maximum energy recovery(MER)network can be obtained by PDM,but the heat transfer efficiency cannot be calculated.With the heatrecovery processes becoming more complex,the PDM has some shortcomings.For example,the operating and investment costs are not considered in this method.

Heattransfer was widely thoughtto originate in 19th century,which had gradually matured in theory and engineering application[3].The various quantity methods have been used to describe the heat transfer rate,but there is no concept of efficiency for transfer processes.Guoet al.[4]introduced a new physical quantity,entransy,based on the analogy between heat and electrical conduction.The entransy of an object describes its heat transfer ability and “thermal potential energy”.The concept of entransy dissipation was introduced to analyze an irreversible heating transfer process.Moreover,Chenet al.[5,6]derived the extremumprinciple ofentransy dissipation to optimize the processes of the heat conduction.This attracts many scholars to carry out a series of in-depth related research in various directions,such as heat conduction[7–9],heat convection[10],the optimal design of heat exchangers[11,12],mass transfer[13,14],heat radiation[15–17],and multiple transfer process[18].

In order to analyze the performance of heat transfer processes,Chenet al.[19]introduced a two-dimension property diagram,temperatureheat flow diagram(T-q·diagram).The area between the process curves of the hot and cold streams represented the total entransy dissipation rate in the whole heat exchanger.The diagram can be used to analyze the irreversibility of heat transfer processes.Wuet al.[20]compared the entransy dissipation rates of three simple chemical processes in the temperature-heat flow rate diagram(T-Q·diagram).This approach was applied to evaluate the performance of self-heat recuperation technology(SHRT).

The theoretical basis for simplifying the complex chemical process was only provided in the previous work,but was not applied to the optimal design of HENs[29].

This article willpropose an energy targetapproach ofHENs based on the concept of entransy and entransy dissipation.In comparison with the PDM,the entransy method of HENs has some obvious advantages,such as accurate calculation of entransy transfer efficiency,minimizing the entransy dissipation and maximizing the entransy recovery.A real case study is used to show the application of the novel method.Thus,the energy-saving potential of the HENs can be obtained based on the entransy transfer efficiency analysis.

2.Model and Theoretical Analysis

2.1.Model of a two-stream heat transfer process with entransy theory

Guoet al.[4]proposed a new physical quantity,entransy,which correspond to electrical potential energy in a capacitor based on the analogy between electrical and thermal systems.The entransy of an object is,

whereQvhis thermal capacity of an object with constant volume,cvis specific heatcapacity atconstantvolume,UhorTrepresents the thermal potential.

For a two-stream heat exchanger,which is operated in steady state,when the temperature drop of the stream is dT,heat flow generating is dQ,and the output entransy is[21]:

It is assumed that there is no heat exchanging with environment,the change of kinetic and potential energy,the effects of conduction and mixing in the direction ofstream can be ignored[22].The heatcapacities and heat transfer coefficients are defined as constant.

With these assumptions,specific heat capacity at constant volume and specific heat capacity at constant pressure are approximately equal,which can be written as

wheremis the mass flow,the subscript h refers to the hot stream,and the subscript c refers to the cold stream.

The entransy change between the hot and cold streams is

where the subscripts in and out denote the inlet and outlet states,respectively.

The entransy dissipation in the whole heatexchange network can be obtained by summing Eqs.(6a)and(6b)

In Eq.(7),we can see that entransy is not completely conserved due to dissipation,which means the entransy dissipation is a measurement of the irreversibility of heat transfer processes.If the quantity of entransy that the hot streams release is absorbed by the cold streams,the entransy dissipation is reduced.So the effective energy utilization is achieved.

The entransy transfer efficiency can be used to evaluate the heat transfer performance of HENs,expressed as.

whereEh,Ecrepresent the quantity of entransy that the hot streams release and the cold streams absorb,respectively.The more entransy that cold streams absorb and the less entransy that hot streams dissipate,the higher entransy transfer efficiency can be obtained.

2.2.Available entransy and the physical meaning of T-Q diagram

Entransy possesses both the nature of“energy”and the heattransfer ability.The temperature represents the potentialofthe heatbecause the heat differs at different temperatures.Hence the entransy of hot streams,which means“potentialenergy”ofheat,can be used effectively by cold streams.

