FATIGUE LIFE PREDICTION METHOD FOR IMPACTED LAMINATES

Xu Ying,Wen Weidong,Cui Haitao

(College of Energy and Power Engineering,NUAA,29 Yudao Street,Nanjing,210016,P.R.China)

INTRODUCTION

Advanced composite materials for its excellent mechanical properties are widely used in the aviation and aerospace fields.In the process of manufacturing and use,composite structures are susceptible to the damage resulting from the impact of foreign objects.It is showed that the impact damage has a significant influence on the compression fatigue performance during the practical use[1-6].As such,it is important to research the fatigue life prediction method for impacted laminate structures.

Ref.[2]proposed an experimental method for estimating the residual fatiguelife of impacted composites by using the thermo-elastic stress analysis(TSA).TSA is used to quantify the stress concentration factors in the impacted composites.The stress concentration factors are used to determine modified stress amplitude that collapses the impact-fatigue data onto a master stress-lifecurve.Compared with the experimental results,it is found that the method is good for predicting the low cycle fatigue life and bad for predicting the high cyclefatigue life.Based on the experimental studies,Refs.[3-5]proposed a constant-life model to predict the fatigue life of unimpacted and impacted composite laminates.Ref.[6]proposed the principle of equivalent damage that the strength reduction induced by impact damage can be equal to the strength reduction induced by fatigue loading.By using the concept and fatigue behavior of unimpacted laminates,Ref.[6]established a fatigue life prediction model for impacted laminates based on the Broutman fatigue life perdition model[7]under two-stage loading.Th eexisting models are established based on the fatigue behavior of impacted laminates.The existing models are the semi-empirical models.The values of parameters in these models must be adjusted to changes of geometry,lay-up and loading condition through a series of experiment.It can be concluded that all existing models for fatigue analysis of impacted laminates have limita-tions which make them unsuitable for the general use.Experimental characterization of fatigue behavior of laminate is time consuming and expensive.By considering the shortcomings of existing models,the necessity for development of more general models with fewer limitations is quite obvious.

This paper proposes a general 3-D progressive damage fatigue life prediction method.The method can predict the fatigue life for impacted laminates under general conditions(geometry,lay-up,loading condition,etc.)based on the progressive damage theory and the results of various types of uniaxial fatigue experiments of unimpacted unidirectional plies.This general model is not limited to a specific geometry,lay-up,loading condition,boundary condition,and loading ratio.As the above conditions are changed,the costs of tests for obtaining model parameters can be significantly reduced compared with semi-empirical models.In order to obtain the impact damage information in the case that no impact test data is available, a whole damage process analysis method of laminated plates under impact loading and fatigue loads after impacted is developed.Based on the whole damage process analysis method,a parametric modeling program in ANSYSplatform is developed to predict the impact damage and fatigue life of impacted laminate structures.

1 FATIGUE LIFE PREDICTION MODEL

1.1 Finite element model of impacted laminates

Based on the ANSYS platform,a 3-D FEM model of impacted laminateis built up with the 3-D 8-nodelayered structural solid element.The element thickness is defined as the single-layer thickness when the adjacent layer of ply angle is different.

The impact-induced damages in laminated plates are simulated by a progressivedamage prediction method of low-velocity impacts on laminated composites[8]before fatigue analysis.The impact damages cause the four kinds of failure modes,including fiber failure,matrix crushing,matrix cracking,and delamination.Load bearing capability in damage region is reduced.In this paper,stiffness is used to reflect the load bearing capability.Stiffness degradation differs in different failure modes.

(1)Fiber failure Assuming that the damage zone cannot endureany load,the law of material performance degradation is that the values of Exx,Eyy,Gx y,Gyz,Gxz,g xy,g yz,and g xz aredegenerated to 7% of initial values.

(2)Matrix cracking Assuming that the transverse load bearing ability decreases due to matrix cracking,the law of material performance degradation is that the values of Eyy,Gxy,Gyz,g xy,and g yz are degenerated to 20%of initial values.

(3)Matrix crushing Assuming that the transverse load bearing ability decreases due to matrix crushing,the law of material performance degradation is that the values of Eyy,Gxy,Gyz,gxy,and gyzare degenerated to 40%of initial values.

