Analysis and research of OPC technology in coal mine monitoring data transmission system

Yue PANG

(Chongqing Jianzhu College, Chongqing 400072, China)

?

Analysis and research of OPC technology in coal mine monitoring data transmission system

Yue PANG*

(Chongqing Jianzhu College, Chongqing 400072, China)

For the high-risk work circumstances of coal mining enterprises, there might be production difficulty caused by some uncertain factors, which could lead to the production risks. Therefore, there is great significance in detecting all the data in time. The coal mine monitoring system was designed by applying the worldly advanced software which was industrial automotive and informatization based on the detection system of the large coal mines, with which the real-time interaction of coal mine field equipment data was realized based on the OPC communication technology and the real-time running condition of equipment can be learned more intuitively through observing the InTouch monitoring interface.

Monitor, OPC technology, Data collection

1 Introduction

With the continuous development of information technology, some mining companies begin to pay more attention to how to realize information management. Monitoring system, as a bridge between coal mine enterprises and the information platforms of integrated automation, plays a very significant role in enterprises management. Thus building a suitable monitoring system to have real-time, effective and accurate reading and transmission of the monitoring data is one of the popular technologies among current researches.

Previous industrial software manufacturers needed to develop driver interface for different hardware independently and the technicians who developed typical software monitor took about a quarter of his time to write communications driver. When the supplier provided a new hardware, software developers had to write a new program. To solve the above problems, OPC standard provides a solution. It established a series of specifications on data access, events, alarm, etc., with which supplier only need to provide the implementation of OPC standard interface without rewriting the upper application software when there was a new hardware. OPC standard can realize seamless communication between the system and equipment without worrying about the inconvenience and additional cost of equipment upgrades, which greatly improves the efficiency of the work. This system completed the access and acquisition of coal mine data based on OPC technology, thus realized the remote monitoring system to have real time reading, access and transmission of data and to guarantee a timely and manner of coal mine working system.