When two objects at different temperatures are in thermal contact,the total quantity of“potential energy”of heat can be transferred,which representthe entransy transfer associated with the heat transfer.Guoet al.[23]considered the entransy as the heat transport potential capacity in an earlierpaper.Chengetal.[24]found thatentransy changes in heat transfer process of an isolated system and a closed system.This principle was called entransy decrease,based on the first and second laws of thermodynamics.That can be written as dG≤0(the equal sign is tenable for an ideal heat transfer process,while the sign of“l(fā)ess than”is tenable for natural heat transfer process),which can be described as the irreversibility of heat transfer process due to entransy loss or heat transfer ability.

The volume changes are not usually considered in heat transfer.AsTis a state quantity andδQis a process quantity,entransyT·δQis obviously a process quantity.Huet al.[25]derived that the entransy flow of a system,which was called the system entransyG,corresponded to a state quantity in a reversible process with constant volume.

Based on the first law of thermodynamics,the energy balance equation can be expressed as.

Eq.(9)points out that in entransy transfer,a portion of the entransy flow will be converted into work entransy,T·δW,which makes no contribution to the heating or cooling of an object.T·dUis the available portion of the entransy flow,which is called the available entransy.

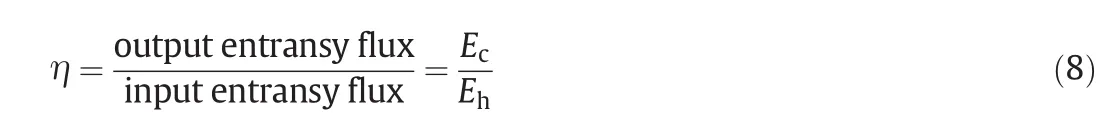

As mentioned above,the heat transfer process of streams can be shown in theT-Qdiagram.It is clear that the heat transfer capability should be enhanced in the HENs.The available entransy,which makes contribution to the heating or cooling streams,needs to be maximized.Thus,the heat transfer performance is improved,and the effective utilization of energy is realized.

3.Novel Method to Setting the Energy Targets

The tasks of HENs synthesis are minimizing capital and operating costs,achieving the initial temperature to the target temperature.The feed,which starts cold and needs to be heated up,is called as a cold stream;conversely which starts hot and needs to be cooled down,is called as a hot stream[26].

Fig.1.The property diagram in heat transfer processes of streams.

