Control system design of automatic down-filling machine based on ARM7TDMI*

Qiao QIAO, Liang-zhi FAN

School of Mechanics and Electronics Engineering, Wuhan Textile University, Wuhan 430073, China

?

Control system design of automatic down-filling machine based on ARM7TDMI*

Qiao QIAO?, Liang-zhi FAN

School of Mechanics and Electronics Engineering, Wuhan Textile University, Wuhan 430073, China

Abstract:The Down-filling machine is an automatic, intelligent, mechanical and electrical device with low-cost, convenient, great efficiency that can reduce labor intensity and improve labor conditions. It can fill down to duvet or down jacket from the container according to weight data exactly. This paper elaborated on several aspects: working principle of automatic Down-filling machine, realization of control system, realization of control strategy based on fuzzy inference, and research of serial communication feedback. The hardware system of Down-filling machine based on ARM7TDMI has been finished. And the system makes software and hardware logical in system frame, and achieves high complex controlling with low cost. In control field, closed-loop control is also implemented in this system. At the same time, the function modules of industry Down-filling machine has been studied, such as man-machine interface, motor control, the use of the FLASH memory AT29C020, the use of weighing sensor, etc. Results show that the system hardware has high stability and fast speed in fuzzy inference.

Key words:Down-filling, Fuzzy inference, ARM7TDMI, Flash, Closed-loop

1.Introduction

With the improvement of living standards, people increase the demand for down products. With the appearance of domestic and foreign enterprises, a great deal of the mechanical products in down industry obtain the rapid development. The down filling machine is an automatic intelligent, mechanism and electric device that can reduce labor intensity and improve labor conditions. We has chosen ARM7TDMI as the CPU of the automatic down-filling system. At the same time, this article introduces the realization of a fuzzy logical controller in the system.

