Research of Vertical Bending Moment in Amidships Calculation Method Caused by the Crash-breaking Way

REN Hui-long,WANG Chuan,LI Hui,ZHAI Shuai-shuai,WANG Jin-feng

(College of Shipbuilding Engineering,Harbin Engineering University,Harbin 150001,China)

Research of Vertical Bending Moment in Amidships Calculation Method Caused by the Crash-breaking Way

REN Hui-long,WANG Chuan,LI Hui,ZHAI Shuai-shuai,WANG Jin-feng

(College of Shipbuilding Engineering,Harbin Engineering University,Harbin 150001,China)

A finite element method is introduced to calculate vertical moment in amidships caused by crash-breaking way.The principle of finite element model is discussed.And ice failure mode is based on multi-surface criterion.The crash-icebreaking way is simulated through the secondary development technology of finite element software.The FORTRAN program is developed to calculate the vertical moment in amidships,which provides a new method to predict ship and ice collision load.

ice crash-breaking way;vertical bending moment;ice failure mode;mode principle;secondary development

1 Introduction

The main feature of icebreaker is to force the way through the level ice at high latitude.Ice force becomes the control load of its security.There are two ice breaking pattern,including continuous and crash icebreaking way.The later one is the main form in thick ice condition.As the wave bending moment calculated in rules method is less than that caused by the ice in thicker ice environment,it is not enough to assess ship strength in wave for icebreaker.Due to the lack of field observations and insufficient understanding of the physics of icebreaking especially by ship,it is difficult to certificate ice failure mode with the physical nature and ice-breaking collision course,which is the key to calculate the ship-ice interaction load and the bending moment.

In recent years,a number of model tests are launched to study on ice mechanical property[1-5],and the research of ice loads has become a new spot.Lindqvist[6]presented a method for the calculation of ice resistance.The method is intended to be a tool in the future decades to calculate ice resistance.Wang[7]proposed contact-crushing-bending ice failure mode to simulate the effect between ice and ocean platform leg;Nguyen[8]and Su[9]used the above method to develop the numerical calculation method and contact algorithm to simulate ship and ice is developed,but there is no research on the structural strength of icebreaker.

He[10]used the finite element method to simulate the ship-ice contact,but the elasticplastic model was used to reflect ice failure mode,which is a rough description with the real sea ice environment.In addition,there is no published literature on the calculation method for the icebreaker structure strength assessment and vertical bending moment caused by the crushing.With the increasing demand of ship for navigation in ice,it is extremely important to develop a suitable ice load calculation method and strength assessment method.

This research in this paper proposes a set of finite element techniques to calculate ice load in order to forecast the vertical bending moment in amidships.The principle of finite element model is discussed.And ice failure mode is based on multi-surface criterion[11],considering the effect of temperature and strain rate on the mechanical properties of ice.And Fortran program is compiled to calculate the bending moment.MSC.DYTRAN is selected to be the finite element analysis tool to create model.The crash-icebreaking way is simulated through the secondary development technology of finite element software.

2 Multi-surface failure criterion for ice

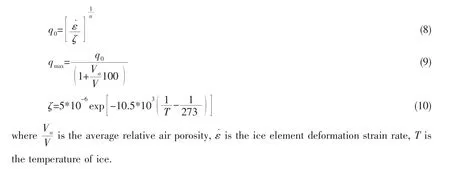

In 3D mode,when the factors such as ice strain rate,cell density and temperature are considered,the failure criterion becomes:

where F1,F2,F3are parameters and J2D,I1and I2are stresses:

where pcand qmaxare the major and minor axes of ellipse;q0is maximum shear stress in fresh ice.

3 Principles of finite element model in ice crash-breaking way

MSC.DYTRAN is selected to be the finite element analysis tool to build model.The user subroutine is applied to use multi-surface failure criterion to determine the constitutive model of ice under different environmental conditions.

