菜籽蛋白加工廢液中多酚和多糖同步提取工藝優(yōu)化

張韋唯,代春華,2,3,熊 鋒,侯福榮,何榮海,2,3※,馬海樂(lè),2,3

(1. 江蘇大學(xué)食品與生物工程學(xué)院,鎮(zhèn)江 212013; 2. 江蘇省農(nóng)產(chǎn)品物理加工重點(diǎn)實(shí)驗(yàn)室,鎮(zhèn)江 212013;3. 江蘇省食品智能制造工程技術(shù)研究中心,鎮(zhèn)江 212013)

菜籽蛋白加工廢液中多酚和多糖同步提取工藝優(yōu)化

張韋唯1,代春華1,2,3,熊 鋒1,侯福榮1,何榮海1,2,3※,馬海樂(lè)1,2,3

(1. 江蘇大學(xué)食品與生物工程學(xué)院,鎮(zhèn)江 212013; 2. 江蘇省農(nóng)產(chǎn)品物理加工重點(diǎn)實(shí)驗(yàn)室,鎮(zhèn)江 212013;3. 江蘇省食品智能制造工程技術(shù)研究中心,鎮(zhèn)江 212013)

為開發(fā)利用菜籽蛋白加工廢液中的生理活性物質(zhì),該研究在單因素試驗(yàn)基礎(chǔ)上,采用Box-Behnken響應(yīng)面試驗(yàn)設(shè)計(jì)法,對(duì)菜籽蛋白加工廢液中多酚和多糖提取工藝條件進(jìn)行優(yōu)化,同時(shí)探究?jī)煞N物質(zhì)的體外抗氧化活性。結(jié)果表明,影響菜籽蛋白加工廢液中多酚和多糖得率的因素大小順序?yàn)椋阂掖俭w積分?jǐn)?shù)>浸提溫度>浸提時(shí)間,最佳提取工藝為:浸提溫度60 ℃、乙醇體積分?jǐn)?shù)65%、浸提時(shí)間31 min,在此條件下多酚得率為2.19%,多糖得率為8.14%;多酚提取物對(duì)DPPH?具有較強(qiáng)清除能力,其半抑制質(zhì)量濃度為0.20 mg/mL,多糖提取物對(duì)DPPH?和?OH均具有較強(qiáng)的清除能力,其半抑制質(zhì)量濃度分別為1.45、2.38 mg/mL;高效液相色譜法初步檢測(cè)表明,菜籽蛋白加工廢液中含有香豆酸、丁香酸、對(duì)香豆酸、芥子酸和苯甲酸。研究結(jié)果為菜籽蛋白加工廢液的再利用提供參考。

提取;工藝;優(yōu)化;多酚;多糖;抗氧化性;菜籽蛋白加工廢液

張韋唯,代春華,熊 鋒,侯福榮,何榮海,馬海樂(lè). 菜籽蛋白加工廢液中多酚和多糖同步提取工藝優(yōu)化[J]. 農(nóng)業(yè)工程學(xué)報(bào),2017,33(7):302-309.doi:10.11975/j.issn.1002-6819.2017.07.040 http://www.tcsae.org

Zhang Weiwei, Dai Chunhua, Xiong Feng, Hou Furong, He Ronghai, Ma Haile. Extraction processing optimization of polyphenols and polysaccharides from rapeseed protein processing waste liquor[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(7): 302-309. (in Chinese with English abstract)doi:10.11975/j.issn.1002-6819.2017.07.040 http://www.tcsae.org

0 引 言

菜籽粕作為油菜籽壓榨榨油后主要副產(chǎn)物,其中蛋白質(zhì)質(zhì)量分?jǐn)?shù)達(dá)35%~42%,菜籽蛋白氨基酸組成合理,已被大量開發(fā)利用[1]。然而,在菜籽粕提取菜籽蛋白制品過(guò)程中排放出大量高濃度有機(jī)廢水,主要來(lái)源于水劑法脫毒制取菜籽濃縮蛋白過(guò)程中所產(chǎn)生的酸洗廢水[2],以及菜籽分離蛋白制備過(guò)程中所產(chǎn)生的酸沉乳清廢水[3]。加工廢液中含有一定濃度的蛋白質(zhì)以及多種天然生理活性產(chǎn)物,包括多酚、多糖、植酸等,另外,酚類物質(zhì)抑制微生物生長(zhǎng),使廢水難降解,而且廢水排放量大,通常是所加工菜籽粕質(zhì)量的 5~10倍,甚至更高,其中的生物活性物質(zhì)在0.5~5 mg/mL之間[4]。研究發(fā)現(xiàn),多酚在阻止自由基的反應(yīng)中能夠起到關(guān)鍵作用,具有較強(qiáng)的抗氧化活性,同時(shí)不同來(lái)源的植物酚類化合物具有多方面的生理功能,例如抗腫瘤、抗輻射、預(yù)防心腦血管疾病、抗突變、延緩人體衰老等[5-9]。湯務(wù)霞等[10]用丙酮作為提取液提取菜籽粕中的多酚類化合物,并以鞣酸和維生素C為對(duì)照,采用 1,1-二苯基-2-三硝基苯肼(1,1-diphenyl-2-picrylhydrazyl radical 2,2-diphenyl-1- (2,4,6- trinitropheny) hydrazyl, DPPH)法進(jìn)行測(cè)定,結(jié)果表明,丙酮多酚提取液具有一定的體外抗氧化能力。劉入銘[11]研究表明,菜籽多酚能夠顯著降低胃腫瘤的發(fā)病率、有效抑制胃黏膜炎癥,而且菜籽多酚能夠下調(diào)胃黏膜炎癥因子 COX-2、mPGES-1及TNF-α誘導(dǎo)mRNA的表達(dá)水平。Kozlowska 等[12]通過(guò)堿解發(fā)現(xiàn)在菜籽中存在 9種酚酸,主要為芥子酸、阿魏酸、p-香豆酸等。菜籽多糖為菜籽粕綜合利用研究中發(fā)現(xiàn)的具有開發(fā)利用價(jià)值的一種生物活性物質(zhì),具有抗氧化、抑瘤等作用[13-15]。然而,菜籽蛋白加工廢液中多酚和多糖的研究卻較少。

本試驗(yàn)采取乙醇浸提法同步提取菜籽蛋白加工廢液中的多酚和多糖,并通過(guò)響應(yīng)面法對(duì)提取工藝進(jìn)行優(yōu)化,同時(shí)對(duì)多酚提取物和多糖提取物的體外抗氧化性進(jìn)行研究,并利用高效液相色譜法(high performance liquid chromatography,HPLC)對(duì)提取出的酚酸組分和含量進(jìn)行初步探討,提升菜籽蛋白加工廢液的可利用程度,實(shí)現(xiàn)菜籽粕加工廢水資源的綜合利用,提高菜籽粕加工過(guò)程的總體經(jīng)濟(jì),獲得高附加值制品。