2 Technical specification of OPC

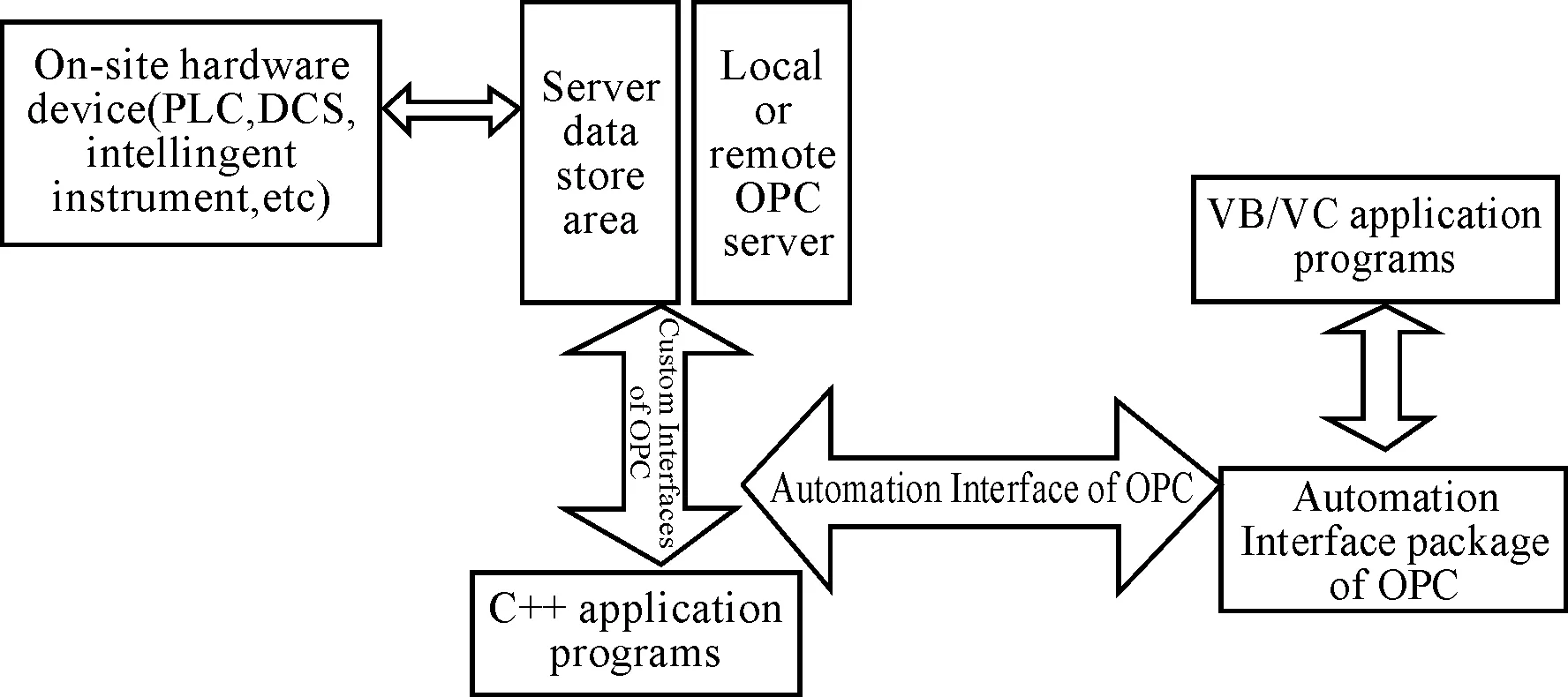

OPC communication technology takes Microsoft’s OLE technology as its basis and is the industry technical standard completed between the connection of the data sources (OPC server) and data users (OPC application) by providing a set of standard OLE/COM interface. It made the software interface between different suppliers of equipment and application programs standard and solved the data exchange interaction problem between them due to the differences between hardware and system, so as to realize the system composition which is not dependent on hardware system.

The most important specification of OPC standard is the OPC data access specification (OPC - DA), and it can ensure that various application softwares run on different platforms and written in different languages can integrate smoothly by standardizing interface in the process of data access. Any data in a local OPC server can be accessed quickly and easily by custom interface of OPC server, and through the automation interface provided by OPC, it can be applied to any defined server custom interface by vendors, thus to achieve the purpose of accessing the remote OPC server. Its typical structure of accessing is shown in Fig.1.

Fig.1 Typical structure cutline of OPC access

3 OPC data collection

The basic objects that the OPC data access specification stipulated are classified into three categories: the server, group and a data Item. Object server contains all the information of server and also is the container of group objects, and can dynamically create or release group objects. Group objects are used to maintain information about itself and also, as the mechanism of OPC items, manage OPC items in logic. OPC item means its connection to the OPC server data. One server corresponding to one OPC server (server object interface), that is a device driver.

In the process of data collection, OPC server completes the dynamic creation of OPC group object and dynamic management, and creates a group object in AddGroup and returns to the interface pointer customer requested. OPC Group provides a way to allow customers to organize data and user can add a group of logically related data as OPC item to the same group, for example to store the liquid level height in the drainage test part of this system. And at the same time we can create multiple set of objects and do their associated settings according to respective attributes. OPC item means the OPC server data connection and has three basic attributes: value, quality and time stamp. The value of the data type is VARIANT, which represents the actual numerical value. The quality identifies the validity of the numerical. The timestamp reflects the time it takes in reading data from the device or the time that the server needs in refreshing the data storage area.

4 OPC data collection process

In OPC server data storage area, the value, quality, timestamp and other related equipment information are stored. The server accesses the hardware of the various devices according to certain refresh rate through the corresponding driver, which sends the field data into data storage area and after that the client directly calls the group objects in the OPC server object to return to pointer by calling the server object interface or by getting group objects. And then call item interface to get the data. The above process is shown in Fig.2.