3.1 Principles of ice element

Ice is a highly nonlinear material.If ice model could not meet the reality,it will directly affect the final simulation results.Through the comparison between an amount of calculation results and test data in related literature,using the six-sided shape element is more appropriate.Small size of ice element will waste a lot of calculation time,but larger element size will affect calculation precision in turn.In order to ensure both accuracy and engineering practice,the element size is a point which should be studied carefully.In this paper,200-300 mm element size is used to simulate the part that is in direct contact with the icebreaker,and the rest ice gradually spreads overall the edge.The all size of the level ice need to satisfy the condition that the time of internal stress wave reflected back is larger than that the physical process ends.Therefore,the ice element of the contact area should be fined and the other grids can be standard.Because the ice sheet size is large enough,it is feasible to set the boundary conditions as rigidly fixed.

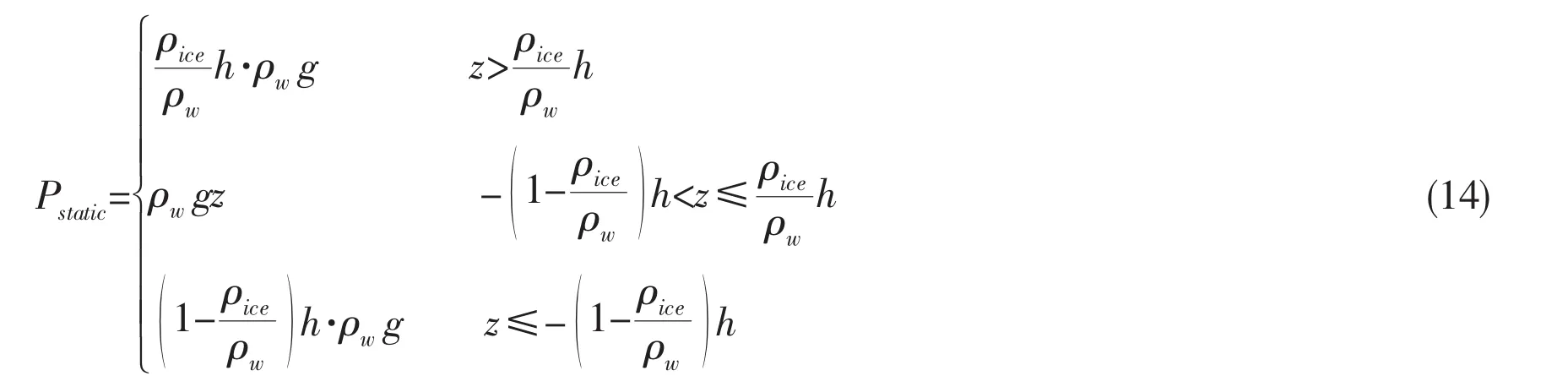

3.2 Loading method of buoyancy force

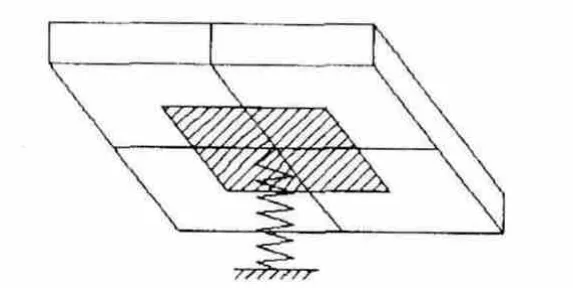

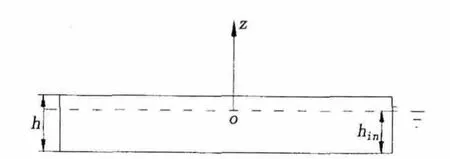

The vertical movement of sea ice is limited by buoyancy.If the effect between water and ice is ignored,the exceeded vertical deformation will cause large deformation to lead to fail.So it is necessary to simulate the ice buoyancy.It will greatly increase the computing time to use fluid-structure interaction effect,and it will lead to calculation fail as water and ice could not form a closure region because of ice failure.Considering that the longitudinal displacement of level ice remains basically unchanged in the whole physical process.The weight and buoyancy effects on a floating ice sheet could be viewed as an one-dimensional nonlinear foundation as shown in Fig.1.