(4)Delamination Assuming that the damage zone cannot endure any normal load,the law of material performance degradation is that the values of Ezz,Gxz,Gyz,g xz,and g yz are degenerated to zero.

1.2 Fatiguef ailure criteria

Under fatigue loading conditions,six different failure modes are considered,i.e.,fiber tension,fiber compression,matrix crushing,matrix-fiber shearing,in terlaminar tension,and in terlaminar compression.So far,the fatigue failure criteria for laminates have been hardly found.Based on the 3-D Hash in failure criterion for static loading[9],this paper deve lopes fatigue failure criterion for the above five kinds of failure modes.Comparing the fatigue failure criterion and the Hash in failure criterion,the main difference is the value of strength.In the Hash in failure criterion,the material properties are constants.But in the fatigue failure criterion,the material properties change with fatigue load parameters,such as the number of fatigue cycles(n),the stress ratio(k),and the fatigue stress(e).The following criteria are used.

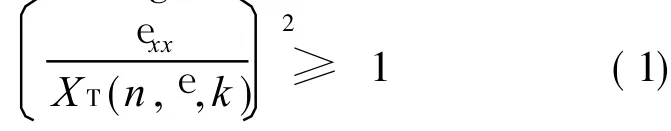

Fiber tension fatigue failure mode(exx>0)

Fiber compression fatigue failuremode(exx<0)

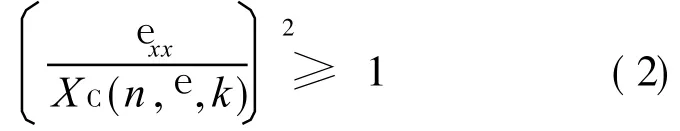

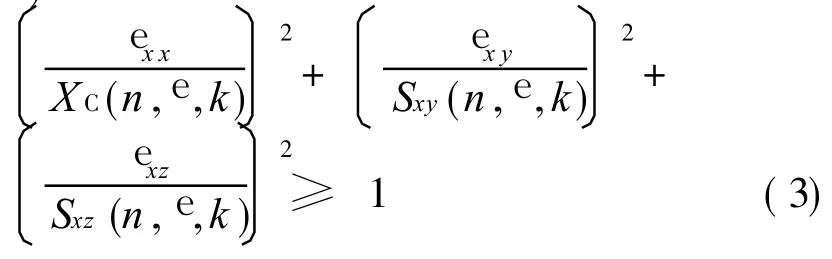

Matrix-fiber shearing fatigue failure mode(e x x<0)

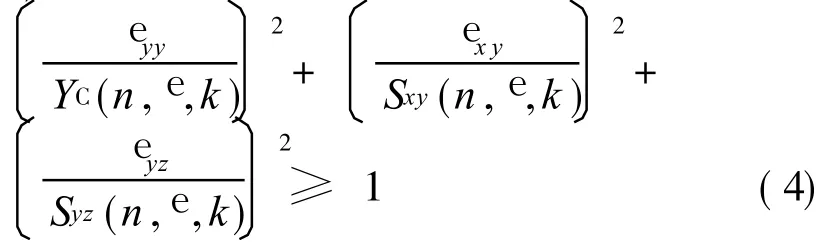

Matrix compression fatigue failure mode(e yy<0)

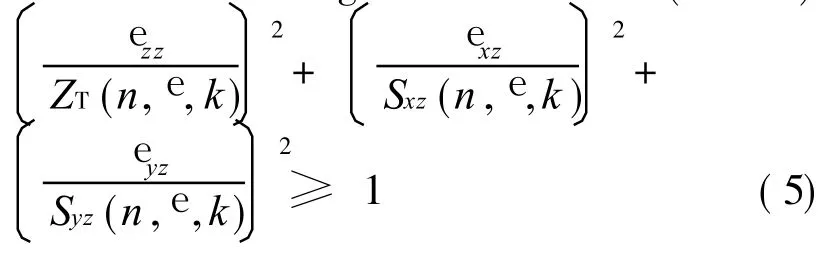

Normal tension fatigue failure mode(e zz≥0)

Normal compression fatigue failure mode(e zz<0)

where Xi(n,e,k),Yi(n,e,k)and Zi(n,e,k)are the longitudinal,the transverse and the normal residual fatigue strength of unidirectional plies under uniaxial fatigue loading conditions,respectively.The subscripts"T"and"C"represent tension and compression.Sxy(n,e,k)is the in-plane shear residual fatigue strength of a unidirectional ply under uniaxial shearing fatigue loading conditions.Sxz(n,e,k)and Syz(n,e,k)are the outplane shear residual fatigue strengths of unidirectional plies under uniaxial shearing fatigueloading conditions.