1 材料與方法

1.1 材料與試劑

菜籽蛋白加工廢液(總糖質(zhì)量濃度14.21 mg/mL,蛋白質(zhì)8.39 mg/mL,總酚2.01 mg/mL)由江蘇天琦生物科技有限公司提供(卡諾拉油菜籽);1,1-二苯基-2-三硝基苯肼,沒(méi)食子酸,香豆酸,3,4-二羥基苯甲酸,苯甲醛,兒茶素,綠原酸,咖啡酸,丁香酸,對(duì)香豆酸,芥子酸,苯甲酸,蘆丁酸,水楊酸,槲皮素均為標(biāo)準(zhǔn)品,購(gòu)自美國(guó) Sigma公司;甲醇(色譜純);無(wú)水乙醇,福林酚等均為分析純,購(gòu)于國(guó)藥集團(tuán)化學(xué)試劑有限公司。

1.2 儀器與設(shè)備

DL-5C型低速冷凍離心機(jī)(上海安亭科學(xué)儀器廠);T6新世紀(jì)型分光光度計(jì)(北京普析通用儀器有限責(zé)任公司);LC-20AT高效液相色譜儀、LC solution工作站、SPD-20AT紫外檢測(cè)器(日本島津公司)。

2 方 法

2.1 廢液中多酚、多糖的提取

將菜籽蛋白加工廢液和無(wú)水乙醇按一定比例混合,在恒溫水浴振蕩器(200 r/min)中按照一定時(shí)間和溫度進(jìn)行浸提,將浸提過(guò)后的料液于冷凍離心機(jī)中(控制在4 ℃左右)以6 000 r/min離心20 min。上清液于40 ℃條件下旋蒸濃縮,真空冷凍干燥(?50 ℃,<20 Pa),得到菜籽多酚提取物;將沉淀物真空冷凍干燥(?50 ℃,<20 Pa),得到菜籽多糖提取物,用于抗氧化活性和酚酸定性定量測(cè)定。

2.2 多酚、多糖的含量測(cè)定

將菜籽多糖粗提物用蒸餾水定容,稀釋到合適濃度,采用苯酚-硫酸法[16]測(cè)定菜籽蛋白加工廢液中多糖的吸光值,依據(jù)葡萄糖標(biāo)準(zhǔn)曲線得出的直線方程計(jì)算菜籽蛋白廢液中多糖得率。

式中E1為多糖得率,%;C1為從標(biāo)準(zhǔn)曲線獲得的反應(yīng)溶液多糖質(zhì)量濃度,mg/mL;V為提取液總體積,mL;F為稀釋倍數(shù);M為廢液總干物質(zhì)量,mg。

將上清液稀釋到合適濃度,采用福林酚法[17]測(cè)定浸提液中多酚的吸光值,根據(jù)沒(méi)食子酸標(biāo)準(zhǔn)曲線回歸方程計(jì)算菜籽蛋白廢液中多酚得率。

式中E2為多酚得率,%;C2為從標(biāo)準(zhǔn)曲線獲得的反應(yīng)溶液多酚質(zhì)量濃度,mg/mL。

2.3 單因素試驗(yàn)

選定浸提溫度(30、40、50、60、70、80 ℃)、乙醇體積分?jǐn)?shù)(20%、30%、40%、50%、60%、70%、80%)、浸提時(shí)間(20、40、60、80、100、120 min)3個(gè)因素做單因素試驗(yàn),考察各單因素水平對(duì)菜籽餅粕加工廢液中多酚得率和多糖得率的影響,確定相關(guān)工藝條件。

2.4 響應(yīng)面優(yōu)化試驗(yàn)設(shè)計(jì)

在單因素試驗(yàn)的基礎(chǔ)上,采用 Box-Behnken中心組合設(shè)計(jì)方法,進(jìn)行三因素三水平的響應(yīng)面試驗(yàn),以浸提溫度A(℃)、乙醇體積分?jǐn)?shù)B(%)、浸提時(shí)間C(min)為自變量,廢液中多酚得率Y1(%)和多糖得率Y2(%)為響應(yīng)值,采用響應(yīng)面統(tǒng)計(jì)分析軟件 Design-Expert 8.0確定最佳提取工藝條件。試驗(yàn)設(shè)計(jì)因素及水平見(jiàn)表1。

表1 Box-Behnken中心組合設(shè)計(jì)的因素和水平表Table1 Factors and levels of Box-Behnken central composite design

2.5 多酚提取物和多糖提取物的體外抗氧化活性試驗(yàn)

2.5.1 DPPH?自由基清除能力測(cè)定

試驗(yàn)方法參考何榮海等[18-19]方法,在優(yōu)化后的提取條件下,將提取物凍干,得到菜籽粗多酚提取物和多糖提取物,配成不同濃度梯度水溶液作待測(cè)樣品備用。在試管中加入 2.0 mL待測(cè)樣品溶液,再加入 2.0 mL 0.2 mmol/L DPPH·無(wú)水乙醇溶液,混勻,室溫下避光靜置30 min,在波長(zhǎng)517 nm處測(cè)定吸光值,按下式計(jì)算待測(cè)樣品清除DPPH·能力(%)。

式中A0為DPPH·無(wú)水乙醇溶液2.0 mL+無(wú)水乙醇溶液2.0 mL的吸光值;Ax為DPPH·無(wú)水乙醇溶液2.0 mL+待測(cè)樣品溶液 2.0 mL的吸光值;Ax0為待測(cè)樣品溶液2.0 mL+無(wú)水乙醇溶液2.0 mL的吸光值。

半抑制濃度(IC50)是指DPPH·的抑制率為50%時(shí)多酚和多糖提取物溶液濃度[20]。IC50值越小,抗氧化能力越強(qiáng)。將試驗(yàn)重復(fù)3次,求得半抑制率的平均值。

2.5.2 ?OH清除能力測(cè)定

試驗(yàn)方法參考張德華等[21-22]方法,利用H2O2與Fe2+混合產(chǎn)生·OH的原理,在體系內(nèi)加入水楊酸捕捉·OH,產(chǎn)生有色物質(zhì),該物質(zhì)在波長(zhǎng)510 nm處有最大吸收。反應(yīng)體系中含8.8 mmol/L H2O21.0 mL、9.0 mmol/L FeSO41.0 mL,9.0 mmol/L水楊酸-乙醇溶液1.0 mL,一定濃度樣品1.0 mL。加H2O2啟動(dòng)反應(yīng),37 ℃反應(yīng)30 min,以蒸餾水為對(duì)照,510 nm處測(cè)定各溶液的吸光度,考慮到樣品本身的吸光度,以 9.0 mmol/L FeSO41.0 mL,9.0 mmol/L水楊酸-乙醇溶液 1.0 mL,相應(yīng)濃度樣品1.0 mL和1.0 mL蒸餾水作為樣品的本底吸光度。按下式計(jì)算·OH清除率(%)