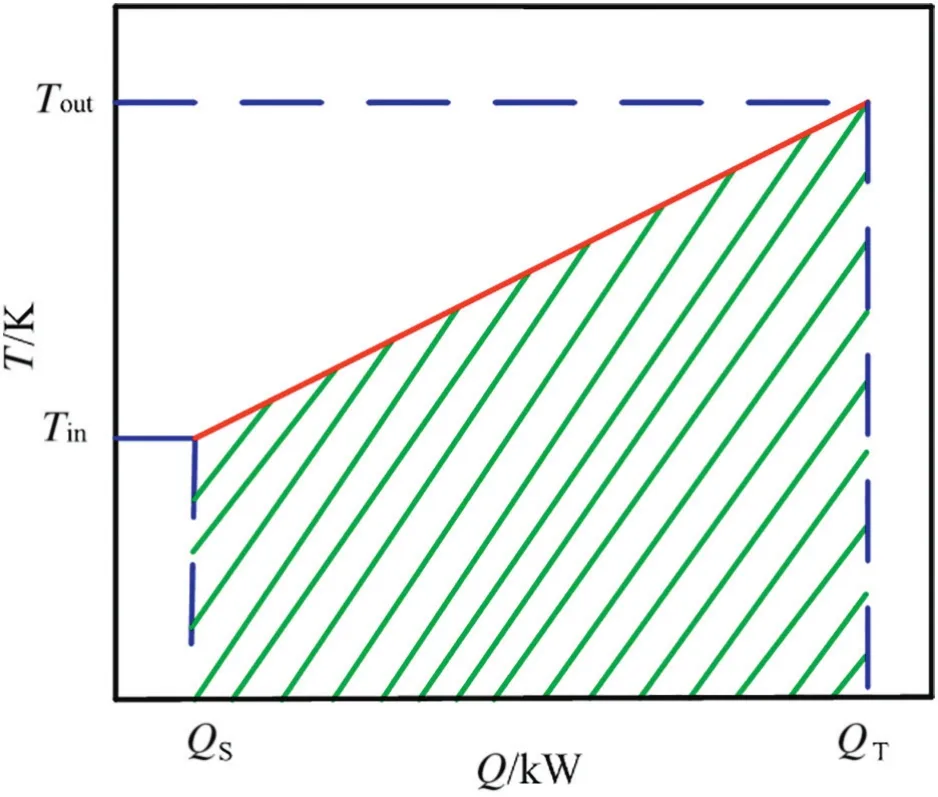

During the heattransferprocesses,the change of heat is equal to the enthalpy change of each stream.In Fig.2,theT-axis is a continuous change and theQ-axis is a relative change.If process curve is shifted along theQ-axis,the change of temperature,heat and entransy will not affect the property of stream.Thus,to handle multiple streams,it is convenient to combine the lines of multiple streams into a single curve.

Fig.2 shows a formation of the hot composite curve.It is formed by three hot streams,whose heat capacity flow rates are named as A,B,C.The enthalpy change can be calculated in a series of every interval temperatures.If there is only one line in an interval,the slope cannot be changed.If multiple lines exit in an interval,the temperature of vertical coordinates in this interval remains unchanged,the enthalpy change of horizontal coordinates added together,which means the vector sum of these lines in this interval can be got.Finally,the line segments are connected end-to-end to form a single curve,shown in Fig.2(b).

Using the same method,the cold composite curve can be obtained.Therefore,the green shade area between the hot and cold streams in Fig.3 is the total entransy dissipation,ΔE,·as shown in Eq.(7).The blue shaded area under the cold composite curve,which is identified as the entransy recovery of the system,indicates that the cold streams effectively utilize the entransy transferred from the hot streams.

For a heat exchanger network,in order to meet the actual industrial production needs,the quantity of entransy that the hot stream releases is not completely absorbed by the cold stream.The entransy required for the cold stream to be heated to the target temperature cannot be provided entirely by the hot stream.Generally we need additional hot and cold utilities in the system.

The maximum energy recovery and the minimum utility requirements can be achieved by the HENs synthesis method,which means that the entransy of all hot streams can possibly be absorbed in maximum by the cold streams.Meanwhile for the maximumentransy recovery,the minimum entransy dissipation and the minimum utility requirements are represented in the optimization of heat exchanger network,shown in Fig.4.

For the design of heat exchangers,considering exchanger area,utility requirements and capital cost with minimum approach temperatureΔTminchanges.There isan optimumvalue forΔTmin,which isusually 10–20 K.

本文所提方法最大的特點在于滿足中軸線提取結(jié)果可視化的基本要求下,實現(xiàn)了全自動化提取。對提取結(jié)果完成拓撲檢查后,直接進行網(wǎng)絡(luò)空間分析。比如對于河網(wǎng)中軸可進行連通性分析。由于本文所選數(shù)據(jù)為河網(wǎng)數(shù)據(jù),以下將對中軸提取結(jié)果建立網(wǎng)絡(luò)拓撲并進行連通性分析。

In Fig.4,the hot and cold composite curves are shifted on theQ-axis and close to each other.Until the two composite curves reach to the predetermined target position(ΔTmin)in a vertical direction,the lower right corner area indicates the minimum entransy of hot utility requirements(Eh,min),which means the cold streams can be entirely heated to target temperature.The lower left corner area indicates the minimum entransy of cold utility requirements(Ec,min),which means the hot streams can be entirely cooled to target temperature.And the overlapped area between the composite curves represents the maximum entransy recovery and the minimum entransy dissipation.

Fig.3.The property diagram in heat transfer processes between hot and cold streams.Meanwhile,the amount of entransy dissipation and entransy recovery are shown in this diagram.

Fig.2.Example of formation of the hot composite curve:(a)A T-Q diagram of three hot streams;(b)The process of forming a hot composite curve through three hot streams.