1.1.Work process of automatic down-filling machine

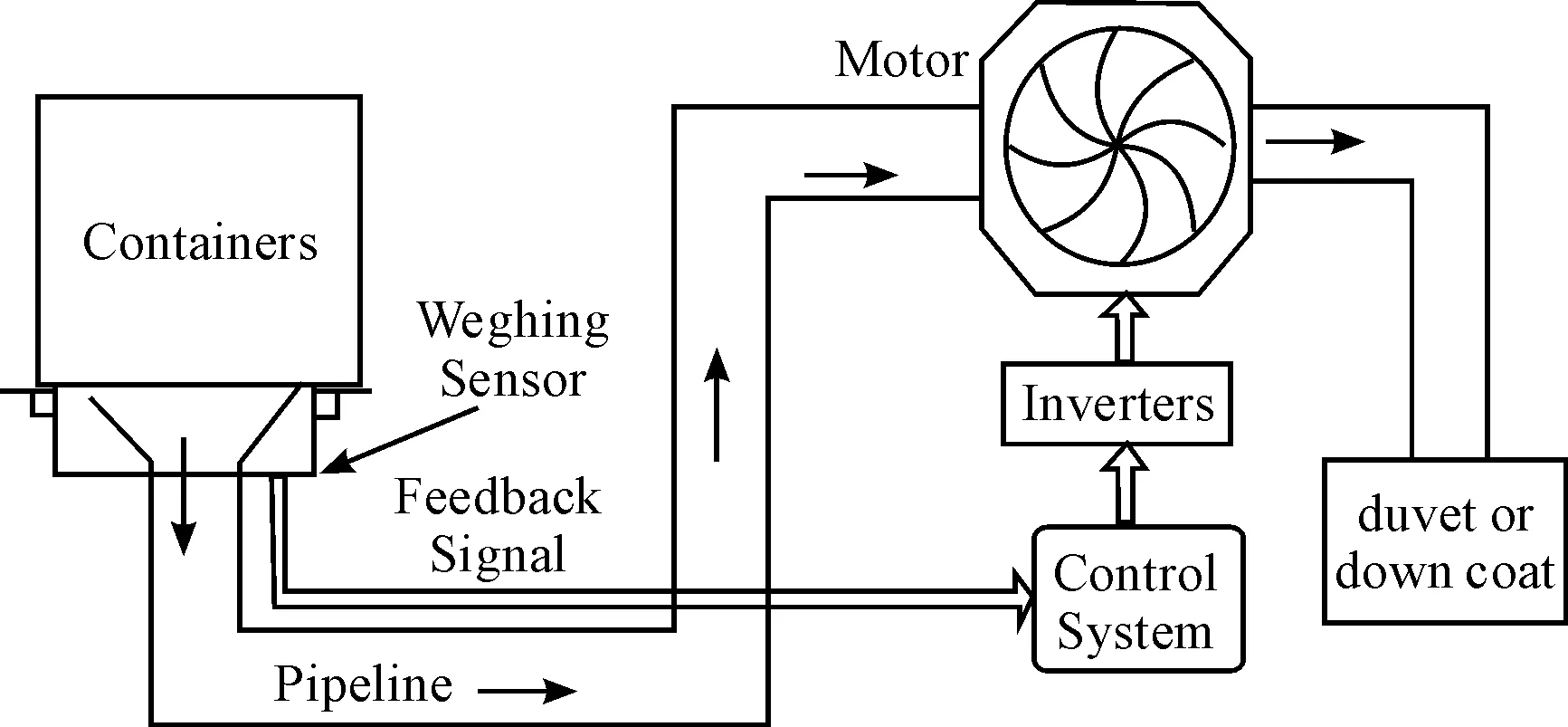

The model of the feather filling machine is shown in Figure 1.

Figure 1.The model of the down-filling machine

Down-filling machine will divert down from the cont- ainer to duvet or down jacket by blower fan. At the same time, by the use of sensor feed- back performance, feather weight will be monitored at any time to get precise filling results.