式中0A′為空白對(duì)照液吸光度;xA′為加入樣品溶液后吸光度;0xA′為不加顯色劑H2O2的樣品溶液本底吸光度。

IC50是指·OH的抑制率為50%時(shí)多酚和多糖提取物溶液濃度[20]。

2.5.3 總還原能力測(cè)定

試驗(yàn)方法參考王振斌等[23-24]方法,2.0 mL樣品與2.0 mL 0.2 mol/L,pH值 6.6的磷酸緩沖液(phosphate buffer saline, PBS)和2.0 mL質(zhì)量分?jǐn)?shù)1%鐵氰化鉀溶液混合均勻后于 50 ℃水浴反應(yīng) 20 min后速冷,再加入2.0 mL質(zhì)量分?jǐn)?shù)10%三氯乙酸(trichloroacetic acid,TCA)溶液,3 000 r/min離心10 min,吸取2.0 mL上清液于試管中,并加入2.0 mL去離子水和0.4 mL 質(zhì)量分?jǐn)?shù)0.1% FeCI3,混合均勻,10 min后在700 nm處測(cè)吸光值。

2.6 高效液相色譜分析

2.6.1 色譜條件

Kromasil C18色譜柱(4.6 mm×250 mm,5μm);柱溫20 ℃,進(jìn)樣量20μL,檢測(cè)波長(zhǎng)280 nm;采用雙泵系統(tǒng),流速0.7 mL/min。流動(dòng)相A為超純水(含0.05%三氟乙酸),流動(dòng)相B為純甲醇。采用梯度洗脫:0~25 min,10%~22% B→25~45 min,22%~65% B→45~53 min,65%~50% B→53~60 min,50%~10% B→60~70 min,10% B。

2.6.2 酚酸標(biāo)準(zhǔn)溶液的配置

精密稱取一定量14種酚類化合物標(biāo)準(zhǔn)品,用5.0 mL甲醇溶解,用超純水分別定容至50 mL容量瓶中,制成單個(gè)酚酸溶液和混合樣品母液。

2.6.3 目標(biāo)單體酚的定量分析

取已知各單體酚濃度的混合樣品母液,梯度進(jìn)樣5、10、15、20、25μL,用高效液相色譜進(jìn)行檢測(cè)。

2.7 數(shù)據(jù)處理與統(tǒng)計(jì)分析

試驗(yàn)數(shù)據(jù)采用Origin 8.6 軟件進(jìn)行分析作圖,SPSS 13.0軟件進(jìn)行方差分析,結(jié)果以平均數(shù)±標(biāo)準(zhǔn)偏差表示,響應(yīng)面設(shè)計(jì)與分析的軟件為Design- Expert 8.0,試驗(yàn)數(shù)據(jù)均為3次平行試驗(yàn)的平均值。

3 結(jié)果與分析

3.1 單因素試驗(yàn)結(jié)果分析

3.1.1 浸提溫度對(duì)浸提效果的影響

固定乙醇體積分?jǐn)?shù)60%、浸提時(shí)間60 min,考察浸提溫度對(duì)多酚得率和多糖得率的影響。由圖 1可知,隨著溫度的升高,多糖得率是先上升后下降。溫度升高,分子運(yùn)動(dòng)加快,細(xì)胞間的摩擦作用使得細(xì)胞破裂,多糖溶解及擴(kuò)散速度加快,得率提高,60 ℃時(shí)多糖得率達(dá)到最高,但隨著溫度繼續(xù)增加,多糖得率顯著下降,可能因?yàn)檫^(guò)高的溫度使部分多糖有效成分被分解。多酚得率在浸提溫度從50 ℃升到60 ℃時(shí),有略微上升趨勢(shì),60 ℃后開始緩慢下降,整體趨勢(shì)較為平緩。一般來(lái)說(shuō)溫度越高越有利于多酚物質(zhì)的提取[25],在高溫條件下會(huì)導(dǎo)致乙醇揮發(fā),使提取液濃度增大,而且較高的溫度會(huì)破壞多酚化學(xué)結(jié)構(gòu),從而影響多酚得率[26-27]。結(jié)合多酚得率和多糖得率的趨勢(shì),最優(yōu)提取溫度在60 ℃附近,中心組合試驗(yàn)選取的溫度范圍為50~70 ℃。

3.1.2 乙醇體積分?jǐn)?shù)對(duì)浸提效果的影響

固定浸提溫度60 ℃、浸提時(shí)間60 min,考察乙醇體積分?jǐn)?shù)對(duì)多酚得率和多糖得率的影響。乙醇體積分?jǐn)?shù)是影響浸提效果的一項(xiàng)重要指標(biāo)。如圖 2所示,隨著乙醇體積分?jǐn)?shù)的增加,菜籽蛋白加工廢液中多酚得率和多糖得率都呈上升趨勢(shì)。乙醇體積分?jǐn)?shù)40%~60%階段,多酚得率明顯上升,60%之后得率上升幅度降低。由于原料是廢液,乙醇體積分?jǐn)?shù)的增大使固體有效成分濃度降低,從而得率持續(xù)上升。而多糖得率在乙醇體積分?jǐn)?shù) 30%~50%階段呈直線上升,50%后多糖得率趨于平緩,說(shuō)明多糖的溶出量已達(dá)飽和。結(jié)合多酚得率和多糖得率的趨勢(shì),最優(yōu)乙醇體積分?jǐn)?shù)在 60%附近,中心組合試驗(yàn)選取的乙醇體積分?jǐn)?shù)范圍為50%~70%。

圖1 提取溫度對(duì)多酚和多糖得率的影響Fig.1 Effect of extraction temperature on yield of polyphenols and polysaccharides

圖2 乙醇體積分?jǐn)?shù)對(duì)多酚和多糖得率的影響Fig.2 Effect of ethanol concentration on yield of polyphenols and polysaccharides

3.1.3 浸提時(shí)間對(duì)浸提效果的影響

固定浸提溫度60 ℃、乙醇體積分?jǐn)?shù)60%,考察浸提時(shí)間對(duì)多酚得率和多糖得率的影響。從圖3中可以看出,15~30 min時(shí)間段,多糖得率上升,30 min后多糖得率呈現(xiàn)波動(dòng)下降的趨勢(shì),所以表明30 min時(shí)多糖溶出量最多。15~30 min時(shí)間段,多酚得率也是上升的,30 min之后多酚擴(kuò)散速度減慢,基本平衡。提取時(shí)間延長(zhǎng)也會(huì)增加能耗,所以,最優(yōu)提取時(shí)間在30 min附近,中心組合試驗(yàn)選取的時(shí)間范圍為15~45 min。

圖3 浸提時(shí)間對(duì)多酚和多糖得率的影響Fig.3 Effect of extraction time on yield of polyphenols and polysaccharides