Fig.2 The work flow chart of OPC technology

5 Overall structure based on OPC monitoring system

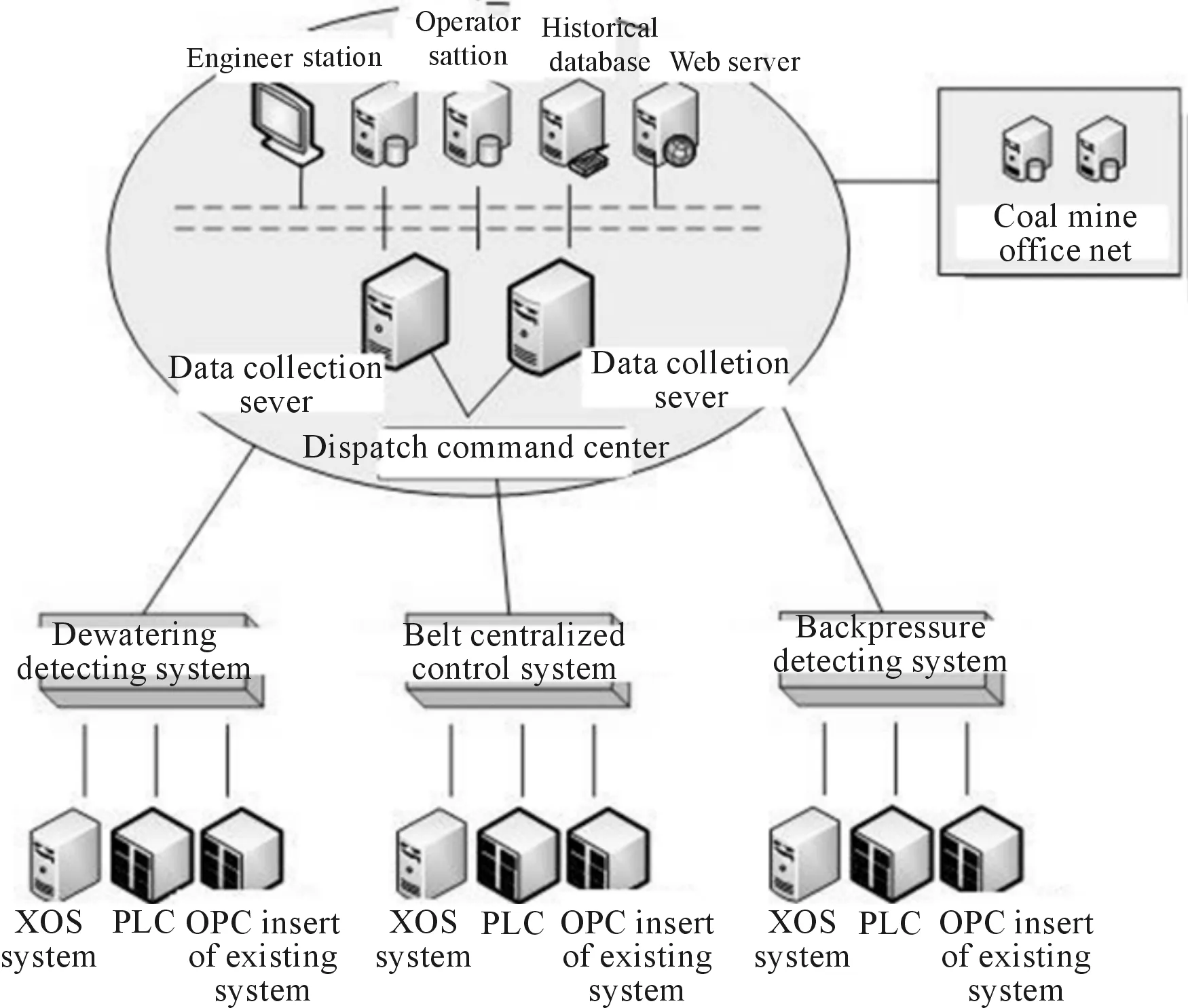

Wonderware Company is the world’s leading supplier of industrial automation and information technology software Its InTouch software has rich functions of graphics and its design is of high flexibility. Also it is an open and extensible man-machine interface, which provides flexibility for custom applications design and provides all kinds of automation ability to connect various of equipments for industry at the same time. OPC, as an excuse standard, consists of the client and the server. OPC server program is installed on the application server and the client application is installed on the server of controlled sub station, thus the whole monitoring system can be divided into three parts: the field data collection, the monitoring center and remote monitoring. The Overall structure is shown in Fig.3 below.

Fig.3 The overall structure of system

1) The field data collection: at the field control station, the data in the PLC and DCS system and equipment were collected into the sub sever station by using OPC interface, and then the sub sever station transmitted the data into the master data collection server in the monitoring center through industrial Ethernet ring net.

2) The monitoring center: in coal mine dispatching command center, to have the development and modeling of drainage monitoring system by connecting OPC server with Wonderware. And the running status of each subsystem was real-time monitored by the combining with InTouch software, and the data analysis, storage, alarm, display and other administrative tasks were performed.