Entropy,which is another kind of physical quantity in thermodynamics,is a measure of the irreversibility of a process and the randomness of a system.The entropy theory is mainly applied to the heat-work conversion optimization in reversible process,but there is an“entropy paradox”[27].That is with the increase of heat exchanger effectiveness,the entropy generation number is also increased.In addition,entropy cannot be used to describe energy quality.However,entransy is developed to describe heat transfer ability of a real system.The entransy dissipation number,which is introduced by the theory of entransy dissipation,can resolve entropy generation paradox.The entransy dissipation number can correctly describe the global performance of the heatexchangers with three different flow arrangements simultaneously[28].Compared with the entropy analysis,the entransy analysis has obvious advantages.

Fig.4.The property diagram in heat transfer processes of all hot and cold streams in the HENs.

4.Case Study

The diesel oil hydrogenation unit of one petrochemical company includes reaction,fractionation,acid gas desulfurization,and the design scale is 3.4 million tons per year.According to limits and measurement methods for emission from light-duty vehicles(China 5),part of the transformation ofthe unitis to meetthe requirements ofthe production of diesel oil.To reduce the external hot utility usage,the optimization of heatexchanger network has a practical significance.The data of hot and cold streams are shown in Tables 1,2.The process flow diagram of the units is shown in Fig.5 and the hot and cold streams are simultaneously represented(red represents hot stream and blue represents cold stream).

Table 1The data of hot streams

Table 2The data of cold streams

4.1.Before setting the energy target of diesel oil hydrogenation unit

According to Table 1,the hot and cold composite curves are shown in Fig.6.As a result,the entransy of hot streams is 6.762×107kW·K while the entransy of cold streams is 6.352×107kW·K.There is no overlapped area between the composite curves,which means the quantity of entransy that the hot streams release is not absorbed by the cold streams.Hence,there are no entransy recovery,the minimum entransy dissipation is 1.311×108kW·K.

4.2.After setting the energy target of diesel oil hydrogenation unit

Itis assumed thatthe minimum approach temperatureΔTminis 10 K.The cold and hot stream composite curves are shown in Fig.7.

As a result,the entransy of hot streams is 6.762×107kW·K,the entransy ofcold streams is 6.352×107kW·K,the entransy of hot utility is 8.543×106kW·K,the entransy of cold utility is 7.428×106kW·K,so the entransy recovery is 5.498×107kW·K,the entransy dissipation is 5.212×106kW·K,and the entransy transfer efficiency is 92.29%.

Using the similar methods mentioned,one can obtain the optimization results of three different minimum approach temperatures:10 K,15 K,and 20 K.The results of comparing three different energy targets are listed in Table 3.

From the results of calculation,we can see that the quantity of entransy is influenced by the variation of temperature difference.Corresponding to the minimum temperature difference,ΔTminis given as 10 K,15 K,and 20 K while the entransy recovery is 5.498× 107kW·K,5.377× 107kW·K,and 5.257× 107kW·K,respectively.The entransy dissipation is 5.212× 106k W·K,5.661×106kW·K,and 6.093×106kW·K.Therefore,the entransy transfer efficiency is 92.29%,91.63%,and 90.99%.It is obvious that the larger the temperature difference,the more hot and cold the utility requirements,the less the entransy recovery,the more the entransy dissipation,and the lower the entransy transfer efficiency.

The heat transfer rate equation could be expressed as.

whereAis the heat transfer area,Uis heat transfer coefficient.ΔTLMis the log mean temperature difference,which expression is

It is found that the heat exchanger area is inversely proportional to the temperature difference.For an actual heat exchanger,the lower values of ΔTmincan lead to larger area and more capital cost.Therefore,in the design of heat exchanger network,we need a comprehensive consideration of operating and capital costs,heat exchanger surface area,process conditions,etc.Finally,the optimal minimum approach temperature,ΔTminand the effective energy utilization can be obtained.

Fig.5.The process flow diagram of diesel oil hydrogenation unit.In the diagram,red represents hot streams and blue represents cold streams.

5.Conclusions

This paper has presented a novel method based on entransy theory forsetting energy targets ofHENs inT-Qdiagram.The hotand cold composite curves can be obtained in theT-Qdiagram.

Fig.6.The heat transfer property diagram of the diesel oil hydrogenation unit before setting the energy target.