3.2 響應(yīng)面法優(yōu)化多酚、多糖的浸提條件

3.2.1 響應(yīng)面試驗(yàn)設(shè)計(jì)及結(jié)果

根據(jù) Box-Behnken試驗(yàn)設(shè)計(jì)的原理,結(jié)合單因素試驗(yàn)的結(jié)果,設(shè)計(jì)試驗(yàn)并得到結(jié)果,如表2所示。

表2 響應(yīng)面試驗(yàn)設(shè)計(jì)及結(jié)果Table2 Experimental result based on Box-Behnken design

運(yùn)用Design-Expert 8.0軟件對(duì)表2試驗(yàn)數(shù)據(jù)進(jìn)行分析,以多酚得率Y1(%)和多糖得率Y2(%)為響應(yīng)值,經(jīng)回歸擬和后得到二次多項(xiàng)式回歸方程

3.2.2 模型的建立與顯著性檢驗(yàn)

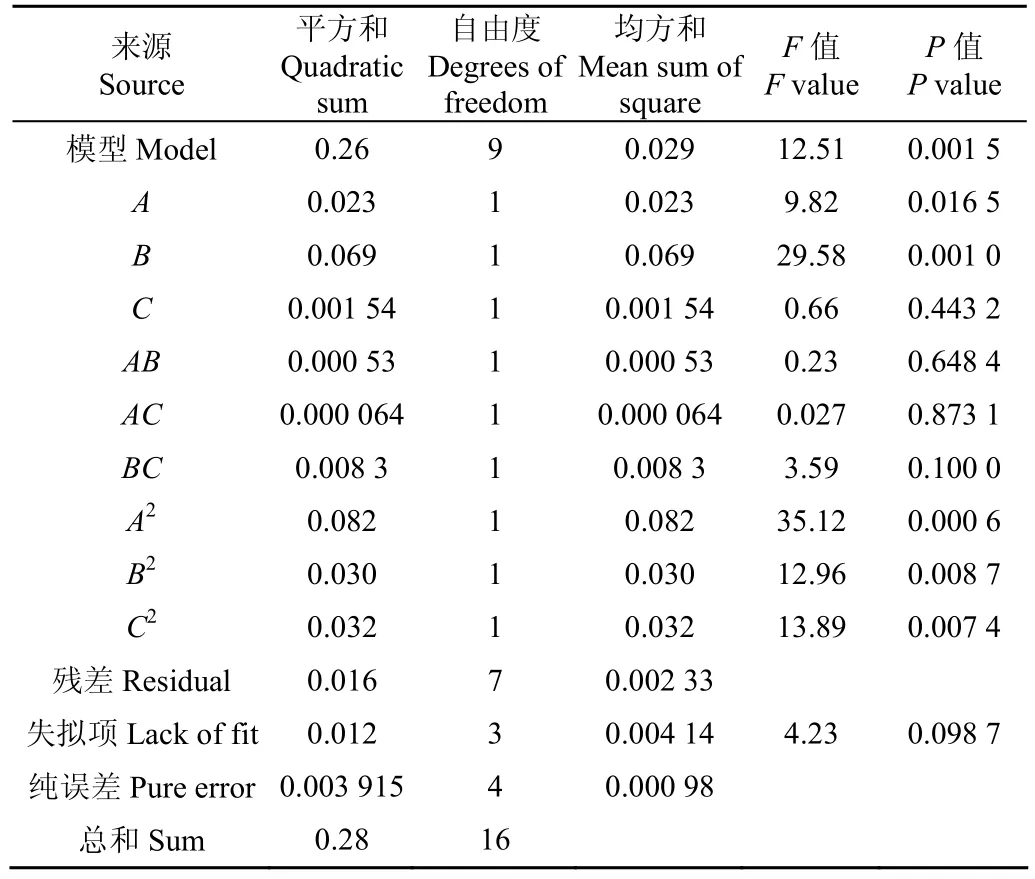

利用Design-Expert 8.0軟件對(duì)表2結(jié)果進(jìn)行統(tǒng)計(jì)及分析,得到方差的分析結(jié)果如表3所示。

表3 多酚得率方差分析表Table3 Variance analysis of polyphenols yield

經(jīng)數(shù)據(jù)分析處理(表 3),多酚得率模型的F值為12.51,P值為0.0015<0.05,說(shuō)明該模型顯著可靠。失擬項(xiàng)不顯著,而且R2=0.9415,R2Adj=0.8662,表明建立的模型和試驗(yàn)擬合良好,是可以對(duì)多酚得率進(jìn)行分析和預(yù)測(cè)的。依F檢驗(yàn)知,因素A、B、A2、B2和C2的P值均小于 0.05,說(shuō)明溫度及其平方項(xiàng)、乙醇體積分?jǐn)?shù)及其平方項(xiàng)、時(shí)間平方項(xiàng)對(duì)多酚得率影響顯著,而因素C(時(shí)間)和各交互相的影響均不顯著。各單因素對(duì)多酚浸提效果的影響依次為:乙醇體積分?jǐn)?shù)(B)>溫度(A)>時(shí)間(C)。

如表4所示,多糖得率模型的F值為16.49,P值為0.000 6<0.001,說(shuō)明該模型極顯著。失擬項(xiàng)的P值為0.056 1>0.05,不顯著,而且R2=0.955 0,R2Adj=0.897 1,表明建立的模型擬合性較好,可以對(duì)多糖得率進(jìn)行分析和預(yù)測(cè)。依F檢驗(yàn)知,因素A、B、A2、B2和C2的P值均小于 0.05,說(shuō)明這些因素對(duì)多糖得率影響顯著,而因素C(時(shí)間)和各交互相的影響都不顯著。各單因素對(duì)多糖浸提效果的影響依次為:乙醇體積分?jǐn)?shù)(B)>溫度(A)>時(shí)間(C)。

表4 多糖得率方差分析表Table4 Variance analysis of polysaccharides yield

3.2.3 響應(yīng)面優(yōu)化

若以多酚得率和多糖兩者作為評(píng)價(jià)指標(biāo),所得的最優(yōu)提取條件是不一致的,因而選用兩者的綜合評(píng)價(jià)指標(biāo)(overall desirability, OD)進(jìn)行綜合評(píng)分。在計(jì)算綜合指標(biāo)之前,采用極差化法將各指標(biāo)進(jìn)行規(guī)格化[28]。由于多酚得率和多糖得率均要求達(dá)到最大化,其規(guī)格化方程為:Di=(Yi?Ymin)/(Ymax?Ymin),其中,Ymax和Ymin分別為各指標(biāo)的最大值與最小值,若某試驗(yàn)的指標(biāo)值為Ymax時(shí),將Di設(shè)為1。反之,某個(gè)指標(biāo)值為Ymin時(shí),Di為0[29]。將兩者權(quán)重系數(shù)均設(shè)為0.5,則綜合評(píng)分為:OD=(0.5D1+0.5D2)。最終得到最佳提取工藝條件為溫度 60.01 ℃,乙醇體積分?jǐn)?shù)65.69%,時(shí)間30.93 min,多酚得率預(yù)測(cè)值2.19%,多糖得率預(yù)測(cè)值8.18%。為了方便試驗(yàn),修正最佳工藝條件為溫度60 ℃,乙醇體積分?jǐn)?shù)65%,時(shí)間31 min,多酚得率實(shí)際值2.19%,多糖得率實(shí)際值8.14%。多酚得率試驗(yàn)值與預(yù)測(cè)值一致,多糖得率試驗(yàn)值比預(yù)測(cè)值高0.04%。