1.2.The main work flow of automatic down-filling machine

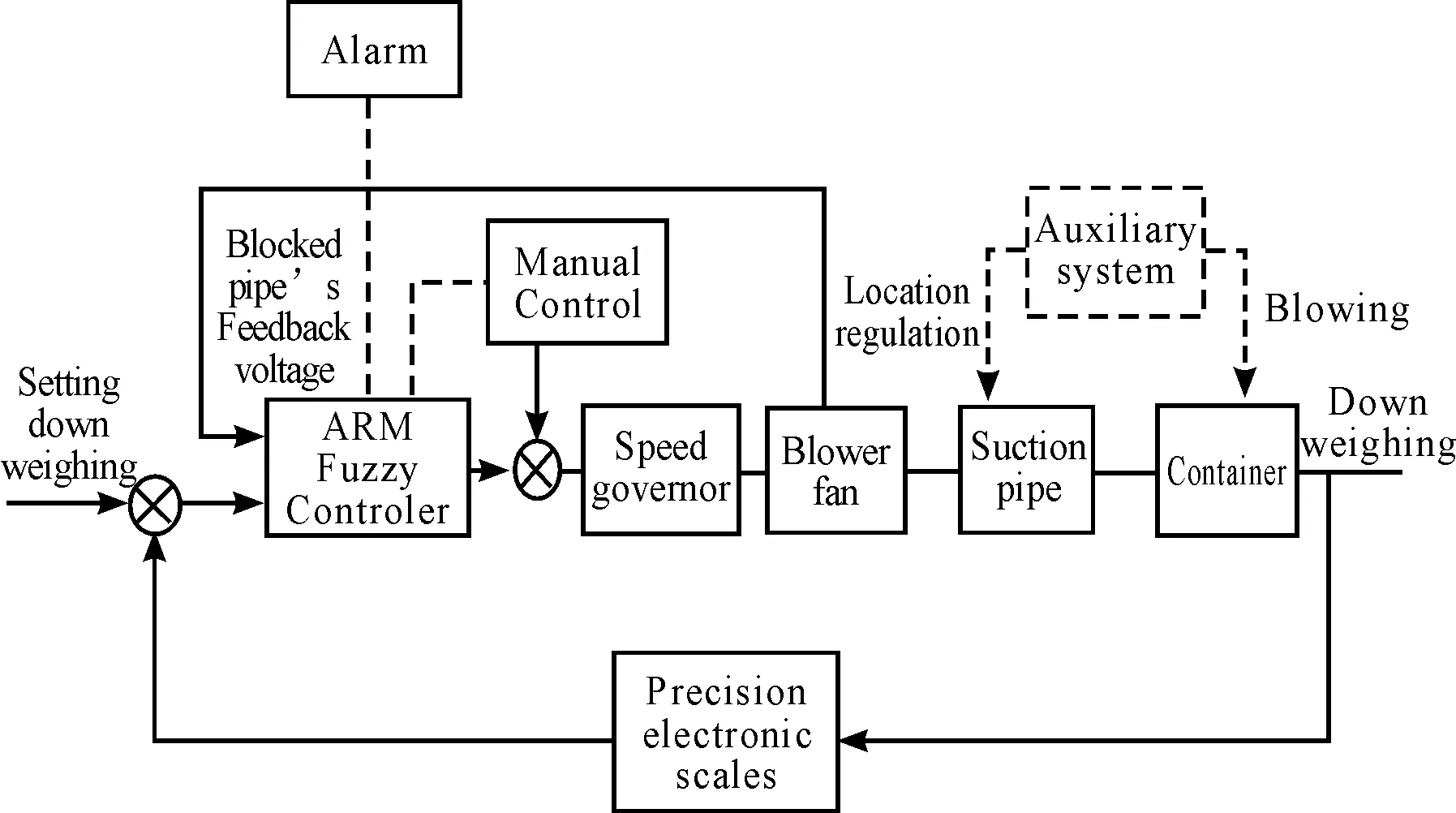

The main work flow of automatic down-filling machine is shown in Figure 2.

For the realization of automatic control, the system has taken the closed-loop feedback control methods[1]. Since the control object - the work motor can not determine the load disturbance, the system uses a fuzzy control algorithm. The control algorithm can avoid the accurate modeling of system, combine experimental and control motor speed.