When the ice floe is on the water surface,the gravity and buoyancy is balanced:

where Viceand Vice_inare the whole ice volume and the ice volume below water.The height of ice below water becomes:

在本文中,我們使用由日本氣象廳研究出的用于震級估計的衰減關系。該衰減關系表述如下(Hoshiba and Ozaki,2013)。設Amax為地震事件發生后用地震儀測得的最大位移。地震的P波和S波震級MP、MS可以表示為從臺站到震源的線性距離(R)、震源深度(D)、P波的最大位移()或整個持續時間的最大位移)的函數:

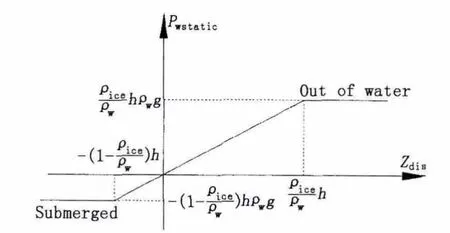

Coordinates system is shown as Fig.2.The relationship between the pressure and displacement is shown in Fig.3.And the foundation pressure Pstaticacting on the ice sheet is function of vertical displacement Zdis,which is expressed as:

The height of ice in the air is:

Fig.1 Schematic plot of nonlinear spring and ice

Fig.2 Coordinates system

Fig.3 Nonlinear foundation response of ice sheet

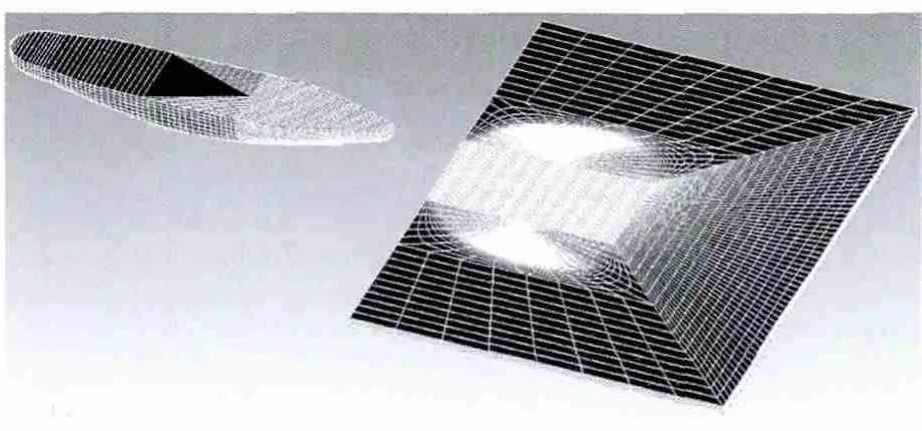

Fig.4 Schematic plot of ship and ice

3.3 Secondary development of finite element software

In this paper,the nonlinear dynamic analysis software MSC.DYTRAN is selected to be a basic tool.As the sea ice is a complex nonlinear material,there is no property which matches ice constitutive model.User subroutine is developed to apply multi-surface failure criterion to define ice construction mode,and modify the program to complete the sea ice model simulation.Principal stress,strain,strain rate are obtained by using the EXFAIL1 function in DYTRAN,the characteristic value of failure is solved by these results to determine whether the ice element fails.