3.3 多酚提取物和多糖提取物的體外抗氧化活性試驗(yàn)

3.3.1 DPPH?自由基清除能力測(cè)定

由圖4可知,多酚提取物質(zhì)量濃度在0.1~0.5 mg/mL范圍內(nèi)DPPH·的清除率從32.63%上升至93.53%,多糖提取物質(zhì)量濃度在0.40~2.40 mg/mL范圍內(nèi)DPPH·的清除率從18.65%上升至77.97%。分析數(shù)據(jù)可知,在選定的多酚提取物和多糖提取物質(zhì)量濃度范圍內(nèi),隨著質(zhì)量濃度的增大,多酚提取物和多糖提取物對(duì)DPPH·自由基的清除率也明顯增加,呈現(xiàn)良好的量效關(guān)系。對(duì)比可以明顯看出:多酚提取物對(duì)DPPH·自由基清除率均高于相同質(zhì)量濃度條件下多糖提取物對(duì)DPPH·的清除率。在多酚提取物的質(zhì)量濃度為0.5 mg/mL時(shí),其DPPH·自由基清除率已經(jīng)達(dá)到93.53%,明顯高于相同質(zhì)量濃度條件下多糖提取物對(duì)DPPH·的清除率。多酚提取物和多糖提取物對(duì)DPPH·自由基的IC50分別為0.20、1.45 mg/mL。史蘭[30]對(duì)菜籽粕有效分離成分的研究中,測(cè)得提取出的菜籽多酚對(duì)DPPH·自由基的IC50為51.00μg/mL。劉琴等[31]用不同溶劑提取出菜籽粕中的多酚,測(cè)得DPPH·清除能力為50.528 0μmol/g。與菜籽粕中提取的多酚活性相比,本試驗(yàn)廢液中提取的多酚活性較低,這可能是菜籽蛋白加工廢液中多酚有效成分含量較低,并且菜籽粕在蛋白加工過(guò)程中部分多酚結(jié)構(gòu)可能被破壞。

圖4 多酚提取物和多糖提取物對(duì)DPPH·的清除能力Fig.4 DPPH· scavenging ratio of polyphenol extracts and polysaccharide extracts

3.3.2 ·OH清除能力測(cè)定

由圖 5可以看出,多酚提取物質(zhì)量濃度在 5.00~30.00 mg/mL范圍內(nèi)·OH的清除率從 36.92%上升至83.62%,多糖提取物質(zhì)量濃度在0.80~3.80 mg/mL范圍內(nèi)·OH的清除率從13.59%上升至78.60%。比較可知,多糖提取物對(duì)·OH的清除能力強(qiáng)于多酚提取物,且隨著樣品質(zhì)量濃度的增加,·OH的清除力不斷增加。整體來(lái)看,多糖提取物對(duì)羥自由基的清除能力要強(qiáng)于多酚提取物。多酚提取物和多糖提取物羥自由基IC50分別為10.85、2.38 mg/mL。朱沛沛等[32]用微波輔助乙醇提取菜籽餅粕多酚,測(cè)得多酚提取液對(duì)羥基的清除率在0~1.4 mg/mL質(zhì)量濃度范圍內(nèi)隨其濃度的增加而增大,最大清除率達(dá)61.37%,比本試驗(yàn)多酚提取物對(duì)羥自由基的清除能力高很多,說(shuō)明廢液中多酚對(duì)羥自由基的清除能力較弱。

圖5 多酚提取物和多糖提取物對(duì)·OH的清除能力Fig.5 ·OH scavenging ratio of polyphenol extracts and polysaccharide extracts

3.3.3 總還原能力測(cè)定

由圖 6可知,隨著濃度的增大,多酚提取物和多糖提取物總還原力都不斷增大,而且呈現(xiàn)良好的量效關(guān)系,對(duì)比可以明顯看出:多酚提取物的總還原力大于多糖提取物的總還原力。

圖6 多酚提取物和多糖提取物的還原能力Fig.6 Reducing abilities of polyphenol extracts and polysaccharide extracts

3.4 HPLC法分析多酚提取物的組成和含量

如圖7a所示,各酚酸組分在混合標(biāo)樣中均有良好的分離度。結(jié)合圖7b分析可知,香豆酸、丁香酸、對(duì)香豆酸、芥子酸和苯甲酸可明顯看出對(duì)應(yīng)峰,表明菜籽蛋白加工廢水中也很有可能含有這些酚酸。荊文光等[33]從菜籽粕中分離得到芥子酸,丁香酸,香草酸,對(duì)羥基苯甲醛、原兒茶酸,對(duì)羥基苯甲酸、龍膽酸等。劉琴等[27]從菜籽粕中鑒定出芥子酸和芥子堿。吳梨[34]用堿解法結(jié)合乙酸乙酯萃取對(duì)菜籽粕、種皮粕和種胚粕中的不溶性多酚分別進(jìn)行了提取和分析,結(jié)果表明菜籽種皮中含有芥子酸及其異構(gòu)體、阿魏酸、香豆酸、羥基苯甲酸、丁香酸、咖啡酸、原兒茶酸等 9種酚酸。大量研究表明,本試驗(yàn)所檢測(cè)出的酚酸都已在菜籽粕中被鑒定出。表 5定量分析結(jié)果可見(jiàn),多酚提取物中所檢測(cè)出的5種酚酸中,芥子酸質(zhì)量分?jǐn)?shù)最多達(dá)到5.57 mg/g,香豆酸2.65 mg/g,其他酚酸含量相對(duì)較少。史蘭[30]對(duì)10個(gè)油菜籽品種的菜籽粕、種皮粕和種胚粕中的不溶性多酚的含量進(jìn)行了分析,結(jié)果表明在種皮粕中芥子酸和原兒茶酸為主要酚酸,芥子酸的質(zhì)量分?jǐn)?shù)為 0.076~0.234 mg/g,占不溶性總酚體積分?jǐn)?shù)的18.07%~47.05%。菜籽粕提蛋白后的廢液中,芥子酸含量依然相對(duì)較多。此工藝為菜籽蛋白加工廢液的再利用提供一定研究基礎(chǔ)。