Figure 2.Diagram of down-filling control system

1.3.Composition of the system hardware modules

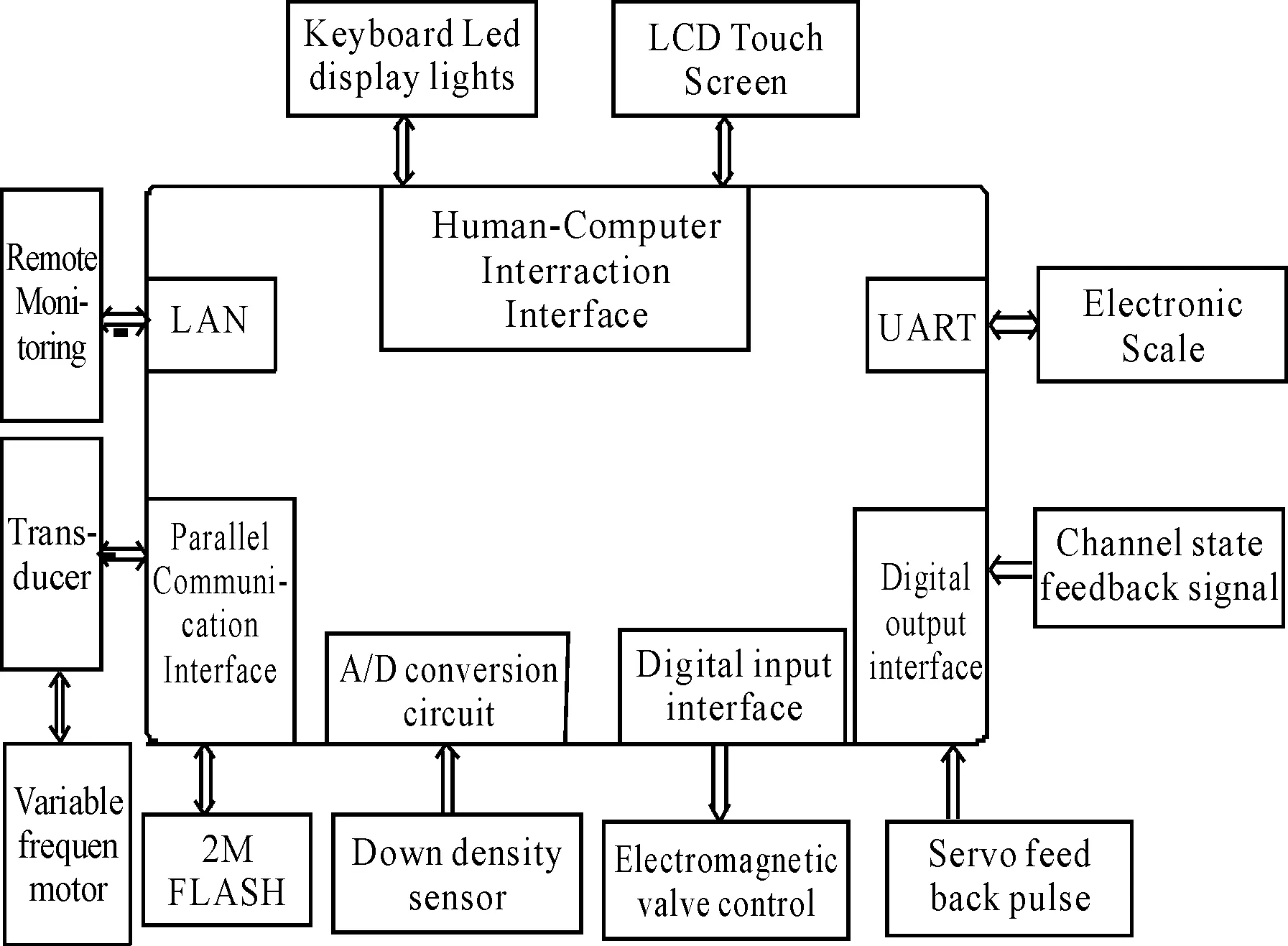

The system has the following function modules: ①Human-Computer Interaction Interface: the system has used LCD-6 inches touch screen and keyboard interface. ② Motor Control :in automatic down -filling machine, motor speed can be adjusted by transducer. Universal transducer’s remote control is in two ways: control of terminal and communications.③Electromagnetic valve control: electromagnetic valve is controlled by electromagnetic relays, including blowing valve, stopping valve, heating valve in the system. ④The system has three sensors: down density sensor, channel state feedback sensor, weighing sensor. ⑤ Detection of down content: The system has chosen PTM-1 sensor that would export TTL signal through serial communication. ⑥Internet Remote Monitoring: it needs the support of the network, the system should supply the LAN interface or interface of MODEM. Through this analysis[2]. Down-filling control system’s hardware functional block is shown in Figure 3.

Figure 3.Hardware functional block of down-filling control system

2.Introduction of the system’s hardware

2.1.Weighing sensor introduction

1) Electronic scale’s communication protocol

Communication protocol is the agreement that should start up prior to the beginning of communication device’s work. Communication between electronic weighing scale and CPU should also be carried out under the certain communication protocol[3].