4 Numerical results and discussions

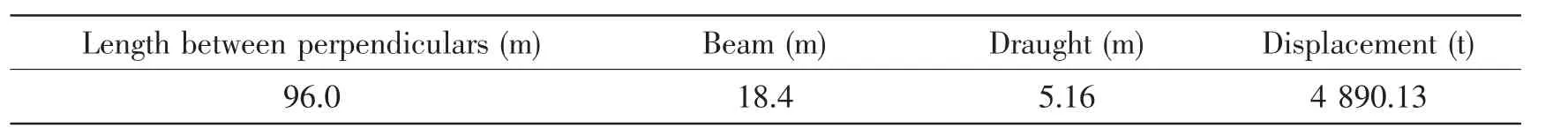

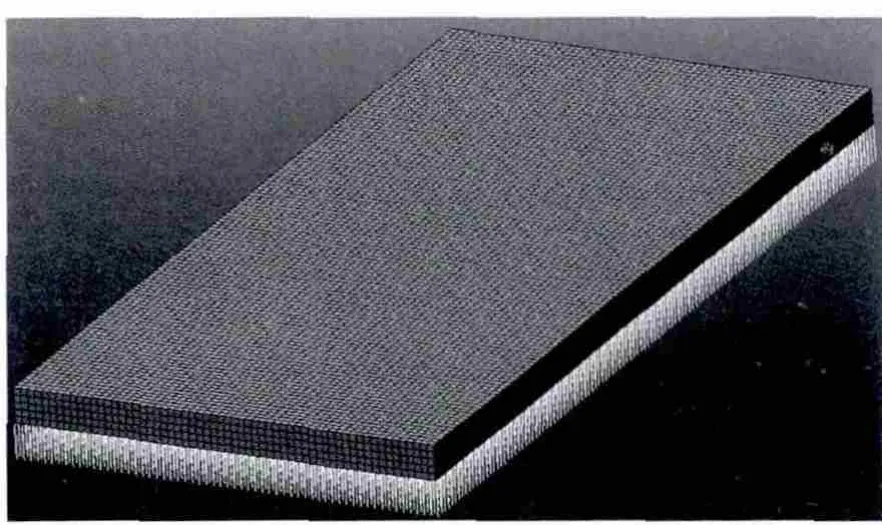

In this paper,a type of icebreaker is selected as the analysis object.Vertical bending moment is calculated in the Polar Regions using this method introduced above.A 3D ship geometry is built up for FEM calculation.The main ship characteristics are given in Tab.1.Six load cases including three speed and two ice thicknesses are chosen to make numerical simulation.According to the modeling principles described in Part 3,Ship ice model(as shown in Fig.4)and spring buoyancy model(as shown in Fig.5)are built up for FEM calculation.The numerical results are as follows.