1.3 Material property degradation

In the previous section,suitable fatigue failure criteriaareestabli shed to detect fatigue failure modes.As failure occurs in a ply of a laminate,material properties of the failed zone are changed by a set of sudden material property degradation rules.This type of change is called the sudden material property degradation.

For a laminated composite under fatigue loading conditions, in the first cycles, the strength of the plies is higher than the stress state.Therefore,during the first cycles,the proposed fatigue failure criterion does not detect any sudden mode of fatigue failure.However,increasing the cyclic loading of the laminate,material properties of each ply are degraded.This type of change is called the gradual material property degradation.

1.3.1 Sudden material property degradation rules

The sudden material property degradation rules for the fatigue failure modes of a unidirectional ply under a multiaxial state of fatigue stress are developed in the following.

(1)Fiber tension fatigue failure mode Assuming that the damage zone cannot endure any load,the law of material performance degradation is that the values of Ex x,Eyy,Gxy,Gyz,Gxz,g xy,g yz,and g xz are degraded to 7% of initial values.

(2)Fiber compression fatigue failure mode Assuming that the damage zone cannot endure any load,the law of material performance degradation is that the values of Exx,Eyy,Gxy,Gyz,Gxz,g xy,g yz,and g xz are degraded to 14% of initial values.

(3)Matrix-fiber shearing fatigue failure mode Assuming that the damage zone cannot endure the shearing load,the law of material performance degradation is that the values of Gxy and gxyare degraded to zero.

(4)Matrix compression fatigue failure mode Assuming that the transverse load bearing ability intends to decrease,the law of material performance degradation is that the values of Eyy,Gxy,Gyz,gxy,and g yz are degenerated to 40%of initial values.

(5)Normal tension and compression fatigue failure mode Assuming that the damage zone cannot endure any normal load,the law of mate-rial performance degradation is that the values of Ezz,Gyz,Gxz,gyz,and gxzare degenerated to zero.1.3.2 Gradual material property degradation rules

The stiffness and strength in laminates are considered in these gradual material property degradation rules.Refs.[10-11]proposed the gradual material property degradation rules for fatigue loading conditions based on the experimental data from unidirectional ply under uniaxial fatigue and a two-parameter power law model presented in Ref.[12].Because of their lower cost of prediction,the rules are used for simulating gradual material property degradation for no damage zone in this paper.

Base on the principle of equivalent damage in Ref.[6],this paper proposes that the strength and stiffness reduction induced by impact damage can be equal to the strength and stiffness reduction induced by fatigue loading.So the rules are also suitable for impact-damage zone.

1.4 Whole-process analysis method for impact damage and post-impact f atigue lif e

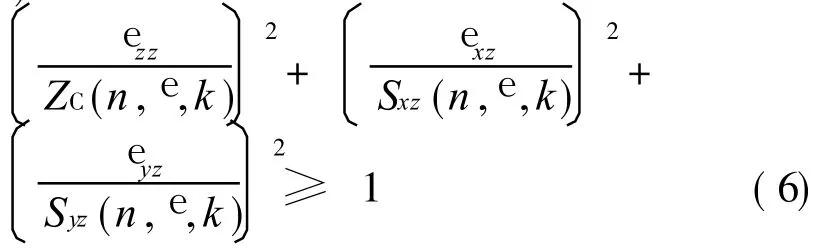

On the ANSYSplatform,a progressive damage of laminated structure simulating program is developed in APDL language.Fig.1demonstrates its flowchart.Module A shows the flowchart for impact loading, and Module B shows the flowchart for post-impact fatigue loading.This program can predict the impact damage,the postimpact fatigue life,and the progressive damage process in impact loading and fatigue loading conditions for laminated structures.