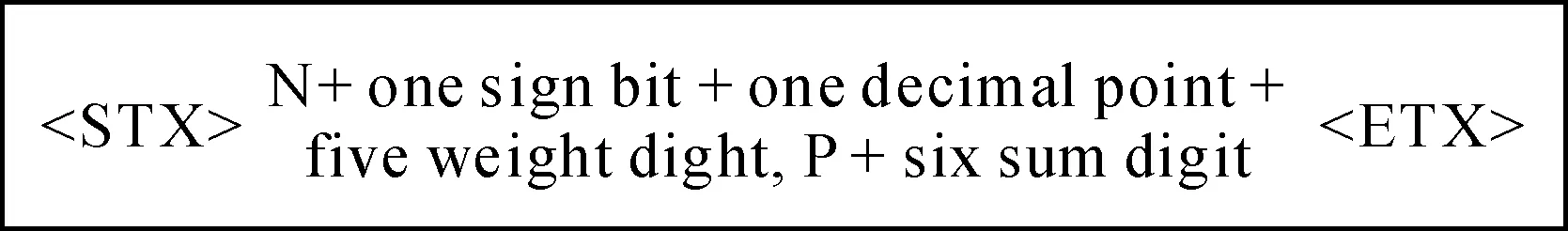

In this system, electronic weighing scale has three optional serial communication ways. The first one is a continuous sending way, and its format is shown in Figure 4.

Figure 4.The format of the communication agreement

Description:

N(Capital):Weight marker;

P(Capital):Amount marker;

The second way is that the electronic weighing scale will send the data after display stability. Its format can refer to Figure 4.

After CPU has detected the right data, it will store the useful data into 2 M flash, and compare with the corresponding data to realize the feedback.

2) Hardware connection

ARM7TDMI has two UART that comply with TTL voltage logic. The electronic weighing scale and CPU should be connected by ASIC-MAX232.The hardware connection is shown in Figure 5.

Figure 5.The circuit diagram of the MAX232 serial communication

2.2.The use of the FLASH memory AT29C020

1) Reading and writing Time Sequence of the FLASH memory AT29C020

This system uses 2M FLASH ASIC-AT29C020 to store information.

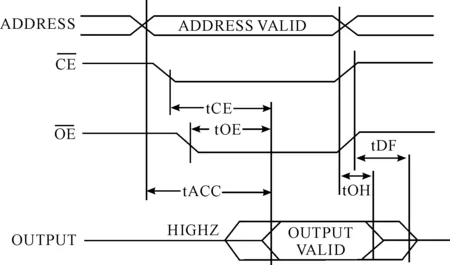

We adopt extended mode of ARM Parallel Port whose connection is very simple. Address lines and data lines will not occupy the same port, which facilitates the control and expansion. Our key task is to read and write AT29C020 by the right Time Sequence[4].Its reading Time Sequence is shown in Figure 6.

Figure 6.Wave forms of reading Time Sequence

Notes:

④ This parameter is characterized and is not 100% tested.

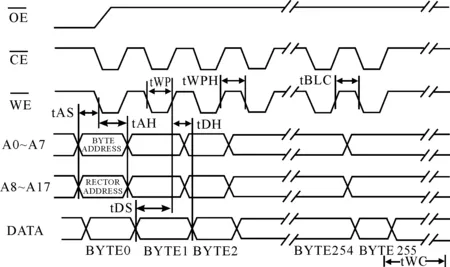

Its writing Time Sequence is shown in Figure 7:

Figure 7.Wave forms of writing Time Sequence

Notes:

③ All words that are not loaded within the sector being programmed will be indeterminate.

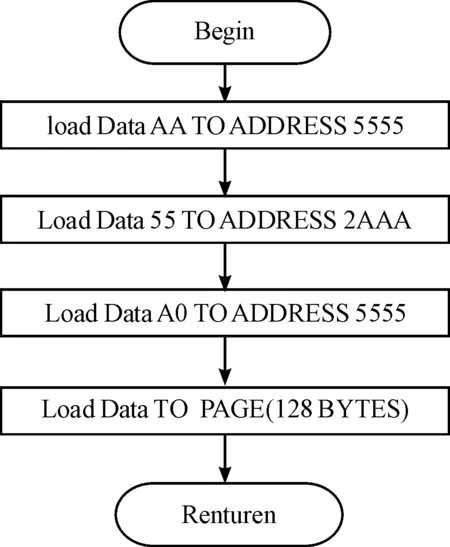

2) The realization of the control procedures of AT29C020

Through reading and writing Time Sequence analysis, we can get Send and Receive Subroutine subprogram, and its command block diagram is shown in Figure 8[4]:

Figure 8.Command block diagram of AT29C020

2.3.Other hardware circuit design

1) Human-computer interaction interface

The system uses SHARP company’s TFT display module-LQ64D141 that adopts 18 RGB input and has 6.4 in visual area.