Fig.7.The heattransfer property diagram of the diesel oilhydrogenation unitafter setting the energy target.

Table 3The results of setting different energy targets,ΔT min=10 K,15 K,20 K

Therefore,the shaded area between the hot and cold composite curves stood for the entransy dissipation.The effectofdifferent temperature differences on entransy recovery was researched.It was found that the higher values of ΔTmincan lead to more hot and cold utility requirements,the more entransy dissipation,the less entransy recovery and the lower entransy transferefficiency.Steps to setthe optimalenergy target of heat exchange network inT-Qdiagram based on entransy theory were determined.

The diesel oil hydrogenation unit of the industrial case study was shown in this paper.Comparing the three different temperature difference results,the optimalenergy targetwas obtained.The entransy recovery was 5.498× 107kW·K,5.377× 107kW·K,and 5.257×107kW·K,and the entransy transfer efficiency was 92.29%,91.63%,and 90.99%in 10 K,15 K,and 20 K,respectively.The higher values of ΔTmincan lead to less entransy recovery,and the entransy transfer efficiency was obviously reduced.Therefore,the entransy theory is more suitable for the analysis of HENs energy efficient use.

Thismethod can be used asa criterion forthe maximum entransy recovery of HENs.This paper has an important guideline value for setting the optimal minimum approach temperature of a heat exchanger network.It is worth making a further study on the synthesis of HENs of entransy theory.The principle and strategy of the synthesis of HENs can be proposed in the future.

Nomenclature

Aheat transfer area,m2

CPheat capacity flowrate,kW·K-1

cvspecific heat at constant volume,kJ·kg-1·K-1

cpspecific heat at constant pressure,kJ·kg-1·K-1

Evhentransy,kW·K

Gsystem entransy,kW·K

mmass,kg·s-1

Q·heat flow rate,W

Qtthe total heat transfer,W

Qvhthermal capacity of an object,J

q·heat flux,W·m-2

Ttemperature,K

Uheat transfer coefficient,kW·m-2·K-1

Uhthermal potential,K

Wwork,J

η entransy transfer efficiency,%

ΔTLMthe log mean temperature difference,K

ΔTminminimum approach temperature,K

Subscripts

c cold stream

h hot stream

in inlet state

outlet outlet state

rev reversible condition

[1]H.Hu,X.H.Zhang,L.L.Lin,The interactions between China's economic growth,energy production and consumption and the related air emissions during 2000–2011,Ecol.Indic.46(46)(2014)38–51.

[2]K.C.Furman,N.V.Sahinidis,A critical review and annotated bibliography for heat exchanger network synthesis in the 20th century,Ind.Eng.Chem.Res.41(10)(2002)2335–2370.

[3]A.E.Bergles,Heat transfer enhancement—The encouragement and accommodation of high heat fluxes,J.Heat Transf.119(1)(1997)8–19.

[4]Z.Y.Guo,H.Y.Zhu,X.G.Liang,Entransy—A physical quantity describing heat transfer ability,Int.J.Heat Mass Transf.50(13)(2007)2545–2556.

[5]X.G.Cheng,Z.X.Li,Z.Y.Guo,Variational principles in heat conduction,J.Eng.Thermophys.25(3)(2004)457–459.(in Chinese)

[6]X.G.Cheng,Entransy and Its Application in Heat Transfer Optimization Ph.D.Thesis Tsinghua University,Beijing,2004.(in Chinese)

[7]Z.H.Xie,L.G.Chen,F.R.Sun,Constructal optimization on T-shaped cavity based on entransy dissipation minimization,Chin.Sci.Bull.54(23)(2009)4418–4427.

[8]S.H.Wei,L.G.Chen,F.R.Sun,Constructal entransy dissipation minimization for“volume-point”heat conduction based on triangular element,Therm.Sci.14(4)(2010)1075–1088.

[9]X.T.Cheng,X.H.Xu,X.G.Liang,Homogenization of temperature field for the thermal radiator in space,J.Eng.Thermophys.31(6)(2010)1031–1033.(in Chinese)

[10]J.A.Meng,Z.J.Chen,Z.X.Li,Z.Y.Guo,Field-coordination analysis and numerical study on turbulent convective heat transfer enhancement,J.Enhanc.Heat Transf.12(1)(2005)73–84.