Tab.1 Main particulars of the icebreaker

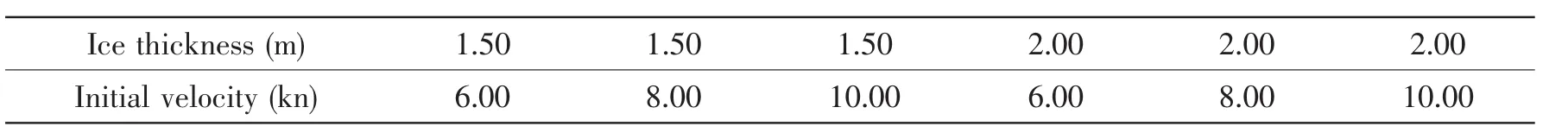

Tab.2 Calculating load case in crash-breaking way

Fig.5 Schematic plot of nonlinear spring on ice sheet

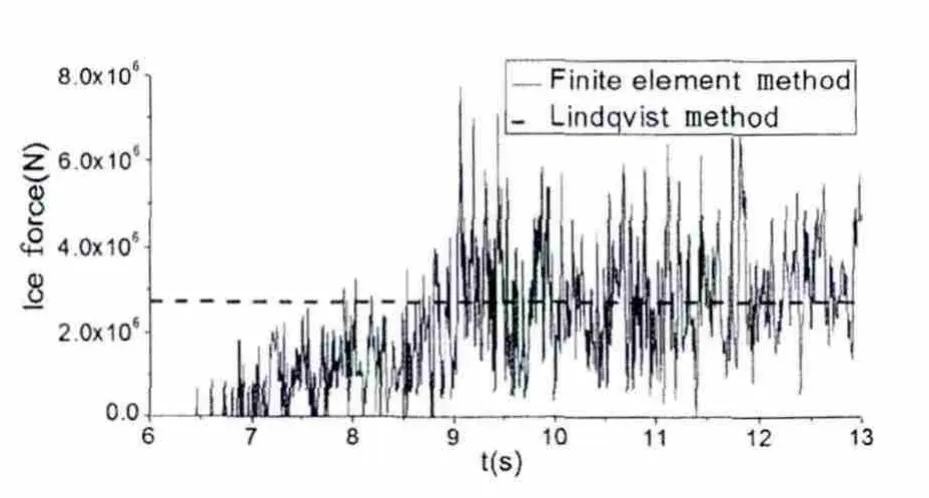

Fig.6 Time history ice force and Lindqvist ice force

4.1 Results of ice force

It is shown the ice force in longitudinal direction at the speed 6 kns,2 m ice thickness from 6 s to 13 s in Fig.6.The mean ice resistance including crushing,bending and submersion components proposed by Lindqvist[6]is also marked in the figure.The stable part of the value is 2 893.63 kN which is to the result 2 714.71 kN calculated by mothod in Ref.[6].Fig.6 shows that the ice force is a process of contact-crushing-bending.Therefore,the ice load is a gradual process from increasing to disappearing.

4.2 Results of vertical bending moment in amidships

The environment load of the ship hull is picked up by the compiling FORTRAN program.Each point motion of the ship could be obtained directly by finite element method.The bending moment in amidships could be obtained by the integration of the force including ice loads,gravity,buoyancy and inertial force load based on D′Alembert principle.