圖7 標(biāo)準(zhǔn)酚酸樣品和菜籽蛋白加工廢液中酚酸檢測(cè)的色譜圖Fig.7 Chromatograms of standard phenolic acids and phenolic acids in rapeseed protein processing waste liquid

表5 多酚提取物所含酚酸的保留時(shí)間、回歸方程、決定系數(shù)和質(zhì)量分?jǐn)?shù)Table5 Retention time, regression equation, determination coefficient and content of standard phenolic acid in polyphenol extracts

4 結(jié) 論

使用乙醇提取菜籽蛋白加工廢液中的多酚和多糖,在單因素的基礎(chǔ)上,以多酚得率和多糖得率為響應(yīng)值,響應(yīng)面優(yōu)化后,得到最佳提取工藝條件為:浸提溫度60 ℃、乙醇體積分?jǐn)?shù) 65%、時(shí)間 31 min,多酚得率為2.19%,多糖得率為8.14%,多酚得率預(yù)測(cè)值為2.19%,多糖得率預(yù)測(cè)值為 8.18%。多酚得率試驗(yàn)值與預(yù)測(cè)值一致,多糖得率試驗(yàn)值比預(yù)測(cè)值高0.04個(gè)百分點(diǎn)。說(shuō)明回歸方程能較真實(shí)地反映各因素對(duì)多酚和多糖得率的影響,證明用響應(yīng)面法優(yōu)多酚和多糖得率回歸模型較可靠。

多酚提取物和多糖提取物的體外抗氧化能力試驗(yàn)結(jié)果表明,多酚和多糖對(duì)不同的自由基的清除能力是不同的,且在測(cè)定的質(zhì)量濃度范圍內(nèi)呈良好的量效關(guān)系。多酚提取物的DPPH·自由基清除率明顯高于相同質(zhì)量濃度條件下多糖提取物對(duì)DPPH·自由基的清除率,而多糖提取物對(duì)羥自由基的清除能力要強(qiáng)于多酚提取物。多酚提取物的總還原力要高于多糖提取物的總還原力。高效液相色譜法初步檢測(cè)結(jié)果表明,菜籽蛋白加工廢液中含有香豆酸、丁香酸、對(duì)香豆酸、芥子酸和苯甲酸,其中芥子酸最多,質(zhì)量分?jǐn)?shù)達(dá)到5.57 mg/g。

[1] 冉仁森,陳錦屏,米瑞芳,等. 油菜籽多肽的制備工藝[J].食品科學(xué),2013,34(23):245-249. Ran Rensen, Chen Jinping, Mi Ruifang, et al. Enzymatic preparation of crude polypeptides from rapeseed meal[J]. Food Science, 2013, 34(23): 245-249. (in Chinese with English abstract)

[2] 蘭文菊,彭密軍,彭勝,等. 酸溶液對(duì)菜籽粕脫毒工藝探討[J]. 中國(guó)糧油學(xué)報(bào),2012,27(11):67-71. Lan Wenju, Peng Mijun, Peng Sheng, et al. Study on the technology of detoxification of rapeseed meal by acid solvent[J]. Journal of the Chinese Cereals and Oils Association, 2012, 27(11): 67-71. (in Chinese with English abstract)

[3] 嚴(yán)梅榮,鞠興榮,王丹丹,等. 堿提酸沉淀方法制取菜籽蛋白質(zhì)的研究[J]. 中國(guó)糧油學(xué)報(bào),2009,24(6):72-75. Yan Meirong, Ju Xingrong, Wang Dandan, et al. Preparation of rapeseed protein by alkali extraction and acid precipitation[J]. Journal of the Chinese Cereals and Oils Association, 2009, 24(6): 72-75. (in Chinese with English abstract)

[4] 沈鳳梅. 菜籽粕加工廢水的資源化利用[D]. 武漢:武漢輕工大學(xué),2014. Sheng Fenmei. Resource Utilization from Rapeseed Meal Processing Wastewater[D]. Wuhan: Wuhan Polytechnic University, 2014. (in Chinese with English abstract)

[5] Zhou Zhengqun, Xiao Jia, Fan Hongxia, et al. Polyphenols from wolfberry and their bioactivities[J]. Food Chemistry, 2017, 214(9): 644-654.

[6] Ali F, Ranneh Y, Ismail A, et al. Identification of phenolic compounds in polyphenols-rich extract of Malaysian cocoa powder using the HPLC-UV-ESI-MS/MS and probing their antioxidant properties[J]. Journal of Food Science and Technology, 2015, 52(4): 2103-2111.

[7] Kang Lina, Ma Tingting, Zhao Pei, et al. The hepatoprotective effect of polyphenols from sphallerocarpus gracilis Stem leaves against CCI4-induced acute hepatic damage in mice[J]. Modern Food Science and Technology, 2015, 31(3): 18-23.

[8] Li Yao, Liao Xia, Xiao Xingning, et al. Progress in research on the antitumor mechanisms of plant polyphenols based on proteomics[J]. Chinese Chamber of Commerce, 2016, 37(3): 235-240.

[9] Shay J, Elbaz H A, Lee I, et al. Molecular mechanisms and therapeutic effects of (-)-epicatechin and other polyphenols in cancer, inflammation, diabetes, and neurodegeneration[J]. Oxidative Medicine and Cellular Longevity, 2015(2015).

[10] 湯務(wù)霞,田景元,湯超. 丙酮法提取菜籽餅多酚及體外抗氧化性研究[J]. 食品工業(yè),2012(1):54-57. Tang Wuxia, Tian Jinyuan, Tang Chao. Polyphenols of repeseed meal by acetone extraction and its antioxidant activity in vitro[J]. Food Industry, 2012(1): 54-57. (in Chinese with English abstract)

[11] 劉入銘. 菜籽多酚對(duì)K19-C2mE轉(zhuǎn)基因鼠胃腫瘤病變的抑制作用[D]. 長(zhǎng)春:吉林大學(xué),2014. Liu Ruming. 4-Vinyl-2, 6-dimethoxyphenol(canolol) Suppresses Gastric Tumor Lesions in K19-C2mE Transgenic Mice[D]. Changchun: Jilin University, 2014. (in Chinese with English abstract)

[12] Kozlowska H, Rotkiewicz D A, Zadernowski R, et al. Phenolic acids in rapeseed and mustard[J]. Journal of the American Oil Chemists' Society, 1983, 60(6): 1119-1123.