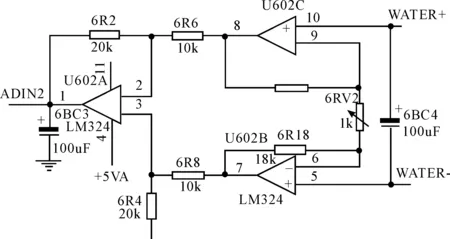

2) Down density sensor circuit design

The system uses a Motorola's down density sensor-MPX10DP.First of all, down density signal will be converted into pressure signal through the sensitive components,then MPX10DP will transform pressure signal into voltage signal[4]. Circuit design drawing is shown in Figure 9:

Figure 9.Design drawings of down density sensor circuit

3) The realization of frequency control system

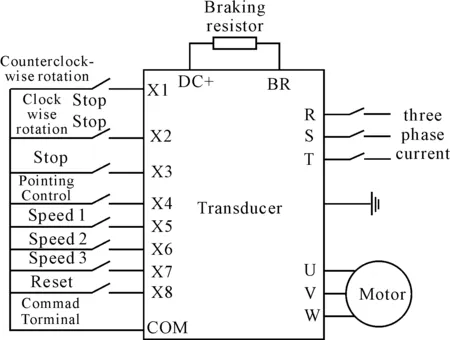

According to the demand for electric motors, the system has chosen the 1.5 kW transducer with external braking resistor. Wiring diagram of frequency control system is shown in Figure 10:

Figure 10.Wiring diagram of frequency control system

Input part : Three-phase current;

Input part : Motor;

Breaking part :Breaking resistor;

Control part: Parallel interface.

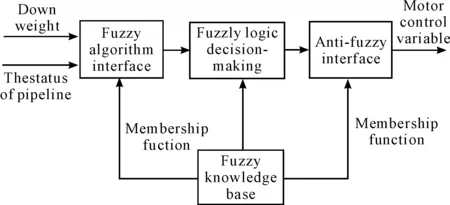

3.The realization of fuzzy inference and control strategy

Down weight is the input data of fuzzy algorithm, and the motor’s frequency control and down -filling time are the output data. The basic experience data from experiment will be made into knowledge database and control strategy will be made into rule database. The algorithm is shown in Figure 11.

Figure 11. Block diagram of fuzzy algorithm

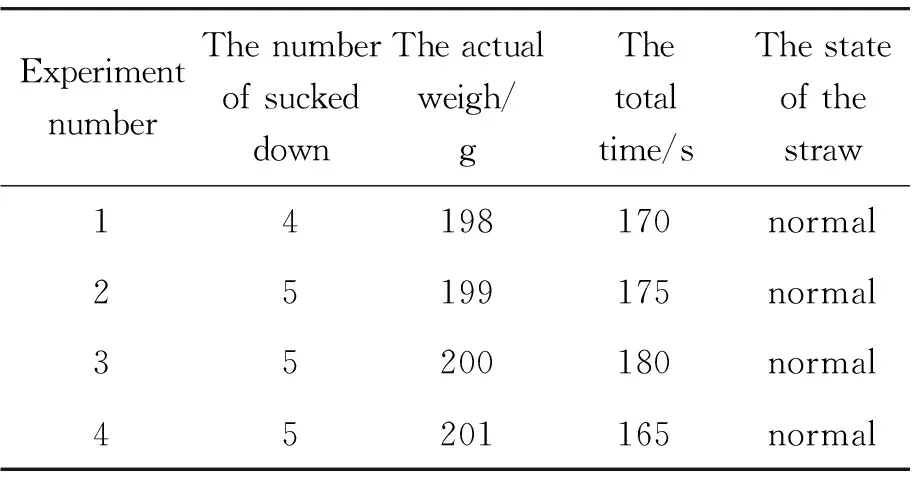

Table 1 represents the experimental tracking data of filling- process of 200 g down

Table 1.Test Data

4.Conclusion

This article has designed the control system of an automatic Down-Filling machine based on ARM7TDMI core. At the same time, the function modules of industry down-Filling machine has been researched, such as man-machine interface, motor control, the use of the FLASH memory AT29C020, the use of weighing sensor, realization of control strategy based on fuzzy inference, etc .