2 APPLICATION AND COMPARISONS

By using the method and the program,the whole-process of damage development and postimpact fatigue life for AS4/3501-6 laminates are studied.The prediction results are compared with the experimental results in Ref.[13].The material constants of composite and coefficients in gradual material property degradation rules are collected from Ref.[14].The stacking sequence is[0/± 45/90]4s.The dimension is 38.1 mm×38.1 mm×4 mm.

2.1 Impact damage analysis

Fig.1 Flowchart of whole-process analysis method for impact damage and post-impact fatigue life

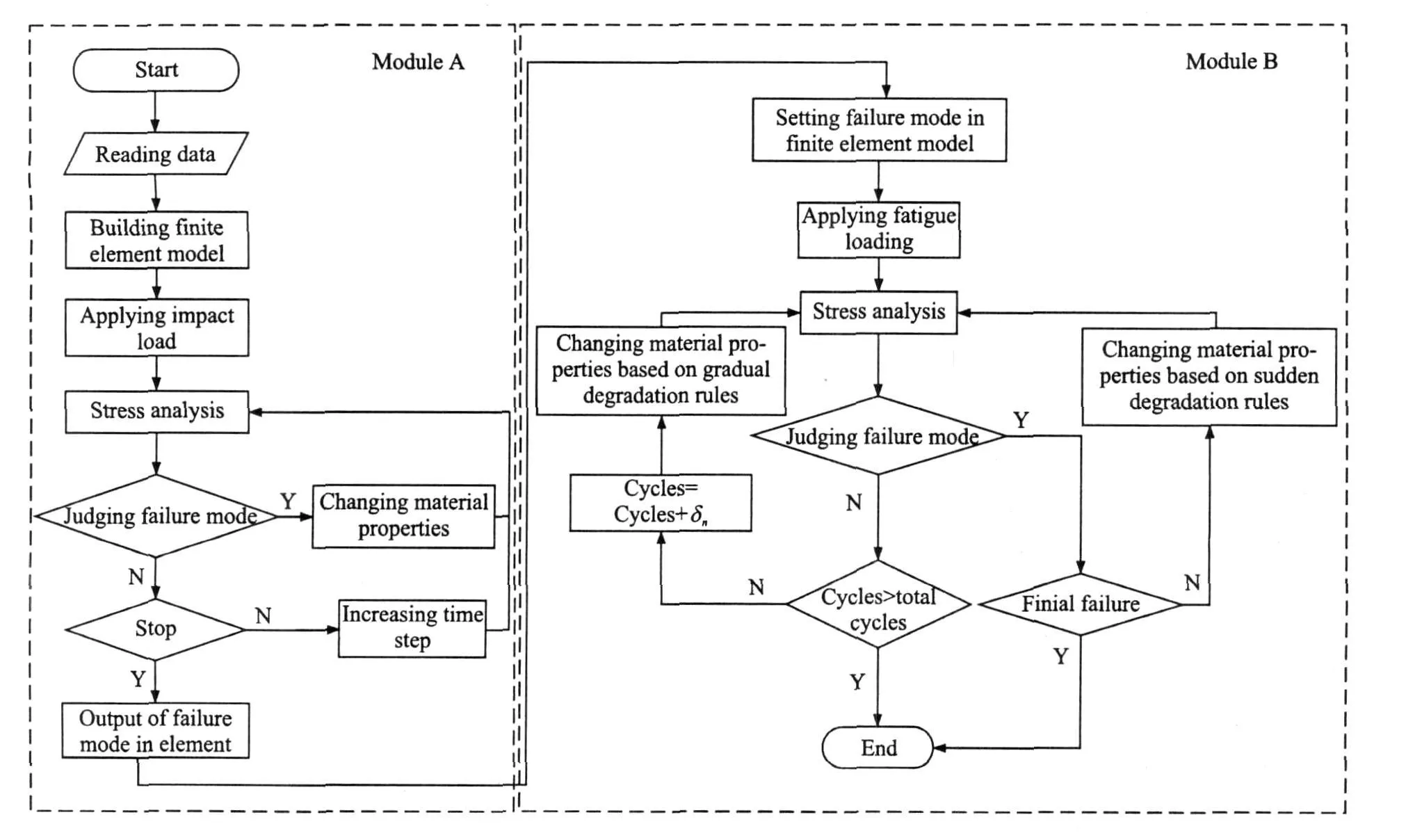

In the impact test,the diameter of impactor is 12.7 mm and impact energy is 2 J.Thereis a 25.4 mm×25.4 mm square cutout in impact fixture(Fig.2).