[13] 稅丹,王立峰,袁建,等. 酸法提取菜籽多糖的抗氧化活性研究[J]. 食品科學(xué),2011,32(21):98-101. Shui Dan, Wang Lifeng, Yuan Jian, et al. Antioxidant effect of rapeseed polysaccharides extracted by hydrochloric acid[J]. Food Science, 2011, 32(21): 98-101. (in Chinese with English abstract)

[14] 朱建飛,唐春紅,吳謀成. 菜籽多糖WPS-1對(duì)小鼠腹腔巨噬細(xì)胞免疫功能的影響[J]. 中國(guó)糧油學(xué)報(bào),2011,26(8):41-49. Zhu Jianfei, Tang Chunhong, Wu Moucheng. Immunomodulating effects of rapeseed polysaccharide WPS-1 on mouse peritoneal macrophage[J]. Journal of the Chinese Cereals and Oils Association, 2011, 26(8): 41-49. (in Chinese with English abstract)

[15] 嚴(yán)奉偉,王辰,嚴(yán)贊開. 菜籽多糖對(duì) S180小鼠肉瘤及其免疫能力的影響[J]. 食品科學(xué),2007,28(4):309-313. Yan Fengwei, Wang Chen, Yan Zankai. Effects of rapeseed polysaccharides(RSPS) on S180 tumor growth inhibition and immune capability enhancement in vivo[J]. Food Science, 2007, 28(4): 309-313. (in Chinese with English abstract)

[16] 池源,王麗波. 苯酚-硫酸法測(cè)定南瓜籽多糖含量的條件優(yōu)化[J]. 食品與機(jī)械,2014,30(1):89-92. Chi Yuan, Wang Libo. Study on phenl-sulfuric acid method for determination of polysaccharide content in pumpkin seeds[J]. Food & Machinery, 2014, 30(1): 89-92. (in Chinese with English abstract)

[17] 游見(jiàn)明,曹新志. 福林酚法測(cè)定茶樹中茶多酚的分布水平[J].湖北農(nóng)業(yè)科學(xué),2013,52(10):2417-2419. You Jianming, Cao Xinzhi. Analysis on the distribution of tea polyphenol in tea tree by folin-ciocalteaut method[J]. Hubei Agricultural Sciences, 2013, 52(10): 2417-2419. (in Chinese with English abstract)

[18] 何榮海,蔣邊,朱培培,等. 枯草芽孢桿菌固態(tài)發(fā)酵菜籽粕生產(chǎn)多肽及降解硫苷的研究[J]. 食品工業(yè)科技,2014,35(10):228-233. He Ronghai, Jiang Bian, Zhu Peipei, et al. Study on solid-state fermentation of rapeseed meal for preparation of peptides and degradation of glucosinolates bybacillus subtilis[J]. Science and Technology of Food Industry, 2014, 35(10): 228-233. (in Chinese with English abstract)

[19] 何榮海,劉磊,蔣邊,等. 枯草芽孢桿菌液態(tài)發(fā)酵菜籽粕制備抗氧化肽[J]. 食品工業(yè)科技,2013,13(12):12-20. He Ronghai, Liu Lei, Jiang Bian. Preparation of antioxidant peptides bybacillus subtilisliquid-state fermentation from rapeseed meal[J]. Science and Technology of Food Industry, 2013, 13(12): 12-20. (in Chinese with English abstract)

[20] Lin Liyun, Liu Hsiuman, Yu Yawen, et al. Quality and antioxidant property of buckwheat enhanced wheat bread[J]. Food Chemistry, 2009, 112(4): 987-991.

[21] 張德華,鄧輝,喬德亮. 植物多糖抗氧化體外實(shí)驗(yàn)方法研究進(jìn)展[J]. 天然產(chǎn)物研究與開發(fā),2015,27(4):747-751. Zhang Dehua, Deng Hui,Qiao Deliang. Research progress on experimental methods on testing in vitro antioxidant activity of plant polysaccharides[J]. Natural Product Research and Development, 2015, 27(4): 747-751. (in Chinese with English abstract)

[22] Zhuang Yuan, Yan Peisheng. Study on hydroxyl radical scavenging ability of fermented kelp waste[J]. Chemical Engineering Transactions, 2016, 51(14): 289-294.

[23] 王振斌,劉加友,馬海樂(lè). 無(wú)花果多糖提取工藝優(yōu)化及其超聲波改性[J]. 農(nóng)業(yè)工程學(xué)報(bào),2014,30(10):262-269. Wang Zhenbin, Liu Jiayou, Ma Haile. Extraction process optimization and ultrasonic modification of polysaccharide from Ficus carica L.[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(10): 262-269. (in Chinese with English abstract)

[24] 趙謀明,鄒晶,趙亞琦. 脫酰胺與雙酶協(xié)同作用提高小麥面筋蛋白酶解效率[J]. 農(nóng)業(yè)工程學(xué)報(bào),2016,32(23):303-308. Zhao Mouming, Zou Jing, Zhao Yaqi, et al. Deamidization and double enzyme synergetic hydrolysis increasing hydrolysis effeciency of wheat gluten[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(23): 303-308. (in Chinese with English abstract)

[25] Harbourne N, Jacquier J C, O’riordan D. Optimisation of the aqueous extraction conditions of phenols from meadowsweet (Filipendula ulmaria L.) for incorporation into beverages[J]. Food Chemistry, 2009, 116(3): 722-729.

[26] 令博,王捷,吳洪斌. 葡萄皮渣多酚超聲波輔助提取工藝響應(yīng)面法優(yōu)化及抗氧化活性研究[J]. 食品科學(xué),2011,32(18):24-29. Ling Bo, Wang Jie, Wu Hongbin. Polyphenols from grape skin: optimization of ultrasonic-assisted extraction process by response surface methodology and antioxidant activity evaluation[J]. Food Science, 2011, 32(18): 24-29. (in Chinese with English abstract)

[27] Prasad K N, Yang E, Yi C, et al. Effects of high pressure extraction on the extraction yield, total phenolic content and antioxidant activity of longan fruit pericarp[J]. Innovative Food Science & Emerging Technologies, 2009, 10(2): 155-159.

[28] 張立軍,袁能文. 線性綜合評(píng)價(jià)模型中指標(biāo)標(biāo)準(zhǔn)化方法的比較與選擇[J]. 統(tǒng)計(jì)與信息論壇,2010,25(8):10-15. Zhang Lijun, Yuan Nengwen. Comparison and selection of index standardization method in linear comprehensive evaluation model[J]. Statistics & Information Forum, 2010, 25(8): 10-15. (in Chinese with English abstract)

[29] 吳建民,陶菊春. 用綜合加權(quán)評(píng)分法優(yōu)化鉆井泥漿配方的研究[J]. 農(nóng)業(yè)工程學(xué)報(bào),2002,18(2):45-48. Wu Jianmin, Tao Juchun. Experimental study on optimizing mud prescription for well drilling by using comprehensively weighted grading method[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2002, 18(2): 45-48. (in Chinese with English abstract)

[30] 史蘭. 菜籽粕中有效成分的提取分離工藝研究[D]. 西安:陜西科技大學(xué),2014. Shi Lan. Study on the Extraction and Separation of Active Ingredients in Rapeseed Meal[D]. Xi’an: Shaanxi Universityof Science & Technology, 2014. (in Chinese with English abstract)