The results show that the system adapts to the needs of industrial production.

References

[1]Huang K N, Huang C F, Li Y C,et al. Temperature measurement system based on ultrasonic phase-shift method[J]. Biomedical Engineering, 2007:294-295.

[2]Matsuse K, Taniguchi S, Yoshizumi T. A speed-sensorless vector control of induction motor operating at high efficiency taking core loss into account. Trans.on Ind.2007,37(3):548-557.

[3]McLean R P.Approximation theory for stochastic variational and Ky Fan inequalities in finite dimensions[J]. Annals of Operations Research, 2006,44(1):43-61.

[4]Garg V K, Raymond J. Magneto-thermal coupled analysis of canned induction motor,Energy Conversion[J].Transactions on Magnetics,2007,5(1).

[5]Dong Jiechao,Han Feng,Yun Yan-ren . SCM control stepper motor S-shaped curve according to the frequency design of lifting[J]. Missiles and Guidance Journal, 2006,26(2):157-169.

(Continued on 73 page)

高速切削Ti6Al4V鋸齒形切屑形成的表征

楊奇彪? 1,陳鵬1,游達章1,劉戰強2

1湖北工業大學 機械工程學院,武漢430068;2山東大學 機械工程學院,濟南250061

基于ARM7TDMI的羽絨充灌設備控制系統設計*

喬橋?,范良志

武漢紡織大學 機電學院,長沙430073

摘要:充絨機是將羽絨按照要求的重量精確地從容器充灌到被服中的一種具有自動化、智能化的機械電氣設備。對自動變頻充絨機的工作原理、充絨過程控制系統實現、基于模糊算法的充絨機控制策略的自動控制系統的實現、變頻調速技術的應用、串口通信反饋實現閉環控制等方面進行了具體而深入的研究,在此基礎上完成了基于ARM7TDMI核的系統硬件設計。實踐證明:系統硬件運行穩定,在進行模糊推理學習時具有更快的速度。 深入研究鋸齒形切屑的形成過程及表征有利于工業生產中的切屑控制。用鋸齒頻率、鋸齒化程度及絕熱剪切帶間距來對鋸齒形切屑進行表征。鑒于Ti6Al4V在加工過程中易于形成鋸齒形切屑,因此選擇Ti6Al4V作為工件材料,通過高速切削Ti6Al4V實驗,收集不同切削速度和每齒進給量下的鋸齒形切屑;將獲得的鋸齒形切屑進行拋磨及腐蝕后,在VHX-600 ESO數碼顯微鏡下觀察切屑形貌,計算不同切削條件下鋸齒頻率、鋸齒化程度及絕熱剪切帶間距。結果表明:隨著切削速度的提高,鋸齒頻率及鋸齒化程度增大,絕熱剪切帶間距減小;隨著每齒進給量的增大,鋸齒頻率減小,鋸齒化程度及絕熱剪切帶間距增大。 鋸齒化程度可以作為普通切削、高速切削及超高速切削的判據。

關鍵詞:羽絨充灌; 模糊算法; ARM7TDMI ;Flash;閉環系統 鋸齒形切屑;高速切削;絕熱剪切帶,Ti6Al4V

中圖分類號:TU96+3 TG506.1

DOI:10.3969/j.issn.1001-3881.2014.06.015

Received: 2013-10-28

*Project supported by National Natural Science Foundation of China(Number: 50805109)

? Qiao QIAO, E-mail: qq526680@163.com