Research on comprehensive index system about product quality monitoring

Liang LYU,Zu-shun HE,Long-jian WU,Hui-ying ZHANG

(Kunming University of Science and Technology,Kunming 659003,China)

1 Introduction

Product quality is relation with human health and survival,which influence the development of social economy.The monitoring work is carried to understand and grasp the quality of the products,find the problem at time,strengthen quality management of the important basic work.Department of industrial management need to build a set of refining and covers different common features of the index system of product quality and use in the management practice based on the macro grasp the overall status of industrial product quality and scientific management decision-making needs.This article tries to product also discussing the establishment of the monitoring index system[1].

2 The necessity of establish product quality indicators

The biggest characteristic of market economy is the fierce competition.Quality use the quantitative analysis method,correctly and objectively evaluate quality and is the key factor that decided the success or failure of the enterprise as the focus of market competition.Quality index system is a science tool to evaluate quality.It is constantly changing with the deepening of quality and quality management,with the constant improvement of China’s market economic system[2].

1)The lack of uniformity and comparability:the assessment content index do not have a unified calculation method,name of the indicators,connotation.So it cannot be used for single parameter of transverse comparison because of the lack of comparability.

2)The lack of dynamic:index has not be set form the formation process of quality,quality resources,continuous quality improvement so analysis index system analysis quality management problems and its change trend hardly.

3 The connotation of product quality testing and development

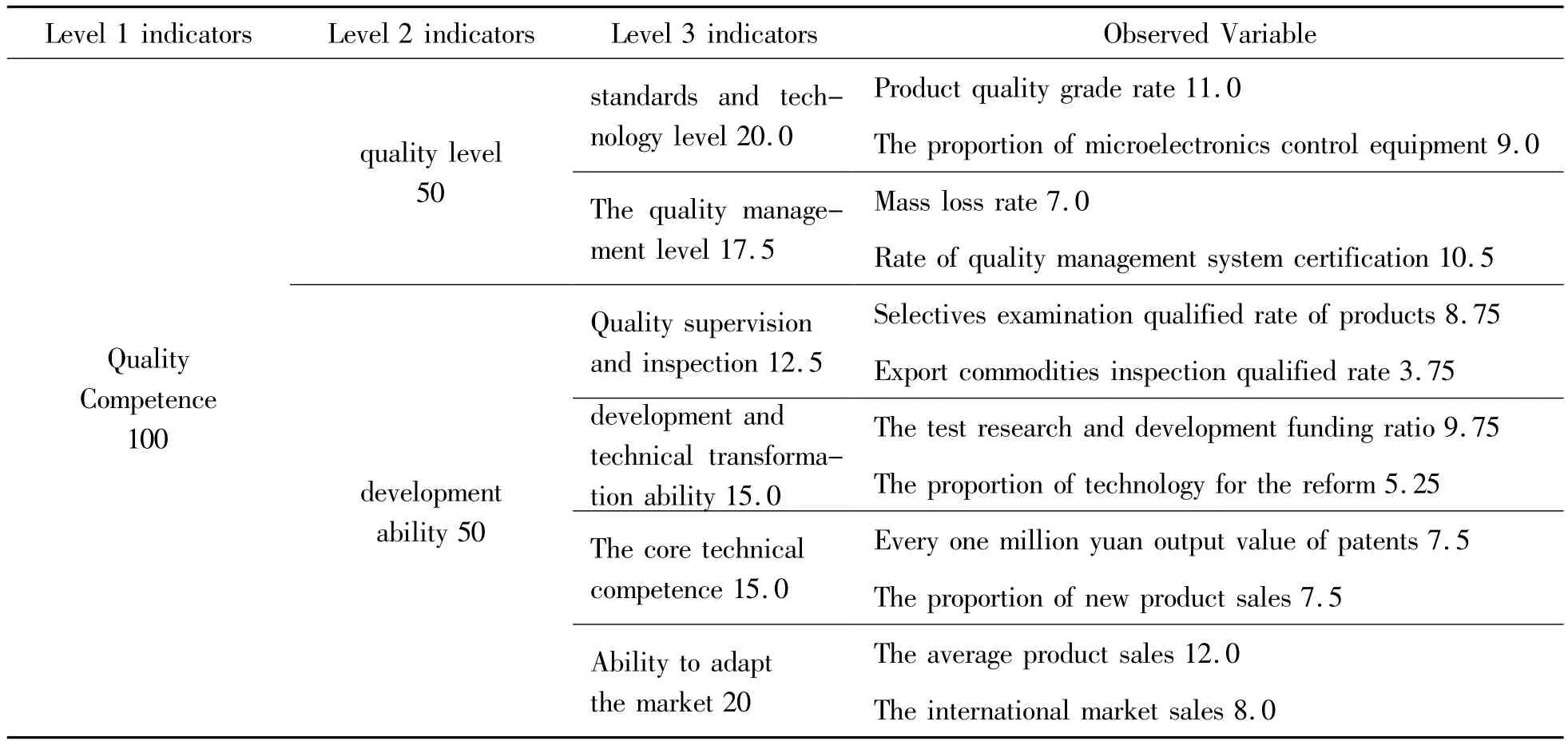

Chinese scholars also has carried on the positive exploration for the design of the quality monitoring indicators.National macroscopic quality evaluation index system research group evaluate the quality competitiveness from two aspects of quality level and develop-ment capacity.I designed the quality competitiveness evaluation indexes and observation variable weights allocation table is shown in Table 1[3].