Fig.2 Finite element model for impact analysis

The finite element model for impact analysis is showed in Fig.2.All contact surfaces are defined as the surface-to-surface contact type.Penetration in contact surface is not allowed.All degrees of freedom are restricted in the upper surface of the upper clamp and the lower surface of the lower clamp.The translational degrees of x and y directions are restricted for the central axis of impactor.

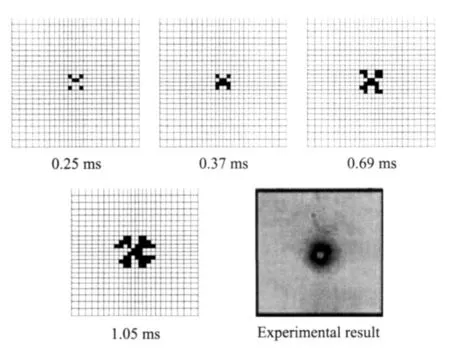

Impact damage propagation of laminated composites is showed in Fig.3.The shape of final impact damage is similar to the test result.The prediction and the test diameters are 12.49 mm and 12.7 mm,respectively.The area error between the prediction and the actual damage is 3.28%.

Fig.3 Impact damage propagation of laminated composites

2.2 Post impact fatigue life prediction

According to the impact damage given by prediction,a finite element model for fatigue analysis is established,as showed in Fig.4.The dark grey shaded area in Fig.4is the impact damage region.

One of the ends of laminate is fixed and the other is applied axial C-C fatigue load.The fatigue loading is 80% and 70% CSAI(Compression of strength after impacting),respectively.The finial failure criterion is that the fiber failure extends to plate edgein all 0°plies.

Fatigue damage propagation of 70% CSAIis showed in Fig.5.The initial impact damage is showed in the first figure of Fig.5.There is large-area matrix crushing damage as applied 10 010 cycles.As applied 20 010 cycles,delamination propagates from the free boundary to the interior of laminate.As applied 30 010 cycles,fiber damage begins to propagate perpendicular to loading direction in some 0°layers.As applied 70 011 cycles,fiber damage propagates to plate edge in all 0°plies.As the damage status agrees with the finial failure criterion,the fatigue life of this laminate is 70 011 cycles.

Fig.5 Fatigue damage propagation of 70% CSAI

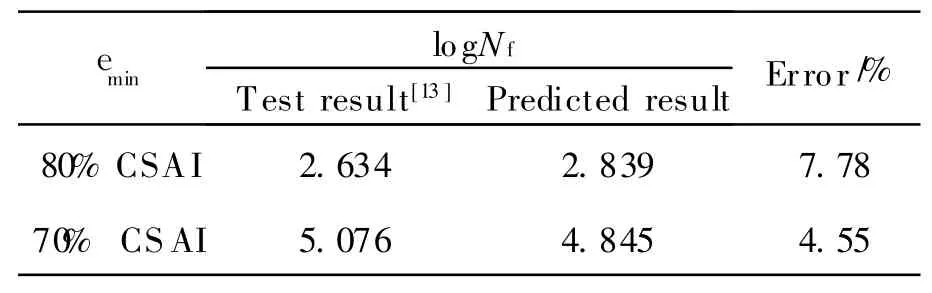

The comprison of the predicted results and the test results[13]is listed in Table 1.The most relative error between the predicted results and the test results is 7.78%.

Table 1 Comparison of fatigue lif e and error of impacted laminated composites

3 CONCLUSIONS

(1)Based on the results of various types of uniaxial fatigue experiments on unimpacted unidirectional plies,a new method is presented to predict the post-impact fatigue life under general fatigue loading conditions.By using the traditional progressive damage model which can simulate the fatigue behavior of unimpacted composite laminates,the 3-D progressive fatigue damage model for impacted laminates is developed.