[31] 劉琴,吳梨,石嘉懌,等. 油菜籽多酚的分布及加工過(guò)程對(duì)菜籽多酚含量的影響[J]. 食品科學(xué),2010,31(19):33-37. Liu Qin, Wu Li, Shi Jiayi, et al. Distribution of polyphenols in rapeseed shell and kernel and effect of oil extraction methods on their content in rapeseed Meal[J]. Food Science, 2010, 31(19): 33-37. (in Chinese with English abstract)

[32] 朱沛沛,李嘉樂(lè),曾懿,等. 菜籽餅粕多酚的提取及其清除羥自由基活性研究[J]. 糧油食品科技,2013,21(1):23-26. Zhu Peipei, Li Jiale, Zeng Yi, et al. Study on extraction of polyphenol from rapeseed meal and the activity of eliminating hydroxy radical[J]. Science and Technology of Cereals,Oils and Foods, 2013, 21(1): 23-26. (in Chinese with English abstract)

[33] 荊文光. 菜籽粕化學(xué)成分和生物活性研究[D]. 北京:中國(guó)中醫(yī)科學(xué)院,2014. Jin Wenguang. Studies on Chemical Constituents and Bioactivity of the Rapeseed Meal (Brassfca napus L)[D]. Beijing: China Academy Chinese medical Science, 2014. (in Chinese with English abstract)

[34] 吳梨. 油菜籽中多酚類化合物及其分布的研究[D]. 南京:南京財(cái)經(jīng)大學(xué),2011. Wu Li. Research on Polyphenolics of Rapeseed[D]. Nanjing: Nanjing University of Finance and Economics, 2011. (in Chinese with English abstract)

Extraction processing optimization of polyphenols and polysaccharides from rapeseed protein processing waste liquor

Zhang Weiwei1, Dai Chunhua1,2,3, Xiong Feng1, Hou Furong1, He Ronghai1,2,3※, Ma Haile1,2,3

(1.School of Food and Biological Engineering,Jiangsu University,Zhenjiang212013,China; 2.Key Laboratory for Physical Processing of Agricultural Products of Jiangsu Province,Zhenjiang212013,China; 3.Food Intelligent Manufacturing Engineering Technology Research Center of Jiangsu Province,Zhenjiang212013,China)

Rapeseed protein processing waste liquor contains a variety of natural antioxidant products, which include polyphenol, polysaccharide, peptide, and so on. To realize the comprehensive utilization of rapeseed protein processing waste liquor and gain high value-added products to improve the overall economy, the extraction efficiency and the antioxidant activities of polyphenols and polysaccharides in waste liquid from production of rapeseed protein were researched in this paper. First of all, effects of extraction temperature, ethanol concentration and extraction time on the extraction rate of polyphenols and polysaccharides from waste liquid were investigated by single-factor experiments to acquire the appropriate ranges of extraction parameters. Then a Box-Behnken design (BBD) was applied to evaluate the effects of extraction temperature, ethanol concentration and extraction time on the extraction efficiency and their interactions at 3 equidistant levels. The ranges of the 3 independent variables i.e. extraction temperature, ethanol concentration and extraction time were 50-70 ℃ , 50%-70% and 15-45 min, respectively, which were based on the results of single-factor experiments. The result indicated that ethanol concentration was the most significant variable, followed by extraction temperature and time according to the regression coefficient significance of the equation and the gradient of slope in 3D (three-dimensional) response surface map. The optimum conditions could be modified as follows: Extraction temperature of 60 ℃, ethanol concentration of 65% and extraction time of 31 min. Under the optimal conditions, extraction ratios of polyphenols and polysaccharides were 2.19% and 8.14%, respectively, which were well-matched with the predicated values of 2.19% and 8.18% obtained from the models. The results revealed that the regression equations and models were reliable to predict the influences of factors on extraction ratios of polyphenols and polysaccharides. In addition, anti-oxidative activities of polyphenols extract and polysaccharides extract in vitro were evaluated by scavenging activity of DPPH (1,1-diphenyl-2-picrylhydrazyl radical 2,2-diphenyl-1-(2,4,6-trinitropheny) hydrazyl) and hydroxyl radical as well as reducing power. The result showed that the DPPH radical scavenging abilities of polyphenols extract and polysaccharides extract increased from 32.63% to 93.53% and from 18.65% to 77.97% with the increasing of their concentrations from 0.10 to 0.50 mg/mL and from 0.40 to 2.40 mg/mL, respectively. Half inhibitory concentrations of polyphenols extract and polysaccharides extract for scavenging DPPH were 0.20 and 1.45 mg/mL respectively according to their regression equation. Hydroxyl radical scavenging abilities of them increased from 36.92% to 83.62% and from 13.59% to 78.60% with the increasing of their concentrations from 5.00 to 30.00 mg/mL and from 0.80 to 3.80 mg/mL, respectively. Half inhibitory concentrations of polyphenols extract and polysaccharides extract for scavenging hydroxyl radical were 10.85 and 2.38 mg/mL respectively according to their regression equation. The reducing abilities also increased with the increasing of the concentrations of polyphenols extract and polysaccharides extract. In contrast, reducing ability of polyphenols extract was stronger than that of polysaccharides extract. From these results, for different free radicals, the scavenging ability of polyphenols and polysaccharides was different, and showed a good dose-effect relationship in the range of mass concentrations. The DPPH free radical scavenging rate and reducing ability of polyphenols extract were both significantly higher than that of polysaccharides extract under the same mass concentration, while the polysaccharides extract had a stronger scavenging ability to hydroxyl radical than polyphenols extract. In the end, the phenolic ingredients in samples were analyzed by HPLC (high performance liquid chromatography). The result indicated that polyphenols extract was rich in phenolic compounds such as cumaric acid, syringic acid, pcoumaric acid, sinapinic acid and benzoic acid. The concentration of cumaric acid was 2.65 mg/g and that of sinapinic acid even reached 5.57 mg/g.

extraction; processing; optimization; polyphenols; polysaccharides; antioxidant ability; rapeseed protein processing waste liquor

10.11975/j.issn.1002-6819.2017.07.040

TS229

A

1002-6819(2017)-07-0302-08

2016-10-19

2017-03-25

國(guó)家重點(diǎn)研發(fā)計(jì)劃(2016YFD0401401);江蘇省重點(diǎn)研發(fā)計(jì)劃(BE2016352);鎮(zhèn)江市農(nóng)業(yè)科技支撐項(xiàng)目(NY2014012);江蘇高校青藍(lán)工程資助項(xiàng)目。

張韋唯,女,江蘇南通人,主要從事功能食品的研究。鎮(zhèn)江 江蘇大學(xué)食品與生物工程學(xué)院,212013。

Email:vivian_jsnt@sina.com

※通信作者:何榮海,男,江蘇丹徒人,博士,教授,主要從事食品物理加工技術(shù)研究。鎮(zhèn)江 江蘇大學(xué)食品與生物工程學(xué)院,212013。

Email:heronghai@ujs.edu.cn