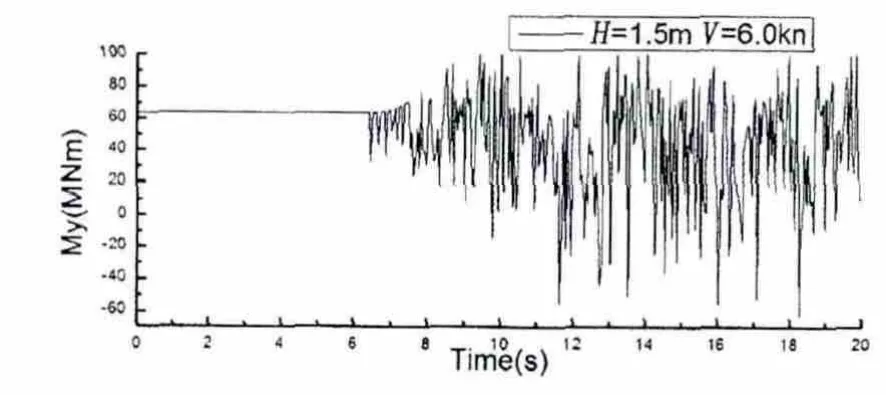

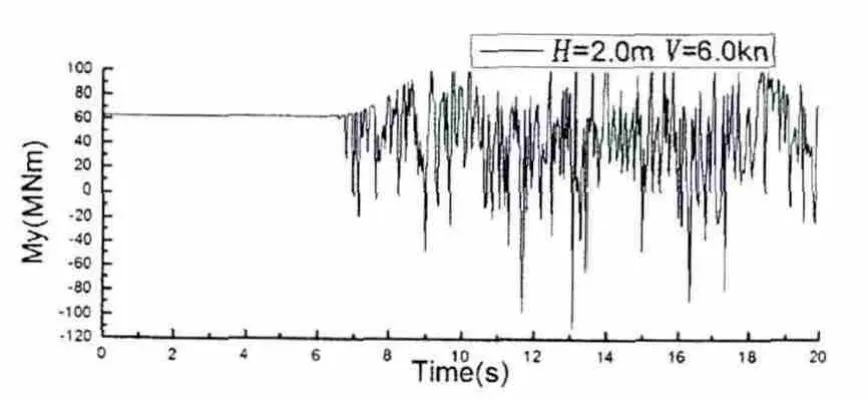

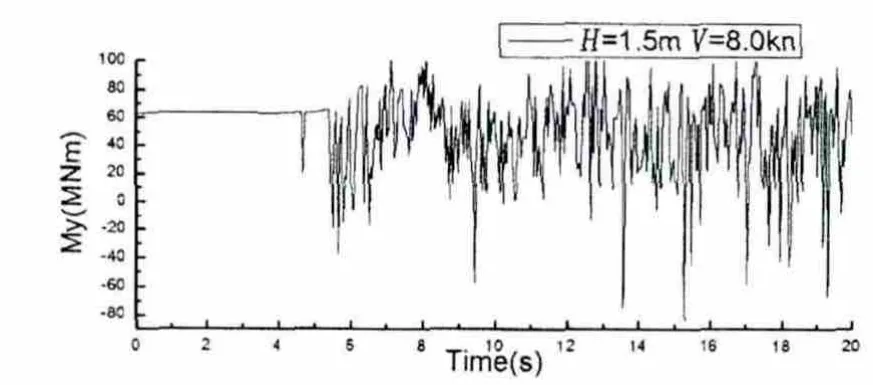

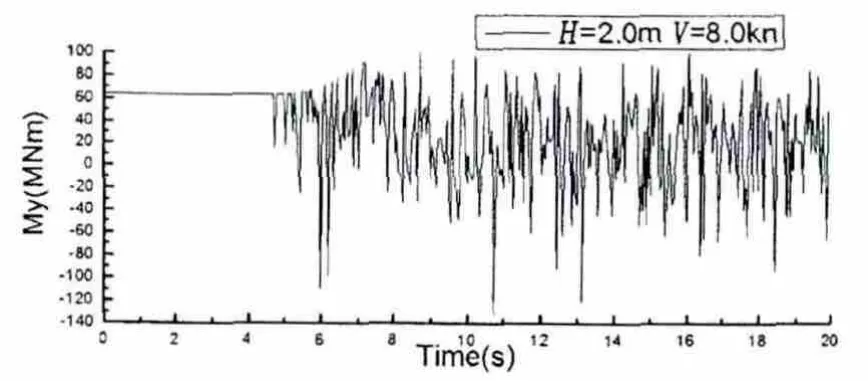

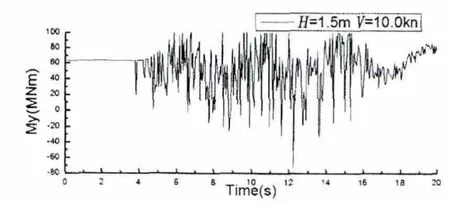

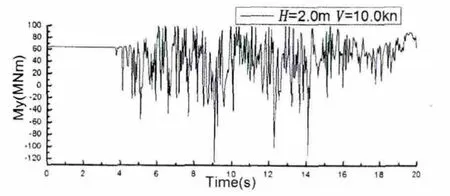

Vertical bending moment in amidship of six load cases are shown from Fig.7 to Fig.12.It is could be seen that the moment is a straight line from 0 sec.to 6 sec.in Fig.7,since the ship model is removed from the ice sheet 15 m away,so the value the line matches shows the hydrostatic moment in amidships.The vertical bending moment at 2 m ice thickness is the 1.5 to 2.0 times as that in 1.5 m.At the same thickness,the bending moment is increasing with the initial velocity.It shows that the ice load has a positive relationship with the ice thickness and initial velocity.The two factors are both the key to determine whether the icebreaker has the ability to break ice in a certain environment.