3) The remote monitoring: to have local system interface be published on Web as required and to release real-time images, historical data, alarm and other relational database data by using Wonderware Information Server, thus scheduling command center can be accessed by remote monitoring through communication methods such as optical fiber or wireless remote control network and so on.

6 Implementation methods and results of system

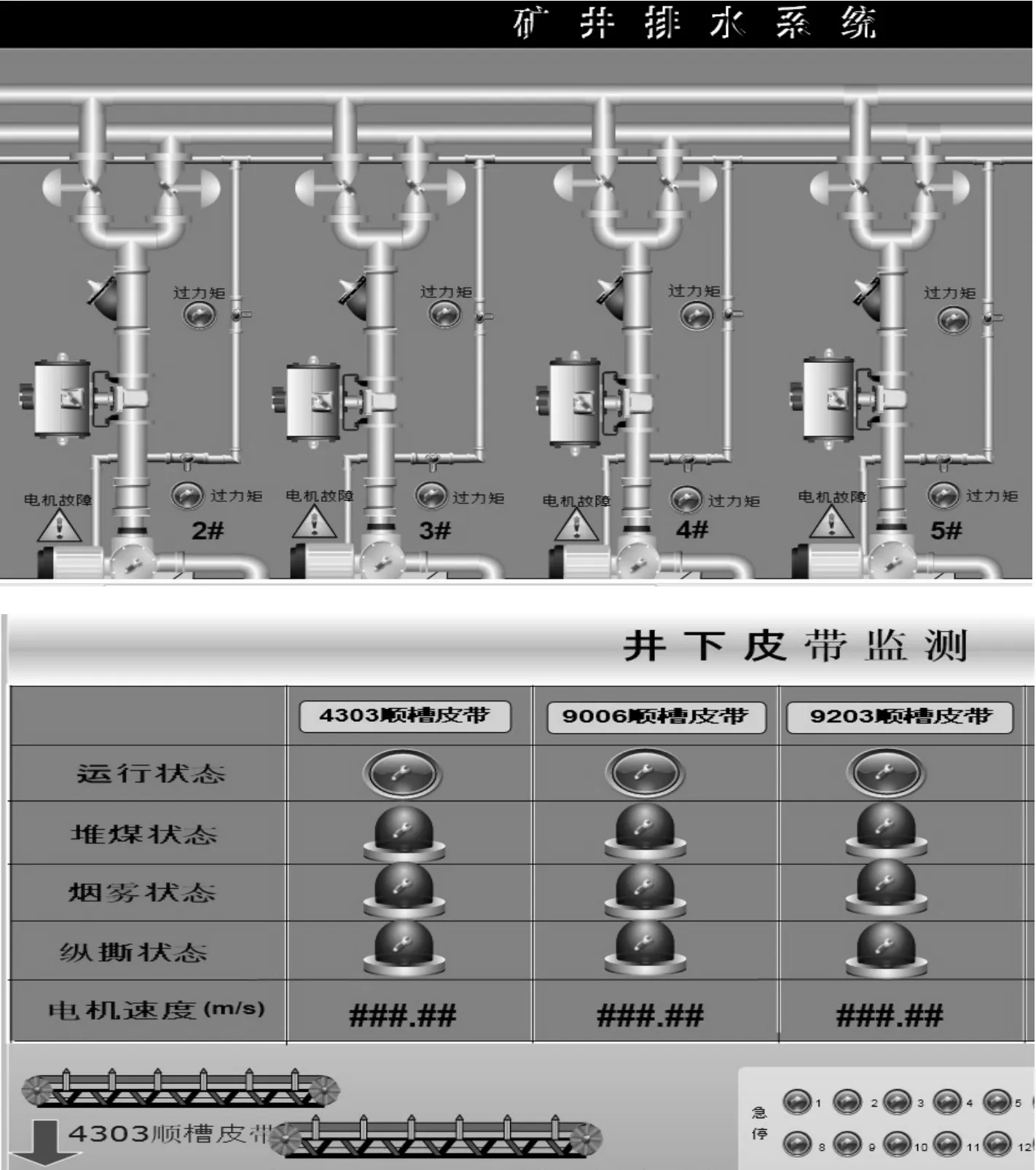

FactorySuite Gateway software in Wonderware configuration component is a protocol converter. It can provide many kinds of data transfer of protocol conversion and is used to connect the client with the data sources. And between the client and the data source, a variety of different data access protocol can be used. The equipment information collected from the scene of industrial can be transmitted into protocol type data as required automatically. It provides the function of OPC server, so FactorySuite Gateway can be activated as an OPC server. Therefore, in order to save the interface time of OPC server object and Group object in writing a lot of development programs, this paper adopted the OPC Server into FactorySuite Gateway software and embedded OPC client in the integrated development environment of ArchestrA IDE at the same time.This system is a safe, reliable, advanced and convenient monitoring system of high technical content and can automatically detect equipment operation, collect field data and provide alarm information according to the actual situation of coal mine and combining the OPC communication technology. Its partial implementation effects are shown in Fig.4.

Fig.4 The homepage of coal mine monitoring system

7 Conclusions

For the remote monitoring of large coal mining enterprises, we designed monitoring system architecture of using OPC in large coal mine and aimed to obtain the real-time data of coal mine monitoring system, through which working status of each link of the system of coal mine can be controlled in time and can facilitate the location and real-time working status in coal mine where has high risk working environment, thus to low the economic losses to a minimum when fault happens. In terms of the system itself, its cost is relatively low. And it has long life cycle and strong system stability. Experiments prove that this kind of remote monitoring device can be read in time and stored in a timely manner, and can show the working state timely.