(2)Whole process analysis method for impact damage and post-impact fatigue life is proposed to predict the damage propagation from impact to fatigue loading.Prediction results of impact damage can be used for post-impact fatigue analysis.When no impact test datais available,it can still predict the fatigue life based on the impact loading conditions and fatigue loading conditions.

(3)The method and its program are examined by simulation of AS4/3501-6 laminates with test results presented in Ref.[13].The most relative error between the predicted and the test results is 7.78%.

[1] Zhang Yan,Zhu Ping,Lai xinming.Low velocity damage analysis in carbon fiber reinforced compoisted plates[J].Acta Material Composite Sinica,2006,23(2):150-157.(in Chinese)

[2] Horn G P,Mackin T J,Kurath P.Estimating the residual fatigue lifetimes of impact-damaged composites using thermoelastic stress analysis[J].Polymer Composites,2001,22(3):420-431.

[3] Beheshty M H,Harris B.A constant-life model of fatigue behaviour for carbon-fibre composites: the effect of impact damage[J].Composites Science and Technology,1998,58(1):9-18.

[4] Beheshty M H,Harris B,Adam T.An empirical fatigue-life model for high-performance fibre composites with and without impact damage[J].Composites Part A:Applied Science and Manufacturing,1999,30(8):971-987.

[5] Beheshty M H,Harris B.Post-impact fatigue behaviour of CFRPand the growth of low-velocity impact damage during fatigue[C]//International Conference on Fatigue of Composites(ICFC 1).Paris,France:[s.n.],1997:355-362.

[6] Kang K W,Kim J K.Fatigue life prediction of impacted carbon/epoxy laminates under constant amplitude loading[J].Composites Part A: Applied Science and Manufacturing,2004,35(5):529-535.

[7] Broutman L J,Sahu S.A new theory to predict cumulative fatigue damage in fiber glass reinforced plastics[C]//ASTM STP.Paris,France: [s.n.],1972,497:170-188.

[8] Xu Ying,Wen Weidong,Cui Haipo.A cumulative damage prediction method of low-velocity impacts on laminated composites[J].Journal of Materials Science& Engineering, 2006,24(1): 77-81. (in Chinese)

[9] Hashin Z,Rotem A.Fatigue failure criterion for fiber reinforced materials[J].Journal of Composite Materials,1973,7:448-464.

[10]Shokrieh M M,Lessard L B.Multiaxial fatigue behaviour of unidirectional plies based on uniaxial fatigue experiments—I:Modelling[J].International Journal of Fatigue,1997,19(3):201-207.

[11]Shokrieh M M,Lessard L B.Progressive fatigue damage modeling of composite materials,Part I:Modeling[J]. Journal of Composite Materials,2000,34(13):1056-1080.

[12]Adam J,Dickson R F,Harris B.A power law fatigue damage model for fibre-reinforced plastic laminates[J].Pro Inst Mech Eng Part C,1986,200(c3):155-165.

[13]Milan M,Hahn H T,Greg P C,et al.Effect of loading parameters on the fatigue behavior of impact damaged composite laminates[J].Composites Science and Technology,1999,59(14):2059-2078.

[14]Shokrieh M M,Lessard L B.Progressive fatigue damage modeling of composite materials,Part II:Material characterization and model verification[J].Journal of Composite Materials,2000,34(13):1081-1116.

Transactions of Nanjing University of Aeronautics and Astronautics2011年1期

Transactions of Nanjing University of Aeronautics and Astronautics2011年1期

- Transactions of Nanjing University of Aeronautics and Astronautics的其它文章

- 拉壓、扭轉(zhuǎn)載荷下鑄鋁合金的億周疲勞性能研究

- 端墻形狀對(duì)蒸汽渦輪效率的影響

- 法國(guó)MBDA爆震和連續(xù)爆震波發(fā)動(dòng)機(jī)的研發(fā)

- 使用液態(tài)化學(xué)循環(huán)的高熱效率動(dòng)力研究

- EXPERIMENTAL STUDY OF FORCED SHOCK TRAIN OSCILLATION IN ISOLATOR UNDER ASYMMETRIC INCOMING FLOW

- VIBRATION NUMERICAL ANALYSISOF COUNTER-ROTATING TURBINE WITH WAKE-FLOWUSING FLUID-STRUCTURE INTERACTION METHOD