Fig.7 Vertical moment with a 6 kns velocity in a 1.5 m thick ice

Fig.8 Vertical moment with a 6 kns velocity in a 2.0 m thick ice

Fig.9 Vertical moment with a 8 kns velocity in a 1.5 m thick ice

Fig.10 Vertical moment with a 8 kns velocity in a 2.0 m thick ice

Fig.11 Vertical moment with a 10 kns velocity in a 1.5 m thick ice

Fig.12 Vertical moment with a 10 kns velocity in a 2.0 m thick ice

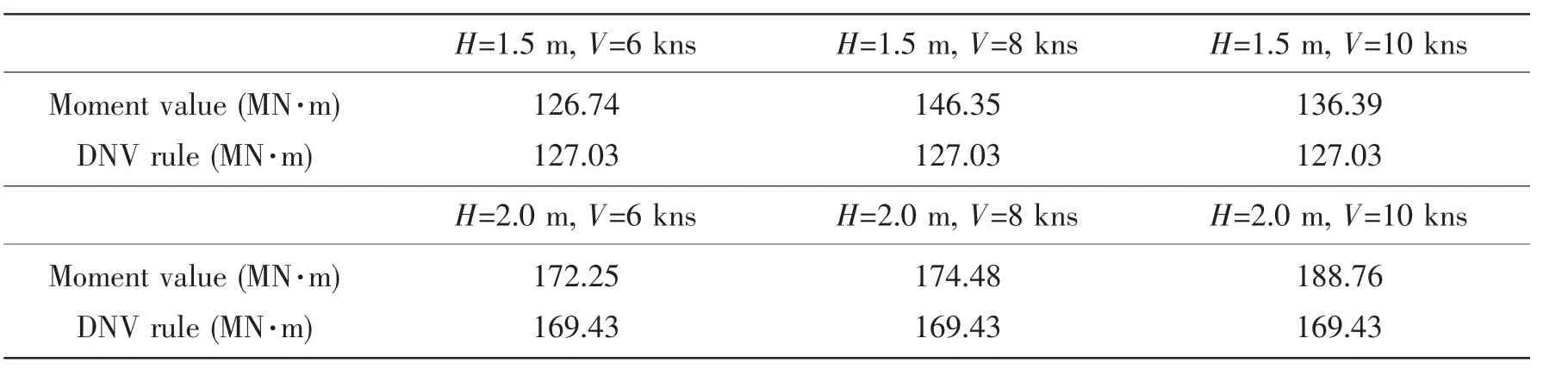

Tab.3 The assessment result of vertical moment in crash-breaking way in polar region

Tab.3 shows the comparison between numerical simulation result in this paper and the Ref.[12].As seen from the tab,the value based on DNV rules has no relationship with the initial velocity.But the speed of the ship will affect the axial loading rate of ice which will affect the mechanical properties of ice.The results in this paper reflect both initial velocity and loading rate of ice.And the direct calculation could show the stress distribution on the ship hull.From the comparison,it is easy to know that the numerical results in this paper are in good agreement with those obtained from DNV rules.It proves that the accuracy of the method is reliable.It is helpful to provide guidance for the design and construction of icebreakers.

5 Conclusions

Process of ship-ice collision is simulated in this paper.Environment force is picked in compiled Fortran program to calculate the bending moment in amidships.The main findings of this study are summarized below.

(1)The simulation results based on multi-failure surface criterion for including ice force and moment are close to the rules.It proves that the principle of element construction and ice simulation proposed in this paper is a practical method.

(2)Ice failure is a process of contact,crush and bending.Therefore,the ice load is not continuous.The fatigue issue will be another main factor which has an effect on structure safety.It should be careful to apply high strength steels to meet the strength requirement while ignoring its fatigue performance.

(3)Bending moment caused by ice has a positive relationship with ice thickness and relative speed of the ship and ice.And the bending moment is also a control load for the ship navigation in ice.Therefore,the actual environment condition is a key point to determine the operation mode.