[1]LU Huiming, ZHU Yaochun. Standardized Control Device: Development, Design and Application of OPC Server[M].Beijing: China Machine Press, 2010:10-15.

[2]OPC Foundation[EB/OL].[2011-11-20].http://www.opcfoundation.org.

[3]SI Jigang. Guide for OPC DA Sever and Client Application Development[M].Beijing: Nanda Automation Technology,2008: 8-9.

[4]Jun Liu, Khiang Wee Lim, Weng Khuen Ho.Using the OPC Standard for Real-Time Process Monitoring and Control[J]. IEEE SOFTWARE, 2006, 15(9): 55-59.

[5]ZHU Haitao. The Norm of OPC at Internet Solid hour Supervise and Control the Application in the System [D].Beijing: Chinese Petroleum University, 2006:17-19.

[6]OPC China Foundation[EB/OL].[2010-10-15].http://www.opcchina.com.cn.

OPC技術(shù)在煤礦監(jiān)測數(shù)據(jù)傳輸系統(tǒng)的應(yīng)用

龐玥*

重慶建筑工程職業(yè)學(xué)院,重慶400072

煤礦企業(yè)由于處于高危工作環(huán)境,可能由于一些不確定因素的影響而產(chǎn)生生產(chǎn)故障,從而發(fā)生危險(xiǎn),所以及時(shí)檢測煤礦的各項(xiàng)數(shù)據(jù)有重大意義。就大型煤礦的檢測系統(tǒng)提出了采用Wonderware工業(yè)自動(dòng)化和信息化軟件完成了煤礦監(jiān)測系統(tǒng)的設(shè)計(jì)開發(fā),以O(shè)PC通信技術(shù)為基礎(chǔ)實(shí)現(xiàn)了煤礦現(xiàn)場設(shè)備數(shù)據(jù)的實(shí)時(shí)交互,通過觀察InTouch監(jiān)控界面可更直觀地了解設(shè)備的實(shí)時(shí)運(yùn)行狀況。

監(jiān)測;OPC技術(shù);數(shù)據(jù)采集

17 January 2015; revised 5 April 2015;

Yue PANG, Lecturer.

E-mail: 93439232@qq.com

10.3969/j.issn.1001-3881.2015.18.023 Document code: A

TP311.1

accepted 6 June 2015

Hydromechatronics Engineering

http://jdy.qks.cqut.edu.cn

E-mail: jdygcyw@126.com

- 機(jī)床與液壓的其它文章

- Manufacturing of self-lubricating diamond tools with Ni-Cr alloy adding with Ni/C

- Vibration response analysis of a lathe spindle by using the ANSYS finite element method

- Car following model with consideration of the vehicle’s mechanical inertia effect and its stability analysis

- Software design for spur gear tooth thickness based on MATLAB/GUI

- Dynamic study on ultrasonic horn

- Based on Cortex-M4 torus worm tester full closed loop control system