[11]X.B.Liu,J.A.Meng,Z.Y.Guo,Entropy generation extremum and entransy dissipation extremum for heat exchanger optimization,Chin.Sci.Bull.54(6)(2009)943–947.

[12]Q.H.Xiao,L.G.Chen,F.R.Sun,Constructal entransy dissipation rate minimization for umbrella-shaped assembly of cylindrical fins,Sci.China Technol.Sci54(1)(2011)211–219.

[13]Q.Chen,J.X.Ren,Z.Y.Guo,The extremum principle of mass entransy dissipation and its application to decontamination ventilation designs in space station cabins,Chin.Sci.Bull.54(16)(2009)2862–2870.

[14]S.J.Xia,L.G.Chen,F.R.Sun,Entransy dissipation minimization for liquid–solid phase processes,Sci.China Technol.Sci.53(4)(2010)960–968.

[15]J.Wu,X.G.Liang,Application ofentransy dissipation extremum principle in radiative heat transfer optimization,Sci.China51(8)(2008)1306–1314.

[16]S.J.Xia,L.G.Chen,F.R.Sun,Optimalpaths for minimizing entransy dissipation during heat transfer processes with generalized radiative heat transfer law,Appl.Math.Model.34(8)(2010)2242-225.

[17]S.P.Wang,Q.L.Chen,B.J.Zhang,An equation of entransy and its application,Chin.Sci.Bull.54(19)(2009)3572–3578.

[18]A.Bejan,Street network theory of organization in nature,J.Adv.Transp.30(2)(1996)85–107.

[19]Q.Chen,Y.C.Xu,Z.Y.Guo,The property diagram in heat transfer and its applications,Chin.Sci.Bull.57(57)(2012)4646–4652.

[20]J.Wu,Z.Y.Guo,Application ofentransy analysis in self-heatrecuperation technology,Ind.Eng.Chem.Res.53(3)(2013)1274–1285.

[21]Z.Y.Guo,X.B.Liu,W.Q.Tao,R.K.Shah,Effectiveness thermal resistance method for heat exchanger design and analysis,Int.J.Heat Mass Transf.53(13–14)(2010)2877–2884.

[22]VDI-Gesellschaft,VDI Heat Atlas,Springer,Berlin,2010.

[23]Z.Y.Guo,X.G.Cheng,Z.Z.Xia,Least dissipation principle of heat transport potential capacity and its application in heat conduction optimization,Chin.Sci.Bull.48(4)(2003)406–410.(in Chinese)

[24]X.T.Cheng,X.G.Liang,Z.Y.Guo,Entransy decrease principle of heat transfer in an isolated system,Chin.Sci.Bull.56(9)(2011)847–854.

[25]G.J.Hu,B.Y.Cao,Z.Y.Guo,Entransy and entropy revisited,Chin.Sci.Bull.56(27)(2011)2974–2977.

[26]I.C.Kemp,Pinch Analysis and Process Integration,Elsevier Ltd.,Oxford,2006.

[27]A.Bejan,Advanced Engineering Thermodynamics,Wiley,New York,1988.

[28]J.F.Guo,L.Cheng,M.T.Xu,Entransy dissipation number and its application to heat exchanger performance,Chin.Sci.Bull.54(15)(2009)2974–2977.

[29]L.Xia,Y.L.Feng,S.G.Xiang,Progress and application of entransy theory in energy saving of chemical processes,CIESC J.67(12)(2016)4915–4921.

Chinese Journal of Chemical Engineering2017年8期

Chinese Journal of Chemical Engineering2017年8期

- Chinese Journal of Chemical Engineering的其它文章

- Step-wise synthesis of work exchange networks involving heat integration based on the transshipment model☆

- The mass and heat transfer process through the door seal of refrigeration☆

- Performance of CO2 absorption in a diameter-varying spray tower☆

- Optimal design of heat exchanger header for coal gasification in supercritical water through CFD simulations☆

- Coupled simulation of recirculation zonal firebox model and detailed kinetic reactor model in an industrial ethylene cracking furnace☆

- Optimization and control of a reactive distillation process for the synthesis of dimethyl carbonate☆