[1]Ralston T D.An analysis of ice sheet indentation[C].Fourth International IAHR Symposium on Ice Problems,1978:7-9.

[2]Stephen J Jones.The confined compressive strength of polycrystalline ice[J].Journal of Glaciology,1982,98(28):171-177.

[3]Timco G W,Weeks W F.A review of the engineering properties of sea ice[J].Cold Regions Science and Technology,2010,60:107-129.

[4]Von Bock und Polach,Ehlers R.Model scale ice-Part A:Experiments[J].Cold Regions Science and Technology,2013,94:74-81.

[5]Erland M Schulson.Brittle failure of ice[J].Engineering Fracture Mechanics,2001,68:1839-1887.

[6]Lindqvist G.A straightforward method for calculation of ice resistance of ships[C].Proceedings of POAC,1989:722-735.[7]Wang S.A dynamic model for breaking pattern of level ice by conical structures[M].Finland:Helsinki University of Technology,2001.

[8]Nguyen D T,S?rb? A H,S?rensen A J.Modeling and control for dynamic positioned vessels in level ice[C].Proceedings of 8th Conference on Manoeuvring and Control of Marine Craft(MCMC’2009).2009:229-236.

[9]Biao Su,Kai Riska.A numerical method for the prediction of ship performace in level ice[J].Cold Regions Science and Technology,2010,60:177-188.

[10]He Fefei.A computational method for ice-breaking loads and ice-breaking capability of Icebreaker[M].Harbin:Harbin Engineering University,2011.

[11]Ahmed Derradji-Aouat.Multi-surface failure criterion for saline ice in the brittle regime[J].Cold Regions Science and Technology,2003,36:47-70.

[12]Rules for Classification of Ships[S].DNV,Norway,2011.

沖撞式破冰引起的船舯垂向彎矩計算方法研究

任慧龍,王 川,李 輝,翟帥帥,王金峰

(哈爾濱工程大學 船舶工程學院,哈爾濱 150001)

文章研究了由沖撞式破冰引起的船舯垂向彎矩的計算方法。確定了模擬沖撞式破冰過程的有限元建模準則,對有限元軟件進行了二次開發,采用多重失效面方式定義冰層的破壞模式。開發了FORTRAN程序,提取環境外載荷,計算由沖撞式破冰引起的船舯垂向彎矩,為預報船冰碰撞載荷提供了一種新的方法。

沖撞式破冰;垂向彎矩;海冰破壞模式;建模準則;二次開發

U661.35

A

任慧龍(1965-),男,哈爾濱工程大學教授,博士生導師;

王金峰(1988-),男,哈爾濱工程大學碩士研究生。

U661.4

A

10.3969/j.issn.1007-7294.2014.09.009

1007-7294(2014)09-1109-08

date:2014-04-26

Supported by the National Natural Science Foundation of China(51109046)

Biography:Ren Hui-long(1965-),male,professor/tutor of Harbin Engineering University,E-mail:renhuilong@263.net;

Wang Chuan(1987-),male,Ph.D.student of Harbin Engineering University,E-mail:1027wangchuan@163.com.

王 川(1987-),男,哈爾濱工程大學博士研究生;

李 輝(1978-),男,博士,哈爾濱工程大學副教授;

翟帥帥(1987-),男,碩士,上海船舶設計研究院工程師;

- 船舶力學的其它文章

- A Rule of Spatial Sampling on Cylindrical Shells for Predicting Radiated Acoustic Field

- Vessel Motion Effects on Nonlinear Dynamics of Deepwater Drilling Riser

- Investigation on Sloshing Effects of Tank Liquid on the FLNG Vessel Responses in Frequency Domain

- Effect of Plastic Zone Size Induced by a Single Dwell Overload on the Fatigue Crack Growth Rate under Cyclic Loading

- Thrust Allocation with Dynamic Forbidden Sectors in Dynamic Positioning System

- Study of Vortex Induced Characteristics of Multi-columns with Low Mass Ratio