Table 1 Quality competitiveness evaluation index and its observation variable weights allocation table

From the practical level,national implementation of quality monitoring index mainly cover product quality grade rate(G),mass loss rate(F),product sales(s),and value of new product each year.State Statistics Bureau reports this four indicators data as an important basic work to Promote the quality every year.

4 Quality index system and evaluation model

4.1 Product index calculation method

Product quality index is relate to the status of the product quality and quality level of job of the floorboard.At this stage it mainly should include the following several indicators[4]:

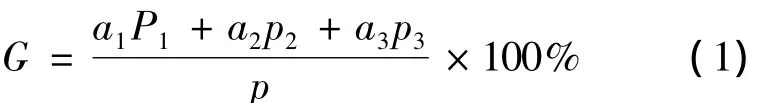

1)Product quality grade rate(G)

It refers to the sum of weighted grade product output value during the reporting period(Weighted classy article output and Weighted product output),grade product output During the same period(the sum of classy article nonconforming product output and output value),calculation formula:

p1,p2and p3are respectively the classy article output during the reporting period,grade a production and nonconforming product output;a1,a2anda3is weighting coefficient of classy article,first-rate and qualified products.It is classified as:a1=1.5,a2=1.0;P is the gross industrial output value during the reporting period(null).

2)The mass loss rate(F)

It is the ratio of the output loss cost and enterprise in the reporting period.

F is the mass loss during the reporting period;Ciis the external cost during the reporting period(null);Ceinternal loss cost during the reporting period(null);Pcis gross industrial output value during the reporting period(null).

The index reflects the quality index of economy.It evaluates the effectiveness of the quality management function and the actual status of the consumption of resources from an economic standpoint.The mass loss of statistical work is close to activities to reduce bad product loss betriebswirt.It has important significance to improve product quality and economic benefit[5].

4.2 Evaluation method model

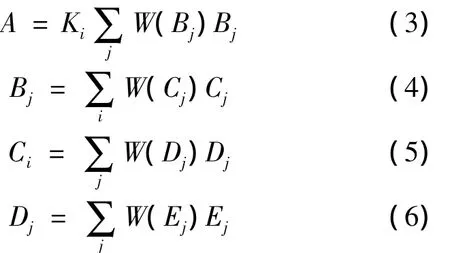

There are a lot of the determination of index weight method.It uses expert scoring method and analytic hierarchy process.It can combine qualitative analysis and quantitative analysis to obtain Scientific and reasonable weights.Each level index value is weighted by the next level of related indexes[6].

Quality comprehensive evaluation value determined by the type:

A is said quality comprehensive evaluation level;Kiis the first layer criteria weights(i=1,2,3,4);W(Bj)is said Bj criteria weights;Bjis BjA standard value of Bj;W(Cr),W(Dj),W(Ej)are according to the weight of each index;Ci,Dj,Ejare said the value of the indicators.

5 Conclusions

This paper discusses the comprehensive quality index system and evaluation method of general framework.Company Groups can set up more adapt to the index system and evaluation model.It should be built according to the industry characteristics and actual management level.Reasonable indicators advanced and scientific evaluation method can reflect the operation of the market conditions.The quality indicators should be comprehensive analyzed.The quality of water level should be accurate assessment,statistics and comprehensive evaluation.It can help to find the crux of enterprise quality to promote enterprise continuous improvement.Quality index system can play its proper role in enhancing enterprise competitiveness.

Acknowledgment

The research was funded by Kunming Non-Ferrous Mining,Metallurgy and Deep Processing of High-end Equipment Manufacturing Engineering Research Center.

[1]Shushan Dong.Index system of industrial product quality implementation guidelines[M].China metrology press.1992.

[2]Electronic industry technology and quality supervision.E-lectronic product quality index system implementation guidelines[M].Publishing House of Electronics Industry.1993

[3]Quality management science research institute in Shanghai.Quality Competence[M].Beijing:Standards press of china,2006:3

[4]Zhilong Wang.Research on China’s equipment manufacturing industry system evolution and evaluation[M].Beijing:Science Press.2007:8.

[5]The quality of national macro level evaluation index system research group.Quality competitiveness research and application[M].Beijing:China metrology press,2009.

[6]Hongjun Zheng.The product quality through research in China[M].Beijing:China Morden Economics Publishing House,2007:8.

- 機床與液壓的其它文章

- Exploration on the calculating formula of main transmission chain structural formulas of machine tools

- Visualization study of the oscillating bubble near the elastic wall

- Study on electro-hydraulic load simulator based on flow compensation method

- Optimal design for amplifier of jet deflector servo valve

- Availability function deployment of the CNC lathe based on multi factors

- Strict greedy design paradigm applied to the stochastic multi-armed bandit problem